Propel GC-MS Knowledge in Advanced Manufacturing Modeling

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GC-MS Technology Evolution and Objectives

Gas Chromatography-Mass Spectrometry (GC-MS) has evolved significantly since its inception in the mid-20th century, transforming from a specialized analytical technique to an indispensable tool in advanced manufacturing processes. The integration of GC-MS technology into manufacturing environments represents a critical advancement in quality control, process optimization, and materials characterization. This evolution has been driven by increasing demands for higher precision, greater sensitivity, and more comprehensive analytical capabilities in industrial settings.

The historical trajectory of GC-MS development shows distinct phases of innovation. Initially developed as separate technologies, gas chromatography and mass spectrometry were first combined in the 1950s, creating a powerful analytical method that could separate and identify complex mixtures. By the 1970s, computerized data systems enhanced the technology's capabilities, while the 1980s and 1990s saw significant miniaturization and automation improvements that made GC-MS more accessible to industrial applications.

Recent technological advancements have focused on improving sensitivity, resolution, and throughput, with modern systems capable of detecting compounds at parts-per-trillion levels. The integration of artificial intelligence and machine learning algorithms has further enhanced data interpretation capabilities, allowing for more sophisticated pattern recognition and predictive analytics in manufacturing contexts.

The primary objective of propelling GC-MS knowledge in advanced manufacturing modeling is to develop comprehensive frameworks that leverage real-time analytical data for process optimization and quality assurance. This includes creating predictive models that can anticipate manufacturing deviations before they occur, establishing correlations between molecular-level data and macroscopic product properties, and developing digital twins that incorporate GC-MS data streams into holistic manufacturing simulations.

Additional objectives include enhancing the integration of GC-MS systems with other analytical technologies to create multi-modal sensing platforms, developing industry-specific reference databases to streamline compound identification in manufacturing environments, and establishing standardized protocols for GC-MS implementation across different manufacturing sectors.

The technological trajectory suggests that future GC-MS systems will become increasingly autonomous, with self-calibrating capabilities and adaptive sampling protocols that respond to manufacturing conditions in real-time. The miniaturization trend is expected to continue, potentially leading to portable or even in-line GC-MS systems that can be deployed directly within production lines, eliminating the need for sample transport and enabling truly continuous monitoring of manufacturing processes.

The historical trajectory of GC-MS development shows distinct phases of innovation. Initially developed as separate technologies, gas chromatography and mass spectrometry were first combined in the 1950s, creating a powerful analytical method that could separate and identify complex mixtures. By the 1970s, computerized data systems enhanced the technology's capabilities, while the 1980s and 1990s saw significant miniaturization and automation improvements that made GC-MS more accessible to industrial applications.

Recent technological advancements have focused on improving sensitivity, resolution, and throughput, with modern systems capable of detecting compounds at parts-per-trillion levels. The integration of artificial intelligence and machine learning algorithms has further enhanced data interpretation capabilities, allowing for more sophisticated pattern recognition and predictive analytics in manufacturing contexts.

The primary objective of propelling GC-MS knowledge in advanced manufacturing modeling is to develop comprehensive frameworks that leverage real-time analytical data for process optimization and quality assurance. This includes creating predictive models that can anticipate manufacturing deviations before they occur, establishing correlations between molecular-level data and macroscopic product properties, and developing digital twins that incorporate GC-MS data streams into holistic manufacturing simulations.

Additional objectives include enhancing the integration of GC-MS systems with other analytical technologies to create multi-modal sensing platforms, developing industry-specific reference databases to streamline compound identification in manufacturing environments, and establishing standardized protocols for GC-MS implementation across different manufacturing sectors.

The technological trajectory suggests that future GC-MS systems will become increasingly autonomous, with self-calibrating capabilities and adaptive sampling protocols that respond to manufacturing conditions in real-time. The miniaturization trend is expected to continue, potentially leading to portable or even in-line GC-MS systems that can be deployed directly within production lines, eliminating the need for sample transport and enabling truly continuous monitoring of manufacturing processes.

