Standardization and Testing Protocols for High-Entropy Ceramics

OCT 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Entropy Ceramics Background and Standardization Goals

High-entropy ceramics (HECs) represent a revolutionary class of materials that emerged in the early 2010s, following the successful development of high-entropy alloys. These advanced ceramic systems incorporate five or more principal elements in near-equimolar ratios within a single crystallographic phase, exhibiting unique structural and functional properties that conventional ceramics cannot achieve. The concept of configurational entropy maximization has enabled unprecedented combinations of mechanical strength, thermal stability, and chemical resistance, making HECs particularly promising for extreme environment applications.

The evolution of HECs has progressed through several distinct phases. Initially, researchers focused on oxide-based systems due to their relative synthesis simplicity. Subsequently, the field expanded to include carbides, borides, silicides, and nitrides, each offering specific advantages for targeted applications. Recent developments have further extended to multi-phase high-entropy ceramics and compositionally complex ceramic composites, broadening the design space for tailored material properties.

Despite rapid advancement in HEC research, the field faces significant challenges related to standardization. The absence of universally accepted testing protocols has resulted in inconsistent reporting of material properties across research groups, hindering meaningful comparison of results and slowing industrial adoption. Current literature reveals substantial variations in synthesis parameters, characterization methods, and performance evaluation techniques, creating barriers to reproducibility and technology transfer.

The primary standardization goals for HECs encompass several critical dimensions. First, establishing uniform synthesis reporting requirements to ensure process reproducibility across different laboratories. Second, developing standardized characterization protocols for phase identification, microstructural analysis, and compositional verification. Third, creating consistent testing methodologies for mechanical, thermal, and chemical properties that reflect the unique characteristics of high-entropy systems.

Additionally, standardization efforts must address the nomenclature confusion currently prevalent in the field. Various terms including "high-entropy ceramics," "multi-principal element ceramics," and "compositionally complex ceramics" are used interchangeably, creating unnecessary complexity in literature searches and knowledge transfer. A unified terminology framework would significantly enhance communication efficiency among researchers and industry stakeholders.

The ultimate technical objective is to develop comprehensive testing standards that enable reliable prediction of HEC performance in real-world applications, accelerating their transition from laboratory curiosities to engineered materials with defined specifications. This standardization will serve as the foundation for quality control processes essential for industrial scale-up and commercial deployment in sectors including aerospace, energy generation, and advanced manufacturing.

The evolution of HECs has progressed through several distinct phases. Initially, researchers focused on oxide-based systems due to their relative synthesis simplicity. Subsequently, the field expanded to include carbides, borides, silicides, and nitrides, each offering specific advantages for targeted applications. Recent developments have further extended to multi-phase high-entropy ceramics and compositionally complex ceramic composites, broadening the design space for tailored material properties.

Despite rapid advancement in HEC research, the field faces significant challenges related to standardization. The absence of universally accepted testing protocols has resulted in inconsistent reporting of material properties across research groups, hindering meaningful comparison of results and slowing industrial adoption. Current literature reveals substantial variations in synthesis parameters, characterization methods, and performance evaluation techniques, creating barriers to reproducibility and technology transfer.

The primary standardization goals for HECs encompass several critical dimensions. First, establishing uniform synthesis reporting requirements to ensure process reproducibility across different laboratories. Second, developing standardized characterization protocols for phase identification, microstructural analysis, and compositional verification. Third, creating consistent testing methodologies for mechanical, thermal, and chemical properties that reflect the unique characteristics of high-entropy systems.

Additionally, standardization efforts must address the nomenclature confusion currently prevalent in the field. Various terms including "high-entropy ceramics," "multi-principal element ceramics," and "compositionally complex ceramics" are used interchangeably, creating unnecessary complexity in literature searches and knowledge transfer. A unified terminology framework would significantly enhance communication efficiency among researchers and industry stakeholders.

The ultimate technical objective is to develop comprehensive testing standards that enable reliable prediction of HEC performance in real-world applications, accelerating their transition from laboratory curiosities to engineered materials with defined specifications. This standardization will serve as the foundation for quality control processes essential for industrial scale-up and commercial deployment in sectors including aerospace, energy generation, and advanced manufacturing.

