GC-MS and XRF: Chemistry Lab Synergy in Innovation

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GC-MS and XRF Technology Evolution and Objectives

Gas Chromatography-Mass Spectrometry (GC-MS) and X-Ray Fluorescence (XRF) technologies have evolved significantly over the past decades, transforming analytical chemistry capabilities across multiple industries. GC-MS emerged in the 1950s when the first successful coupling of gas chromatography with mass spectrometry was achieved, while XRF has roots dating back to the early 20th century with the discovery of X-ray characteristic emissions from elements.

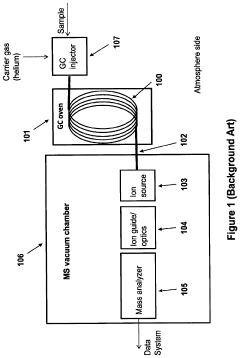

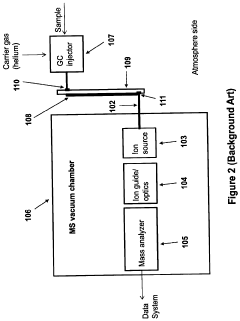

The evolution of GC-MS has been marked by continuous improvements in sensitivity, resolution, and data processing capabilities. Early systems were large, expensive, and required significant expertise to operate. Modern GC-MS instruments have become more compact, automated, and user-friendly, with detection limits reaching parts-per-trillion levels. The development of various ionization techniques, including electron impact (EI), chemical ionization (CI), and more recently, soft ionization methods, has expanded the range of compounds that can be analyzed.

XRF technology has similarly progressed from basic wavelength-dispersive systems to advanced energy-dispersive instruments with enhanced sensitivity and spatial resolution. The introduction of silicon drift detectors (SDDs) in the 1990s revolutionized XRF by enabling faster acquisition times and improved energy resolution. Portable XRF analyzers, developed in the early 2000s, have democratized elemental analysis by bringing laboratory-grade capabilities to field applications.

The convergence of these technologies represents a significant trend, with complementary data from both techniques providing comprehensive chemical characterization. GC-MS excels at identifying and quantifying organic compounds, while XRF provides rapid, non-destructive elemental analysis. This synergy addresses the growing demand for multi-dimensional analytical approaches in complex sample matrices.

Current technological objectives focus on further miniaturization, increased automation, and enhanced data integration. There is a push toward developing more portable, field-deployable systems that maintain laboratory-grade performance. Machine learning and artificial intelligence are being incorporated to improve data interpretation and pattern recognition, particularly for complex mixtures and unknown compounds.

Another key objective is the development of more sustainable analytical methods, with reduced solvent consumption, lower energy requirements, and minimized waste generation. This aligns with broader industry trends toward green chemistry and sustainable laboratory practices.

The integration of these technologies with other analytical platforms, such as liquid chromatography, infrared spectroscopy, and nuclear magnetic resonance, represents an emerging frontier. This multi-modal approach aims to provide more comprehensive chemical fingerprinting capabilities, essential for applications ranging from environmental monitoring to pharmaceutical development and forensic analysis.

The evolution of GC-MS has been marked by continuous improvements in sensitivity, resolution, and data processing capabilities. Early systems were large, expensive, and required significant expertise to operate. Modern GC-MS instruments have become more compact, automated, and user-friendly, with detection limits reaching parts-per-trillion levels. The development of various ionization techniques, including electron impact (EI), chemical ionization (CI), and more recently, soft ionization methods, has expanded the range of compounds that can be analyzed.

XRF technology has similarly progressed from basic wavelength-dispersive systems to advanced energy-dispersive instruments with enhanced sensitivity and spatial resolution. The introduction of silicon drift detectors (SDDs) in the 1990s revolutionized XRF by enabling faster acquisition times and improved energy resolution. Portable XRF analyzers, developed in the early 2000s, have democratized elemental analysis by bringing laboratory-grade capabilities to field applications.

