Compare GC-MS vs Wet Chemical Methods for VOC Testing

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

VOC Testing Evolution and Objectives

Volatile Organic Compounds (VOCs) testing methodologies have evolved significantly over the past several decades, driven by increasing environmental awareness and regulatory requirements. The journey began in the 1970s with rudimentary wet chemical methods that offered limited sensitivity and specificity. These early approaches relied primarily on colorimetric reactions and gravimetric analyses, providing only basic qualitative and semi-quantitative results for a narrow range of compounds.

The 1980s marked a pivotal shift with the introduction of Gas Chromatography-Mass Spectrometry (GC-MS) technology into environmental testing. This revolutionary approach enabled scientists to separate, identify, and quantify complex mixtures of VOCs with unprecedented precision. The technological advancement addressed many limitations of traditional wet chemical methods, particularly in terms of detection limits and compound specificity.

Throughout the 1990s and early 2000s, both methodologies continued to develop in parallel. Wet chemical methods became more standardized and refined for specific applications, while GC-MS systems became more sensitive, automated, and accessible. This period saw the establishment of key regulatory frameworks for VOC monitoring across industries, from indoor air quality assessment to industrial emissions control.

Recent developments have focused on enhancing the speed, portability, and cost-effectiveness of VOC testing. Modern GC-MS systems have been miniaturized and optimized for field deployment, while advanced wet chemical methods have incorporated novel reagents and detection systems to improve performance. The integration of digital technologies and data analytics has further transformed both approaches, enabling real-time monitoring and comprehensive data interpretation.

The primary objective of this technical research is to conduct a comprehensive comparison between GC-MS and wet chemical methodologies for VOC testing across multiple dimensions. We aim to evaluate their respective analytical capabilities, including detection limits, compound specificity, and quantification accuracy. Additionally, we will assess practical considerations such as sample preparation requirements, analysis time, equipment costs, and technical expertise needed for implementation.

Furthermore, this research seeks to identify the optimal testing scenarios for each methodology based on specific industry requirements, regulatory compliance needs, and operational constraints. By examining case studies across various sectors, we intend to develop a decision framework that guides technology selection based on application-specific parameters. The ultimate goal is to provide evidence-based recommendations that enable organizations to select the most appropriate VOC testing approach for their particular circumstances, balancing analytical performance with practical feasibility.

The 1980s marked a pivotal shift with the introduction of Gas Chromatography-Mass Spectrometry (GC-MS) technology into environmental testing. This revolutionary approach enabled scientists to separate, identify, and quantify complex mixtures of VOCs with unprecedented precision. The technological advancement addressed many limitations of traditional wet chemical methods, particularly in terms of detection limits and compound specificity.

Throughout the 1990s and early 2000s, both methodologies continued to develop in parallel. Wet chemical methods became more standardized and refined for specific applications, while GC-MS systems became more sensitive, automated, and accessible. This period saw the establishment of key regulatory frameworks for VOC monitoring across industries, from indoor air quality assessment to industrial emissions control.

Recent developments have focused on enhancing the speed, portability, and cost-effectiveness of VOC testing. Modern GC-MS systems have been miniaturized and optimized for field deployment, while advanced wet chemical methods have incorporated novel reagents and detection systems to improve performance. The integration of digital technologies and data analytics has further transformed both approaches, enabling real-time monitoring and comprehensive data interpretation.

The primary objective of this technical research is to conduct a comprehensive comparison between GC-MS and wet chemical methodologies for VOC testing across multiple dimensions. We aim to evaluate their respective analytical capabilities, including detection limits, compound specificity, and quantification accuracy. Additionally, we will assess practical considerations such as sample preparation requirements, analysis time, equipment costs, and technical expertise needed for implementation.

Furthermore, this research seeks to identify the optimal testing scenarios for each methodology based on specific industry requirements, regulatory compliance needs, and operational constraints. By examining case studies across various sectors, we intend to develop a decision framework that guides technology selection based on application-specific parameters. The ultimate goal is to provide evidence-based recommendations that enable organizations to select the most appropriate VOC testing approach for their particular circumstances, balancing analytical performance with practical feasibility.