Market Analysis for GC-MS in Advanced Manufacturing

The Gas Chromatography-Mass Spectrometry (GC-MS) market in advanced manufacturing is experiencing robust growth, driven by increasing demands for quality control, process optimization, and regulatory compliance. Current market valuations indicate that the global GC-MS market size exceeds $2.3 billion, with a compound annual growth rate of approximately 6.8% projected through 2028. Within this broader market, the advanced manufacturing segment represents nearly 22% of total market share, making it one of the fastest-growing application areas.

Key market drivers include the rising adoption of Industry 4.0 technologies that require precise analytical capabilities for real-time monitoring and control of manufacturing processes. The integration of GC-MS systems with automated production lines has created a new market segment focused on inline quality assurance, which is growing at nearly 9% annually. This trend is particularly evident in semiconductor manufacturing, pharmaceutical production, and advanced materials development sectors.

Regional analysis reveals that North America currently dominates the GC-MS market in advanced manufacturing with approximately 38% market share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is demonstrating the highest growth rate, fueled by rapid industrialization in China, India, and South Korea, where manufacturing sectors are increasingly adopting sophisticated analytical technologies.

Customer segmentation shows distinct market needs across different manufacturing verticals. The pharmaceutical and biotechnology sectors prioritize high sensitivity and compliance with regulatory standards, while electronics manufacturers focus on detection of ultra-trace contaminants. Automotive and aerospace industries primarily utilize GC-MS for materials testing and quality verification of components.

Pricing trends indicate a gradual decrease in entry-level GC-MS systems, making the technology more accessible to small and medium-sized manufacturers. However, premium systems with advanced capabilities such as high-resolution mass spectrometry, automated sample preparation, and specialized software for manufacturing applications command significant price premiums, often 40-60% higher than standard configurations.

Market challenges include the high initial investment cost, technical expertise requirements for operation and maintenance, and integration complexities with existing manufacturing systems. These factors have created opportunities for service-based business models, with GC-MS analysis-as-a-service growing at nearly 12% annually, particularly among smaller manufacturers unable to justify in-house systems.

Future market growth is expected to be driven by miniaturization of GC-MS systems for point-of-use applications in manufacturing environments, enhanced software capabilities for predictive quality control, and integration with artificial intelligence for automated interpretation of complex analytical data.

Key market drivers include the rising adoption of Industry 4.0 technologies that require precise analytical capabilities for real-time monitoring and control of manufacturing processes. The integration of GC-MS systems with automated production lines has created a new market segment focused on inline quality assurance, which is growing at nearly 9% annually. This trend is particularly evident in semiconductor manufacturing, pharmaceutical production, and advanced materials development sectors.

Regional analysis reveals that North America currently dominates the GC-MS market in advanced manufacturing with approximately 38% market share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is demonstrating the highest growth rate, fueled by rapid industrialization in China, India, and South Korea, where manufacturing sectors are increasingly adopting sophisticated analytical technologies.

Customer segmentation shows distinct market needs across different manufacturing verticals. The pharmaceutical and biotechnology sectors prioritize high sensitivity and compliance with regulatory standards, while electronics manufacturers focus on detection of ultra-trace contaminants. Automotive and aerospace industries primarily utilize GC-MS for materials testing and quality verification of components.

Pricing trends indicate a gradual decrease in entry-level GC-MS systems, making the technology more accessible to small and medium-sized manufacturers. However, premium systems with advanced capabilities such as high-resolution mass spectrometry, automated sample preparation, and specialized software for manufacturing applications command significant price premiums, often 40-60% higher than standard configurations.

Market challenges include the high initial investment cost, technical expertise requirements for operation and maintenance, and integration complexities with existing manufacturing systems. These factors have created opportunities for service-based business models, with GC-MS analysis-as-a-service growing at nearly 12% annually, particularly among smaller manufacturers unable to justify in-house systems.

Future market growth is expected to be driven by miniaturization of GC-MS systems for point-of-use applications in manufacturing environments, enhanced software capabilities for predictive quality control, and integration with artificial intelligence for automated interpretation of complex analytical data.

