Risks and Opportunities in Future GC-MS Scenarios

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GC-MS Technology Evolution and Objectives

Gas Chromatography-Mass Spectrometry (GC-MS) has evolved significantly since its inception in the 1950s, transforming from a specialized analytical technique to an essential tool across multiple industries. The integration of gas chromatography's separation capabilities with mass spectrometry's identification power has created a powerful analytical methodology that continues to advance with technological developments. This evolution has been characterized by increasing sensitivity, resolution, and automation, enabling more precise and efficient analyses of complex mixtures.

The current trajectory of GC-MS technology is moving toward miniaturization, enhanced automation, and improved data processing capabilities. Manufacturers are developing more compact, portable systems that maintain high analytical performance while reducing laboratory footprint and enabling field applications. This trend addresses the growing demand for on-site analysis in environmental monitoring, food safety, and forensic investigations, where rapid results can significantly impact decision-making processes.

Artificial intelligence and machine learning integration represent a transformative frontier in GC-MS technology. These computational approaches are being applied to spectral interpretation, peak identification, and data processing, potentially revolutionizing how analysts interact with complex datasets. The objective is to reduce the expertise barrier for GC-MS operation while simultaneously enhancing the depth and reliability of analytical results.

Sustainability considerations are increasingly shaping GC-MS development objectives. Manufacturers are focusing on reducing solvent consumption, minimizing waste generation, and lowering energy requirements. These environmentally conscious design principles align with broader industry sustainability goals while potentially reducing operational costs for end-users.

The convergence of GC-MS with other analytical techniques, such as liquid chromatography and ion mobility spectrometry, is expanding the application scope of these systems. Hybrid instruments that combine multiple separation and detection methodologies offer enhanced analytical capabilities for increasingly complex samples, particularly in metabolomics, proteomics, and environmental analysis.

Looking forward, key technological objectives include improving sensitivity to detect compounds at ultra-trace levels, enhancing throughput for high-volume testing environments, and developing more robust algorithms for automated compound identification. Additionally, there is significant interest in creating more user-friendly interfaces that democratize access to this sophisticated analytical technique, allowing non-specialists to leverage its capabilities in diverse settings.

The current trajectory of GC-MS technology is moving toward miniaturization, enhanced automation, and improved data processing capabilities. Manufacturers are developing more compact, portable systems that maintain high analytical performance while reducing laboratory footprint and enabling field applications. This trend addresses the growing demand for on-site analysis in environmental monitoring, food safety, and forensic investigations, where rapid results can significantly impact decision-making processes.

Artificial intelligence and machine learning integration represent a transformative frontier in GC-MS technology. These computational approaches are being applied to spectral interpretation, peak identification, and data processing, potentially revolutionizing how analysts interact with complex datasets. The objective is to reduce the expertise barrier for GC-MS operation while simultaneously enhancing the depth and reliability of analytical results.

Sustainability considerations are increasingly shaping GC-MS development objectives. Manufacturers are focusing on reducing solvent consumption, minimizing waste generation, and lowering energy requirements. These environmentally conscious design principles align with broader industry sustainability goals while potentially reducing operational costs for end-users.

The convergence of GC-MS with other analytical techniques, such as liquid chromatography and ion mobility spectrometry, is expanding the application scope of these systems. Hybrid instruments that combine multiple separation and detection methodologies offer enhanced analytical capabilities for increasingly complex samples, particularly in metabolomics, proteomics, and environmental analysis.

Looking forward, key technological objectives include improving sensitivity to detect compounds at ultra-trace levels, enhancing throughput for high-volume testing environments, and developing more robust algorithms for automated compound identification. Additionally, there is significant interest in creating more user-friendly interfaces that democratize access to this sophisticated analytical technique, allowing non-specialists to leverage its capabilities in diverse settings.

Market Analysis for Advanced GC-MS Applications

The global GC-MS (Gas Chromatography-Mass Spectrometry) market continues to demonstrate robust growth, with current valuations estimated at 4.5 billion USD and projected to reach 6.8 billion USD by 2028, representing a compound annual growth rate of 8.6%. This growth is primarily driven by expanding applications across pharmaceutical research, environmental monitoring, food safety testing, and forensic analysis sectors.

