GC-MS Noise Isolation Techniques: Application in Labs

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GC-MS Technology Evolution and Objectives

Gas Chromatography-Mass Spectrometry (GC-MS) has evolved significantly since its inception in the 1950s when the first successful coupling of these two analytical techniques was achieved. The initial systems were bulky, expensive, and primarily limited to specialized research facilities. By the 1970s, technological advancements led to more compact and reliable systems, expanding their accessibility to broader scientific communities. The 1980s and 1990s witnessed substantial improvements in computerization and automation, transforming GC-MS from a purely research tool into a routine analytical instrument.

The evolution of noise isolation techniques in GC-MS has paralleled the overall development of the technology. Early systems suffered from significant signal-to-noise ratio challenges, limiting detection capabilities and analytical precision. Progressive innovations in electronic filtering, signal processing algorithms, and detector technologies have continuously enhanced the ability to isolate meaningful signals from background noise.

Modern GC-MS systems incorporate sophisticated noise reduction strategies including advanced electronic filtering circuits, digital signal processing, and software-based noise recognition algorithms. These developments have dramatically improved detection limits, allowing for the identification and quantification of compounds at increasingly lower concentrations, often reaching parts-per-trillion levels in optimized systems.

The primary objective of noise isolation techniques in laboratory applications is to enhance analytical sensitivity and reliability. This involves distinguishing genuine analyte signals from various noise sources including electronic noise, chemical background, column bleed, and environmental interferences. Effective noise isolation directly impacts the accuracy of compound identification, the precision of quantitative analysis, and the overall reliability of analytical results.

Current technological goals focus on developing more intelligent and adaptive noise filtering systems that can automatically identify and compensate for different noise patterns in real-time. Machine learning algorithms are increasingly being integrated to recognize complex noise signatures and distinguish them from authentic analyte signals, even in challenging matrices.

Another significant objective is the miniaturization and portability of high-performance GC-MS systems without compromising noise isolation capabilities. This trend aims to extend laboratory-grade analytical performance to field applications, environmental monitoring, and point-of-care diagnostics, where noise challenges are often more severe due to less controlled conditions.

The convergence of improved hardware components, advanced signal processing techniques, and artificial intelligence promises to further revolutionize noise isolation in GC-MS, potentially enabling new applications in metabolomics, environmental monitoring, food safety, forensic science, and clinical diagnostics where trace analysis is critical.

The evolution of noise isolation techniques in GC-MS has paralleled the overall development of the technology. Early systems suffered from significant signal-to-noise ratio challenges, limiting detection capabilities and analytical precision. Progressive innovations in electronic filtering, signal processing algorithms, and detector technologies have continuously enhanced the ability to isolate meaningful signals from background noise.

Modern GC-MS systems incorporate sophisticated noise reduction strategies including advanced electronic filtering circuits, digital signal processing, and software-based noise recognition algorithms. These developments have dramatically improved detection limits, allowing for the identification and quantification of compounds at increasingly lower concentrations, often reaching parts-per-trillion levels in optimized systems.

The primary objective of noise isolation techniques in laboratory applications is to enhance analytical sensitivity and reliability. This involves distinguishing genuine analyte signals from various noise sources including electronic noise, chemical background, column bleed, and environmental interferences. Effective noise isolation directly impacts the accuracy of compound identification, the precision of quantitative analysis, and the overall reliability of analytical results.

Current technological goals focus on developing more intelligent and adaptive noise filtering systems that can automatically identify and compensate for different noise patterns in real-time. Machine learning algorithms are increasingly being integrated to recognize complex noise signatures and distinguish them from authentic analyte signals, even in challenging matrices.

Another significant objective is the miniaturization and portability of high-performance GC-MS systems without compromising noise isolation capabilities. This trend aims to extend laboratory-grade analytical performance to field applications, environmental monitoring, and point-of-care diagnostics, where noise challenges are often more severe due to less controlled conditions.

The convergence of improved hardware components, advanced signal processing techniques, and artificial intelligence promises to further revolutionize noise isolation in GC-MS, potentially enabling new applications in metabolomics, environmental monitoring, food safety, forensic science, and clinical diagnostics where trace analysis is critical.