Technical Challenges and Global Development Status

GC-MS technology in advanced manufacturing faces significant technical challenges despite its widespread adoption. The primary obstacle remains the complex interpretation of mass spectra, particularly when analyzing unknown compounds in manufacturing environments. Current algorithms struggle with accurate identification when dealing with mixed samples containing multiple compounds, which is common in industrial settings. This challenge is compounded by the need for real-time analysis in modern manufacturing processes, where traditional GC-MS methods often require time-consuming sample preparation and analysis procedures.

Sensitivity limitations present another major hurdle, especially when detecting trace contaminants in high-purity manufacturing environments such as semiconductor fabrication. The technology must evolve to achieve lower detection limits without sacrificing reliability or increasing false positives, which could trigger costly manufacturing shutdowns.

Globally, GC-MS development shows distinct regional characteristics. North America leads in innovation, with approximately 40% of new GC-MS patents originating from the United States, particularly focused on software algorithms and data processing improvements. The European market emphasizes environmental applications, with significant research dedicated to detecting manufacturing pollutants at increasingly lower concentrations.

Asia, particularly Japan and China, has emerged as the fastest-growing region for GC-MS technology development. Chinese manufacturers have made remarkable progress in producing more affordable instruments while gradually closing the performance gap with Western counterparts. Japan continues to excel in miniaturization and automation of GC-MS systems, making them more suitable for integration into manufacturing lines.

Recent technological breakthroughs include the development of portable GC-MS systems capable of on-site analysis, though these still lack the sensitivity of laboratory instruments. Machine learning integration represents another significant advancement, with neural networks demonstrating promising results in compound identification accuracy, though requiring extensive training datasets specific to manufacturing environments.

Standardization remains problematic across the industry, with different manufacturers using proprietary data formats and analysis methods. This fragmentation hinders the development of universal solutions and complicates data sharing between different manufacturing facilities or research institutions.

The integration of GC-MS with other analytical techniques, such as infrared spectroscopy or nuclear magnetic resonance, shows promise for overcoming individual limitations of each technology, but increases system complexity and cost. Finding the optimal balance between comprehensive analysis capabilities and practical implementation in manufacturing settings continues to challenge researchers and engineers worldwide.

Sensitivity limitations present another major hurdle, especially when detecting trace contaminants in high-purity manufacturing environments such as semiconductor fabrication. The technology must evolve to achieve lower detection limits without sacrificing reliability or increasing false positives, which could trigger costly manufacturing shutdowns.

Globally, GC-MS development shows distinct regional characteristics. North America leads in innovation, with approximately 40% of new GC-MS patents originating from the United States, particularly focused on software algorithms and data processing improvements. The European market emphasizes environmental applications, with significant research dedicated to detecting manufacturing pollutants at increasingly lower concentrations.

Asia, particularly Japan and China, has emerged as the fastest-growing region for GC-MS technology development. Chinese manufacturers have made remarkable progress in producing more affordable instruments while gradually closing the performance gap with Western counterparts. Japan continues to excel in miniaturization and automation of GC-MS systems, making them more suitable for integration into manufacturing lines.

Recent technological breakthroughs include the development of portable GC-MS systems capable of on-site analysis, though these still lack the sensitivity of laboratory instruments. Machine learning integration represents another significant advancement, with neural networks demonstrating promising results in compound identification accuracy, though requiring extensive training datasets specific to manufacturing environments.

Standardization remains problematic across the industry, with different manufacturers using proprietary data formats and analysis methods. This fragmentation hinders the development of universal solutions and complicates data sharing between different manufacturing facilities or research institutions.

The integration of GC-MS with other analytical techniques, such as infrared spectroscopy or nuclear magnetic resonance, shows promise for overcoming individual limitations of each technology, but increases system complexity and cost. Finding the optimal balance between comprehensive analysis capabilities and practical implementation in manufacturing settings continues to challenge researchers and engineers worldwide.

