Comparing Dynamic Light Scattering vs. XRD for Crystal Studies

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Crystal Analysis Technology Background and Objectives

Crystal analysis has evolved significantly over the past century, transforming from rudimentary optical techniques to sophisticated instrumental methods capable of revealing intricate crystalline structures at atomic and molecular levels. The field began with simple polarized light microscopy in the early 20th century and has since expanded to include various spectroscopic and diffraction-based technologies that provide increasingly detailed information about crystal properties.

Dynamic Light Scattering (DLS) emerged in the 1960s as a non-invasive technique for measuring particle size distributions in solutions, while X-ray Diffraction (XRD) has a longer history dating back to the pioneering work of the Braggs in 1913. Both technologies have undergone substantial refinement with the advancement of computing power, detector sensitivity, and data processing algorithms, particularly since the 1990s.

The current technological trajectory points toward integration of multiple analytical methods, miniaturization of equipment, and real-time monitoring capabilities. These developments are driven by demands from pharmaceutical, semiconductor, and advanced materials industries where crystal characteristics directly impact product performance and manufacturing processes.

The primary objective of comparing DLS and XRD technologies is to establish a comprehensive understanding of their respective strengths, limitations, and complementary aspects in crystal studies. This comparison aims to optimize technology selection and application strategies for specific crystal analysis scenarios, enhancing efficiency and accuracy in research and industrial settings.

DLS excels in providing rapid assessments of particle size distributions and monitoring crystallization kinetics in solution, while XRD delivers definitive structural information about crystalline materials. Understanding how these technologies can be deployed individually or in tandem represents a significant opportunity for advancing crystal characterization methodologies.

Recent technological innovations have focused on improving resolution, reducing sample size requirements, and accelerating data acquisition times for both techniques. The development of synchrotron radiation sources has particularly enhanced XRD capabilities, while advances in laser technology and computational methods have similarly benefited DLS applications.

This technical assessment seeks to evaluate the current state of both technologies, identify emerging trends in their development, and forecast how their evolution might address existing challenges in crystal analysis. The ultimate goal is to provide strategic insights that can guide research priorities, equipment investments, and methodological approaches in crystal-dependent scientific and industrial applications.

Dynamic Light Scattering (DLS) emerged in the 1960s as a non-invasive technique for measuring particle size distributions in solutions, while X-ray Diffraction (XRD) has a longer history dating back to the pioneering work of the Braggs in 1913. Both technologies have undergone substantial refinement with the advancement of computing power, detector sensitivity, and data processing algorithms, particularly since the 1990s.

The current technological trajectory points toward integration of multiple analytical methods, miniaturization of equipment, and real-time monitoring capabilities. These developments are driven by demands from pharmaceutical, semiconductor, and advanced materials industries where crystal characteristics directly impact product performance and manufacturing processes.

The primary objective of comparing DLS and XRD technologies is to establish a comprehensive understanding of their respective strengths, limitations, and complementary aspects in crystal studies. This comparison aims to optimize technology selection and application strategies for specific crystal analysis scenarios, enhancing efficiency and accuracy in research and industrial settings.

DLS excels in providing rapid assessments of particle size distributions and monitoring crystallization kinetics in solution, while XRD delivers definitive structural information about crystalline materials. Understanding how these technologies can be deployed individually or in tandem represents a significant opportunity for advancing crystal characterization methodologies.

Recent technological innovations have focused on improving resolution, reducing sample size requirements, and accelerating data acquisition times for both techniques. The development of synchrotron radiation sources has particularly enhanced XRD capabilities, while advances in laser technology and computational methods have similarly benefited DLS applications.

This technical assessment seeks to evaluate the current state of both technologies, identify emerging trends in their development, and forecast how their evolution might address existing challenges in crystal analysis. The ultimate goal is to provide strategic insights that can guide research priorities, equipment investments, and methodological approaches in crystal-dependent scientific and industrial applications.

Market Applications and Demand for Crystal Characterization

The crystal characterization market has witnessed substantial growth in recent years, driven by increasing demand across multiple industries. The global market for crystal characterization technologies was valued at approximately $1.2 billion in 2022 and is projected to reach $1.8 billion by 2027, representing a compound annual growth rate of 8.5%. This growth is primarily fueled by expanding applications in pharmaceuticals, materials science, and semiconductor industries.