Market Analysis for Laboratory Analytical Instruments

The laboratory analytical instruments market is experiencing robust growth, valued at approximately $30.2 billion in 2022 and projected to reach $45.6 billion by 2028, with a compound annual growth rate (CAGR) of 6.8%. Gas Chromatography-Mass Spectrometry (GC-MS) systems represent a significant segment within this market, accounting for roughly 18% of the total market share. The demand for advanced noise isolation techniques in GC-MS applications is primarily driven by increasing requirements for higher sensitivity, accuracy, and reliability in analytical results across various industries.

Pharmaceutical and biotechnology sectors remain the largest end-users of GC-MS systems with noise isolation capabilities, constituting approximately 35% of the market demand. These industries require ultra-sensitive detection capabilities for drug development, quality control, and regulatory compliance. The environmental testing segment follows closely at 28%, where trace analysis of contaminants demands superior noise reduction technologies to achieve lower detection limits.

Regional analysis indicates North America leads the market with a 38% share, followed by Europe (29%) and Asia-Pacific (24%). The Asia-Pacific region, particularly China and India, is witnessing the fastest growth rate at 8.5% annually, attributed to expanding pharmaceutical manufacturing, environmental monitoring requirements, and increasing R&D investments.

Key market trends influencing noise isolation techniques in GC-MS include the integration of artificial intelligence and machine learning algorithms for automated noise filtering, which has seen a 45% adoption increase in high-end laboratory instruments over the past three years. Additionally, miniaturization of GC-MS systems for point-of-need testing is creating new market opportunities, with portable systems incorporating advanced noise reduction technologies growing at 12.3% annually.

Customer demand analysis reveals that laboratories are increasingly prioritizing noise isolation capabilities when purchasing new analytical equipment, with 72% of procurement specialists citing improved signal-to-noise ratio as a critical decision factor. The return on investment for advanced noise isolation technologies is typically realized within 14-18 months through increased productivity, reduced need for sample re-runs, and enhanced data quality.

Competitive pricing analysis shows that GC-MS systems with premium noise isolation features command a price premium of 15-25% compared to standard models. However, the total cost of ownership calculations demonstrate that these systems ultimately provide cost advantages through improved operational efficiency and reduced maintenance requirements.

Pharmaceutical and biotechnology sectors remain the largest end-users of GC-MS systems with noise isolation capabilities, constituting approximately 35% of the market demand. These industries require ultra-sensitive detection capabilities for drug development, quality control, and regulatory compliance. The environmental testing segment follows closely at 28%, where trace analysis of contaminants demands superior noise reduction technologies to achieve lower detection limits.

Regional analysis indicates North America leads the market with a 38% share, followed by Europe (29%) and Asia-Pacific (24%). The Asia-Pacific region, particularly China and India, is witnessing the fastest growth rate at 8.5% annually, attributed to expanding pharmaceutical manufacturing, environmental monitoring requirements, and increasing R&D investments.

Key market trends influencing noise isolation techniques in GC-MS include the integration of artificial intelligence and machine learning algorithms for automated noise filtering, which has seen a 45% adoption increase in high-end laboratory instruments over the past three years. Additionally, miniaturization of GC-MS systems for point-of-need testing is creating new market opportunities, with portable systems incorporating advanced noise reduction technologies growing at 12.3% annually.

Customer demand analysis reveals that laboratories are increasingly prioritizing noise isolation capabilities when purchasing new analytical equipment, with 72% of procurement specialists citing improved signal-to-noise ratio as a critical decision factor. The return on investment for advanced noise isolation technologies is typically realized within 14-18 months through increased productivity, reduced need for sample re-runs, and enhanced data quality.

Competitive pricing analysis shows that GC-MS systems with premium noise isolation features command a price premium of 15-25% compared to standard models. However, the total cost of ownership calculations demonstrate that these systems ultimately provide cost advantages through improved operational efficiency and reduced maintenance requirements.

Current Noise Challenges in GC-MS Systems

Gas Chromatography-Mass Spectrometry (GC-MS) systems face several significant noise challenges that impact analytical performance in laboratory settings. The primary noise sources include electronic noise, chemical noise, and thermal noise, each contributing to reduced sensitivity and accuracy in analytical results.

Electronic noise manifests as baseline fluctuations and random signal variations originating from the instrument's electronic components. This includes detector noise, amplifier noise, and digitization errors in the signal processing chain. Modern GC-MS systems typically exhibit electronic noise in the range of 2-5 Hz, which can mask low-abundance analyte signals and compromise detection limits.