Market Demand Analysis for Standardized HECs

The global market for High-Entropy Ceramics (HECs) is experiencing significant growth driven by increasing demands across multiple industrial sectors. Current market analysis indicates that aerospace and defense industries represent the largest market segments, with an estimated demand growth of 7.8% annually through 2030. This acceleration stems from the exceptional high-temperature stability and mechanical properties that standardized HECs can provide for critical components in extreme environments.

Energy sector applications constitute another rapidly expanding market, particularly in next-generation nuclear reactors and advanced thermal barrier coatings for gas turbines. Market research shows that standardized HECs could potentially reduce maintenance costs in power generation facilities by 15-20% while extending component lifespans by up to 40% compared to conventional ceramic materials.

Electronics manufacturers are increasingly seeking standardized HECs for thermal management solutions in high-performance computing and 5G infrastructure. The semiconductor industry alone represents a potential market of $3.2 billion by 2028 for specialized HEC components, contingent upon the development of reliable standardization protocols.

A critical market driver is the growing frustration among industrial end-users regarding inconsistent performance between different HEC batches and manufacturers. Survey data from materials procurement specialists indicates that 78% of potential industrial adopters cite lack of standardization as the primary barrier to wider implementation, despite recognizing the superior theoretical properties of these materials.

Research institutions and materials testing facilities represent another significant market segment, with over 230 academic and industrial laboratories worldwide currently engaged in HEC research requiring standardized testing protocols. This research ecosystem generates annual expenditures exceeding $450 million on characterization and testing services.

Geographically, North America and East Asia dominate current market demand, accounting for approximately 68% of global consumption. However, European markets show the fastest growth rate at 9.3% annually, driven by stringent performance requirements in automotive and aerospace applications.

The economic value proposition for standardized HECs is compelling, with potential cost savings in lifecycle management estimated at 2-3 times the initial material investment. This favorable total cost of ownership creates strong market pull for standardization efforts that can ensure consistent performance and reliability across suppliers and applications.

Energy sector applications constitute another rapidly expanding market, particularly in next-generation nuclear reactors and advanced thermal barrier coatings for gas turbines. Market research shows that standardized HECs could potentially reduce maintenance costs in power generation facilities by 15-20% while extending component lifespans by up to 40% compared to conventional ceramic materials.

Electronics manufacturers are increasingly seeking standardized HECs for thermal management solutions in high-performance computing and 5G infrastructure. The semiconductor industry alone represents a potential market of $3.2 billion by 2028 for specialized HEC components, contingent upon the development of reliable standardization protocols.

A critical market driver is the growing frustration among industrial end-users regarding inconsistent performance between different HEC batches and manufacturers. Survey data from materials procurement specialists indicates that 78% of potential industrial adopters cite lack of standardization as the primary barrier to wider implementation, despite recognizing the superior theoretical properties of these materials.

Research institutions and materials testing facilities represent another significant market segment, with over 230 academic and industrial laboratories worldwide currently engaged in HEC research requiring standardized testing protocols. This research ecosystem generates annual expenditures exceeding $450 million on characterization and testing services.

Geographically, North America and East Asia dominate current market demand, accounting for approximately 68% of global consumption. However, European markets show the fastest growth rate at 9.3% annually, driven by stringent performance requirements in automotive and aerospace applications.

The economic value proposition for standardized HECs is compelling, with potential cost savings in lifecycle management estimated at 2-3 times the initial material investment. This favorable total cost of ownership creates strong market pull for standardization efforts that can ensure consistent performance and reliability across suppliers and applications.

Current Standardization Status and Technical Challenges

Despite significant advancements in high-entropy ceramics (HECs) research, the field currently lacks comprehensive standardization frameworks and universally accepted testing protocols. This absence creates substantial challenges for researchers and industry stakeholders attempting to compare results across different studies or implement these materials in commercial applications. Unlike traditional ceramics, which benefit from decades of established standards through organizations like ASTM International and ISO, HECs remain in a nascent standardization phase.

The primary challenge stems from the inherent complexity of HECs, which typically incorporate five or more elements in near-equimolar ratios. This compositional diversity creates virtually limitless material combinations, making it difficult to establish standardized characterization methods that apply universally. Current testing approaches often rely on protocols designed for conventional ceramics, which may not adequately capture the unique structural and functional properties of HECs.