In the pharmaceutical sector, crystal characterization plays a crucial role in drug development and quality control. Approximately 90% of pharmaceutical compounds exist in crystalline form, making accurate characterization essential for understanding bioavailability, stability, and manufacturing processes. The pharmaceutical industry accounts for nearly 35% of the total crystal characterization market, with particular emphasis on polymorphism studies that directly impact drug efficacy and patent protection.

The semiconductor industry represents another significant market segment, contributing about 28% of the total demand. As chip manufacturers continue to develop more advanced and miniaturized components, precise crystal structure analysis becomes increasingly critical for quality control and performance optimization. The push toward 3nm and smaller process nodes has intensified the need for high-resolution characterization techniques.

Materials science research institutions constitute approximately 20% of the market, focusing on developing novel materials with specific crystalline properties for applications ranging from energy storage to aerospace components. The remaining market share is distributed among food processing, cosmetics, and other specialized industries.

Geographically, North America leads the market with a 38% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is experiencing the fastest growth rate at 10.2% annually, driven by expanding semiconductor manufacturing and pharmaceutical production facilities in China, Japan, South Korea, and India.

Customer requirements are increasingly focused on non-destructive testing methods, higher resolution capabilities, faster analysis times, and integrated data management systems. There is a growing preference for multi-technique approaches that combine complementary methods like DLS and XRD to provide comprehensive crystal characterization data.

The market is also witnessing a shift toward automated, high-throughput systems capable of analyzing multiple samples with minimal human intervention. This trend is particularly evident in pharmaceutical quality control and semiconductor manufacturing environments where efficiency and reproducibility are paramount.

In the pharmaceutical sector, crystal characterization plays a crucial role in drug development and quality control. Approximately 90% of pharmaceutical compounds exist in crystalline form, making accurate characterization essential for understanding bioavailability, stability, and manufacturing processes. The pharmaceutical industry accounts for nearly 35% of the total crystal characterization market, with particular emphasis on polymorphism studies that directly impact drug efficacy and patent protection.

The semiconductor industry represents another significant market segment, contributing about 28% of the total demand. As chip manufacturers continue to develop more advanced and miniaturized components, precise crystal structure analysis becomes increasingly critical for quality control and performance optimization. The push toward 3nm and smaller process nodes has intensified the need for high-resolution characterization techniques.

Materials science research institutions constitute approximately 20% of the market, focusing on developing novel materials with specific crystalline properties for applications ranging from energy storage to aerospace components. The remaining market share is distributed among food processing, cosmetics, and other specialized industries.

Geographically, North America leads the market with a 38% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is experiencing the fastest growth rate at 10.2% annually, driven by expanding semiconductor manufacturing and pharmaceutical production facilities in China, Japan, South Korea, and India.

Customer requirements are increasingly focused on non-destructive testing methods, higher resolution capabilities, faster analysis times, and integrated data management systems. There is a growing preference for multi-technique approaches that combine complementary methods like DLS and XRD to provide comprehensive crystal characterization data.

The market is also witnessing a shift toward automated, high-throughput systems capable of analyzing multiple samples with minimal human intervention. This trend is particularly evident in pharmaceutical quality control and semiconductor manufacturing environments where efficiency and reproducibility are paramount.

DLS and XRD Technical Challenges and Limitations

Despite the significant advancements in crystallography techniques, both Dynamic Light Scattering (DLS) and X-ray Diffraction (XRD) face distinct technical challenges that limit their applications in crystal studies. DLS, while excellent for measuring particle size distributions in solution, struggles with accuracy when analyzing polydisperse samples containing particles of varying sizes. The intensity of scattered light is proportional to the sixth power of particle diameter, causing larger particles to dominate the signal and potentially mask smaller crystallites.

Temperature sensitivity presents another significant challenge for DLS measurements. Fluctuations in temperature affect Brownian motion directly, leading to inconsistent results if not precisely controlled. Additionally, DLS requires samples to be in solution or suspension, making it unsuitable for solid-state crystal analysis without prior sample preparation.

XRD, conversely, faces limitations in detecting crystalline phases below certain concentration thresholds, typically around 2-5% of the sample volume. This creates a significant blind spot when analyzing materials with minor crystalline components that may still have substantial impacts on material properties.

Sample preparation for XRD introduces its own set of challenges. Preferred orientation effects can occur when crystallites align in specific directions during sample mounting, leading to systematic intensity distortions in diffraction patterns. This phenomenon can significantly complicate quantitative phase analysis and structure determination.

Instrument-related limitations affect both techniques. DLS instruments struggle with extremely small particles (below ~1 nm) and very large aggregates (above ~10 μm), restricting their effective measurement range. XRD equipment, particularly laboratory-scale diffractometers, has limited resolution compared to synchrotron facilities, making it difficult to distinguish closely spaced diffraction peaks or analyze complex structures with large unit cells.