Chemical noise presents a more complex challenge, arising from column bleed, sample matrix effects, and co-eluting compounds. Column bleed increases significantly at higher temperatures, introducing siloxane-based background signals that interfere with analyte identification. Matrix effects from complex biological or environmental samples can generate inconsistent baselines and unpredictable background signals that vary between analyses.

Thermal noise becomes particularly problematic in temperature-programmed GC runs, where changing temperatures affect detector response characteristics. Temperature fluctuations as small as 0.1°C can produce measurable baseline drift, especially in sensitive MS detectors like electron multipliers and photomultiplier tubes.

Signal-to-noise ratio (SNR) degradation represents a critical limitation in trace analysis applications. Current GC-MS systems typically achieve SNRs of 10:1 to 100:1 for standard analyses, but environmental and clinical applications often require detection of compounds at sub-ppb levels where noise interference becomes the limiting factor.

Spectral interference from isobaric compounds (compounds with identical mass-to-charge ratios) creates identification challenges that are exacerbated by noise. This becomes particularly problematic in complex matrices like biological fluids, environmental samples, and food products where hundreds of compounds may be present simultaneously.

Data processing limitations also contribute to noise challenges. Current algorithms for baseline correction, peak deconvolution, and spectral matching struggle with high noise levels, often requiring manual intervention that introduces operator subjectivity and reduces throughput.

Instrument-specific noise patterns vary significantly between manufacturers and models, complicating the development of universal noise reduction strategies. For instance, quadrupole MS systems exhibit different noise characteristics compared to time-of-flight or ion trap instruments, necessitating customized approaches to noise management for each instrument type.

Electronic noise manifests as baseline fluctuations and random signal variations originating from the instrument's electronic components. This includes detector noise, amplifier noise, and digitization errors in the signal processing chain. Modern GC-MS systems typically exhibit electronic noise in the range of 2-5 Hz, which can mask low-abundance analyte signals and compromise detection limits.

Chemical noise presents a more complex challenge, arising from column bleed, sample matrix effects, and co-eluting compounds. Column bleed increases significantly at higher temperatures, introducing siloxane-based background signals that interfere with analyte identification. Matrix effects from complex biological or environmental samples can generate inconsistent baselines and unpredictable background signals that vary between analyses.

Thermal noise becomes particularly problematic in temperature-programmed GC runs, where changing temperatures affect detector response characteristics. Temperature fluctuations as small as 0.1°C can produce measurable baseline drift, especially in sensitive MS detectors like electron multipliers and photomultiplier tubes.

Signal-to-noise ratio (SNR) degradation represents a critical limitation in trace analysis applications. Current GC-MS systems typically achieve SNRs of 10:1 to 100:1 for standard analyses, but environmental and clinical applications often require detection of compounds at sub-ppb levels where noise interference becomes the limiting factor.

Spectral interference from isobaric compounds (compounds with identical mass-to-charge ratios) creates identification challenges that are exacerbated by noise. This becomes particularly problematic in complex matrices like biological fluids, environmental samples, and food products where hundreds of compounds may be present simultaneously.

Data processing limitations also contribute to noise challenges. Current algorithms for baseline correction, peak deconvolution, and spectral matching struggle with high noise levels, often requiring manual intervention that introduces operator subjectivity and reduces throughput.

Instrument-specific noise patterns vary significantly between manufacturers and models, complicating the development of universal noise reduction strategies. For instance, quadrupole MS systems exhibit different noise characteristics compared to time-of-flight or ion trap instruments, necessitating customized approaches to noise management for each instrument type.

Contemporary Noise Isolation Solutions

01 Digital signal processing techniques for noise reduction

Various digital signal processing algorithms can be applied to GC-MS data to isolate and reduce noise. These techniques include digital filtering, wavelet transforms, and Fourier analysis to separate signal from noise components. Advanced mathematical models can be implemented to identify and remove baseline drift, random noise, and electronic interference patterns from the mass spectrometry data, resulting in cleaner chromatograms and more accurate peak identification.- Digital signal processing techniques for noise reduction: Various digital signal processing algorithms can be applied to GC-MS data to isolate and reduce noise. These techniques include digital filtering, wavelet transforms, and Fourier analysis to separate signal from noise components. Advanced computational methods can identify and remove baseline drift, random noise, and electronic interference patterns from mass spectrometry data, resulting in cleaner spectra and improved detection limits.