Market Demand Analysis for VOC Testing Solutions

The global market for Volatile Organic Compound (VOC) testing solutions has experienced significant growth in recent years, driven primarily by increasing environmental regulations and growing awareness of indoor air quality concerns. The market size for VOC testing equipment and services was valued at approximately $970 million in 2022 and is projected to reach $1.4 billion by 2028, representing a compound annual growth rate of 6.2%.

Environmental regulatory frameworks across North America, Europe, and Asia-Pacific regions have become increasingly stringent regarding VOC emissions, creating substantial demand for reliable testing methodologies. The European Union's implementation of the Industrial Emissions Directive and the REACH regulation has particularly accelerated market growth in Europe, while the EPA's Clean Air Act amendments continue to drive demand in the United States.

Industry-specific requirements represent another significant market driver. The construction and building materials sector accounts for nearly 35% of the VOC testing market, as manufacturers seek compliance with green building standards such as LEED certification. The automotive industry follows closely, constituting approximately 28% of market demand, primarily focused on interior air quality testing and emissions compliance.

Healthcare facilities have emerged as a rapidly growing segment, with increasing recognition of the impact of VOCs on patient outcomes and staff well-being. This sector is expected to show the highest growth rate at 8.7% annually through 2028, as hospitals implement more comprehensive air quality monitoring programs.

Consumer preference shifts toward eco-friendly and low-VOC products have created additional market opportunities. Retail giants and consumer goods manufacturers increasingly require VOC certification for products, expanding testing requirements across supply chains. This trend is particularly pronounced in children's products, furniture, and household goods categories.

The market demonstrates distinct regional characteristics, with North America currently holding the largest market share at 38%, followed by Europe at 32% and Asia-Pacific at 24%. However, the Asia-Pacific region is projected to witness the fastest growth rate due to rapid industrialization, increasing environmental awareness, and strengthening regulatory frameworks in countries like China and India.

Cost considerations remain a significant factor influencing market dynamics. While GC-MS testing solutions command premium pricing due to their precision and comprehensive capabilities, wet chemical methods maintain substantial market share in cost-sensitive segments and applications requiring only basic compliance verification. This price-performance trade-off continues to shape purchasing decisions, particularly among small and medium enterprises.

Environmental regulatory frameworks across North America, Europe, and Asia-Pacific regions have become increasingly stringent regarding VOC emissions, creating substantial demand for reliable testing methodologies. The European Union's implementation of the Industrial Emissions Directive and the REACH regulation has particularly accelerated market growth in Europe, while the EPA's Clean Air Act amendments continue to drive demand in the United States.

Industry-specific requirements represent another significant market driver. The construction and building materials sector accounts for nearly 35% of the VOC testing market, as manufacturers seek compliance with green building standards such as LEED certification. The automotive industry follows closely, constituting approximately 28% of market demand, primarily focused on interior air quality testing and emissions compliance.

Healthcare facilities have emerged as a rapidly growing segment, with increasing recognition of the impact of VOCs on patient outcomes and staff well-being. This sector is expected to show the highest growth rate at 8.7% annually through 2028, as hospitals implement more comprehensive air quality monitoring programs.

Consumer preference shifts toward eco-friendly and low-VOC products have created additional market opportunities. Retail giants and consumer goods manufacturers increasingly require VOC certification for products, expanding testing requirements across supply chains. This trend is particularly pronounced in children's products, furniture, and household goods categories.

The market demonstrates distinct regional characteristics, with North America currently holding the largest market share at 38%, followed by Europe at 32% and Asia-Pacific at 24%. However, the Asia-Pacific region is projected to witness the fastest growth rate due to rapid industrialization, increasing environmental awareness, and strengthening regulatory frameworks in countries like China and India.

Cost considerations remain a significant factor influencing market dynamics. While GC-MS testing solutions command premium pricing due to their precision and comprehensive capabilities, wet chemical methods maintain substantial market share in cost-sensitive segments and applications requiring only basic compliance verification. This price-performance trade-off continues to shape purchasing decisions, particularly among small and medium enterprises.