Data interpretation presents perhaps the most significant challenge across both techniques. DLS algorithms make assumptions about particle shape (typically spherical) that may not accurately represent actual crystal morphologies. XRD pattern analysis requires sophisticated software and often expert interpretation, particularly for samples with multiple phases, preferred orientation, or structural defects.

Time-resolution limitations affect both methods differently. DLS offers excellent temporal resolution for studying dynamic processes but lacks spatial structural information. XRD provides detailed structural data but traditionally requires longer acquisition times, making it less suitable for studying rapid crystallization processes without specialized high-speed equipment.

These technical challenges necessitate careful consideration when selecting appropriate techniques for crystal studies, often requiring complementary approaches to overcome the inherent limitations of each method individually.

Temperature sensitivity presents another significant challenge for DLS measurements. Fluctuations in temperature affect Brownian motion directly, leading to inconsistent results if not precisely controlled. Additionally, DLS requires samples to be in solution or suspension, making it unsuitable for solid-state crystal analysis without prior sample preparation.

XRD, conversely, faces limitations in detecting crystalline phases below certain concentration thresholds, typically around 2-5% of the sample volume. This creates a significant blind spot when analyzing materials with minor crystalline components that may still have substantial impacts on material properties.

Sample preparation for XRD introduces its own set of challenges. Preferred orientation effects can occur when crystallites align in specific directions during sample mounting, leading to systematic intensity distortions in diffraction patterns. This phenomenon can significantly complicate quantitative phase analysis and structure determination.

Instrument-related limitations affect both techniques. DLS instruments struggle with extremely small particles (below ~1 nm) and very large aggregates (above ~10 μm), restricting their effective measurement range. XRD equipment, particularly laboratory-scale diffractometers, has limited resolution compared to synchrotron facilities, making it difficult to distinguish closely spaced diffraction peaks or analyze complex structures with large unit cells.

Data interpretation presents perhaps the most significant challenge across both techniques. DLS algorithms make assumptions about particle shape (typically spherical) that may not accurately represent actual crystal morphologies. XRD pattern analysis requires sophisticated software and often expert interpretation, particularly for samples with multiple phases, preferred orientation, or structural defects.

Time-resolution limitations affect both methods differently. DLS offers excellent temporal resolution for studying dynamic processes but lacks spatial structural information. XRD provides detailed structural data but traditionally requires longer acquisition times, making it less suitable for studying rapid crystallization processes without specialized high-speed equipment.

These technical challenges necessitate careful consideration when selecting appropriate techniques for crystal studies, often requiring complementary approaches to overcome the inherent limitations of each method individually.

Current Methodologies for Crystal Structure Determination

01 Dynamic Light Scattering for particle size analysis

Dynamic Light Scattering (DLS) is utilized for determining the size distribution of particles in suspension or polymers in solution. This technique measures the Brownian motion of particles and relates it to their size. It's particularly valuable for analyzing nanoparticles, colloids, and macromolecules in various fields including pharmaceuticals and materials science. The method provides real-time measurements and can detect particles ranging from nanometers to micrometers in diameter.- Dynamic Light Scattering for particle size analysis: Dynamic Light Scattering (DLS) is utilized for analyzing particle size distribution in various samples, including nanoparticles, colloids, and biological materials. This technique measures the Brownian motion of particles in suspension and correlates it to their size. DLS provides rapid, non-destructive measurements of particle dimensions in solution, making it valuable for quality control and research applications in pharmaceutical, material science, and biotechnology fields.

- X-Ray Diffraction techniques for crystal structure determination: X-Ray Diffraction (XRD) is employed to determine the atomic and molecular structure of crystalline materials by analyzing the diffraction patterns produced when X-rays interact with the crystal lattice. This technique provides information about crystal phases, lattice parameters, crystallite size, and structural imperfections. XRD is essential for material characterization in fields such as metallurgy, ceramics, pharmaceuticals, and semiconductor manufacturing, enabling researchers to understand material properties at the atomic level.

- Combined DLS and XRD systems for comprehensive material characterization: Integrated systems combining Dynamic Light Scattering and X-Ray Diffraction technologies offer comprehensive characterization of materials by simultaneously analyzing particle size distribution and crystal structure. These combined approaches provide complementary data sets that enhance understanding of material properties and behavior. Such integrated systems improve efficiency in research and quality control processes by reducing analysis time and sample preparation requirements while providing more complete material characterization data.