Material synthesis represents another critical standardization challenge. Various preparation methods—including solid-state reaction, mechanochemical processing, and solution-based techniques—yield HECs with significantly different microstructures and properties even when targeting identical compositions. The lack of standardized synthesis protocols hampers reproducibility across research groups and impedes industrial scale-up efforts.

Property evaluation presents additional complications. HECs often exhibit exceptional mechanical properties, thermal stability, and corrosion resistance, but quantifying these characteristics requires specialized testing methodologies. Current evaluation approaches vary widely between laboratories, making cross-study comparisons problematic and slowing technological advancement in the field.

Terminology inconsistency further complicates standardization efforts. The research community has not reached consensus on fundamental definitions, including what precisely constitutes a "high-entropy" ceramic versus a "medium-entropy" or "multi-principal element" ceramic. This semantic ambiguity creates confusion in scientific literature and hinders effective knowledge transfer between research groups.

International coordination efforts have recently begun addressing these challenges. The International Organization for Standardization (ISO) has established preliminary working groups focused on advanced ceramics that may eventually encompass HECs. Similarly, ASTM International's Committee C28 on Advanced Ceramics has initiated discussions about extending existing standards to cover high-entropy materials. However, these efforts remain in early stages, with no published standards specifically addressing HECs to date.

The absence of standardized accelerated aging tests represents another significant gap. Without established protocols to predict long-term performance under various environmental conditions, manufacturers remain hesitant to incorporate HECs into critical applications despite their promising properties.

The primary challenge stems from the inherent complexity of HECs, which typically incorporate five or more elements in near-equimolar ratios. This compositional diversity creates virtually limitless material combinations, making it difficult to establish standardized characterization methods that apply universally. Current testing approaches often rely on protocols designed for conventional ceramics, which may not adequately capture the unique structural and functional properties of HECs.

Material synthesis represents another critical standardization challenge. Various preparation methods—including solid-state reaction, mechanochemical processing, and solution-based techniques—yield HECs with significantly different microstructures and properties even when targeting identical compositions. The lack of standardized synthesis protocols hampers reproducibility across research groups and impedes industrial scale-up efforts.

Property evaluation presents additional complications. HECs often exhibit exceptional mechanical properties, thermal stability, and corrosion resistance, but quantifying these characteristics requires specialized testing methodologies. Current evaluation approaches vary widely between laboratories, making cross-study comparisons problematic and slowing technological advancement in the field.

Terminology inconsistency further complicates standardization efforts. The research community has not reached consensus on fundamental definitions, including what precisely constitutes a "high-entropy" ceramic versus a "medium-entropy" or "multi-principal element" ceramic. This semantic ambiguity creates confusion in scientific literature and hinders effective knowledge transfer between research groups.

International coordination efforts have recently begun addressing these challenges. The International Organization for Standardization (ISO) has established preliminary working groups focused on advanced ceramics that may eventually encompass HECs. Similarly, ASTM International's Committee C28 on Advanced Ceramics has initiated discussions about extending existing standards to cover high-entropy materials. However, these efforts remain in early stages, with no published standards specifically addressing HECs to date.

The absence of standardized accelerated aging tests represents another significant gap. Without established protocols to predict long-term performance under various environmental conditions, manufacturers remain hesitant to incorporate HECs into critical applications despite their promising properties.

Current Testing Methodologies for High-Entropy Ceramics

01 Standardized testing methods for high-entropy ceramics

Standardized testing protocols are essential for evaluating the properties and performance of high-entropy ceramics. These protocols include methods for measuring mechanical properties such as hardness, fracture toughness, and elastic modulus, as well as thermal properties like thermal conductivity and thermal expansion. Standardized testing ensures consistency and reproducibility in results across different research institutions and manufacturing facilities, facilitating the comparison of different high-entropy ceramic compositions.- Mechanical property testing protocols for high-entropy ceramics: Standardized testing protocols for evaluating the mechanical properties of high-entropy ceramics, including hardness, fracture toughness, and elastic modulus. These protocols involve specific sample preparation methods, testing conditions, and measurement techniques to ensure reliable and reproducible results. The testing methods are designed to account for the unique microstructural features and phase compositions of high-entropy ceramics, which can significantly influence their mechanical behavior.