Current GC-MS Modeling Solutions in Manufacturing

01 GC-MS instrumentation and system design

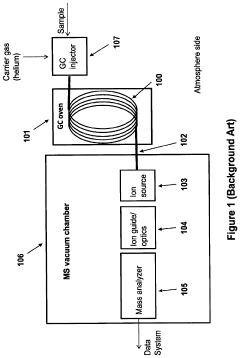

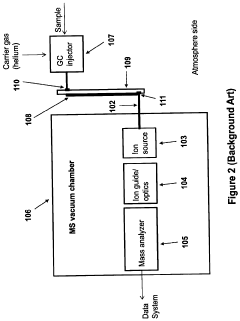

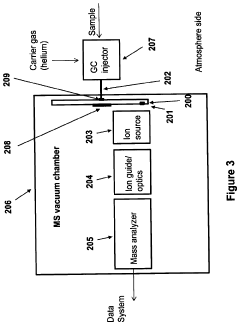

Gas Chromatography-Mass Spectrometry (GC-MS) systems consist of specialized hardware components designed for efficient separation and detection of compounds. These systems include innovative column designs, ionization sources, detectors, and integrated data processing units. Advanced instrumentation features automated sample handling, temperature control mechanisms, and vacuum systems that enhance analytical precision and throughput. Modern GC-MS equipment incorporates miniaturized components and modular designs to improve portability and application flexibility.- GC-MS Instrumentation and System Design: Gas Chromatography-Mass Spectrometry (GC-MS) systems integrate separation and identification capabilities. These systems typically consist of a gas chromatograph for compound separation based on volatility and interaction with the column, coupled with a mass spectrometer for molecular identification. Modern designs focus on improving sensitivity, resolution, and automation capabilities while reducing analysis time and maintenance requirements.

- Sample Preparation and Introduction Techniques: Effective sample preparation is crucial for GC-MS analysis, involving extraction, concentration, and derivatization methods to make compounds suitable for gas-phase analysis. Various introduction techniques include direct injection, headspace sampling, solid-phase microextraction (SPME), and thermal desorption. These techniques aim to improve detection limits, reduce matrix interference, and enhance chromatographic separation for complex samples.

- Method Development and Optimization: Developing optimized GC-MS methods involves selecting appropriate column types, temperature programs, carrier gas flow rates, and mass spectrometric parameters. Method optimization focuses on achieving adequate separation of target compounds while minimizing analysis time. Advanced techniques include multidimensional chromatography and specialized detection modes to enhance selectivity and sensitivity for specific applications.

- Data Analysis and Interpretation: GC-MS data analysis involves processing complex chromatograms and mass spectra to identify and quantify compounds. Modern software tools employ algorithms for peak detection, deconvolution, library searching, and statistical analysis. Advanced techniques include machine learning approaches for automated compound identification, pattern recognition in complex mixtures, and handling large datasets from high-throughput analyses.

- Applications in Various Fields: GC-MS technology finds applications across numerous fields including environmental monitoring, food safety analysis, forensic science, pharmaceutical research, and metabolomics. Specialized applications include detection of pesticides, pollutants, drugs, explosives, and biomarkers. Recent developments focus on portable and field-deployable systems, real-time monitoring capabilities, and integration with other analytical techniques for comprehensive sample characterization.

02 Sample preparation and introduction techniques

Effective sample preparation is crucial for GC-MS analysis, involving extraction, concentration, and derivatization methods to enhance compound volatility and detection sensitivity. Various techniques include solid-phase microextraction (SPME), headspace sampling, thermal desorption, and liquid-liquid extraction. Automated sample introduction systems improve reproducibility and reduce contamination risks. Specialized preparation protocols have been developed for different sample matrices including environmental samples, biological fluids, and industrial products, ensuring optimal compound separation and identification.Expand Specific Solutions03 Data analysis and interpretation methods

Advanced software algorithms and computational methods are essential for processing complex GC-MS data. These include peak detection, deconvolution techniques, library matching, and quantification methods. Machine learning approaches enhance compound identification accuracy and reduce false positives. Specialized databases and spectral libraries support the identification of unknown compounds across various applications. Statistical analysis tools help in pattern recognition and biomarker discovery, particularly important in metabolomics and environmental monitoring applications.Expand Specific Solutions04 Application-specific GC-MS methods

