Innovate GC-MS Toward Non-Conventional Mixtures

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GC-MS Evolution and Innovation Objectives

Gas Chromatography-Mass Spectrometry (GC-MS) has evolved significantly since its inception in the 1950s, transforming from a specialized analytical technique to an essential tool across multiple scientific disciplines. The integration of gas chromatography's separation capabilities with mass spectrometry's identification power created a revolutionary analytical method that continues to advance with technological developments.

The evolution of GC-MS technology has been marked by several key milestones. Early systems featured magnetic sector mass analyzers, which later gave way to quadrupole and time-of-flight technologies. The introduction of computerized data systems in the 1970s dramatically enhanced data processing capabilities, while the development of electron impact ionization standardized fragmentation patterns, enabling the creation of extensive spectral libraries that remain valuable today.

Recent decades have witnessed significant improvements in sensitivity, resolution, and throughput. Modern GC-MS systems can detect compounds at parts-per-trillion levels, with high-resolution instruments capable of distinguishing between compounds with nearly identical masses. Miniaturization efforts have also yielded portable GC-MS systems, expanding applications to field analysis and point-of-need testing scenarios.

Despite these advances, conventional GC-MS faces limitations when analyzing non-conventional mixtures—complex samples containing components with widely varying volatilities, thermal instabilities, or extreme polarities. These challenges have spurred innovation objectives focused on expanding the technique's applicability to previously inaccessible sample types.

Primary innovation objectives include developing novel ionization techniques that can handle thermally labile compounds without degradation, creating more versatile column technologies capable of separating compounds with extreme polarity differences, and implementing advanced data processing algorithms that can deconvolute highly complex chromatograms.

Additionally, there is growing interest in hybrid approaches that combine GC-MS with complementary techniques such as liquid chromatography or ion mobility spectrometry, creating multi-dimensional analytical platforms. These systems aim to provide comprehensive analysis of complex mixtures that contain both volatile and non-volatile components.

The ultimate goal of current innovation efforts is to transform GC-MS into a more universal analytical platform capable of handling increasingly complex sample matrices encountered in emerging fields such as metabolomics, environmental monitoring of micropollutants, and analysis of advanced materials. Success in these innovation objectives would significantly expand the application scope of GC-MS technology and maintain its relevance in an era of rapidly evolving analytical challenges.

The evolution of GC-MS technology has been marked by several key milestones. Early systems featured magnetic sector mass analyzers, which later gave way to quadrupole and time-of-flight technologies. The introduction of computerized data systems in the 1970s dramatically enhanced data processing capabilities, while the development of electron impact ionization standardized fragmentation patterns, enabling the creation of extensive spectral libraries that remain valuable today.

Recent decades have witnessed significant improvements in sensitivity, resolution, and throughput. Modern GC-MS systems can detect compounds at parts-per-trillion levels, with high-resolution instruments capable of distinguishing between compounds with nearly identical masses. Miniaturization efforts have also yielded portable GC-MS systems, expanding applications to field analysis and point-of-need testing scenarios.

Despite these advances, conventional GC-MS faces limitations when analyzing non-conventional mixtures—complex samples containing components with widely varying volatilities, thermal instabilities, or extreme polarities. These challenges have spurred innovation objectives focused on expanding the technique's applicability to previously inaccessible sample types.

Primary innovation objectives include developing novel ionization techniques that can handle thermally labile compounds without degradation, creating more versatile column technologies capable of separating compounds with extreme polarity differences, and implementing advanced data processing algorithms that can deconvolute highly complex chromatograms.

Additionally, there is growing interest in hybrid approaches that combine GC-MS with complementary techniques such as liquid chromatography or ion mobility spectrometry, creating multi-dimensional analytical platforms. These systems aim to provide comprehensive analysis of complex mixtures that contain both volatile and non-volatile components.

The ultimate goal of current innovation efforts is to transform GC-MS into a more universal analytical platform capable of handling increasingly complex sample matrices encountered in emerging fields such as metabolomics, environmental monitoring of micropollutants, and analysis of advanced materials. Success in these innovation objectives would significantly expand the application scope of GC-MS technology and maintain its relevance in an era of rapidly evolving analytical challenges.