GC-MS and Wet Chemical Methods: Current Status and Challenges

Gas Chromatography-Mass Spectrometry (GC-MS) has emerged as the gold standard for Volatile Organic Compound (VOC) testing across multiple industries. This sophisticated analytical technique combines the separation capabilities of gas chromatography with the detection specificity of mass spectrometry, enabling precise identification and quantification of complex VOC mixtures at parts-per-billion levels. Current GC-MS systems feature advanced technologies including triple quadrupole mass analyzers, time-of-flight detection, and automated sample preparation systems that significantly enhance analytical performance.

Despite its advantages, GC-MS faces several technical challenges. The high equipment costs (typically $50,000-$500,000) create significant barriers to entry for smaller laboratories. Operational complexity necessitates specialized training and expertise, while maintenance requirements contribute to substantial ongoing costs. Sample preparation remains labor-intensive despite automation advances, and the technique struggles with highly polar or thermally unstable compounds that may degrade during analysis.

Traditional wet chemical methods for VOC testing, including colorimetric techniques, titration, and spectrophotometric methods, continue to maintain relevance in specific applications. These approaches offer advantages in terms of accessibility, with equipment costs typically under $10,000, and can be performed with minimal specialized training. Recent innovations in microfluidic platforms and smartphone-integrated colorimetric readers have revitalized these techniques for field applications.

However, wet chemical methods face significant limitations in analytical performance. They typically offer poorer detection limits (parts-per-million rather than parts-per-billion), limited compound specificity, and reduced accuracy compared to instrumental methods. Many traditional wet chemical approaches also involve hazardous reagents that present environmental and safety concerns.

The geographical distribution of these technologies reveals interesting patterns. GC-MS dominance is concentrated in North America, Western Europe, and East Asia, particularly in regulatory, research, and high-value manufacturing settings. Wet chemical methods maintain stronger presence in developing regions and field-testing applications where cost and portability outweigh analytical performance requirements.

Current research focuses on addressing the limitations of both approaches. For GC-MS, miniaturization efforts aim to develop portable, lower-cost systems with simplified interfaces. Meanwhile, wet chemical methods are being enhanced through novel selective reagents, microfluidic platforms, and digital integration to improve specificity and sensitivity while reducing environmental impact.

Despite its advantages, GC-MS faces several technical challenges. The high equipment costs (typically $50,000-$500,000) create significant barriers to entry for smaller laboratories. Operational complexity necessitates specialized training and expertise, while maintenance requirements contribute to substantial ongoing costs. Sample preparation remains labor-intensive despite automation advances, and the technique struggles with highly polar or thermally unstable compounds that may degrade during analysis.

Traditional wet chemical methods for VOC testing, including colorimetric techniques, titration, and spectrophotometric methods, continue to maintain relevance in specific applications. These approaches offer advantages in terms of accessibility, with equipment costs typically under $10,000, and can be performed with minimal specialized training. Recent innovations in microfluidic platforms and smartphone-integrated colorimetric readers have revitalized these techniques for field applications.

However, wet chemical methods face significant limitations in analytical performance. They typically offer poorer detection limits (parts-per-million rather than parts-per-billion), limited compound specificity, and reduced accuracy compared to instrumental methods. Many traditional wet chemical approaches also involve hazardous reagents that present environmental and safety concerns.

The geographical distribution of these technologies reveals interesting patterns. GC-MS dominance is concentrated in North America, Western Europe, and East Asia, particularly in regulatory, research, and high-value manufacturing settings. Wet chemical methods maintain stronger presence in developing regions and field-testing applications where cost and portability outweigh analytical performance requirements.

Current research focuses on addressing the limitations of both approaches. For GC-MS, miniaturization efforts aim to develop portable, lower-cost systems with simplified interfaces. Meanwhile, wet chemical methods are being enhanced through novel selective reagents, microfluidic platforms, and digital integration to improve specificity and sensitivity while reducing environmental impact.