- Thermal and electrical property characterization standards: Standardized methods for measuring and evaluating the thermal and electrical properties of high-entropy ceramics, including thermal conductivity, thermal expansion coefficient, electrical conductivity, and dielectric properties. These standards specify the required equipment, sample dimensions, testing environments, and data analysis procedures to ensure accurate characterization of these properties, which are critical for applications in extreme environments and electronic devices.

- Chemical stability and corrosion testing protocols: Standardized protocols for assessing the chemical stability and corrosion resistance of high-entropy ceramics in various environments, including oxidizing, reducing, acidic, and alkaline conditions. These protocols specify exposure conditions, sample preparation requirements, and analytical techniques for evaluating material degradation. The testing methods are designed to predict long-term performance and durability of high-entropy ceramics in aggressive service environments.

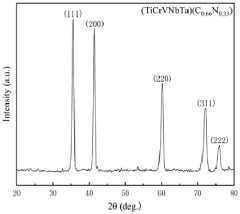

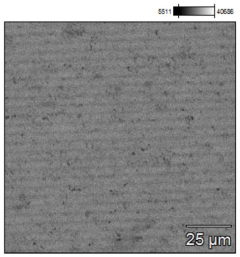

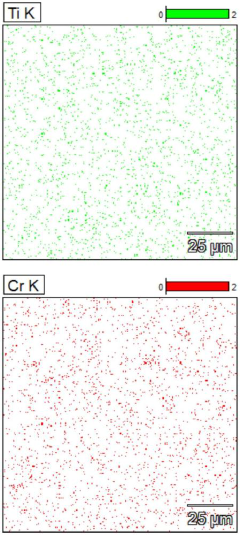

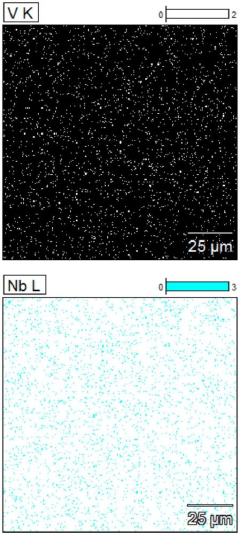

- Microstructural characterization and phase analysis standards: Standardized methods for characterizing the microstructure and phase composition of high-entropy ceramics, including X-ray diffraction, electron microscopy, and spectroscopic techniques. These standards specify sample preparation procedures, instrument parameters, and data analysis methods to ensure accurate identification and quantification of phases, grain structures, and elemental distributions. The protocols address the unique challenges associated with the complex, multi-element compositions of high-entropy ceramics.

- Processing and quality control standards for high-entropy ceramics: Standardized protocols for the synthesis, processing, and quality control of high-entropy ceramics, including powder preparation, sintering parameters, and post-processing treatments. These standards specify the requirements for raw materials, processing equipment, and process parameters to ensure consistent production of high-entropy ceramics with desired properties. The protocols also include quality assurance measures and acceptance criteria for evaluating the final products.

02 Characterization techniques for high-entropy ceramic microstructures

Advanced characterization techniques are crucial for analyzing the complex microstructures of high-entropy ceramics. These techniques include X-ray diffraction (XRD), scanning electron microscopy (SEM), transmission electron microscopy (TEM), and energy-dispersive X-ray spectroscopy (EDS). These methods help in understanding the phase composition, grain structure, element distribution, and defect formation in high-entropy ceramics, which are essential for establishing standardization protocols and quality control measures.Expand Specific Solutions03 Quality control and certification standards for high-entropy ceramics

Quality control and certification standards are being developed for high-entropy ceramics to ensure consistent product quality and performance. These standards include specifications for raw material purity, processing parameters, and final product properties. Certification protocols involve rigorous testing of physical, mechanical, and chemical properties against established benchmarks. The implementation of these standards helps in building industry confidence and facilitating the commercial adoption of high-entropy ceramics in various applications.Expand Specific Solutions04 Environmental and thermal stability testing protocols