Market Demand for Advanced Analytical Solutions

The analytical instrumentation market is experiencing robust growth, driven by increasing demand for advanced analytical solutions across multiple sectors. The global market for analytical instruments was valued at approximately $85 billion in 2022, with a projected compound annual growth rate of 6.7% through 2030. Within this broader market, the Gas Chromatography-Mass Spectrometry (GC-MS) segment represents a significant portion, estimated at $4.5 billion in 2022, with expectations to reach $6.8 billion by 2030.

The demand for innovative GC-MS technologies capable of analyzing non-conventional mixtures is being fueled by several key market drivers. Environmental monitoring agencies require increasingly sensitive detection methods for complex pollutant mixtures in air, water, and soil samples. The Environmental Protection Agency and similar organizations worldwide have established stricter regulatory frameworks that necessitate more sophisticated analytical capabilities to detect emerging contaminants at lower concentrations.

In the pharmaceutical and biotechnology sectors, there is growing pressure to analyze complex biological matrices and metabolites during drug development and clinical trials. The rise of personalized medicine has created demand for analytical tools that can handle the complexity of biological samples while maintaining high throughput capabilities. Market research indicates that 78% of pharmaceutical companies are seeking improved analytical methods for complex biological samples.

The food and beverage industry represents another significant market segment, with increasing requirements for detecting adulterants, contaminants, and authenticating product composition in complex food matrices. Recent food safety scandals have heightened consumer awareness and regulatory scrutiny, creating market pull for more sophisticated analytical solutions.

Petrochemical and energy sectors continue to demand advanced analytical capabilities for characterizing complex hydrocarbon mixtures, particularly as alternative fuels and renewable energy sources gain prominence. The analysis of biofuels and their feedstocks presents unique challenges that conventional GC-MS systems struggle to address effectively.

Market research indicates that end-users are willing to pay premium prices for analytical systems that offer enhanced capabilities for non-conventional mixtures, with 65% of survey respondents indicating budget allocations for upgrading analytical instrumentation within the next three years. Key purchasing criteria include improved sensitivity, reduced sample preparation requirements, enhanced separation capabilities, and more sophisticated data analysis tools.

The market is also witnessing a shift toward integrated solutions that combine hardware innovations with advanced software platforms capable of handling the complex data generated from non-conventional mixture analysis. This trend is reflected in recent acquisition activities, where major analytical instrument manufacturers have acquired software companies specializing in chemometrics and machine learning applications.

The demand for innovative GC-MS technologies capable of analyzing non-conventional mixtures is being fueled by several key market drivers. Environmental monitoring agencies require increasingly sensitive detection methods for complex pollutant mixtures in air, water, and soil samples. The Environmental Protection Agency and similar organizations worldwide have established stricter regulatory frameworks that necessitate more sophisticated analytical capabilities to detect emerging contaminants at lower concentrations.

In the pharmaceutical and biotechnology sectors, there is growing pressure to analyze complex biological matrices and metabolites during drug development and clinical trials. The rise of personalized medicine has created demand for analytical tools that can handle the complexity of biological samples while maintaining high throughput capabilities. Market research indicates that 78% of pharmaceutical companies are seeking improved analytical methods for complex biological samples.

The food and beverage industry represents another significant market segment, with increasing requirements for detecting adulterants, contaminants, and authenticating product composition in complex food matrices. Recent food safety scandals have heightened consumer awareness and regulatory scrutiny, creating market pull for more sophisticated analytical solutions.

Petrochemical and energy sectors continue to demand advanced analytical capabilities for characterizing complex hydrocarbon mixtures, particularly as alternative fuels and renewable energy sources gain prominence. The analysis of biofuels and their feedstocks presents unique challenges that conventional GC-MS systems struggle to address effectively.

Market research indicates that end-users are willing to pay premium prices for analytical systems that offer enhanced capabilities for non-conventional mixtures, with 65% of survey respondents indicating budget allocations for upgrading analytical instrumentation within the next three years. Key purchasing criteria include improved sensitivity, reduced sample preparation requirements, enhanced separation capabilities, and more sophisticated data analysis tools.