The convergence of these technologies represents a significant trend, with complementary data from both techniques providing comprehensive chemical characterization. GC-MS excels at identifying and quantifying organic compounds, while XRF provides rapid, non-destructive elemental analysis. This synergy addresses the growing demand for multi-dimensional analytical approaches in complex sample matrices.

Current technological objectives focus on further miniaturization, increased automation, and enhanced data integration. There is a push toward developing more portable, field-deployable systems that maintain laboratory-grade performance. Machine learning and artificial intelligence are being incorporated to improve data interpretation and pattern recognition, particularly for complex mixtures and unknown compounds.

Another key objective is the development of more sustainable analytical methods, with reduced solvent consumption, lower energy requirements, and minimized waste generation. This aligns with broader industry trends toward green chemistry and sustainable laboratory practices.

The integration of these technologies with other analytical platforms, such as liquid chromatography, infrared spectroscopy, and nuclear magnetic resonance, represents an emerging frontier. This multi-modal approach aims to provide more comprehensive chemical fingerprinting capabilities, essential for applications ranging from environmental monitoring to pharmaceutical development and forensic analysis.

Market Applications and Demand Analysis

The global market for analytical instrumentation has witnessed significant growth, with GC-MS and XRF technologies emerging as critical tools across multiple industries. The combined market for these technologies exceeded $10 billion in 2022, with projections indicating a compound annual growth rate of 5.7% through 2028. This growth is primarily driven by increasing demand for precise analytical capabilities in pharmaceuticals, environmental monitoring, materials science, and industrial quality control.

In the pharmaceutical sector, the demand for GC-MS technology has intensified due to stringent regulatory requirements for drug development and quality assurance. Pharmaceutical companies are increasingly investing in advanced analytical technologies to ensure compliance with evolving regulatory standards while accelerating drug discovery processes. The integration of GC-MS with XRF capabilities allows for comprehensive chemical profiling, significantly reducing development timelines and associated costs.

Environmental monitoring represents another substantial market segment, with government agencies and private organizations deploying these technologies for pollution assessment, water quality analysis, and soil contamination studies. The growing public awareness regarding environmental health has prompted regulatory bodies worldwide to implement stricter monitoring protocols, thereby expanding the market for integrated analytical solutions combining GC-MS and XRF capabilities.

The materials science and manufacturing sectors demonstrate robust demand for XRF technology, particularly for non-destructive elemental analysis in quality control processes. Industries ranging from aerospace to electronics manufacturing utilize XRF for rapid composition verification and contaminant detection. When paired with GC-MS capabilities, these systems provide unprecedented insights into both elemental composition and molecular structure, enabling more comprehensive material characterization.

Food safety and agricultural applications represent emerging market opportunities, with increasing regulatory focus on contaminant detection and nutritional analysis. The ability to simultaneously analyze organic compounds via GC-MS and elemental composition via XRF offers significant advantages for comprehensive food safety assessment, driving adoption across the global food production chain.

Regional market analysis reveals North America and Europe as leading consumers of these technologies, accounting for approximately 60% of global market share. However, Asia-Pacific regions, particularly China and India, demonstrate the highest growth rates, driven by expanding industrial bases, increasing environmental concerns, and growing investment in research infrastructure. This regional diversification presents significant opportunities for technology providers to develop market-specific solutions addressing unique regulatory and application requirements.

In the pharmaceutical sector, the demand for GC-MS technology has intensified due to stringent regulatory requirements for drug development and quality assurance. Pharmaceutical companies are increasingly investing in advanced analytical technologies to ensure compliance with evolving regulatory standards while accelerating drug discovery processes. The integration of GC-MS with XRF capabilities allows for comprehensive chemical profiling, significantly reducing development timelines and associated costs.

Environmental monitoring represents another substantial market segment, with government agencies and private organizations deploying these technologies for pollution assessment, water quality analysis, and soil contamination studies. The growing public awareness regarding environmental health has prompted regulatory bodies worldwide to implement stricter monitoring protocols, thereby expanding the market for integrated analytical solutions combining GC-MS and XRF capabilities.