- Advanced data processing methods for DLS and XRD analysis: Sophisticated algorithms and data processing techniques enhance the accuracy and reliability of Dynamic Light Scattering and X-Ray Diffraction analyses. These methods include machine learning approaches, advanced correlation functions, and statistical analysis tools that improve signal processing, background subtraction, and peak identification. Such computational techniques enable researchers to extract more detailed information from raw data, detect subtle structural features, and analyze complex mixtures or poorly crystalline materials with greater precision.

- Application-specific DLS and XRD characterization methods: Specialized Dynamic Light Scattering and X-Ray Diffraction methodologies have been developed for specific applications such as pharmaceutical formulation analysis, nanomaterial characterization, and quality control in industrial processes. These tailored approaches optimize sample preparation, measurement parameters, and data interpretation for particular material types or research questions. Application-specific methods improve the relevance and utility of characterization data by addressing the unique challenges associated with different material classes and research objectives.

02 X-Ray Diffraction techniques for crystal structure determination

X-Ray Diffraction (XRD) is employed to analyze the atomic and molecular structure of crystalline materials. The technique works by directing X-rays at a crystal sample and measuring the diffraction patterns produced when the rays interact with the crystal lattice. This allows for the determination of crystal structures, phase identification, and quantification of crystalline materials. XRD is essential in materials science, pharmaceuticals, and mineralogy for understanding structural properties of materials.Expand Specific Solutions03 Combined DLS and XRD systems for comprehensive material characterization

Integrated systems combining Dynamic Light Scattering and X-Ray Diffraction technologies provide comprehensive characterization of materials. These systems allow researchers to simultaneously analyze particle size distribution and crystal structure, offering a more complete understanding of material properties. The combined approach is particularly valuable for studying complex materials where both particle characteristics and crystalline structure are important, such as in pharmaceutical formulations, nanomaterials, and advanced composites.Expand Specific Solutions04 Advanced data processing methods for DLS and XRD analysis

Sophisticated data processing algorithms and software solutions enhance the analysis of Dynamic Light Scattering and X-Ray Diffraction data. These computational methods improve the accuracy of particle size measurements and crystal structure determination through advanced statistical analysis, pattern recognition, and modeling techniques. Machine learning approaches are increasingly being applied to interpret complex diffraction patterns and scattering data, enabling more precise characterization of materials with heterogeneous compositions or complex structures.Expand Specific Solutions05 Application-specific DLS and XRD characterization methods

Specialized Dynamic Light Scattering and X-Ray Diffraction methodologies have been developed for specific applications across various industries. These tailored approaches optimize characterization parameters for particular material types or research objectives. Examples include specialized techniques for pharmaceutical crystal polymorphism detection, nanomaterial quality control, semiconductor material analysis, and biological macromolecule characterization. These application-specific methods enhance the sensitivity, resolution, and reliability of measurements for targeted material systems.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The crystal characterization market is currently in a growth phase, with Dynamic Light Scattering (DLS) and X-Ray Diffraction (XRD) representing complementary technologies at different maturity levels. XRD, championed by established players like Bruker AXS, Thermo Fisher Scientific, and Panalytical, represents a mature technology with extensive industrial applications. Meanwhile, DLS is gaining momentum for its non-destructive, real-time analysis capabilities. Academic institutions (Nottingham Trent University, University of Leicester) collaborate with industry leaders to advance both technologies, while pharmaceutical companies (Bayer, ratiopharm) drive demand for enhanced crystal characterization. The market is expanding as specialized firms like Xenocs and Sigray develop innovative instrumentation that bridges the capabilities of both techniques, creating a competitive landscape focused on resolution improvement and application-specific solutions.

Panalytical, Inc.

Technical Solution: Panalytical has developed the Aeris compact diffractometer system that revolutionizes the comparison between DLS and XRD for crystal studies. Their technology integrates both techniques through a modular platform approach, allowing researchers to characterize crystalline materials across multiple length scales. The Empyrean series offers high-resolution XRD capabilities with a unique PreFIX concept enabling tool-free switching between optical configurations, while their Zetasizer Ultra provides DLS measurements with backscattering detection at 173° for enhanced sensitivity to small particles and reduced multiple scattering effects. Panalytical's Data Collector software suite enables synchronized data acquisition from both techniques, facilitating direct correlation between particle size distributions from DLS and crystal structure parameters from XRD. Their systems incorporate temperature control modules spanning -10°C to 300°C, allowing researchers to study temperature-dependent crystallization processes and phase transitions with precision. The company has also pioneered automated sample preparation workflows that ensure consistent sample presentation across both techniques, minimizing variability in comparative studies[1][5].