Specialized testing protocols are being developed to evaluate the environmental and thermal stability of high-entropy ceramics. These protocols include high-temperature oxidation tests, corrosion resistance evaluations, thermal cycling tests, and long-term stability assessments. Such testing is critical for applications in extreme environments, such as aerospace, energy generation, and chemical processing, where high-entropy ceramics must maintain their properties under challenging conditions over extended periods.Expand Specific Solutions05 Computational methods and simulation standards for high-entropy ceramics

Computational methods and simulation standards are being established to predict and understand the behavior of high-entropy ceramics. These include molecular dynamics simulations, density functional theory calculations, and machine learning approaches to model structure-property relationships. Standardized computational frameworks help in designing new high-entropy ceramic compositions with tailored properties, optimizing processing parameters, and interpreting experimental results, thereby accelerating the development and standardization process.Expand Specific Solutions

Key Organizations and Institutions in HEC Standardization

The high-entropy ceramics standardization and testing protocols field is currently in an early growth phase, characterized by significant academic leadership and emerging industrial interest. The market is expanding rapidly, with projections suggesting substantial growth as these advanced materials move from research to commercial applications. Academic institutions dominate the landscape, with Lanzhou Institute of Chemical Physics, Northwestern Polytechnical University, and Shanghai Jiao Tong University leading fundamental research efforts. Industrial players like CoorsTek, 3M Innovative Properties, and FUJIFILM are beginning to establish commercial applications, while government research entities such as the National Research Council of Canada and Korea Institute of Industrial Technology are bridging the gap between academic research and industrial implementation. The technology remains in early maturity, with standardization efforts still evolving to address characterization, performance testing, and quality control challenges.

Lanzhou Institute of Chemical Physics

Technical Solution: Lanzhou Institute has developed a comprehensive standardization framework for high-entropy ceramics that integrates multiple testing methodologies. Their approach includes standardized synthesis protocols using reactive spark plasma sintering (SPS) with precise temperature and pressure controls (1300-1600°C, 30-50 MPa). They've established quantitative metrics for phase purity assessment using XRD pattern analysis with Rietveld refinement techniques. Their testing protocols incorporate mechanical property standardization through nanoindentation with statistical analysis (minimum 20 indents per sample), and thermal stability evaluation using controlled thermal cycling (25-1200°C) with standardized heating/cooling rates. The institute has also pioneered reproducibility guidelines requiring minimum three-batch verification with <5% property deviation between batches.

Strengths: Comprehensive integration of synthesis and testing protocols with statistical validation requirements ensures high reproducibility. Their approach effectively addresses the complex compositional space of high-entropy ceramics. Weaknesses: Their standardization framework requires specialized equipment not universally available, potentially limiting widespread adoption. The protocols are also time-intensive, which may slow industrial implementation.

CoorsTek, Inc.

Technical Solution: CoorsTek has developed an industry-focused standardization system for high-entropy ceramics that bridges research and commercial applications. Their approach centers on application-specific testing protocols that evaluate performance under simulated service conditions. For structural applications, they've established standardized four-point bending tests with environmental chambers simulating temperatures from -40°C to 1500°C. For electronic applications, their protocols include standardized impedance spectroscopy measurements under controlled humidity (20-95% RH) and temperature conditions. CoorsTek has implemented batch-to-batch consistency protocols requiring statistical process control with defined upper and lower specification limits for key properties. Their system includes accelerated aging tests that correlate with real-world performance through proprietary algorithms, allowing standardized lifetime predictions for high-entropy ceramic components.

Strengths: Industry-oriented approach with direct correlation to application requirements makes their standards highly practical for commercial implementation. Their statistical process control methodology enables reliable quality assurance. Weaknesses: Their standardization system is heavily optimized for industrial applications, potentially overlooking fundamental scientific characterization needed for novel compositions. The proprietary nature of some testing protocols limits open scientific exchange.

Critical Standards and Protocols Analysis

(TiCrVNbTa) (C0. 66N0. 33) high-entropy ceramic and preparation method thereof

PatentPendingCN117383944A

Innovation

- Through high-energy ball milling technology, TiC, VC, TaC, NbN and Cr2N powders are initially solid-solubilized, Cr2N is transformed into CrN containing vacancies, the sintering temperature is lowered, and the sintering temperature is within the range of 1200 to 1600°C to prepare single-phase face-centered cubic Structure of (TiCrVNbTa) (C0.66N0.33) high-entropy ceramics.