GC-MS techniques have been adapted for specialized applications across multiple fields. In environmental monitoring, methods focus on detecting trace pollutants in air, water, and soil samples. For pharmaceutical analysis, GC-MS protocols emphasize impurity profiling and quality control. In forensic science, specialized approaches target the identification of drugs, explosives, and fire accelerants. Food safety applications include pesticide residue analysis and flavor compound characterization. Clinical diagnostics utilize GC-MS for metabolite profiling and disease biomarker identification.Expand Specific Solutions05 Method validation and quality control

Rigorous validation protocols ensure GC-MS analytical reliability and reproducibility. These include determination of detection limits, linearity ranges, precision, and accuracy metrics. Internal standards and calibration methods are employed to compensate for matrix effects and instrument variations. Quality control procedures involve regular system suitability testing, blank analyses, and certified reference materials. Standardized operating procedures have been developed to meet regulatory requirements in various industries, including pharmaceutical, environmental, and food testing sectors.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The Gas Chromatography-Mass Spectrometry (GC-MS) technology landscape in advanced manufacturing modeling is currently in a growth phase, with an estimated market size exceeding $2 billion globally. The competitive landscape features established analytical instrumentation leaders like Siemens Industry Software and Onto Innovation alongside diversified technology corporations such as Oracle, Qualcomm, and Huawei Cloud. Academic institutions including Zhejiang University and Northwestern Polytechnical University are advancing fundamental research, while specialized players like Entech Instruments focus on niche applications. The technology is approaching maturity in traditional manufacturing but remains in development for AI-integrated applications, with companies like Snorkel AI and UiPath working on automation solutions that leverage GC-MS data for predictive modeling and quality control in advanced manufacturing environments.

Koninklijke Philips NV

Technical Solution: Philips has developed advanced GC-MS modeling systems primarily focused on healthcare product manufacturing and medical device production. Their technology integrates GC-MS analysis into quality assurance workflows for pharmaceutical and medical device manufacturing. The system features specialized algorithms for detecting extractables and leachables in medical-grade polymers and components. Philips' modeling approach incorporates regulatory compliance parameters directly into the analytical framework, ensuring manufactured products meet stringent healthcare standards. Their platform includes specialized libraries for healthcare-relevant compounds and contaminants, enabling rapid identification of potential issues in manufacturing processes. The technology employs a risk-based modeling approach that prioritizes detection and quantification of compounds based on their potential patient impact, creating a more efficient quality control process specifically tailored for healthcare manufacturing applications.

Strengths: Exceptional regulatory compliance integration and specialized expertise in healthcare manufacturing requirements. Comprehensive validation protocols aligned with medical device and pharmaceutical standards. Weaknesses: Highly specialized for healthcare applications with limited applicability to other manufacturing sectors without significant customization.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed advanced GC-MS (Gas Chromatography-Mass Spectrometry) modeling systems specifically tailored for petroleum manufacturing processes. Their technology integrates real-time GC-MS data acquisition with predictive modeling algorithms to optimize refining operations. The company's approach combines machine learning with traditional chromatographic analysis to identify trace contaminants and predict process inefficiencies before they impact production quality. ExxonMobil's system features automated calibration routines that maintain accuracy across varying operational conditions and feedstock compositions. Their modeling framework incorporates digital twin technology that simulates manufacturing processes with GC-MS data as a key input parameter, allowing for virtual testing of process modifications without disrupting actual production.

Strengths: Highly specialized for petroleum industry applications with proven implementation across global refineries. Superior integration with existing manufacturing control systems. Weaknesses: Limited applicability outside petrochemical manufacturing contexts, requiring significant customization for other industries.

Critical Patents and Innovations in GC-MS Modeling

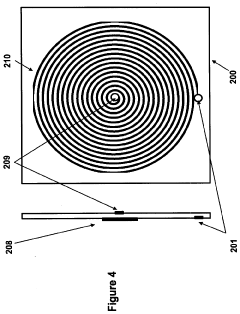

Portable MEMS GC-ms system

PatentActiveUS20200378930A1

Innovation

- The integration of a MEMS GC column with an integrated heater inside the MS vacuum system, leveraging the high thermal isolation properties of a vacuum to minimize heating power losses, and incorporating non-active cooling methods like a periodically activated cold finger for efficient temperature control.