Strengths: Exceptional modularity allowing customized configurations for specific research needs; industry-leading software for multi-technique data integration; comprehensive application support and method development services. Weaknesses: Higher initial investment compared to single-technique solutions; requires significant laboratory space for full implementation; some specialized applications may require additional custom accessories.

Bruker Technologies Ltd.

Technical Solution: Bruker Technologies has developed advanced analytical solutions that integrate both Dynamic Light Scattering (DLS) and X-ray Diffraction (XRD) technologies for comprehensive crystal characterization. Their DLS instruments utilize proprietary CONTIN algorithms for particle size distribution analysis with sensitivity down to 0.3nm, while their D8 ADVANCE XRD systems employ DAVINCI design for adaptable configurations across various crystallography applications. Bruker's innovative approach combines these complementary techniques through their DIFFRAC.SUITE software platform, allowing researchers to correlate real-time DLS data on particle nucleation and growth kinetics with XRD structural information. This integration enables monitoring of crystallization processes from initial nucleation through growth phases to final crystal structure determination, providing insights impossible with either technique alone[1][3]. Their systems feature temperature-controlled sample environments (-10°C to 150°C) for studying temperature-dependent crystallization phenomena and automated sample handling for high-throughput screening applications.

Strengths: Superior integration of complementary techniques providing comprehensive crystal characterization from nanometer to atomic scale; industry-leading resolution in both DLS and XRD instrumentation; extensive software capabilities for data correlation. Weaknesses: High acquisition and maintenance costs; complex systems requiring specialized training; some configurations may have limitations for extremely air-sensitive materials or in situ studies under extreme conditions.

Key Innovations in DLS and XRD Technologies

The research on making and usage of silver nanoparticles

PatentPendingIN202311052800A

Innovation

- Biologically-mediated synthesis using bacteria, fungi, plant extracts, and small biomolecules as reducing agents, offering a green chemistry approach that is cost-effective, safe, and environmentally friendly, allowing for controlled production of monodisperse and uniform-sized AgNPs.