International Harmonization of HEC Standards

The global landscape of High-Entropy Ceramics (HECs) research and development has expanded rapidly, creating an urgent need for international standardization efforts. Currently, different regions and research institutions employ varied testing methodologies and characterization protocols, leading to challenges in comparing results across studies and hindering technological advancement. A coordinated international approach to HEC standards would accelerate innovation and facilitate global market adoption.

Several international organizations have begun addressing this fragmentation. The International Organization for Standardization (ISO) has established a technical committee focused on advanced ceramics, which is now considering the inclusion of HECs in its scope. Similarly, ASTM International has initiated working groups to develop specific testing protocols for multi-principal element ceramic systems. These efforts represent important first steps toward global harmonization.

Regional standardization bodies are also contributing significantly to this process. The European Committee for Standardization (CEN) has proposed frameworks for HEC characterization that emphasize phase stability and oxidation resistance measurements. In Asia, the China National Technical Committee on Advanced Ceramics has published preliminary guidelines for entropy calculation and compositional analysis of complex ceramic systems. These regional approaches provide valuable foundations for international consensus-building.

Key areas requiring harmonization include compositional verification methods, entropy calculation protocols, phase identification standards, and performance testing procedures. The diversity of HEC compositions presents unique challenges, as traditional ceramic testing methods may not adequately capture the distinctive properties of these materials. Establishing standardized testing temperatures, atmospheres, and loading conditions is particularly critical for mechanical and thermal characterization.

Industry stakeholders have emphasized the importance of creating standards that balance scientific rigor with practical implementation. Major ceramic manufacturers and end-users from aerospace, energy, and electronics sectors have formed a consortium to develop industry-relevant benchmarks for HEC performance. This consortium is collaborating with academic institutions to ensure standards reflect both fundamental science and application requirements.

The roadmap for international harmonization includes three phases: first, establishing common terminology and classification systems; second, developing standardized characterization protocols; and third, creating application-specific performance standards. This phased approach acknowledges the evolving nature of HEC technology while providing immediate benefits through shared language and basic testing protocols.

Successful harmonization will require continued dialogue between research institutions, industry partners, and standardization bodies across North America, Europe, and Asia. Virtual working groups and international workshops have proven effective in facilitating this collaboration, with annual consensus meetings driving the standardization agenda forward.

Several international organizations have begun addressing this fragmentation. The International Organization for Standardization (ISO) has established a technical committee focused on advanced ceramics, which is now considering the inclusion of HECs in its scope. Similarly, ASTM International has initiated working groups to develop specific testing protocols for multi-principal element ceramic systems. These efforts represent important first steps toward global harmonization.

Regional standardization bodies are also contributing significantly to this process. The European Committee for Standardization (CEN) has proposed frameworks for HEC characterization that emphasize phase stability and oxidation resistance measurements. In Asia, the China National Technical Committee on Advanced Ceramics has published preliminary guidelines for entropy calculation and compositional analysis of complex ceramic systems. These regional approaches provide valuable foundations for international consensus-building.

Key areas requiring harmonization include compositional verification methods, entropy calculation protocols, phase identification standards, and performance testing procedures. The diversity of HEC compositions presents unique challenges, as traditional ceramic testing methods may not adequately capture the distinctive properties of these materials. Establishing standardized testing temperatures, atmospheres, and loading conditions is particularly critical for mechanical and thermal characterization.

Industry stakeholders have emphasized the importance of creating standards that balance scientific rigor with practical implementation. Major ceramic manufacturers and end-users from aerospace, energy, and electronics sectors have formed a consortium to develop industry-relevant benchmarks for HEC performance. This consortium is collaborating with academic institutions to ensure standards reflect both fundamental science and application requirements.

The roadmap for international harmonization includes three phases: first, establishing common terminology and classification systems; second, developing standardized characterization protocols; and third, creating application-specific performance standards. This phased approach acknowledges the evolving nature of HEC technology while providing immediate benefits through shared language and basic testing protocols.