The market is also witnessing a shift toward integrated solutions that combine hardware innovations with advanced software platforms capable of handling the complex data generated from non-conventional mixture analysis. This trend is reflected in recent acquisition activities, where major analytical instrument manufacturers have acquired software companies specializing in chemometrics and machine learning applications.

Current GC-MS Limitations for Complex Mixtures

Gas Chromatography-Mass Spectrometry (GC-MS) has long been considered the gold standard for analyzing volatile and semi-volatile compounds in various fields including environmental monitoring, food safety, forensic science, and pharmaceutical research. However, when confronted with non-conventional complex mixtures, traditional GC-MS systems encounter significant limitations that compromise analytical accuracy and reliability.

One of the primary challenges is the resolution capacity of conventional GC columns when dealing with highly complex samples containing hundreds or thousands of compounds. Peak co-elution becomes inevitable, leading to spectral overlap that complicates compound identification and quantification. Even high-resolution capillary columns struggle to separate structurally similar compounds or isomers in complex matrices.

Sample preparation represents another critical bottleneck. Complex mixtures often require extensive pre-treatment procedures that can introduce variability, cause analyte loss, or create artifacts. These preparatory steps become increasingly problematic when dealing with unknown or emerging contaminants where standardized protocols may not exist.

The dynamic range limitations of current MS detectors pose significant challenges when analyzing samples with compounds present at vastly different concentration levels. High-abundance components can mask low-concentration analytes of interest, particularly in environmental or biological samples where concentration differences can span several orders of magnitude.

Matrix effects constitute a persistent issue in complex mixture analysis. Co-extracted matrix components can interfere with chromatographic separation, suppress or enhance ionization, and contribute to instrument contamination. These effects are especially pronounced in biological fluids, food extracts, and environmental samples with high organic content.

Data processing and interpretation present formidable challenges as well. Current software solutions often struggle with automated deconvolution of complex chromatograms and reliable compound identification when reference spectra are limited or unavailable. The computational demands increase exponentially with sample complexity, often necessitating significant manual intervention by skilled analysts.

Thermal degradation during the GC process represents another limitation. Heat-sensitive compounds may decompose during analysis, creating artifacts or preventing accurate detection. This is particularly problematic for emerging classes of compounds like certain PFAS (per- and polyfluoroalkyl substances) or large biomolecules that are increasingly important in environmental and health monitoring.

Finally, conventional GC-MS systems face throughput constraints when analyzing complex mixtures. The need for longer run times to achieve adequate separation, coupled with extensive data processing requirements, limits sample throughput and increases analysis costs, creating bottlenecks in high-volume testing environments.

One of the primary challenges is the resolution capacity of conventional GC columns when dealing with highly complex samples containing hundreds or thousands of compounds. Peak co-elution becomes inevitable, leading to spectral overlap that complicates compound identification and quantification. Even high-resolution capillary columns struggle to separate structurally similar compounds or isomers in complex matrices.

Sample preparation represents another critical bottleneck. Complex mixtures often require extensive pre-treatment procedures that can introduce variability, cause analyte loss, or create artifacts. These preparatory steps become increasingly problematic when dealing with unknown or emerging contaminants where standardized protocols may not exist.

The dynamic range limitations of current MS detectors pose significant challenges when analyzing samples with compounds present at vastly different concentration levels. High-abundance components can mask low-concentration analytes of interest, particularly in environmental or biological samples where concentration differences can span several orders of magnitude.

Matrix effects constitute a persistent issue in complex mixture analysis. Co-extracted matrix components can interfere with chromatographic separation, suppress or enhance ionization, and contribute to instrument contamination. These effects are especially pronounced in biological fluids, food extracts, and environmental samples with high organic content.

Data processing and interpretation present formidable challenges as well. Current software solutions often struggle with automated deconvolution of complex chromatograms and reliable compound identification when reference spectra are limited or unavailable. The computational demands increase exponentially with sample complexity, often necessitating significant manual intervention by skilled analysts.