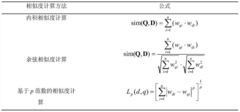

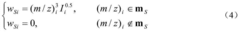

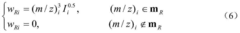

Gas chromatography-mass spectrometer spectrogram matching method

PatentInactiveCN104504706A

Innovation

- A new mass spectrum matching method is adopted, including screening of unknown substance spectra and standard mass spectra, peak intensity scaling and similarity calculation based on vector space model. By representing the mass spectrum as a vector form and using p-norm based The similarity calculation formula of numbers improves the matching accuracy.

Integration with Industry 4.0 and Digital Twins

The integration of GC-MS technology with Industry 4.0 and Digital Twin frameworks represents a transformative approach to advanced manufacturing modeling. This convergence enables real-time analytical capabilities that fundamentally enhance production processes through continuous monitoring and adaptive control systems.

Industry 4.0 principles emphasize interconnectivity, automation, machine learning, and real-time data analytics. When GC-MS systems are incorporated into this framework, they provide critical chemical composition data that can be immediately processed and utilized for quality control decisions. The integration typically involves connecting GC-MS instruments to industrial IoT networks, allowing analytical results to feed directly into manufacturing execution systems (MES) and enterprise resource planning (ERP) platforms.

Digital Twin technology creates virtual replicas of physical manufacturing processes, enabling simulation, prediction, and optimization without disrupting actual production. GC-MS data serves as a vital input for these digital models, providing accurate chemical fingerprints that help maintain fidelity between the physical and virtual environments. This integration allows manufacturers to predict product quality variations based on process parameters and raw material characteristics before actual production occurs.

Several implementation architectures have emerged for this integration. Edge computing configurations place data processing capabilities near GC-MS instruments, reducing latency for time-critical applications. Cloud-based architectures offer scalable storage and processing power for complex modeling and historical trend analysis. Hybrid approaches balance these benefits by distributing computational tasks according to time-sensitivity and resource requirements.

The practical benefits of this integration include significant reductions in quality control cycle times, with some implementations reporting 60-80% decreases compared to traditional laboratory testing workflows. Predictive maintenance capabilities have also improved, as subtle changes in chemical profiles often indicate equipment degradation before mechanical symptoms appear. This predictive capability has been documented to reduce unplanned downtime by up to 45% in chemical manufacturing facilities.

Challenges remain in standardizing data formats and communication protocols between analytical instruments and manufacturing systems. Efforts by organizations such as the Analytical Information Markup Language (AnIML) consortium are working to establish common frameworks that facilitate seamless integration. Additionally, cybersecurity concerns must be addressed as analytical instruments become more connected to enterprise networks, potentially creating new vulnerability points.

Industry 4.0 principles emphasize interconnectivity, automation, machine learning, and real-time data analytics. When GC-MS systems are incorporated into this framework, they provide critical chemical composition data that can be immediately processed and utilized for quality control decisions. The integration typically involves connecting GC-MS instruments to industrial IoT networks, allowing analytical results to feed directly into manufacturing execution systems (MES) and enterprise resource planning (ERP) platforms.

Digital Twin technology creates virtual replicas of physical manufacturing processes, enabling simulation, prediction, and optimization without disrupting actual production. GC-MS data serves as a vital input for these digital models, providing accurate chemical fingerprints that help maintain fidelity between the physical and virtual environments. This integration allows manufacturers to predict product quality variations based on process parameters and raw material characteristics before actual production occurs.

Several implementation architectures have emerged for this integration. Edge computing configurations place data processing capabilities near GC-MS instruments, reducing latency for time-critical applications. Cloud-based architectures offer scalable storage and processing power for complex modeling and historical trend analysis. Hybrid approaches balance these benefits by distributing computational tasks according to time-sensitivity and resource requirements.

The practical benefits of this integration include significant reductions in quality control cycle times, with some implementations reporting 60-80% decreases compared to traditional laboratory testing workflows. Predictive maintenance capabilities have also improved, as subtle changes in chemical profiles often indicate equipment degradation before mechanical symptoms appear. This predictive capability has been documented to reduce unplanned downtime by up to 45% in chemical manufacturing facilities.