- Hardware-based noise isolation solutions: Hardware modifications and improvements in GC-MS systems can significantly reduce noise at the source. These include improved ion source designs, enhanced detector shielding, temperature-stabilized components, and vibration isolation platforms. Specialized electronic circuits for signal amplification and noise cancellation can also be implemented to improve the signal-to-noise ratio before data acquisition.

- Machine learning and AI approaches for noise identification: Machine learning algorithms and artificial intelligence techniques can be trained to recognize and isolate noise patterns in GC-MS data. These approaches use pattern recognition to distinguish between actual analyte signals and various types of noise. Neural networks, support vector machines, and other classification algorithms can adaptively learn to filter out instrument-specific noise patterns, improving data quality across different operating conditions.

- Chemometric methods for noise reduction: Chemometric approaches apply statistical and mathematical methods to extract meaningful information from complex GC-MS data while minimizing noise interference. Principal component analysis (PCA), multivariate curve resolution, and other multivariate statistical techniques can separate chemical signals from background noise. These methods are particularly effective for handling complex samples with overlapping peaks and varying noise levels.

- Real-time adaptive noise filtering techniques: Real-time adaptive filtering systems can continuously monitor and adjust to changing noise conditions during GC-MS analysis. These systems use feedback mechanisms to identify emerging noise patterns and apply appropriate filtering parameters dynamically. Adaptive algorithms can compensate for instrument drift, environmental changes, and sample-specific interference, maintaining optimal signal quality throughout the analytical run.

02 Hardware-based noise isolation methods

Hardware modifications and improvements in GC-MS systems can significantly reduce noise at the source. These include enhanced ion source designs, improved vacuum systems, electromagnetic shielding, and temperature-stabilized detector components. Physical isolation of sensitive components from vibration and electromagnetic interference sources can prevent noise introduction. Advanced detector technologies with higher signal-to-noise ratios enable better discrimination between analyte signals and background noise.Expand Specific Solutions03 Machine learning and AI approaches for noise identification

Machine learning algorithms and artificial intelligence techniques are increasingly being applied to GC-MS data processing for noise isolation. These approaches can learn to recognize patterns of noise versus genuine signals across multiple samples, enabling automated noise filtering. Neural networks and other AI models can be trained to distinguish between instrument artifacts and true chemical signals, improving the reliability of trace compound detection even in noisy data environments.Expand Specific Solutions04 Chromatographic pre-processing techniques

Various pre-processing methods can be applied to chromatographic data before mass spectral analysis to reduce noise. These include baseline correction algorithms, peak alignment techniques, and smoothing functions that help distinguish true signals from random fluctuations. Retention time normalization and peak deconvolution methods can separate overlapping signals from noise, while background subtraction techniques can remove consistent noise patterns from the chromatographic data.Expand Specific Solutions05 Statistical methods for noise characterization and removal

Statistical approaches provide powerful tools for characterizing and removing noise in GC-MS data. Principal component analysis (PCA) and other multivariate statistical techniques can separate systematic noise from meaningful chemical information. Standard deviation filters, moving averages, and outlier detection algorithms help identify and remove random noise components. Statistical thresholding techniques can be applied to distinguish low-intensity signals from background noise based on their statistical properties.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The GC-MS noise isolation techniques market is currently in a growth phase, with increasing demand driven by expanding applications in pharmaceutical, environmental, and forensic laboratories. The market size is estimated to exceed $1.5 billion globally, with projected annual growth of 5-7%. Leading players include established analytical instrumentation companies like Thermo Finnigan Corp. and Shimadzu Corp., who dominate with comprehensive GC-MS solutions featuring advanced noise reduction algorithms. Waters Corp. (through Micromass UK) and LECO Corp. are competing through specialized time-of-flight technologies offering superior signal-to-noise ratios. Regional players like Shanghai Research Institute of Chemical Industry and NUCTECH are gaining market share in emerging economies by developing cost-effective solutions tailored to local laboratory requirements, though technological maturity still lags behind industry leaders.

Thermo Finnigan Corp.