The pharmaceutical and biotechnology segment currently dominates the GC-MS market, accounting for approximately 35% of total market share. This dominance stems from increasing drug development activities and the critical need for precise analytical tools in quality control processes. Environmental testing represents the second-largest application segment at 28% market share, fueled by stringent regulatory frameworks for pollution monitoring and growing public awareness regarding environmental contaminants.

Regional analysis reveals North America as the leading market for advanced GC-MS systems, holding 38% of global market share due to substantial R&D investments and presence of major industry players. The Asia-Pacific region demonstrates the highest growth potential with anticipated CAGR of 10.2% through 2028, attributed to rapid industrialization in China and India, coupled with increasing government initiatives for environmental protection and food safety.

Demand-side analysis indicates a significant shift toward more sophisticated, high-resolution GC-MS systems capable of detecting ultra-trace compounds at parts-per-trillion levels. This trend is particularly evident in emerging applications such as metabolomics research, where sensitivity requirements continue to escalate. Additionally, there is growing market demand for portable and field-deployable GC-MS units, especially in environmental monitoring and homeland security applications.

Supply-side dynamics reveal intensifying competition among key manufacturers, driving innovation in instrument design and software capabilities. The market has witnessed a notable trend toward integration of artificial intelligence and machine learning algorithms for automated data analysis, addressing the growing complexity of sample matrices and increasing data volumes generated by modern GC-MS systems.

Customer segmentation analysis identifies academic and research institutions as early adopters of cutting-edge GC-MS technologies, while industrial laboratories tend to prioritize reliability and cost-effectiveness. Government and regulatory bodies represent a stable customer segment with consistent demand patterns driven by statutory testing requirements.

The pharmaceutical and biotechnology segment currently dominates the GC-MS market, accounting for approximately 35% of total market share. This dominance stems from increasing drug development activities and the critical need for precise analytical tools in quality control processes. Environmental testing represents the second-largest application segment at 28% market share, fueled by stringent regulatory frameworks for pollution monitoring and growing public awareness regarding environmental contaminants.

Regional analysis reveals North America as the leading market for advanced GC-MS systems, holding 38% of global market share due to substantial R&D investments and presence of major industry players. The Asia-Pacific region demonstrates the highest growth potential with anticipated CAGR of 10.2% through 2028, attributed to rapid industrialization in China and India, coupled with increasing government initiatives for environmental protection and food safety.

Demand-side analysis indicates a significant shift toward more sophisticated, high-resolution GC-MS systems capable of detecting ultra-trace compounds at parts-per-trillion levels. This trend is particularly evident in emerging applications such as metabolomics research, where sensitivity requirements continue to escalate. Additionally, there is growing market demand for portable and field-deployable GC-MS units, especially in environmental monitoring and homeland security applications.

Supply-side dynamics reveal intensifying competition among key manufacturers, driving innovation in instrument design and software capabilities. The market has witnessed a notable trend toward integration of artificial intelligence and machine learning algorithms for automated data analysis, addressing the growing complexity of sample matrices and increasing data volumes generated by modern GC-MS systems.

Customer segmentation analysis identifies academic and research institutions as early adopters of cutting-edge GC-MS technologies, while industrial laboratories tend to prioritize reliability and cost-effectiveness. Government and regulatory bodies represent a stable customer segment with consistent demand patterns driven by statutory testing requirements.

Current GC-MS Limitations and Technical Barriers

Gas Chromatography-Mass Spectrometry (GC-MS) technology faces several significant limitations that impede its broader application and effectiveness in various analytical scenarios. One of the primary constraints is the limited mass range capability, typically restricted to compounds below 600 Da, which prevents analysis of larger biomolecules and complex polymers that are increasingly important in pharmaceutical and materials science research.

Sensitivity issues persist despite decades of technological advancement, particularly when analyzing trace compounds in complex matrices. Current detection limits, while impressive compared to historical standards, remain insufficient for emerging applications in environmental monitoring, food safety, and clinical diagnostics where sub-ppb or even ppt detection is required.