The materials science and manufacturing sectors demonstrate robust demand for XRF technology, particularly for non-destructive elemental analysis in quality control processes. Industries ranging from aerospace to electronics manufacturing utilize XRF for rapid composition verification and contaminant detection. When paired with GC-MS capabilities, these systems provide unprecedented insights into both elemental composition and molecular structure, enabling more comprehensive material characterization.

Food safety and agricultural applications represent emerging market opportunities, with increasing regulatory focus on contaminant detection and nutritional analysis. The ability to simultaneously analyze organic compounds via GC-MS and elemental composition via XRF offers significant advantages for comprehensive food safety assessment, driving adoption across the global food production chain.

Regional market analysis reveals North America and Europe as leading consumers of these technologies, accounting for approximately 60% of global market share. However, Asia-Pacific regions, particularly China and India, demonstrate the highest growth rates, driven by expanding industrial bases, increasing environmental concerns, and growing investment in research infrastructure. This regional diversification presents significant opportunities for technology providers to develop market-specific solutions addressing unique regulatory and application requirements.

Current Technical Challenges and Limitations

Despite the significant advancements in both Gas Chromatography-Mass Spectrometry (GC-MS) and X-Ray Fluorescence (XRF) technologies, several technical challenges and limitations persist that hinder their optimal integration and synergistic application in modern chemistry laboratories. These challenges span across hardware compatibility, data integration, sensitivity disparities, and operational complexities.

Sample preparation remains a critical bottleneck in the synergistic workflow between GC-MS and XRF. While XRF requires minimal sample preparation for solid samples, GC-MS often necessitates complex extraction, derivatization, and purification procedures. This disparity creates workflow inefficiencies when attempting to analyze the same sample with both techniques, particularly for heterogeneous materials or complex matrices.

Data integration presents another significant challenge. The fundamentally different data outputs from GC-MS (time-resolved molecular fragmentation patterns) and XRF (elemental composition) lack standardized integration protocols. Current software solutions typically handle each data type separately, requiring manual correlation and interpretation by skilled analysts, which introduces potential for human error and interpretation bias.

Sensitivity and detection limit disparities between the two techniques complicate complementary analysis. GC-MS offers exceptional sensitivity for organic compounds (often in the ppb range), while XRF typically operates in the ppm range for most elements. This discrepancy creates analytical gaps when attempting to correlate trace organic compounds with their elemental constituents.

Instrument footprint and laboratory space requirements pose practical limitations. Both technologies require substantial bench space, specialized utilities, and controlled environmental conditions. The combined spatial requirements often exceed the capacity of standard laboratories, particularly in academic or small industrial settings, limiting widespread adoption of the integrated approach.

Cost considerations represent a significant barrier to implementation. High-end GC-MS and XRF systems each typically cost between $100,000-$500,000, with additional expenses for specialized accessories, maintenance contracts, and trained personnel. This substantial investment often forces laboratories to prioritize one technology over the other, limiting synergistic applications.

Calibration and quality control challenges emerge when attempting to validate complementary methods. The lack of certified reference materials suitable for both techniques complicates method validation and introduces uncertainty in comparative analyses. This is particularly problematic for novel applications where established protocols do not exist.

Expertise requirements present a human resource challenge. Proficiency in both GC-MS and XRF typically requires different educational backgrounds and skill sets. Finding analysts competent in both techniques or facilitating effective collaboration between specialists remains difficult for many organizations, limiting the realization of the full potential of these complementary technologies.

Sample preparation remains a critical bottleneck in the synergistic workflow between GC-MS and XRF. While XRF requires minimal sample preparation for solid samples, GC-MS often necessitates complex extraction, derivatization, and purification procedures. This disparity creates workflow inefficiencies when attempting to analyze the same sample with both techniques, particularly for heterogeneous materials or complex matrices.

Data integration presents another significant challenge. The fundamentally different data outputs from GC-MS (time-resolved molecular fragmentation patterns) and XRF (elemental composition) lack standardized integration protocols. Current software solutions typically handle each data type separately, requiring manual correlation and interpretation by skilled analysts, which introduces potential for human error and interpretation bias.