Technical Solution: Thermo Finnigan has developed advanced GC-MS noise isolation techniques centered around their proprietary Orbitrap technology. Their approach combines hardware and software solutions to address noise at multiple levels. On the hardware side, they implement advanced ion optics systems with improved ion transmission efficiency and reduced background noise. Their mass analyzers feature enhanced resolution capabilities (>120,000 FWHM) that can separate closely related compounds from background interference. The software component includes sophisticated algorithms for baseline correction, peak deconvolution, and automated noise filtering. Their XCALIBUR data system incorporates advanced signal processing techniques that can identify and remove electronic noise, chemical background, and column bleed patterns. Additionally, they've implemented machine learning algorithms that can adaptively learn noise patterns specific to individual laboratory environments and automatically adjust filtering parameters accordingly.

Strengths: Superior mass accuracy (<1 ppm) allows for confident compound identification even in noisy matrices. Integration of hardware and software solutions provides comprehensive noise management. Weaknesses: Higher cost compared to competitors, complex systems require specialized training, and some proprietary algorithms lack transparency in their noise filtering methodology.

Micromass UK Ltd.

Technical Solution: Micromass UK (now part of Waters Corporation) has developed sophisticated GC-MS noise isolation techniques centered around their Q-Tof hybrid mass spectrometry platforms. Their approach combines quadrupole pre-filtering with high-resolution time-of-flight analysis to achieve superior noise discrimination. The initial quadrupole stage acts as a mass filter that can selectively transmit ions of interest while rejecting background ions, significantly reducing chemical noise before detection. Their orthogonal acceleration time-of-flight (oa-TOF) technology provides an additional dimension of noise reduction by separating ions based on their exact mass-to-charge ratios with resolution exceeding 40,000 FWHM. Micromass has implemented advanced ion optics including their patented T-Wave ion mobility separation, which adds another dimension of separation based on molecular shape, further distinguishing analyte signals from isobaric interferences and chemical noise. On the software side, their MassLynx platform incorporates sophisticated algorithms for background subtraction and spectral cleaning. Their QuanLynx module features dynamic noise thresholding that adapts to changing baseline conditions throughout analytical runs. Additionally, their MSe data acquisition strategy captures both low and high collision energy data simultaneously, allowing for improved confidence in compound identification even in noisy matrices.

Strengths: Exceptional mass accuracy (<3 ppm) allows confident compound identification even in complex matrices, and the combination of quadrupole filtering with TOF resolution provides multi-dimensional noise reduction. Weaknesses: Higher complexity and cost compared to single-analyzer systems, and some noise reduction algorithms may occasionally filter out legitimate low-abundance signals if parameters aren't carefully optimized.

Critical Patents in GC-MS Signal Processing

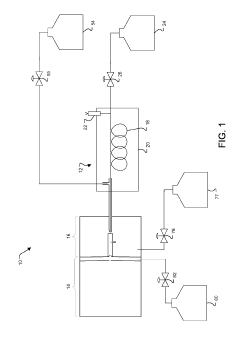

Large Volume Gas Chromatography Injection Port

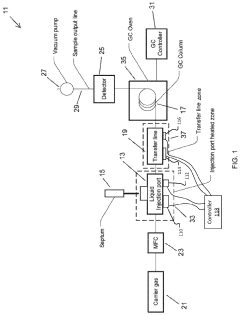

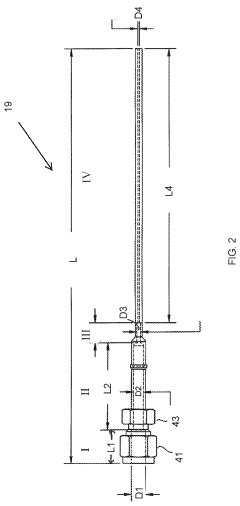

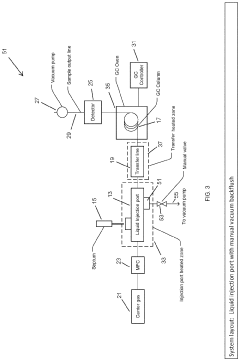

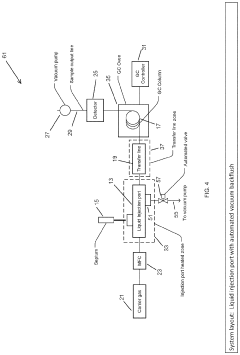

PatentActiveUS20220082538A1

Innovation

- A method and system that condense solvent vapors before entering a temporally-resolving separator, such as a GC column, allowing larger sample volumes to be injected without splitting, thereby maintaining analytes in the vapor phase and enhancing detection sensitivity.