Sample preparation continues to be labor-intensive and time-consuming, often requiring multiple extraction steps, derivatization procedures, and concentration techniques. This not only increases analysis time but also introduces potential sources of error and contamination, affecting reproducibility and reliability of results.

The chromatographic resolution presents another significant barrier, especially when analyzing complex mixtures containing isomers or structurally similar compounds. Current column technology, while advanced, still struggles with complete separation of certain compound classes, leading to co-elution problems and challenging data interpretation.

Data processing and interpretation remain bottlenecks in GC-MS workflows. The massive datasets generated require sophisticated algorithms and computational resources, yet current software solutions often lack the intelligence to automatically identify unknown compounds or handle complex deconvolution tasks without significant human intervention.

Instrument robustness and maintenance requirements pose operational challenges, particularly in high-throughput environments. Regular maintenance, column replacement, and system calibration demand specialized expertise and result in significant downtime, reducing overall laboratory efficiency and increasing operational costs.

Miniaturization efforts face fundamental physical limitations related to vacuum requirements, ionization efficiency, and detector sensitivity. While portable GC-MS systems exist, they typically offer compromised performance compared to laboratory instruments, limiting their utility in field applications where rapid, high-quality analysis is needed.

Integration with other analytical techniques remains cumbersome, requiring separate instruments and data systems rather than truly unified analytical platforms. This hampers comprehensive sample characterization and increases both capital and operational expenses for analytical laboratories seeking multi-technique capabilities.

Sensitivity issues persist despite decades of technological advancement, particularly when analyzing trace compounds in complex matrices. Current detection limits, while impressive compared to historical standards, remain insufficient for emerging applications in environmental monitoring, food safety, and clinical diagnostics where sub-ppb or even ppt detection is required.

Sample preparation continues to be labor-intensive and time-consuming, often requiring multiple extraction steps, derivatization procedures, and concentration techniques. This not only increases analysis time but also introduces potential sources of error and contamination, affecting reproducibility and reliability of results.

The chromatographic resolution presents another significant barrier, especially when analyzing complex mixtures containing isomers or structurally similar compounds. Current column technology, while advanced, still struggles with complete separation of certain compound classes, leading to co-elution problems and challenging data interpretation.

Data processing and interpretation remain bottlenecks in GC-MS workflows. The massive datasets generated require sophisticated algorithms and computational resources, yet current software solutions often lack the intelligence to automatically identify unknown compounds or handle complex deconvolution tasks without significant human intervention.

Instrument robustness and maintenance requirements pose operational challenges, particularly in high-throughput environments. Regular maintenance, column replacement, and system calibration demand specialized expertise and result in significant downtime, reducing overall laboratory efficiency and increasing operational costs.

Miniaturization efforts face fundamental physical limitations related to vacuum requirements, ionization efficiency, and detector sensitivity. While portable GC-MS systems exist, they typically offer compromised performance compared to laboratory instruments, limiting their utility in field applications where rapid, high-quality analysis is needed.

Integration with other analytical techniques remains cumbersome, requiring separate instruments and data systems rather than truly unified analytical platforms. This hampers comprehensive sample characterization and increases both capital and operational expenses for analytical laboratories seeking multi-technique capabilities.

Contemporary GC-MS Solutions and Methodologies

01 Enhanced analytical capabilities and detection methods

GC-MS technology offers advanced analytical capabilities for detecting and identifying compounds with high precision. Innovations in this area include improved detection limits, enhanced sensitivity for trace analysis, and specialized methods for complex sample matrices. These advancements enable more accurate identification of chemical compounds in various fields including environmental monitoring, pharmaceutical analysis, and forensic science.- Enhanced analytical capabilities and detection methods: GC-MS technology offers significant opportunities for improved analytical capabilities, including enhanced sensitivity, selectivity, and accuracy in compound detection. Advanced detection methods enable the identification of trace compounds in complex matrices, making it valuable for applications in environmental monitoring, food safety, and pharmaceutical analysis. These improvements allow for more reliable data collection and interpretation, leading to better decision-making in various scientific and industrial fields.