Sensitivity and detection limit disparities between the two techniques complicate complementary analysis. GC-MS offers exceptional sensitivity for organic compounds (often in the ppb range), while XRF typically operates in the ppm range for most elements. This discrepancy creates analytical gaps when attempting to correlate trace organic compounds with their elemental constituents.

Instrument footprint and laboratory space requirements pose practical limitations. Both technologies require substantial bench space, specialized utilities, and controlled environmental conditions. The combined spatial requirements often exceed the capacity of standard laboratories, particularly in academic or small industrial settings, limiting widespread adoption of the integrated approach.

Cost considerations represent a significant barrier to implementation. High-end GC-MS and XRF systems each typically cost between $100,000-$500,000, with additional expenses for specialized accessories, maintenance contracts, and trained personnel. This substantial investment often forces laboratories to prioritize one technology over the other, limiting synergistic applications.

Calibration and quality control challenges emerge when attempting to validate complementary methods. The lack of certified reference materials suitable for both techniques complicates method validation and introduces uncertainty in comparative analyses. This is particularly problematic for novel applications where established protocols do not exist.

Expertise requirements present a human resource challenge. Proficiency in both GC-MS and XRF typically requires different educational backgrounds and skill sets. Finding analysts competent in both techniques or facilitating effective collaboration between specialists remains difficult for many organizations, limiting the realization of the full potential of these complementary technologies.

Integrated Analytical Solutions and Workflows

01 Complementary analytical capabilities of GC-MS and XRF

The integration of Gas Chromatography-Mass Spectrometry (GC-MS) and X-Ray Fluorescence (XRF) technologies provides complementary analytical capabilities. GC-MS excels at identifying organic compounds and volatile substances at molecular level, while XRF is effective for elemental analysis of inorganic materials. This synergy allows for comprehensive characterization of complex samples, enabling both molecular composition and elemental content analysis in various applications including environmental monitoring, material science, and forensic investigations.- Complementary analytical capabilities of GC-MS and XRF: GC-MS (Gas Chromatography-Mass Spectrometry) and XRF (X-Ray Fluorescence) technologies offer complementary analytical capabilities when used together. GC-MS excels at identifying organic compounds and volatile substances at molecular level, while XRF provides elemental analysis and is particularly effective for detecting metals and inorganic elements. This synergistic combination allows for comprehensive material characterization across both organic and inorganic components, enabling more complete analytical profiles than either technology alone could provide.

- Multi-technique analytical systems integration: Integrated analytical systems that combine GC-MS and XRF technologies within unified platforms or workflows represent an important advancement in materials analysis. These systems feature shared sample preparation protocols, coordinated data acquisition, and integrated software interfaces that allow for streamlined analysis. The integration reduces analysis time, minimizes sample handling, and enables correlation of complementary data sets. Such systems are particularly valuable in complex sample analysis where both elemental composition and molecular structure determination are required.

- Environmental and geological applications: The synergistic use of GC-MS and XRF technologies has significant applications in environmental monitoring and geological analysis. In environmental studies, this combination allows for simultaneous detection of organic pollutants (via GC-MS) and heavy metals or other inorganic contaminants (via XRF) in soil, water, and air samples. For geological applications, the technologies together provide comprehensive characterization of rock and mineral samples, with XRF determining elemental composition while GC-MS identifies organic biomarkers that can indicate geological processes or fossil fuel potential.

- Advanced material characterization and quality control: The combination of GC-MS and XRF enables advanced material characterization and quality control across multiple industries. This analytical synergy is particularly valuable for complex materials where both organic composition and elemental makeup are critical quality parameters. Applications include polymer analysis, where XRF can identify inorganic additives while GC-MS characterizes the organic polymer components; pharmaceutical analysis, where both active ingredients and trace elements are monitored; and cultural heritage conservation, where understanding both pigment elements and binding media is essential.

- Data fusion and correlation methodologies: Advanced data fusion and correlation methodologies have been developed to maximize the synergistic potential of GC-MS and XRF technologies. These approaches include multivariate statistical techniques, machine learning algorithms, and specialized software tools that can integrate and correlate data from both analytical methods. By applying these data fusion techniques, researchers can identify relationships between elemental composition and molecular structure, enabling deeper insights into material properties, formation processes, and degradation mechanisms that would not be apparent when analyzing data from each technique separately.