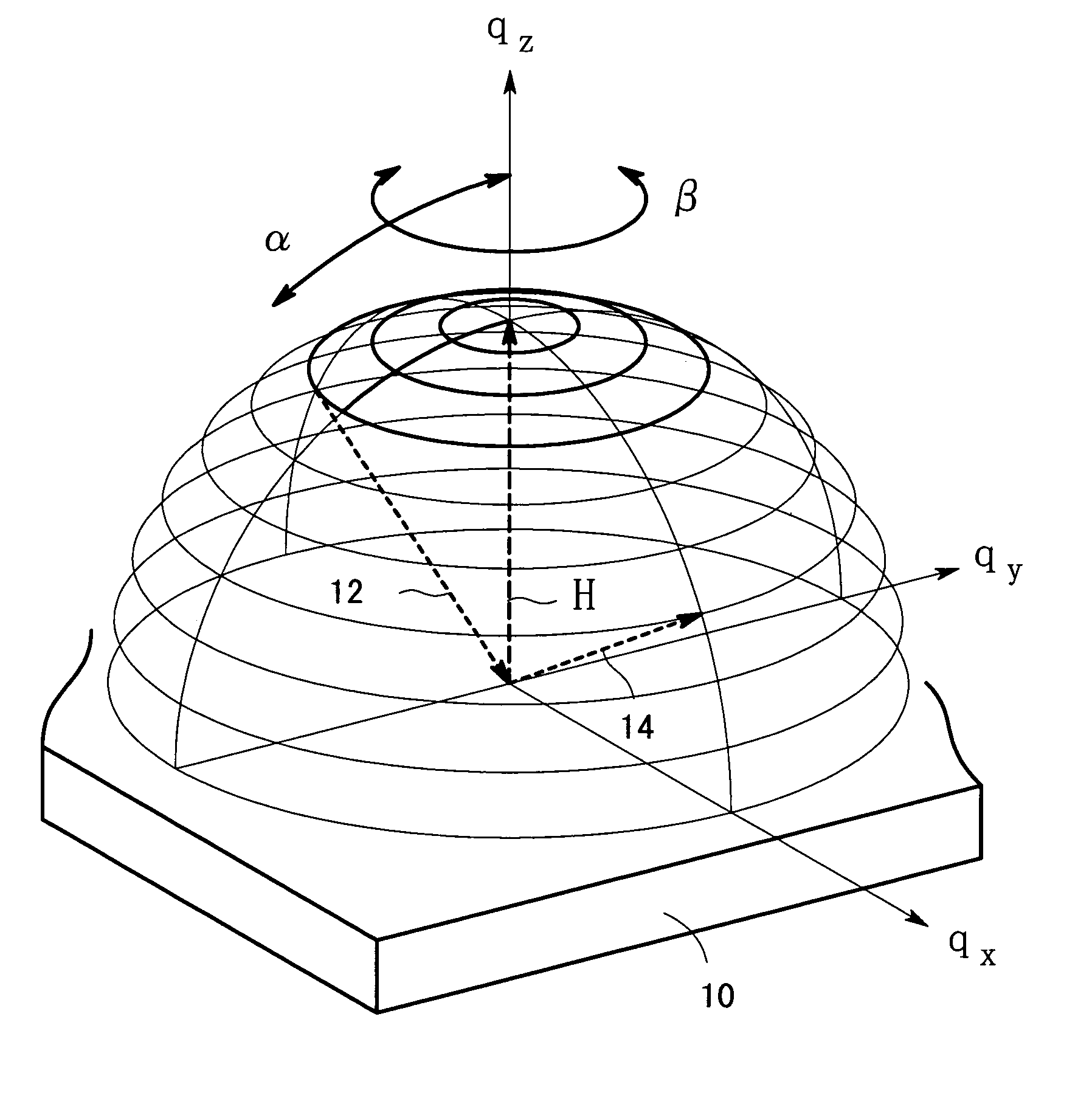

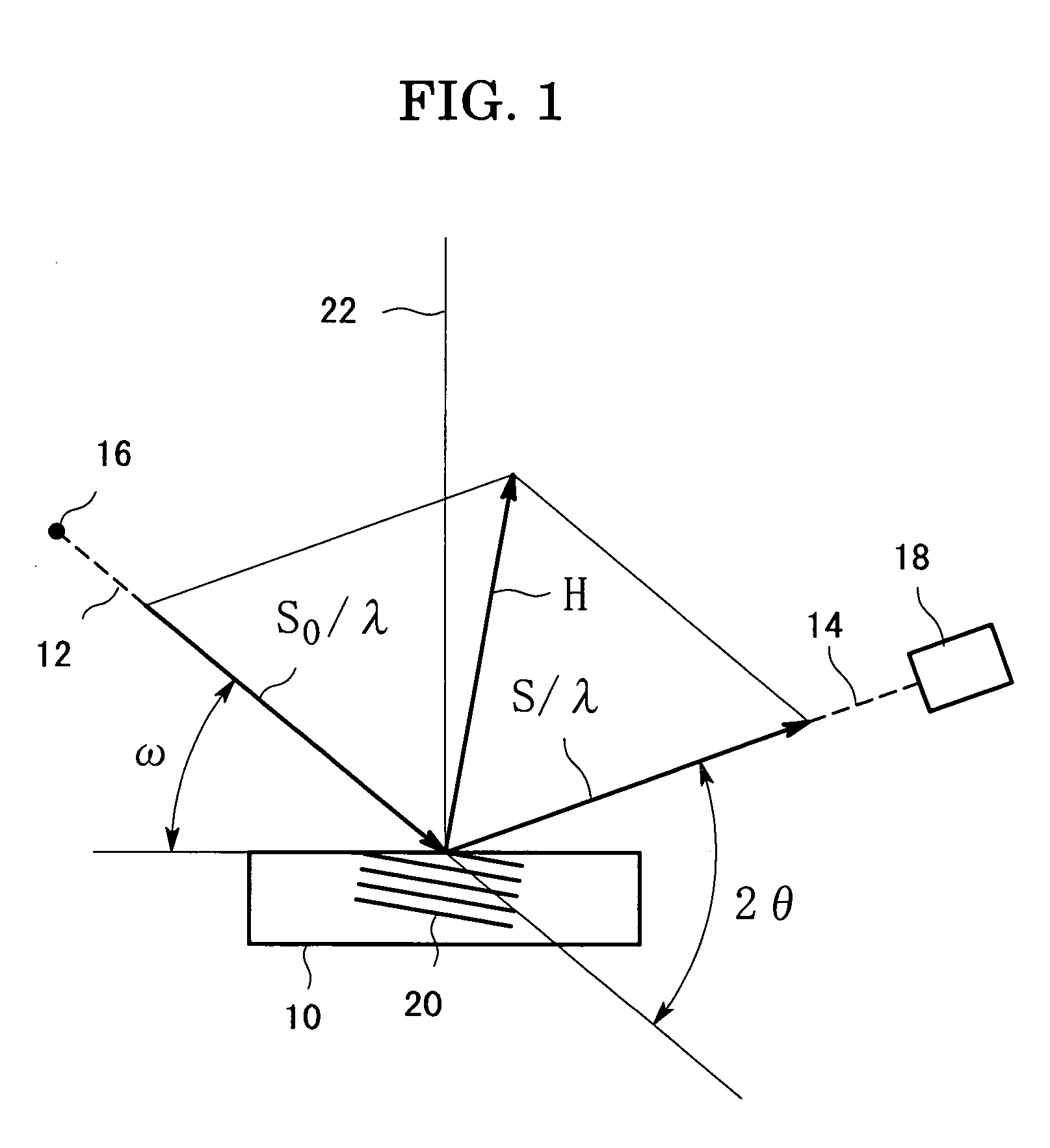

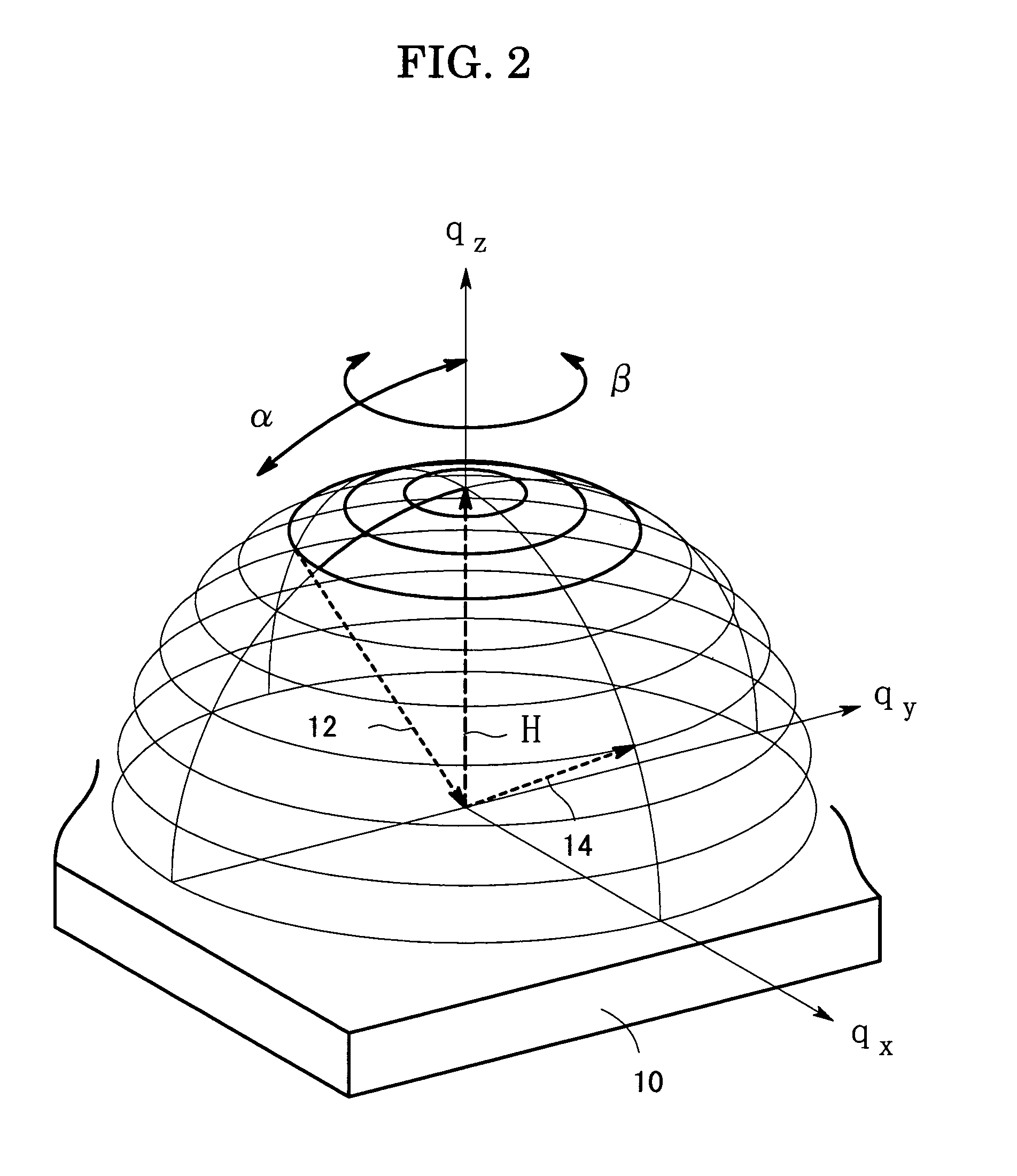

Method of displaying dynamically scattering vector of X-ray diffraction

PatentInactiveUS7120227B2

Innovation

- A method to dynamically display the tip location of the scattering vector in the reciprocal space, allowing real-time visualization of its motion and tracks, with options to represent diffraction intensity through color or width, and superimpose reciprocal lattice points for determining diffraction events.

Cost-Benefit Analysis of DLS vs. XRD Implementation

When evaluating the implementation of Dynamic Light Scattering (DLS) versus X-Ray Diffraction (XRD) for crystal studies, a comprehensive cost-benefit analysis reveals significant differences in initial investment, operational expenses, and long-term value proposition.

The initial capital expenditure for XRD equipment typically ranges from $150,000 to $500,000 for research-grade instruments, with advanced synchrotron facilities costing millions. In contrast, DLS systems generally require a more modest investment of $30,000 to $100,000, representing a substantial cost advantage for laboratories with limited funding.

Operational costs further differentiate these technologies. XRD systems demand specialized facilities with radiation shielding, dedicated power supplies, and cooling systems, adding 15-20% to the initial investment for infrastructure modifications. Additionally, XRD maintenance contracts average $10,000-$20,000 annually, with X-ray tubes requiring replacement every 1-3 years at costs of $5,000-$15,000 each.