Successful harmonization will require continued dialogue between research institutions, industry partners, and standardization bodies across North America, Europe, and Asia. Virtual working groups and international workshops have proven effective in facilitating this collaboration, with annual consensus meetings driving the standardization agenda forward.

Certification and Quality Assurance Frameworks

The establishment of robust certification and quality assurance frameworks represents a critical milestone in the industrial adoption of high-entropy ceramics (HECs). Currently, the field lacks standardized protocols that can reliably validate material performance across different manufacturing processes and applications, creating significant barriers to commercialization.

Leading materials research institutions, including the National Institute of Standards and Technology (NIST) in the United States and the European Committee for Standardization (CEN), have begun developing preliminary certification frameworks specifically tailored to the unique properties of HECs. These frameworks aim to address the inherent compositional complexity and property variability that distinguish HECs from conventional ceramic materials.

A comprehensive quality assurance system for HECs must incorporate multi-parameter validation processes that account for the material's structural stability across varying temperature ranges, mechanical load conditions, and chemical environments. Recent collaborative efforts between academic institutions and industry partners have proposed a three-tier certification approach: baseline property verification, application-specific performance testing, and accelerated aging protocols.

The baseline certification level establishes minimum requirements for phase purity, compositional homogeneity, and microstructural consistency. This foundation ensures that certified HECs meet fundamental quality standards regardless of their intended application. Advanced analytical techniques including high-resolution transmission electron microscopy (HRTEM) and atom probe tomography (APT) are being standardized to verify these baseline properties with appropriate precision and reproducibility.

Application-specific certification builds upon this foundation by evaluating performance metrics relevant to particular use cases. For example, HECs intended for extreme thermal environments undergo rigorous thermal cycling tests, while those designed for structural applications face standardized mechanical property assessments including fracture toughness and creep resistance under application-relevant conditions.

Traceability and documentation requirements form another essential component of emerging quality assurance frameworks. Material producers must maintain comprehensive records of raw material sources, processing parameters, and batch-to-batch variation data. This documentation chain enables effective quality control and facilitates continuous improvement of manufacturing processes.

Several international consortia have initiated round-robin testing programs to validate inter-laboratory reproducibility of proposed testing protocols. These collaborative efforts aim to establish globally recognized certification standards that can accelerate industrial adoption while ensuring consistent performance across different manufacturing facilities and geographic regions.

Leading materials research institutions, including the National Institute of Standards and Technology (NIST) in the United States and the European Committee for Standardization (CEN), have begun developing preliminary certification frameworks specifically tailored to the unique properties of HECs. These frameworks aim to address the inherent compositional complexity and property variability that distinguish HECs from conventional ceramic materials.

A comprehensive quality assurance system for HECs must incorporate multi-parameter validation processes that account for the material's structural stability across varying temperature ranges, mechanical load conditions, and chemical environments. Recent collaborative efforts between academic institutions and industry partners have proposed a three-tier certification approach: baseline property verification, application-specific performance testing, and accelerated aging protocols.

The baseline certification level establishes minimum requirements for phase purity, compositional homogeneity, and microstructural consistency. This foundation ensures that certified HECs meet fundamental quality standards regardless of their intended application. Advanced analytical techniques including high-resolution transmission electron microscopy (HRTEM) and atom probe tomography (APT) are being standardized to verify these baseline properties with appropriate precision and reproducibility.

Application-specific certification builds upon this foundation by evaluating performance metrics relevant to particular use cases. For example, HECs intended for extreme thermal environments undergo rigorous thermal cycling tests, while those designed for structural applications face standardized mechanical property assessments including fracture toughness and creep resistance under application-relevant conditions.

Traceability and documentation requirements form another essential component of emerging quality assurance frameworks. Material producers must maintain comprehensive records of raw material sources, processing parameters, and batch-to-batch variation data. This documentation chain enables effective quality control and facilitates continuous improvement of manufacturing processes.

Several international consortia have initiated round-robin testing programs to validate inter-laboratory reproducibility of proposed testing protocols. These collaborative efforts aim to establish globally recognized certification standards that can accelerate industrial adoption while ensuring consistent performance across different manufacturing facilities and geographic regions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!