Comparative Analysis of Current VOC Testing Techniques

01 Comparative analysis of GC-MS and wet chemical methods

Gas Chromatography-Mass Spectrometry (GC-MS) and wet chemical methods offer different advantages in analytical testing. GC-MS provides higher sensitivity for volatile compounds and can detect trace amounts of substances, while wet chemical methods are often more accessible and cost-effective for routine analysis. Comparative studies show that GC-MS typically offers better detection limits and specificity, whereas wet chemical methods may be more suitable for field testing and situations requiring rapid results without sophisticated equipment.- GC-MS method optimization for enhanced sensitivity and accuracy: Gas Chromatography-Mass Spectrometry (GC-MS) methods can be optimized to improve sensitivity and accuracy in analytical testing. This involves adjusting parameters such as temperature programming, carrier gas flow rates, and detector settings. Advanced GC-MS techniques incorporate internal standards and calibration curves to enhance quantitative accuracy. These optimizations allow for detection of trace compounds at lower concentrations while maintaining high precision in complex sample matrices.

- Comparative analysis of GC-MS versus wet chemical methods: Comparative studies between GC-MS and traditional wet chemical methods demonstrate different strengths in analytical applications. GC-MS typically offers superior sensitivity and specificity for volatile and semi-volatile compounds, while wet chemical methods may provide advantages in simplicity, cost-effectiveness, and applicability to certain sample types. The selection between these methodologies depends on factors such as required detection limits, sample complexity, and available resources. In some cases, combining both approaches yields complementary data for comprehensive analysis.

- Sample preparation techniques to improve testing efficiency: Advanced sample preparation techniques significantly impact the efficiency and accuracy of both GC-MS and wet chemical testing methods. Innovations include automated extraction systems, solid-phase microextraction (SPME), and matrix-matched calibration approaches. These techniques reduce analysis time, minimize contamination risks, and improve reproducibility. Proper sample preparation also helps eliminate matrix interference effects, leading to more reliable quantitative results and higher sample throughput in analytical laboratories.

- Method validation protocols for analytical reliability: Comprehensive validation protocols are essential for establishing the reliability of both GC-MS and wet chemical testing methods. These protocols evaluate key performance parameters including linearity, precision, accuracy, specificity, limit of detection (LOD), limit of quantification (LOQ), and robustness. Statistical approaches such as recovery studies and uncertainty measurements help quantify method performance. Properly validated methods ensure consistent results across different operators, instruments, and laboratories, which is critical for regulatory compliance and quality assurance in analytical testing.

- Application-specific testing method development: Tailored analytical methods are developed for specific applications to optimize the balance between accuracy, efficiency, and sensitivity. For environmental monitoring, food safety, pharmaceutical analysis, and forensic investigations, customized GC-MS and wet chemical methods address unique matrix challenges and target analyte requirements. These specialized approaches may incorporate modified extraction procedures, specialized derivatization techniques, or custom detection parameters. Application-specific method development ensures that analytical performance meets the particular needs of each testing scenario while maximizing resource efficiency.

02 Sensitivity enhancements in analytical testing methods

Various techniques have been developed to enhance the sensitivity of both GC-MS and wet chemical testing methods. These include sample preparation optimization, derivatization techniques for GC-MS, and concentration steps for wet chemical methods. Advanced detector technologies in GC-MS systems have significantly improved detection limits, while modifications to traditional wet chemical protocols, such as colorimetric intensification and fluorescence-based detection, have enhanced their sensitivity for specific analytes.Expand Specific Solutions03 Efficiency improvements in testing workflows

Innovations in both GC-MS and wet chemical testing have focused on improving efficiency through automation, miniaturization, and integrated systems. Automated sample preparation, high-throughput GC-MS configurations, and rapid wet chemical test kits have reduced analysis time and labor requirements. Multi-analyte detection methods allow for simultaneous testing of multiple parameters, while portable and field-deployable systems enable on-site analysis, eliminating transportation delays and sample degradation issues.Expand Specific Solutions04 Accuracy validation and calibration techniques

Ensuring accuracy in analytical testing requires robust validation and calibration protocols. For GC-MS, this includes internal standardization, matrix-matched calibration, and quality control samples. Wet chemical methods rely on standard reference materials, calibration curves, and replicate analyses. Statistical methods for data evaluation, such as limit of detection calculations and uncertainty measurements, are essential for both approaches. Regular proficiency testing and inter-laboratory comparisons help maintain analytical quality and reliability across different testing facilities.Expand Specific Solutions05 Application-specific method selection criteria