02 Multi-technique analytical systems combining GC-MS and XRF

Integrated analytical systems that combine GC-MS and XRF technologies in a single platform or workflow have been developed to enhance analytical efficiency. These systems allow for sequential or simultaneous analysis of samples using both techniques, reducing sample preparation requirements and analysis time. The combined approach provides more comprehensive data sets and improves the reliability of results through cross-validation between techniques, particularly valuable for complex matrices in environmental, geological, and industrial applications.Expand Specific Solutions03 Data fusion and correlation methods for GC-MS and XRF results

Advanced data processing methods have been developed to correlate and integrate results from GC-MS and XRF analyses. These computational approaches include multivariate statistical analysis, machine learning algorithms, and chemometric methods that can identify relationships between molecular composition and elemental content. The correlation of data from both techniques enhances pattern recognition, improves classification accuracy, and provides deeper insights into sample characteristics and origin, particularly useful for authentication, quality control, and forensic applications.Expand Specific Solutions04 Environmental and geological applications of combined GC-MS and XRF analysis

The synergistic use of GC-MS and XRF technologies has significant applications in environmental monitoring and geological studies. This combined approach allows for comprehensive characterization of soil, sediment, and water samples by identifying both organic pollutants (via GC-MS) and heavy metals or mineral content (via XRF). The integration of these techniques enables better understanding of contaminant sources, transport mechanisms, weathering processes, and biogeochemical cycles, supporting more effective environmental remediation strategies and resource exploration.Expand Specific Solutions05 Material authentication and quality control using GC-MS and XRF

The combination of GC-MS and XRF technologies provides powerful tools for authentication and quality control of various materials including pharmaceuticals, cultural heritage items, and industrial products. GC-MS identifies organic markers, additives, and degradation products, while XRF determines elemental composition and detects inorganic adulterants or contaminants. This multi-analytical approach enables comprehensive fingerprinting of materials, detection of counterfeits, assessment of degradation processes, and verification of manufacturing consistency, enhancing quality assurance processes across multiple industries.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The GC-MS and XRF technology market is currently in a growth phase, with increasing integration between these complementary analytical techniques creating new innovation opportunities. The global market size for these technologies is expanding steadily, driven by applications in pharmaceuticals, materials science, and environmental monitoring. In terms of technical maturity, established players like Shimadzu Corporation and Olympus IMS lead with comprehensive commercial solutions, while academic institutions such as MIT, Zhejiang University, and The Salk Institute are advancing fundamental research. Emerging companies like Sigray and Spectra Analysis Instruments are introducing specialized innovations. The competitive landscape shows a healthy balance between large analytical instrument manufacturers and niche technology providers, with increasing collaboration between industry and academic research centers driving synergistic applications.

Shimadzu Corp.

Technical Solution: Shimadzu Corporation has developed advanced integrated GC-MS and XRF systems that enable comprehensive chemical analysis workflows. Their GCMS-TQ™ series combines triple quadrupole technology with high-sensitivity detectors, achieving detection limits in the femtogram range for trace analysis[1]. Their proprietary Smart MRM™ technology optimizes multiple reaction monitoring parameters automatically, significantly reducing method development time. For XRF analysis, Shimadzu's EDX-7000/8000 series features semiconductor detectors with high-count rate processing capabilities and proprietary calibration algorithms that correct for matrix effects[2]. Their innovation lies in the seamless integration of both technologies through unified software platforms like LabSolutions™, which enables cross-technique data correlation and interpretation. Shimadzu has also pioneered miniaturized portable XRF devices with comparable sensitivity to benchtop systems, allowing for field analysis that complements laboratory GC-MS findings[3].

Strengths: Exceptional sensitivity in both GC-MS and XRF technologies; comprehensive software integration allowing for multimodal data analysis; extensive application development support with ready-to-use methods for various industries. Weaknesses: Higher initial investment costs compared to single-technique instruments; complex systems require specialized training; maintenance costs can be significant for facilities utilizing both technologies simultaneously.