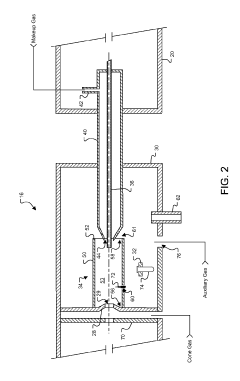

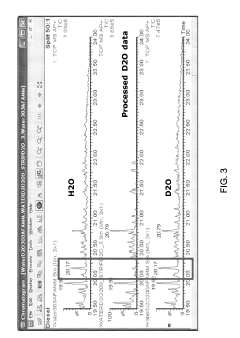

Performing chemical reactions and/or ionization during gas chromatography-mass spectrometry runs

PatentActiveUS10386333B2

Innovation

- The use of an atmospheric pressure ionization source that can switch between protonation and deuteration conditions, or inhibit/promote the addition of halogens to aromatic analytes, allowing for real-time chemical reactions and enhanced detection capabilities without reagent changes.

Regulatory Standards for Analytical Precision

The regulatory landscape governing analytical precision in laboratory environments has become increasingly stringent, particularly for GC-MS noise isolation techniques. The United States Food and Drug Administration (FDA) has established comprehensive guidelines under 21 CFR Part 11, which mandates electronic record integrity and validation protocols for analytical instruments, including GC-MS systems. These regulations require laboratories to demonstrate consistent noise reduction capabilities and maintain precision levels within established parameters.

Similarly, the International Organization for Standardization (ISO) has developed ISO 17025, which specifically addresses the technical competence of testing and calibration laboratories. This standard requires documented evidence of noise isolation procedures and validation of analytical methods, with particular emphasis on signal-to-noise ratio improvements. Laboratories seeking accreditation must demonstrate their ability to consistently isolate and mitigate instrumental noise in GC-MS applications.

The European Medicines Agency (EMA) has implemented guidelines that establish minimum acceptable signal-to-noise ratios for various analytical applications. For trace analysis in pharmaceutical testing, these guidelines typically require S/N ratios exceeding 10:1, necessitating advanced noise isolation techniques. Compliance with these standards has driven innovation in both hardware and software solutions for noise reduction.

In environmental testing, the Environmental Protection Agency (EPA) Method 8270 for semi-volatile organic compounds specifies performance criteria that include noise threshold requirements. These standards mandate that laboratories implement effective noise isolation strategies to achieve detection limits in the parts-per-billion range while maintaining analytical precision.

Industry-specific standards have also emerged, such as those from the Association of Official Analytical Chemists (AOAC), which provide method validation guidelines specifically addressing noise isolation in chromatographic techniques. These standards typically require demonstration of method robustness against various noise sources, including electronic interference, thermal fluctuations, and column bleed.

Regulatory bodies increasingly require laboratories to implement Quality by Design (QbD) principles in analytical method development, emphasizing the need for systematic noise isolation strategies rather than post-analysis corrections. This approach necessitates comprehensive understanding of noise sources and implementation of preventive measures throughout the analytical workflow.

Compliance with these regulatory standards typically requires laboratories to maintain detailed documentation of noise isolation procedures, validation protocols, and ongoing system suitability tests. This documentation must demonstrate traceability and reproducibility of noise reduction techniques, often requiring specialized software solutions for data management and compliance reporting.

Similarly, the International Organization for Standardization (ISO) has developed ISO 17025, which specifically addresses the technical competence of testing and calibration laboratories. This standard requires documented evidence of noise isolation procedures and validation of analytical methods, with particular emphasis on signal-to-noise ratio improvements. Laboratories seeking accreditation must demonstrate their ability to consistently isolate and mitigate instrumental noise in GC-MS applications.

The European Medicines Agency (EMA) has implemented guidelines that establish minimum acceptable signal-to-noise ratios for various analytical applications. For trace analysis in pharmaceutical testing, these guidelines typically require S/N ratios exceeding 10:1, necessitating advanced noise isolation techniques. Compliance with these standards has driven innovation in both hardware and software solutions for noise reduction.

In environmental testing, the Environmental Protection Agency (EPA) Method 8270 for semi-volatile organic compounds specifies performance criteria that include noise threshold requirements. These standards mandate that laboratories implement effective noise isolation strategies to achieve detection limits in the parts-per-billion range while maintaining analytical precision.