The selection between GC-MS and wet chemical methods depends on specific application requirements. Factors influencing this choice include the nature of the analyte, required detection limits, sample matrix complexity, available resources, and regulatory requirements. GC-MS is preferred for complex mixtures requiring component separation and identification, while wet chemical methods may be more suitable for targeted analyses of specific compounds or properties. Hybrid approaches combining both methodologies can provide comprehensive analytical solutions for challenging samples.Expand Specific Solutions

Key Industry Players in VOC Testing Equipment and Services

The VOC testing market is in a growth phase, with GC-MS and wet chemical methods representing contrasting approaches in analytical technology. The market is expanding due to increasing environmental regulations and industrial quality control requirements, estimated at approximately $1.2 billion globally. GC-MS technology has reached higher maturity, offering superior sensitivity and specificity, as evidenced by innovations from companies like Entech Instruments and Markes International who specialize in advanced sample preconcentration systems. Meanwhile, wet chemical methods remain relevant for specific applications due to lower cost and simplicity. Companies like SGS-CSTC and Jiangsu Kangda Testing Technology are integrating both methodologies to provide comprehensive testing services, while research institutions such as Technion Research Foundation and Tongji University continue developing hybrid approaches to optimize testing efficiency.

Entech Instruments, Inc.

Technical Solution: Entech Instruments has developed specialized GC-MS sample preparation systems that address key limitations in traditional VOC analysis. Their technology focuses on whole-air sampling and preconcentration techniques that preserve sample integrity while enhancing analytical sensitivity. Entech's patented Silonite™ coating technology prevents active compound adsorption on sampling equipment surfaces, a common source of data bias in VOC analysis. Their multi-stage preconcentration systems employ sequential cryogenic trapping to effectively separate VOCs from moisture and CO2, which typically interfere with analysis. The company's automated canister cleaning systems ensure ultra-low background levels, critical for trace VOC detection. Entech's integrated approach includes specialized hardware for both field sampling (canisters, bags, and on-site concentrators) and laboratory analysis, with automated systems that maintain sample integrity throughout the analytical process. Their technology enables detection limits in the parts-per-trillion range while minimizing artifacts that plague conventional methods.

Strengths: Exceptional sample integrity preservation; effective elimination of moisture and CO2 interference; ultra-low detection limits; comprehensive sampling-to-analysis workflow solutions; reduced analytical bias. Weaknesses: Higher complexity and cost compared to basic wet chemical methods; requires specialized training; longer setup time; more complex quality control procedures; higher maintenance requirements than simpler analytical approaches.

Focused Photonics (Hangzhou), Inc.

Technical Solution: Focused Photonics has developed an innovative hybrid approach to VOC testing that combines elements of both GC-MS and wet chemical methodologies. Their technology integrates traditional GC-MS with spectroscopic techniques and automated chemical derivatization processes. The company's systems employ specialized pre-concentration techniques with selective chemical reactions that enhance detection of specific VOC classes. Their automated platforms incorporate microfluidic technology for precise handling of small sample volumes and reagents, reducing chemical waste compared to traditional wet methods. Focused Photonics' systems feature multi-channel detection capabilities, allowing simultaneous analysis via mass spectrometry and spectrophotometric methods, providing complementary data streams that enhance compound identification confidence. Their technology includes real-time monitoring capabilities with automated calibration and quality control procedures, making it suitable for continuous environmental monitoring applications. The integration of machine learning algorithms enables adaptive method optimization based on sample characteristics.

Strengths: Complementary detection mechanisms enhance identification confidence; reduced chemical waste compared to traditional wet methods; automated calibration and quality control; real-time monitoring capabilities; adaptive method optimization. Weaknesses: Complex system integration requires specialized maintenance; higher initial investment than standalone methods; more complex data interpretation requiring specialized expertise; potential for chemical interference in hybrid detection approach.