Panalytical, Inc.

Technical Solution: Panalytical has developed a revolutionary approach to materials characterization by creating synergistic workflows between their Zetium XRF spectrometer and GC-MS systems. Their XRF technology employs SumXcore processing technology that combines multiple detectors (proportional counter, scintillation, and semiconductor) to optimize element detection across the periodic table[1]. The company's innovation lies in their fusion of chemometric algorithms with hardware advancements, allowing for direct correlation between elemental composition (XRF) and molecular structure (GC-MS). Their SuperQ software platform incorporates machine learning algorithms that can predict molecular structures based on elemental ratios, significantly accelerating materials discovery processes[2]. Panalytical's systems feature standardless analysis capabilities using Fundamental Parameters approaches that reduce the need for extensive calibration standards. Their latest innovation includes the development of micro-XRF capabilities with beam sizes down to 500μm that can be mapped to specific GC-MS fractions for comprehensive characterization of heterogeneous samples[3].

Strengths: Industry-leading XRF resolution and sensitivity; sophisticated software integration between techniques; robust standardless analysis capabilities reducing operational costs; excellent application support across multiple industries. Weaknesses: Systems require significant laboratory space; higher initial investment compared to standalone instruments; complex data integration workflows require specialized expertise to fully leverage the technology's capabilities.

Key Patents and Breakthroughs in Spectroscopy

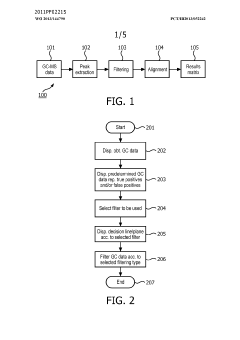

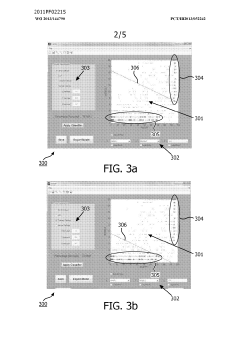

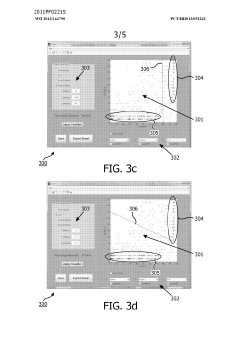

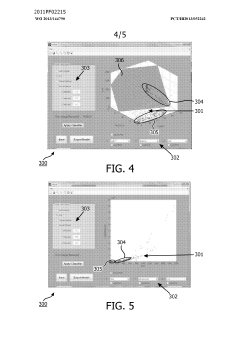

Method and system for filtering gas chromatography-mass spectrometry data

PatentWO2013144790A1

Innovation

- A method and system for filtering GC-MS data that distinguishes between true and false positives, allowing users to visually select filtering methods based on predetermined data structures and decision lines or planes, reducing data noise and improving processing efficiency.

Portable MEMS GC-ms system

PatentActiveUS20200378930A1

Innovation

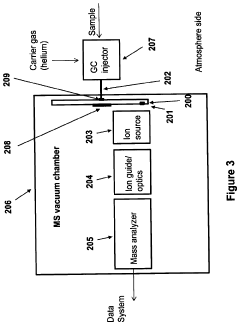

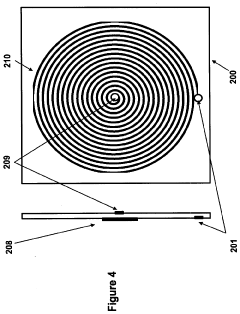

- The integration of a MEMS GC column with an integrated heater inside the MS vacuum system, leveraging the high thermal isolation properties of a vacuum to minimize heating power losses, and incorporating non-active cooling methods like a periodically activated cold finger for efficient temperature control.