Thermal degradation during the GC process represents another limitation. Heat-sensitive compounds may decompose during analysis, creating artifacts or preventing accurate detection. This is particularly problematic for emerging classes of compounds like certain PFAS (per- and polyfluoroalkyl substances) or large biomolecules that are increasingly important in environmental and health monitoring.

Finally, conventional GC-MS systems face throughput constraints when analyzing complex mixtures. The need for longer run times to achieve adequate separation, coupled with extensive data processing requirements, limits sample throughput and increases analysis costs, creating bottlenecks in high-volume testing environments.

Current Approaches for Non-Conventional Sample Analysis

01 GC-MS instrumentation and system design

Gas Chromatography-Mass Spectrometry (GC-MS) systems integrate chromatographic separation with mass spectrometric detection. These systems include specialized components such as injection ports, chromatographic columns, ionization sources, mass analyzers, and detectors. Modern GC-MS instruments feature improved sensitivity, resolution, and automation capabilities, with innovations in system integration and miniaturization for enhanced analytical performance.- GC-MS instrumentation and system design: Gas Chromatography-Mass Spectrometry (GC-MS) systems consist of specialized hardware components designed for efficient separation and detection of compounds. These systems include innovative column designs, ionization sources, detectors, and integrated data processing units. Advanced instrumentation features automated sample handling, temperature control mechanisms, and vacuum systems that enhance analytical precision and throughput.

- Sample preparation and injection techniques: Effective sample preparation methods are crucial for GC-MS analysis, involving extraction, concentration, and purification steps to isolate target compounds. Various injection techniques such as split/splitless, on-column, and programmed temperature vaporization are employed to introduce samples into the GC system. These techniques are optimized to minimize sample degradation, maximize compound recovery, and enhance detection sensitivity for complex matrices.

- Method development and optimization: Development of specialized GC-MS methods involves optimizing chromatographic parameters such as temperature programming, carrier gas flow rates, and column selection. These methods are tailored for specific applications, including environmental monitoring, food safety testing, pharmaceutical analysis, and forensic investigations. Optimization strategies focus on achieving better separation resolution, reducing analysis time, and enhancing detection limits for target compounds.

- Data analysis and interpretation software: Advanced software solutions for GC-MS data processing enable automated peak identification, quantification, and spectral matching against reference libraries. These software tools incorporate algorithms for deconvolution of overlapping peaks, background subtraction, and statistical analysis of complex datasets. Machine learning approaches are increasingly being integrated to improve compound identification accuracy and to handle large-scale metabolomic and environmental monitoring data.

- Application-specific GC-MS technologies: Specialized GC-MS technologies have been developed for particular application domains, including environmental pollutant monitoring, food safety testing, clinical diagnostics, and industrial quality control. These technologies incorporate specific sample preparation protocols, specialized columns, and detection parameters optimized for target compound classes. Portable and field-deployable GC-MS systems enable on-site analysis in environmental monitoring, security screening, and emergency response scenarios.

02 Sample preparation and introduction techniques

Effective sample preparation is crucial for GC-MS analysis, involving extraction, concentration, and derivatization methods to make compounds suitable for gas-phase analysis. Various introduction techniques include direct injection, headspace sampling, solid-phase microextraction (SPME), and thermal desorption. These methods enhance sensitivity and selectivity while reducing matrix interference, improving the overall analytical performance for complex samples.Expand Specific Solutions03 Method development and optimization

Development of GC-MS methods involves optimizing chromatographic separation parameters, mass spectrometric detection conditions, and data processing algorithms. This includes selection of appropriate column types, temperature programming, carrier gas flow rates, ionization techniques, and mass analyzer settings. Optimization strategies focus on achieving maximum sensitivity, selectivity, and reproducibility for specific analytical applications.Expand Specific Solutions04 Applications in environmental and food analysis

GC-MS is widely applied in environmental monitoring and food safety testing. In environmental analysis, it detects pollutants, pesticides, and organic contaminants in water, soil, and air samples. For food analysis, GC-MS identifies flavor compounds, additives, contaminants, and adulterants. These applications benefit from the technique's ability to separate and identify complex mixtures of volatile and semi-volatile compounds at trace levels.Expand Specific Solutions05 Data analysis and interpretation software