Technical Innovations in GC-MS and Wet Chemical Methods

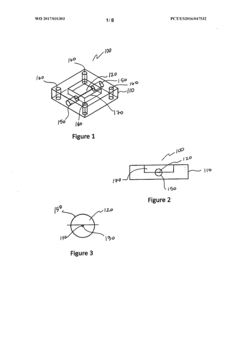

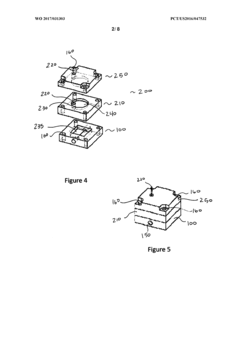

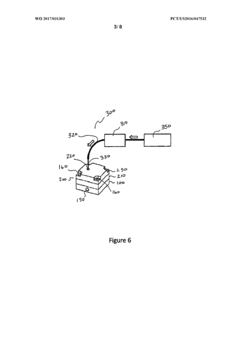

Analyte sensor and method of use

PatentWO2017031303A1

Innovation

- A sensor assembly utilizing a metal substrate with a polymer waveguide that optically couples fiber optic cables, employing heat stripping absorption spectroscopy to capture, pre-concentrate, and quantify analytes by adjusting temperature thresholds and analyzing absorption spectra to determine concentrations of VOCs like acetone and toluene.

Regulatory Standards and Compliance Requirements for VOC Testing

Regulatory frameworks for Volatile Organic Compounds (VOC) testing vary significantly across regions, with the United States Environmental Protection Agency (EPA) and the European Union's REACH regulation being the most influential globally. The EPA's Method TO-15 specifically addresses VOC analysis using GC-MS techniques, requiring detection limits in the parts per billion (ppb) range for ambient air monitoring. This method mandates specific calibration procedures, quality control measures, and reporting formats that laboratories must adhere to when utilizing GC-MS technology.

In contrast, traditional wet chemical methods are governed by different regulatory standards, including EPA Method 24 for determining VOC content in paints and coatings. This method specifies gravimetric procedures and calculation formulas that differ substantially from instrumental approaches. The American Society for Testing and Materials (ASTM) has developed several standard test methods for VOC determination using wet chemical techniques, including ASTM D2369 and ASTM D3960.

Compliance requirements also differ based on the testing methodology employed. GC-MS methods typically require more stringent laboratory accreditation standards, including ISO/IEC 17025 certification with specific scope listings for chromatographic analysis. Laboratories must demonstrate proficiency through regular participation in performance evaluation studies and maintain extensive documentation of instrument calibration, maintenance, and quality control procedures.

For industries subject to emissions monitoring, the choice between GC-MS and wet chemical methods has significant compliance implications. Many regulatory frameworks now specify preferred methodologies for particular applications, with GC-MS increasingly becoming the reference method for enforcement actions. The Clean Air Act in the United States and similar legislation in other countries establish legally binding VOC emission limits that necessitate accurate, defensible testing methodologies.

International harmonization efforts are underway to standardize VOC testing requirements across borders, with organizations like the International Organization for Standardization (ISO) developing consensus standards that incorporate both instrumental and wet chemical approaches. ISO 16000 series standards address VOC emissions from building materials and consumer products, providing testing protocols that can be referenced in regulatory frameworks worldwide.

Emerging regulations are increasingly focusing on specific VOC compounds of concern rather than total VOC measurements, favoring the compound-specific capabilities of GC-MS over traditional wet chemical methods. This trend is particularly evident in regulations targeting indoor air quality and consumer product safety, where the identification of individual compounds with health implications is becoming a priority for compliance requirements.

In contrast, traditional wet chemical methods are governed by different regulatory standards, including EPA Method 24 for determining VOC content in paints and coatings. This method specifies gravimetric procedures and calculation formulas that differ substantially from instrumental approaches. The American Society for Testing and Materials (ASTM) has developed several standard test methods for VOC determination using wet chemical techniques, including ASTM D2369 and ASTM D3960.

Compliance requirements also differ based on the testing methodology employed. GC-MS methods typically require more stringent laboratory accreditation standards, including ISO/IEC 17025 certification with specific scope listings for chromatographic analysis. Laboratories must demonstrate proficiency through regular participation in performance evaluation studies and maintain extensive documentation of instrument calibration, maintenance, and quality control procedures.

For industries subject to emissions monitoring, the choice between GC-MS and wet chemical methods has significant compliance implications. Many regulatory frameworks now specify preferred methodologies for particular applications, with GC-MS increasingly becoming the reference method for enforcement actions. The Clean Air Act in the United States and similar legislation in other countries establish legally binding VOC emission limits that necessitate accurate, defensible testing methodologies.