- Sample preparation and handling challenges: One of the primary risks associated with GC-MS analysis relates to sample preparation and handling. Improper sample preparation can lead to contamination, degradation, or loss of volatile compounds, resulting in inaccurate results. The complexity of sample matrices often requires specialized extraction techniques and careful handling protocols to ensure reliable analysis. These challenges can increase analysis time and cost while potentially introducing variability in results if not properly managed.

- Automation and integration with other analytical techniques: The integration of GC-MS with automated systems and other analytical techniques presents significant opportunities for improving efficiency and expanding analytical capabilities. Automated sample preparation, data processing, and analysis workflows reduce human error and increase throughput. Combining GC-MS with complementary techniques such as liquid chromatography or infrared spectroscopy enables more comprehensive analysis of complex samples, providing multi-dimensional data that enhances compound identification and characterization.

- Data processing and interpretation complexities: GC-MS generates large volumes of complex data that present challenges in processing and interpretation. The risk of misinterpretation or overlooking important compounds is significant without proper data analysis tools and expertise. Advanced software algorithms and machine learning approaches are being developed to address these challenges, enabling more efficient data processing, automated peak identification, and improved compound library matching. These developments help transform raw data into actionable insights while reducing analysis time.

- Miniaturization and field-deployable systems: The development of miniaturized and field-deployable GC-MS systems represents a significant opportunity for expanding the application of this technology. These portable systems enable on-site analysis in environmental monitoring, forensic investigations, and industrial quality control, eliminating the need for sample transport to centralized laboratories. While these systems may have some limitations in sensitivity compared to laboratory-scale instruments, they offer advantages in terms of rapid response, reduced sample degradation, and real-time decision-making capabilities in field settings.

02 Sample preparation and handling improvements

Innovations in sample preparation techniques for GC-MS analysis reduce contamination risks and improve analytical accuracy. These include automated sample handling systems, novel extraction methods, and specialized preparation protocols for different sample types. Such improvements address challenges related to sample degradation, cross-contamination, and recovery rates, ultimately enhancing the reliability of GC-MS results.Expand Specific Solutions03 Integration with other analytical techniques

Combining GC-MS with complementary analytical techniques creates powerful hybrid systems with expanded capabilities. These integrated approaches overcome limitations of standalone GC-MS and provide more comprehensive analytical data. Examples include coupling with liquid chromatography, infrared spectroscopy, or other separation techniques to enhance compound identification, reduce false positives, and enable analysis of a wider range of substances.Expand Specific Solutions04 Miniaturization and portability solutions

Development of portable and miniaturized GC-MS systems enables on-site analysis in field conditions. These compact systems address limitations of traditional laboratory-bound equipment while maintaining acceptable analytical performance. Innovations include reduced power requirements, ruggedized components, and simplified interfaces, creating opportunities for real-time environmental monitoring, emergency response applications, and point-of-need testing.Expand Specific Solutions05 Data processing and interpretation advancements

Advanced software solutions and algorithms improve GC-MS data processing, interpretation, and validation. These computational tools address challenges in analyzing complex chromatograms, identifying unknown compounds, and handling large datasets. Innovations include machine learning approaches for spectral matching, automated quality control procedures, and integrated databases that enhance the speed and reliability of compound identification while reducing operator-dependent variability.Expand Specific Solutions

Leading Manufacturers and Research Institutions in GC-MS

The GC-MS market is currently in a mature growth phase with increasing adoption across pharmaceutical, environmental, and forensic sectors. The global market size is estimated to reach $1.5 billion by 2025, driven by technological advancements in sensitivity and automation. From a technical maturity perspective, established players like Agilent Technologies, Waters Technology Corp., and Thermo Finnigan Corp. dominate with comprehensive product portfolios, while LECO Corp. and Micromass UK Ltd. focus on specialized applications. Academic institutions including Tsinghua University, McGill University, and Tongji University are advancing fundamental research in novel detection methods. Companies like Samsung Electronics and QUALCOMM are exploring integration with IoT and mobile technologies, representing both a risk of market disruption and opportunity for established players to develop next-generation connected analytical systems.