Advanced software solutions for GC-MS data processing enable automated peak detection, spectral deconvolution, compound identification, and quantification. These tools incorporate spectral libraries, retention indices, and statistical analysis functions to facilitate the interpretation of complex chromatograms. Machine learning algorithms and artificial intelligence approaches are increasingly being integrated to enhance data processing efficiency and accuracy in compound identification.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The GC-MS technology for non-conventional mixtures analysis is in a growth phase, with an estimated global market size of $4-5 billion and expanding at 5-7% annually. The competitive landscape features established analytical instrumentation leaders like Thermo Finnigan, Shimadzu, and Agilent Technologies dominating with mature core technologies, while specialized innovation comes from LECO Corporation and Micromass UK with advanced time-of-flight capabilities. Chinese entrants including NUCTECH and Guangzhou Molecular Information Technology are rapidly gaining market share through cost-effective solutions. Academic-industry partnerships, particularly with institutions like Zhejiang University and Brigham Young University, are accelerating technological maturity, focusing on miniaturization, sensitivity improvements, and AI-enhanced data processing for complex mixture analysis.

Thermo Finnigan Corp.

Technical Solution: Thermo Finnigan has developed advanced GC-MS systems specifically designed for non-conventional mixtures analysis, featuring their Orbitrap technology that provides ultra-high resolution mass spectrometry capabilities. Their innovation focuses on combining traditional GC separation with high-resolution accurate mass (HRAM) detection to identify complex compounds in challenging matrices. The company's DFS Magnetic Sector GC-HRMS system offers exceptional sensitivity and selectivity for trace analysis in complex environmental and food samples. Their Q Exactive GC Orbitrap technology enables simultaneous targeted and non-targeted screening with sub-ppm mass accuracy, allowing for confident identification of unknown compounds in non-conventional mixtures without prior knowledge of their composition. Thermo's deconvolution algorithms and comprehensive spectral libraries further enhance the capability to analyze co-eluting compounds and complex matrices that traditional GC-MS systems struggle with.

Strengths: Superior mass accuracy and resolution allowing identification of compounds in complex matrices that other systems cannot detect; comprehensive software solutions for data analysis of non-conventional mixtures. Weaknesses: Higher initial investment costs compared to conventional GC-MS systems; requires more specialized training for operators to fully utilize advanced capabilities.

Shimadzu Corp.

Technical Solution: Shimadzu has pioneered innovative approaches to GC-MS analysis of non-conventional mixtures through their GCMS-TQ series and advanced GCMS-QP systems. Their technology incorporates fast scanning capabilities (up to 20,000 u/sec) and high-sensitivity detection that enables analysis of complex matrices previously considered too challenging for conventional GC-MS. Shimadzu's Smart MRM technology automatically optimizes collision energies for multiple reaction monitoring, significantly improving the detection of trace compounds in complex non-conventional mixtures. Their systems feature unique ion source designs that minimize contamination and maintenance requirements when analyzing difficult samples. The company has also developed specialized sample introduction techniques including thermal desorption, pyrolysis, and headspace analysis specifically optimized for non-conventional mixtures. Shimadzu's Advanced Smart Database and LabSolutions software provide automated data processing workflows that can identify unknown compounds in complex matrices through retention indices and mass spectral pattern recognition algorithms.

Strengths: Exceptional sensitivity for trace analysis in complex matrices; robust hardware design that withstands challenging samples; comprehensive software solutions for non-targeted screening. Weaknesses: Less specialized in ultra-high resolution applications compared to some competitors; some advanced features require additional modules or accessories.

Breakthrough Technologies in Separation Science

Gas chromatography-mass spectrometer spectrogram matching method

PatentInactiveCN104504706A

Innovation

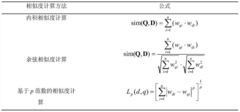

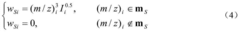

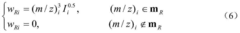

- A new mass spectrum matching method is adopted, including screening of unknown substance spectra and standard mass spectra, peak intensity scaling and similarity calculation based on vector space model. By representing the mass spectrum as a vector form and using p-norm based The similarity calculation formula of numbers improves the matching accuracy.