International harmonization efforts are underway to standardize VOC testing requirements across borders, with organizations like the International Organization for Standardization (ISO) developing consensus standards that incorporate both instrumental and wet chemical approaches. ISO 16000 series standards address VOC emissions from building materials and consumer products, providing testing protocols that can be referenced in regulatory frameworks worldwide.

Emerging regulations are increasingly focusing on specific VOC compounds of concern rather than total VOC measurements, favoring the compound-specific capabilities of GC-MS over traditional wet chemical methods. This trend is particularly evident in regulations targeting indoor air quality and consumer product safety, where the identification of individual compounds with health implications is becoming a priority for compliance requirements.

Cost-Benefit Analysis of Different VOC Testing Approaches

When evaluating VOC testing methodologies, cost-benefit analysis reveals significant differences between GC-MS and wet chemical approaches. GC-MS systems require substantial initial capital investment, typically ranging from $50,000 to $250,000 depending on configuration and capabilities. Additionally, these systems necessitate specialized laboratory infrastructure, including controlled environments and gas supply systems, further increasing setup costs.

Operational expenses for GC-MS include maintenance contracts ($5,000-15,000 annually), consumables such as carrier gases and columns, and skilled technician salaries. However, the per-sample analysis cost decreases significantly with higher testing volumes, making GC-MS economically advantageous for high-throughput laboratories processing hundreds of samples monthly.

Wet chemical methods present a contrasting financial profile with lower initial investment (typically $5,000-20,000) for basic equipment like spectrophotometers and chemical reagents. These methods require less specialized infrastructure, making them accessible to smaller facilities with limited resources. The per-sample cost remains relatively stable regardless of testing volume, typically ranging from $30-100 per sample.

Time efficiency considerations reveal GC-MS offers rapid results (30-60 minutes per sample) with minimal hands-on time once automated sequences are established. Wet chemical approaches generally require 1-4 hours per sample with significant hands-on technician involvement, increasing labor costs and reducing throughput capacity.

Accuracy and reliability metrics favor GC-MS, which provides superior detection limits (often in ppb range) and comprehensive compound identification capabilities. This precision reduces false positives/negatives and associated remediation costs. Wet chemical methods, while adequate for screening, may require confirmatory testing when regulatory compliance is critical, potentially doubling testing expenses.

Long-term value assessment indicates GC-MS systems maintain significant resale value (30-50% after 5-7 years) and can be upgraded rather than replaced as technology advances. The versatility of GC-MS also allows laboratories to expand testing services without additional major equipment purchases. Wet chemical methods offer flexibility for occasional testing needs but become less economical as testing requirements increase in volume or complexity.

Operational expenses for GC-MS include maintenance contracts ($5,000-15,000 annually), consumables such as carrier gases and columns, and skilled technician salaries. However, the per-sample analysis cost decreases significantly with higher testing volumes, making GC-MS economically advantageous for high-throughput laboratories processing hundreds of samples monthly.

Wet chemical methods present a contrasting financial profile with lower initial investment (typically $5,000-20,000) for basic equipment like spectrophotometers and chemical reagents. These methods require less specialized infrastructure, making them accessible to smaller facilities with limited resources. The per-sample cost remains relatively stable regardless of testing volume, typically ranging from $30-100 per sample.

Time efficiency considerations reveal GC-MS offers rapid results (30-60 minutes per sample) with minimal hands-on time once automated sequences are established. Wet chemical approaches generally require 1-4 hours per sample with significant hands-on technician involvement, increasing labor costs and reducing throughput capacity.

Accuracy and reliability metrics favor GC-MS, which provides superior detection limits (often in ppb range) and comprehensive compound identification capabilities. This precision reduces false positives/negatives and associated remediation costs. Wet chemical methods, while adequate for screening, may require confirmatory testing when regulatory compliance is critical, potentially doubling testing expenses.

Long-term value assessment indicates GC-MS systems maintain significant resale value (30-50% after 5-7 years) and can be upgraded rather than replaced as technology advances. The versatility of GC-MS also allows laboratories to expand testing services without additional major equipment purchases. Wet chemical methods offer flexibility for occasional testing needs but become less economical as testing requirements increase in volume or complexity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!