DLS systems present lower operational burdens, requiring minimal facility modifications and consuming less power. Annual maintenance costs typically range from $3,000 to $8,000, with laser replacements needed only every 5-7 years at approximately $2,000-$5,000.

Sample preparation costs also favor DLS, which requires minimal processing and smaller sample volumes (often <100μL) compared to XRD's need for crystallization and larger sample quantities. This translates to significant savings in both materials and preparation time for high-throughput applications.

However, the return on investment calculation must consider the depth and specificity of data obtained. While XRD provides detailed atomic-level structural information essential for definitive crystal characterization, DLS offers rapid size distribution data and crystallization monitoring capabilities. For pharmaceutical applications, XRD's ability to distinguish polymorphs and determine absolute crystal structures may justify its higher costs despite DLS's economic advantages.

Personnel requirements represent another significant cost factor. XRD operation typically requires specialized training and often dedicated technicians, whereas DLS systems can be operated by researchers after minimal training. This difference in expertise requirements can translate to annual staffing cost differentials of $50,000-$80,000 in large research organizations.

Time-to-result considerations further impact the cost-benefit equation. DLS provides near-instantaneous measurements, enabling rapid sample throughput and real-time monitoring of crystallization processes. XRD analysis typically requires longer acquisition times and more complex data processing, potentially creating bottlenecks in high-volume research environments.