Industry-specific standards have also emerged, such as those from the Association of Official Analytical Chemists (AOAC), which provide method validation guidelines specifically addressing noise isolation in chromatographic techniques. These standards typically require demonstration of method robustness against various noise sources, including electronic interference, thermal fluctuations, and column bleed.

Regulatory bodies increasingly require laboratories to implement Quality by Design (QbD) principles in analytical method development, emphasizing the need for systematic noise isolation strategies rather than post-analysis corrections. This approach necessitates comprehensive understanding of noise sources and implementation of preventive measures throughout the analytical workflow.

Compliance with these regulatory standards typically requires laboratories to maintain detailed documentation of noise isolation procedures, validation protocols, and ongoing system suitability tests. This documentation must demonstrate traceability and reproducibility of noise reduction techniques, often requiring specialized software solutions for data management and compliance reporting.

Cost-Benefit Analysis of Noise Reduction Technologies

When evaluating noise reduction technologies for GC-MS systems, a comprehensive cost-benefit analysis reveals significant financial implications across different implementation scenarios. Initial investment costs for advanced noise isolation technologies range from $5,000 for basic digital filtering solutions to over $50,000 for comprehensive hardware-software integrated systems. These figures must be weighed against the quantifiable benefits that emerge from enhanced analytical precision.

Laboratory productivity gains represent a primary benefit, with studies indicating a 15-30% reduction in analysis time when effective noise reduction technologies are implemented. This translates to approximately 2-3 additional samples processed per day in a standard analytical laboratory setting. Over a typical five-year equipment lifecycle, this efficiency improvement can generate $75,000-150,000 in additional revenue for commercial laboratories.

Maintenance economics also factor significantly into the cost-benefit equation. Advanced noise reduction systems typically reduce instrument downtime by 20-25%, primarily by minimizing false positives and reducing the frequency of recalibration procedures. This operational improvement saves approximately $8,000-12,000 annually in maintenance costs and lost productivity for a typical mid-sized laboratory.

Consumable usage presents another area of financial impact. Enhanced signal-to-noise ratios allow for smaller sample volumes and reduced carrier gas consumption, generating savings of $3,000-5,000 annually for laboratories processing 50+ samples weekly. These savings compound when considering the extended column life resulting from more stable operating conditions.

Return on investment calculations indicate that mid-range noise reduction technologies ($15,000-25,000) typically achieve breakeven within 18-24 months in high-throughput environments. However, this timeline extends to 30-36 months for research laboratories with lower sample volumes. The most sophisticated systems may require up to 48 months to achieve ROI, though they deliver superior analytical capabilities that may justify the extended payback period.

Opportunity costs must also be considered, particularly regarding research applications where improved detection limits enable new analytical capabilities. Laboratories implementing advanced noise reduction technologies report an average 35% increase in successful method development projects, creating significant competitive advantages that, while difficult to quantify precisely, represent substantial long-term value.

Laboratory productivity gains represent a primary benefit, with studies indicating a 15-30% reduction in analysis time when effective noise reduction technologies are implemented. This translates to approximately 2-3 additional samples processed per day in a standard analytical laboratory setting. Over a typical five-year equipment lifecycle, this efficiency improvement can generate $75,000-150,000 in additional revenue for commercial laboratories.

Maintenance economics also factor significantly into the cost-benefit equation. Advanced noise reduction systems typically reduce instrument downtime by 20-25%, primarily by minimizing false positives and reducing the frequency of recalibration procedures. This operational improvement saves approximately $8,000-12,000 annually in maintenance costs and lost productivity for a typical mid-sized laboratory.

Consumable usage presents another area of financial impact. Enhanced signal-to-noise ratios allow for smaller sample volumes and reduced carrier gas consumption, generating savings of $3,000-5,000 annually for laboratories processing 50+ samples weekly. These savings compound when considering the extended column life resulting from more stable operating conditions.

Return on investment calculations indicate that mid-range noise reduction technologies ($15,000-25,000) typically achieve breakeven within 18-24 months in high-throughput environments. However, this timeline extends to 30-36 months for research laboratories with lower sample volumes. The most sophisticated systems may require up to 48 months to achieve ROI, though they deliver superior analytical capabilities that may justify the extended payback period.

Opportunity costs must also be considered, particularly regarding research applications where improved detection limits enable new analytical capabilities. Laboratories implementing advanced noise reduction technologies report an average 35% increase in successful method development projects, creating significant competitive advantages that, while difficult to quantify precisely, represent substantial long-term value.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!