Sample Preparation Advancements

Sample preparation methodologies for GC-MS and XRF analyses have undergone significant advancements in recent years, dramatically improving analytical efficiency and accuracy. Traditional sample preparation techniques often required time-consuming processes that limited throughput and introduced potential contamination risks. Modern innovations have addressed these challenges through automation, miniaturization, and novel extraction methods.

Automated sample preparation systems now integrate seamlessly with both GC-MS and XRF instruments, reducing manual handling errors and increasing reproducibility. These systems can perform multiple preparation steps including weighing, extraction, filtration, and concentration with minimal human intervention. The integration of robotic sample handlers has decreased preparation time by up to 60% while improving precision by eliminating operator variability.

Microextraction techniques represent another breakthrough, particularly for GC-MS applications. Solid-phase microextraction (SPME), stir bar sorptive extraction (SBSE), and liquid-phase microextraction (LPME) have revolutionized sample preparation by reducing solvent consumption and enabling direct extraction from complex matrices. These techniques are especially valuable for environmental and biological samples where analyte concentrations may be extremely low.

For XRF analysis, pressed pellet and fusion methods have been refined to address matrix effects and heterogeneity issues. Advanced fusion techniques using automated fluxers now produce homogeneous glass disks with exceptional reproducibility. Newer low-dilution fusion methods maintain sensitivity while reducing the amount of flux required, preserving detection limits for trace elements.

Nanomaterial-based sorbents have emerged as powerful tools for selective extraction prior to both GC-MS and XRF analyses. Functionalized magnetic nanoparticles, carbon nanotubes, and metal-organic frameworks offer unprecedented selectivity and capacity for target analytes. These materials enable rapid extraction through magnetic separation or enhanced surface interactions, significantly reducing sample preparation time while improving recovery rates.

Green chemistry principles have also influenced sample preparation advancement, with solvent-free or reduced-solvent methods gaining prominence. Pressurized hot water extraction, supercritical fluid extraction, and mechanochemical approaches provide environmentally friendly alternatives that maintain or enhance analytical performance while reducing laboratory waste and exposure to hazardous chemicals.

Cross-platform sample preparation protocols that simultaneously prepare samples for both GC-MS and XRF analysis represent the cutting edge of laboratory efficiency. These unified workflows enable comprehensive characterization of samples using complementary techniques without duplicating preparation efforts, maximizing information yield while minimizing resource expenditure.

Automated sample preparation systems now integrate seamlessly with both GC-MS and XRF instruments, reducing manual handling errors and increasing reproducibility. These systems can perform multiple preparation steps including weighing, extraction, filtration, and concentration with minimal human intervention. The integration of robotic sample handlers has decreased preparation time by up to 60% while improving precision by eliminating operator variability.

Microextraction techniques represent another breakthrough, particularly for GC-MS applications. Solid-phase microextraction (SPME), stir bar sorptive extraction (SBSE), and liquid-phase microextraction (LPME) have revolutionized sample preparation by reducing solvent consumption and enabling direct extraction from complex matrices. These techniques are especially valuable for environmental and biological samples where analyte concentrations may be extremely low.

For XRF analysis, pressed pellet and fusion methods have been refined to address matrix effects and heterogeneity issues. Advanced fusion techniques using automated fluxers now produce homogeneous glass disks with exceptional reproducibility. Newer low-dilution fusion methods maintain sensitivity while reducing the amount of flux required, preserving detection limits for trace elements.

Nanomaterial-based sorbents have emerged as powerful tools for selective extraction prior to both GC-MS and XRF analyses. Functionalized magnetic nanoparticles, carbon nanotubes, and metal-organic frameworks offer unprecedented selectivity and capacity for target analytes. These materials enable rapid extraction through magnetic separation or enhanced surface interactions, significantly reducing sample preparation time while improving recovery rates.

Green chemistry principles have also influenced sample preparation advancement, with solvent-free or reduced-solvent methods gaining prominence. Pressurized hot water extraction, supercritical fluid extraction, and mechanochemical approaches provide environmentally friendly alternatives that maintain or enhance analytical performance while reducing laboratory waste and exposure to hazardous chemicals.