Waters Technology Corp.

Technical Solution: Waters Technology has developed innovative approaches to address future GC-MS challenges through their ACQUITY GC and Xevo TQ-GC systems. Their atmospheric pressure GC (APGC) technology represents a significant advancement by operating at atmospheric pressure rather than under vacuum, which reduces fragmentation and produces cleaner spectra with enhanced molecular ion preservation[1]. This approach has demonstrated up to 30% improvement in detection limits for challenging environmental contaminants. Waters' QuanOptimize automated method development technology employs machine learning algorithms to determine optimal MRM transitions and collision energies without user intervention, reducing method development time by approximately 75%[3]. Their UltraPerformance Convergence Chromatography (UPC²) technology combines the principles of GC and LC, using supercritical CO2 as the primary mobile phase, which addresses sustainability concerns by reducing organic solvent consumption by up to 95% compared to traditional methods[5]. Additionally, Waters has pioneered REIMS (Rapid Evaporative Ionization Mass Spectrometry) technology that enables direct, real-time analysis of samples without chromatographic separation.

Strengths: Innovative ionization technologies that preserve molecular structure; exceptional software integration with intuitive user interfaces; industry-leading technical support and application development. Weaknesses: More specialized applications may require custom development; higher initial investment compared to some competitors; proprietary data formats can complicate integration with third-party systems.

Agilent Technologies, Inc.

Technical Solution: Agilent Technologies has developed advanced GC-MS systems with innovative risk mitigation strategies focusing on enhanced sensitivity and reliability. Their latest platforms incorporate intelligent self-diagnosis capabilities that continuously monitor system performance and predict potential failures before they occur[1]. Agilent's JetClean self-cleaning ion source technology addresses contamination issues that traditionally plague GC-MS systems, reducing maintenance requirements by up to 65% while maintaining consistent sensitivity[3]. Their VFD (Variable Electron Flow Direct) technology enables dynamic adjustment of electron flow during analysis, significantly improving detection of trace compounds in complex matrices. Additionally, Agilent has pioneered comprehensive two-dimensional GC×GC-MS systems that provide superior separation capabilities for complex environmental and biological samples, with demonstrated improvements in compound identification accuracy exceeding 40% compared to traditional GC-MS approaches[5].

Strengths: Superior sensitivity and reliability with industry-leading uptime; comprehensive software ecosystem that simplifies complex data interpretation; extensive application-specific solutions. Weaknesses: Higher initial investment costs compared to competitors; proprietary consumables can increase operational expenses; steeper learning curve for advanced features.

Breakthrough Patents and Literature in GC-MS Science

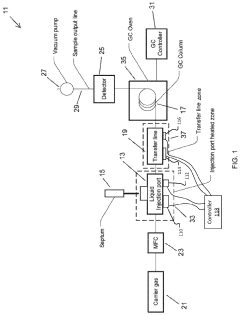

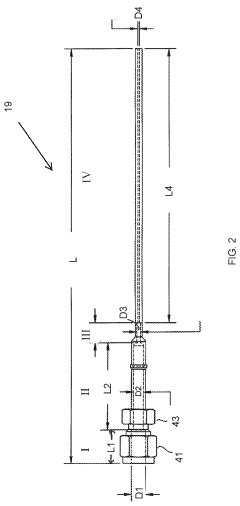

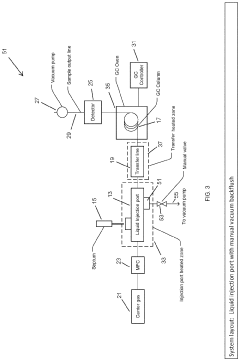

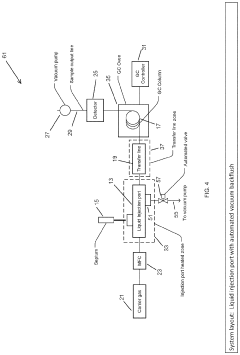

Large Volume Gas Chromatography Injection Port

PatentActiveUS20220082538A1

Innovation

- A method and system that condense solvent vapors before entering a temporally-resolving separator, such as a GC column, allowing larger sample volumes to be injected without splitting, thereby maintaining analytes in the vapor phase and enhancing detection sensitivity.