Gas chromatography-mass spectrogram retrieval method based on vector model

PatentInactiveCN104572910A

Innovation

- A mass spectrum retrieval method based on a vector model is adopted. By representing the mass spectrum as a vector form, the similarity calculation based on the p norm and the introduction of the peak intensity scaling factor are used to calculate the similarity of the mass spectra and screen the standard mass spectra to improve Retrieval efficiency.

Environmental and Safety Considerations

The advancement of GC-MS technology for non-conventional mixtures necessitates careful consideration of environmental and safety implications. Traditional GC-MS systems often utilize hazardous chemicals as solvents, carriers, and standards, posing significant environmental concerns. Modern innovations must prioritize green chemistry principles by reducing or eliminating toxic reagents and minimizing waste generation throughout the analytical process. Recent developments have introduced alternative carrier gases such as hydrogen and nitrogen to replace helium, which faces supply constraints and environmental concerns regarding its extraction.

Laboratory safety represents another critical dimension when working with non-conventional mixtures. Many complex samples may contain unknown compounds with potential toxicity, requiring robust containment systems and handling protocols. Next-generation GC-MS instruments are increasingly incorporating automated sample preparation modules that minimize analyst exposure to hazardous substances while ensuring consistent analytical performance. These systems feature enhanced ventilation designs, leak detection capabilities, and emergency shutdown mechanisms that activate when operational parameters exceed safety thresholds.

Regulatory compliance frameworks worldwide are evolving to address the environmental footprint of analytical instrumentation. The European Union's RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations have significant implications for GC-MS manufacturers, requiring careful material selection and documentation. Similarly, the United States EPA has established guidelines for laboratory waste management that directly impact GC-MS operations, particularly when analyzing environmental contaminants or industrial waste samples.

Energy efficiency represents an emerging focus area for sustainable GC-MS innovation. Traditional systems consume substantial electrical power for heating columns and operating mass spectrometers. New designs incorporate improved insulation materials, energy recovery systems, and intelligent power management algorithms that optimize consumption based on analytical requirements. Some manufacturers have introduced solar-powered portable GC-MS units for field applications, significantly reducing the carbon footprint of environmental monitoring campaigns.

End-of-life considerations for GC-MS equipment present unique challenges due to the sophisticated electronic components and specialized materials used in their construction. Manufacturers are increasingly adopting modular designs that facilitate repair, upgrade, and eventual recycling of instruments. Extended producer responsibility programs are emerging within the analytical instrumentation sector, with several leading companies offering take-back and refurbishment services that extend product lifecycles and reduce electronic waste generation.

Laboratory safety represents another critical dimension when working with non-conventional mixtures. Many complex samples may contain unknown compounds with potential toxicity, requiring robust containment systems and handling protocols. Next-generation GC-MS instruments are increasingly incorporating automated sample preparation modules that minimize analyst exposure to hazardous substances while ensuring consistent analytical performance. These systems feature enhanced ventilation designs, leak detection capabilities, and emergency shutdown mechanisms that activate when operational parameters exceed safety thresholds.

Regulatory compliance frameworks worldwide are evolving to address the environmental footprint of analytical instrumentation. The European Union's RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations have significant implications for GC-MS manufacturers, requiring careful material selection and documentation. Similarly, the United States EPA has established guidelines for laboratory waste management that directly impact GC-MS operations, particularly when analyzing environmental contaminants or industrial waste samples.

Energy efficiency represents an emerging focus area for sustainable GC-MS innovation. Traditional systems consume substantial electrical power for heating columns and operating mass spectrometers. New designs incorporate improved insulation materials, energy recovery systems, and intelligent power management algorithms that optimize consumption based on analytical requirements. Some manufacturers have introduced solar-powered portable GC-MS units for field applications, significantly reducing the carbon footprint of environmental monitoring campaigns.