Cross-platform sample preparation protocols that simultaneously prepare samples for both GC-MS and XRF analysis represent the cutting edge of laboratory efficiency. These unified workflows enable comprehensive characterization of samples using complementary techniques without duplicating preparation efforts, maximizing information yield while minimizing resource expenditure.

Data Integration and AI-Assisted Analysis

The integration of data from GC-MS and XRF technologies represents a significant frontier in analytical chemistry. Modern laboratories are increasingly implementing sophisticated data integration frameworks that allow for comprehensive sample analysis across multiple analytical platforms. These systems enable scientists to correlate molecular composition data from GC-MS with elemental analysis from XRF, providing a more complete characterization of complex samples than either technique could achieve independently.

Artificial intelligence and machine learning algorithms are revolutionizing how this integrated data is processed and interpreted. Deep learning models can now identify patterns across multimodal analytical datasets that would be imperceptible to human analysts. For instance, AI systems can correlate trace element signatures detected by XRF with specific organic compound profiles from GC-MS, revealing subtle relationships between elemental composition and molecular structure.

Cloud-based platforms have emerged as essential infrastructure for this data-intensive approach. These platforms provide the computational resources needed for processing large analytical datasets while facilitating collaboration among geographically dispersed research teams. Real-time data processing capabilities allow for immediate feedback during experimental procedures, optimizing laboratory workflows and accelerating discovery timelines.

Predictive analytics represents another transformative application of AI in this domain. By training on historical datasets from both GC-MS and XRF analyses, machine learning models can predict sample properties or experimental outcomes with increasing accuracy. This capability is particularly valuable in quality control applications, where rapid assessment of material composition is critical.

Natural language processing (NLP) technologies are being deployed to extract insights from the scientific literature, connecting experimental data with published knowledge. These systems can automatically identify relevant research papers, experimental protocols, or reference data that may inform the interpretation of integrated GC-MS and XRF results.

The development of standardized data formats and ontologies is facilitating seamless information exchange between different analytical platforms and software systems. These standards ensure that data from GC-MS and XRF instruments can be meaningfully combined regardless of manufacturer or model, promoting interoperability across the analytical chemistry ecosystem.

Visualization tools specifically designed for multimodal analytical data are enabling scientists to explore complex relationships through interactive dashboards and 3D representations. These tools transform abstract numerical data into intuitive visual formats, making it easier to communicate findings and generate new hypotheses based on integrated analytical results.

Artificial intelligence and machine learning algorithms are revolutionizing how this integrated data is processed and interpreted. Deep learning models can now identify patterns across multimodal analytical datasets that would be imperceptible to human analysts. For instance, AI systems can correlate trace element signatures detected by XRF with specific organic compound profiles from GC-MS, revealing subtle relationships between elemental composition and molecular structure.

Cloud-based platforms have emerged as essential infrastructure for this data-intensive approach. These platforms provide the computational resources needed for processing large analytical datasets while facilitating collaboration among geographically dispersed research teams. Real-time data processing capabilities allow for immediate feedback during experimental procedures, optimizing laboratory workflows and accelerating discovery timelines.

Predictive analytics represents another transformative application of AI in this domain. By training on historical datasets from both GC-MS and XRF analyses, machine learning models can predict sample properties or experimental outcomes with increasing accuracy. This capability is particularly valuable in quality control applications, where rapid assessment of material composition is critical.

Natural language processing (NLP) technologies are being deployed to extract insights from the scientific literature, connecting experimental data with published knowledge. These systems can automatically identify relevant research papers, experimental protocols, or reference data that may inform the interpretation of integrated GC-MS and XRF results.

The development of standardized data formats and ontologies is facilitating seamless information exchange between different analytical platforms and software systems. These standards ensure that data from GC-MS and XRF instruments can be meaningfully combined regardless of manufacturer or model, promoting interoperability across the analytical chemistry ecosystem.

Visualization tools specifically designed for multimodal analytical data are enabling scientists to explore complex relationships through interactive dashboards and 3D representations. These tools transform abstract numerical data into intuitive visual formats, making it easier to communicate findings and generate new hypotheses based on integrated analytical results.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!