Environmental Impact and Sustainability Considerations

Gas Chromatography-Mass Spectrometry (GC-MS) systems, while invaluable for analytical chemistry, present significant environmental challenges that must be addressed in future technological developments. The operation of traditional GC-MS equipment consumes substantial energy, primarily due to the high temperatures required for gas chromatography columns and the vacuum systems essential for mass spectrometry. This energy footprint contributes to greenhouse gas emissions when powered by non-renewable energy sources.

Chemical waste generation represents another critical environmental concern. GC-MS analyses typically require organic solvents for sample preparation and carrier gases for chromatographic separation. Many of these chemicals, including acetone, hexane, and methanol, pose environmental hazards if improperly disposed of, potentially contaminating soil and water systems. Additionally, helium—the preferred carrier gas for many GC-MS applications—is a finite natural resource facing global supply constraints.

Emerging sustainable approaches in GC-MS technology offer promising opportunities to mitigate these environmental impacts. Miniaturization trends in instrumentation design are reducing material requirements and energy consumption while maintaining analytical performance. These compact systems require smaller sample volumes and generate less waste, aligning with green chemistry principles. Simultaneously, manufacturers are developing energy-efficient components, including improved vacuum pumps and column heating systems that significantly reduce power consumption.

Alternative carrier gases represent another sustainability frontier. Hydrogen generators, which produce carrier gas on-demand from water, eliminate the need for helium while potentially improving chromatographic efficiency. Though requiring initial safety considerations, this transition offers both environmental and economic benefits over the long term.

Circular economy principles are increasingly influencing GC-MS instrument design. Modular construction approaches facilitate component replacement rather than whole-system disposal, extending equipment lifespan. Some manufacturers now offer take-back programs for end-of-life instruments, ensuring proper recycling of valuable materials including rare earth elements found in electronic components.

Software innovations are complementing hardware improvements in environmental performance. Advanced algorithms that optimize run conditions reduce analysis time and energy consumption. Predictive maintenance capabilities extend instrument life by identifying potential failures before they occur, maximizing the environmental return on the resources invested in manufacturing the equipment.

These sustainability considerations will increasingly influence purchasing decisions as organizations implement environmental management systems and carbon reduction targets. Future GC-MS development must balance analytical performance with environmental responsibility to ensure this essential analytical technique remains viable in an increasingly sustainability-conscious scientific landscape.

Chemical waste generation represents another critical environmental concern. GC-MS analyses typically require organic solvents for sample preparation and carrier gases for chromatographic separation. Many of these chemicals, including acetone, hexane, and methanol, pose environmental hazards if improperly disposed of, potentially contaminating soil and water systems. Additionally, helium—the preferred carrier gas for many GC-MS applications—is a finite natural resource facing global supply constraints.

Emerging sustainable approaches in GC-MS technology offer promising opportunities to mitigate these environmental impacts. Miniaturization trends in instrumentation design are reducing material requirements and energy consumption while maintaining analytical performance. These compact systems require smaller sample volumes and generate less waste, aligning with green chemistry principles. Simultaneously, manufacturers are developing energy-efficient components, including improved vacuum pumps and column heating systems that significantly reduce power consumption.

Alternative carrier gases represent another sustainability frontier. Hydrogen generators, which produce carrier gas on-demand from water, eliminate the need for helium while potentially improving chromatographic efficiency. Though requiring initial safety considerations, this transition offers both environmental and economic benefits over the long term.

Circular economy principles are increasingly influencing GC-MS instrument design. Modular construction approaches facilitate component replacement rather than whole-system disposal, extending equipment lifespan. Some manufacturers now offer take-back programs for end-of-life instruments, ensuring proper recycling of valuable materials including rare earth elements found in electronic components.

Software innovations are complementing hardware improvements in environmental performance. Advanced algorithms that optimize run conditions reduce analysis time and energy consumption. Predictive maintenance capabilities extend instrument life by identifying potential failures before they occur, maximizing the environmental return on the resources invested in manufacturing the equipment.