End-of-life considerations for GC-MS equipment present unique challenges due to the sophisticated electronic components and specialized materials used in their construction. Manufacturers are increasingly adopting modular designs that facilitate repair, upgrade, and eventual recycling of instruments. Extended producer responsibility programs are emerging within the analytical instrumentation sector, with several leading companies offering take-back and refurbishment services that extend product lifecycles and reduce electronic waste generation.

Interdisciplinary Applications and Integration

The integration of GC-MS technology across diverse scientific disciplines represents a significant frontier for analytical innovation. As non-conventional mixtures increasingly challenge traditional analytical approaches, GC-MS systems are finding novel applications beyond their original domains, creating valuable interdisciplinary bridges.

In environmental science, advanced GC-MS techniques are being adapted to analyze complex soil and water contaminant mixtures that contain both volatile and semi-volatile compounds of varying polarities. These applications often integrate GC-MS with complementary technologies like LC-MS to provide comprehensive environmental monitoring solutions that address regulatory requirements across multiple jurisdictions.

The food science sector has embraced GC-MS innovations for authenticating complex natural products and detecting adulterants in food matrices. By combining GC-MS with chemometric approaches and artificial intelligence, researchers have developed authentication protocols for high-value commodities like honey, olive oil, and wine, where conventional analysis often fails to detect sophisticated adulteration.

Forensic science represents another interdisciplinary frontier, where GC-MS adaptations are crucial for analyzing complex biological matrices containing both endogenous and exogenous compounds. The integration of GC-MS with portable technologies has enabled on-site forensic investigations, fundamentally changing evidence collection protocols and chain-of-custody procedures.

In pharmaceutical research, GC-MS innovations are being integrated with high-throughput screening platforms to accelerate drug discovery processes. This integration allows for rapid metabolite profiling and impurity identification in complex biological matrices, supporting both preclinical and clinical studies with more comprehensive analytical data.

The materials science field has adopted specialized GC-MS techniques for analyzing outgassing from novel composite materials and polymers under various environmental conditions. These applications often integrate thermal analysis with GC-MS to provide insights into material degradation mechanisms and long-term stability characteristics.

Perhaps most promising is the integration of GC-MS with Internet of Things (IoT) platforms and cloud computing resources, creating networked analytical systems capable of real-time data sharing across disciplines. These integrated systems enable collaborative research between environmental scientists, toxicologists, and public health experts, facilitating more comprehensive approaches to complex analytical challenges like emerging contaminant identification or global food safety monitoring.

In environmental science, advanced GC-MS techniques are being adapted to analyze complex soil and water contaminant mixtures that contain both volatile and semi-volatile compounds of varying polarities. These applications often integrate GC-MS with complementary technologies like LC-MS to provide comprehensive environmental monitoring solutions that address regulatory requirements across multiple jurisdictions.

The food science sector has embraced GC-MS innovations for authenticating complex natural products and detecting adulterants in food matrices. By combining GC-MS with chemometric approaches and artificial intelligence, researchers have developed authentication protocols for high-value commodities like honey, olive oil, and wine, where conventional analysis often fails to detect sophisticated adulteration.

Forensic science represents another interdisciplinary frontier, where GC-MS adaptations are crucial for analyzing complex biological matrices containing both endogenous and exogenous compounds. The integration of GC-MS with portable technologies has enabled on-site forensic investigations, fundamentally changing evidence collection protocols and chain-of-custody procedures.

In pharmaceutical research, GC-MS innovations are being integrated with high-throughput screening platforms to accelerate drug discovery processes. This integration allows for rapid metabolite profiling and impurity identification in complex biological matrices, supporting both preclinical and clinical studies with more comprehensive analytical data.

The materials science field has adopted specialized GC-MS techniques for analyzing outgassing from novel composite materials and polymers under various environmental conditions. These applications often integrate thermal analysis with GC-MS to provide insights into material degradation mechanisms and long-term stability characteristics.

Perhaps most promising is the integration of GC-MS with Internet of Things (IoT) platforms and cloud computing resources, creating networked analytical systems capable of real-time data sharing across disciplines. These integrated systems enable collaborative research between environmental scientists, toxicologists, and public health experts, facilitating more comprehensive approaches to complex analytical challenges like emerging contaminant identification or global food safety monitoring.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!