Challenges remain in standardizing data formats and communication protocols between analytical instruments and manufacturing systems. Efforts by organizations such as the Analytical Information Markup Language (AnIML) consortium are working to establish common frameworks that facilitate seamless integration. Additionally, cybersecurity concerns must be addressed as analytical instruments become more connected to enterprise networks, potentially creating new vulnerability points.

Environmental and Regulatory Compliance Factors

The integration of GC-MS technology in advanced manufacturing processes necessitates careful consideration of environmental and regulatory compliance factors. Manufacturing facilities utilizing gas chromatography-mass spectrometry must adhere to increasingly stringent global environmental regulations, particularly regarding emissions control, waste management, and chemical safety. The Environmental Protection Agency (EPA) in the United States and similar bodies worldwide have established specific guidelines for analytical laboratories and manufacturing environments that employ volatile organic compounds and other chemicals commonly analyzed by GC-MS systems.

Regulatory frameworks such as REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) in Europe and similar programs in Asia-Pacific regions directly impact how GC-MS technology is implemented in manufacturing settings. These regulations mandate comprehensive chemical inventory management, detailed reporting of hazardous substances, and strict protocols for handling analytical waste. Manufacturers must demonstrate compliance through regular environmental impact assessments and documentation of chemical lifecycle management.

Energy consumption represents another critical compliance factor for GC-MS implementation. Modern manufacturing facilities face mounting pressure to reduce carbon footprints while maintaining analytical precision. The significant power requirements of GC-MS systems, particularly those operating continuously in production environments, necessitate energy efficiency strategies to meet sustainability targets and comply with emerging carbon reduction regulations.

Water usage and contamination prevention constitute additional regulatory considerations. GC-MS operations often require high-purity water systems and generate potentially contaminated wastewater. Advanced manufacturing facilities must implement water conservation measures and treatment systems that align with local discharge regulations and global water stewardship initiatives.

Worker safety regulations intersect significantly with GC-MS implementation in manufacturing environments. Occupational exposure limits for solvents, carrier gases, and analytical standards must be strictly monitored and controlled. Regulatory bodies such as OSHA in the United States mandate specific training, ventilation requirements, and safety protocols for personnel working with analytical instrumentation and associated chemicals.

The transportation and disposal of GC-MS consumables and waste present further regulatory challenges. International agreements like the Basel Convention govern cross-border movement of hazardous materials, while local regulations dictate proper disposal procedures. Manufacturers must establish compliant supply chains for analytical consumables and implement certified waste management programs that meet increasingly complex requirements for chemical waste handling.

Regulatory frameworks such as REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) in Europe and similar programs in Asia-Pacific regions directly impact how GC-MS technology is implemented in manufacturing settings. These regulations mandate comprehensive chemical inventory management, detailed reporting of hazardous substances, and strict protocols for handling analytical waste. Manufacturers must demonstrate compliance through regular environmental impact assessments and documentation of chemical lifecycle management.

Energy consumption represents another critical compliance factor for GC-MS implementation. Modern manufacturing facilities face mounting pressure to reduce carbon footprints while maintaining analytical precision. The significant power requirements of GC-MS systems, particularly those operating continuously in production environments, necessitate energy efficiency strategies to meet sustainability targets and comply with emerging carbon reduction regulations.

Water usage and contamination prevention constitute additional regulatory considerations. GC-MS operations often require high-purity water systems and generate potentially contaminated wastewater. Advanced manufacturing facilities must implement water conservation measures and treatment systems that align with local discharge regulations and global water stewardship initiatives.

Worker safety regulations intersect significantly with GC-MS implementation in manufacturing environments. Occupational exposure limits for solvents, carrier gases, and analytical standards must be strictly monitored and controlled. Regulatory bodies such as OSHA in the United States mandate specific training, ventilation requirements, and safety protocols for personnel working with analytical instrumentation and associated chemicals.

The transportation and disposal of GC-MS consumables and waste present further regulatory challenges. International agreements like the Basel Convention govern cross-border movement of hazardous materials, while local regulations dictate proper disposal procedures. Manufacturers must establish compliant supply chains for analytical consumables and implement certified waste management programs that meet increasingly complex requirements for chemical waste handling.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!