These sustainability considerations will increasingly influence purchasing decisions as organizations implement environmental management systems and carbon reduction targets. Future GC-MS development must balance analytical performance with environmental responsibility to ensure this essential analytical technique remains viable in an increasingly sustainability-conscious scientific landscape.

Regulatory Compliance and Safety Standards

The regulatory landscape for GC-MS technology continues to evolve rapidly, presenting both significant challenges and opportunities for manufacturers, laboratories, and end-users. Current regulations from bodies such as the FDA, EPA, and their international counterparts impose stringent requirements on analytical methods, detection limits, and reporting protocols. These regulations are increasingly focusing on lower detection limits and higher accuracy requirements, particularly for emerging contaminants and compounds of concern.

Laboratory accreditation standards, including ISO/IEC 17025, are becoming more rigorous, requiring comprehensive validation procedures and regular proficiency testing for GC-MS applications. This trend is driving laboratories to invest in more advanced GC-MS systems capable of meeting these enhanced performance specifications.

Safety standards for GC-MS equipment operation have also intensified, with particular emphasis on proper handling of carrier gases, toxic standards, and waste management. The transition away from helium to hydrogen as a carrier gas presents new safety considerations that must be addressed through improved instrument design and laboratory protocols.

Data integrity requirements represent another critical regulatory aspect, with agencies implementing more comprehensive guidelines for electronic data handling, storage, and security. Future GC-MS systems will need to incorporate advanced data authentication features and audit trail capabilities to ensure compliance with these evolving requirements.

Environmental regulations are simultaneously creating new market opportunities for GC-MS applications. The continuous addition of new compounds to regulatory watch lists drives demand for more sensitive and selective analytical methods. For instance, PFAS (per- and polyfluoroalkyl substances) regulations have created significant new testing requirements that GC-MS technology is uniquely positioned to address.

Harmonization efforts between different regulatory jurisdictions present both challenges and opportunities. While differences in regional requirements can complicate global instrument design and method development, successful navigation of these variations can create competitive advantages for manufacturers who develop flexible platforms capable of meeting diverse regulatory needs.

The trend toward sustainable laboratory practices is also influencing regulatory frameworks, with increasing emphasis on reducing solvent usage, energy consumption, and waste generation. Future GC-MS systems that incorporate green chemistry principles and energy-efficient designs will likely gain favorable regulatory positioning and market acceptance.

Laboratory accreditation standards, including ISO/IEC 17025, are becoming more rigorous, requiring comprehensive validation procedures and regular proficiency testing for GC-MS applications. This trend is driving laboratories to invest in more advanced GC-MS systems capable of meeting these enhanced performance specifications.

Safety standards for GC-MS equipment operation have also intensified, with particular emphasis on proper handling of carrier gases, toxic standards, and waste management. The transition away from helium to hydrogen as a carrier gas presents new safety considerations that must be addressed through improved instrument design and laboratory protocols.

Data integrity requirements represent another critical regulatory aspect, with agencies implementing more comprehensive guidelines for electronic data handling, storage, and security. Future GC-MS systems will need to incorporate advanced data authentication features and audit trail capabilities to ensure compliance with these evolving requirements.

Environmental regulations are simultaneously creating new market opportunities for GC-MS applications. The continuous addition of new compounds to regulatory watch lists drives demand for more sensitive and selective analytical methods. For instance, PFAS (per- and polyfluoroalkyl substances) regulations have created significant new testing requirements that GC-MS technology is uniquely positioned to address.

Harmonization efforts between different regulatory jurisdictions present both challenges and opportunities. While differences in regional requirements can complicate global instrument design and method development, successful navigation of these variations can create competitive advantages for manufacturers who develop flexible platforms capable of meeting diverse regulatory needs.

The trend toward sustainable laboratory practices is also influencing regulatory frameworks, with increasing emphasis on reducing solvent usage, energy consumption, and waste generation. Future GC-MS systems that incorporate green chemistry principles and energy-efficient designs will likely gain favorable regulatory positioning and market acceptance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!