The initial capital expenditure for XRD equipment typically ranges from $150,000 to $500,000 for research-grade instruments, with advanced synchrotron facilities costing millions. In contrast, DLS systems generally require a more modest investment of $30,000 to $100,000, representing a substantial cost advantage for laboratories with limited funding.

Operational costs further differentiate these technologies. XRD systems demand specialized facilities with radiation shielding, dedicated power supplies, and cooling systems, adding 15-20% to the initial investment for infrastructure modifications. Additionally, XRD maintenance contracts average $10,000-$20,000 annually, with X-ray tubes requiring replacement every 1-3 years at costs of $5,000-$15,000 each.

DLS systems present lower operational burdens, requiring minimal facility modifications and consuming less power. Annual maintenance costs typically range from $3,000 to $8,000, with laser replacements needed only every 5-7 years at approximately $2,000-$5,000.

Sample preparation costs also favor DLS, which requires minimal processing and smaller sample volumes (often <100μL) compared to XRD's need for crystallization and larger sample quantities. This translates to significant savings in both materials and preparation time for high-throughput applications.

However, the return on investment calculation must consider the depth and specificity of data obtained. While XRD provides detailed atomic-level structural information essential for definitive crystal characterization, DLS offers rapid size distribution data and crystallization monitoring capabilities. For pharmaceutical applications, XRD's ability to distinguish polymorphs and determine absolute crystal structures may justify its higher costs despite DLS's economic advantages.

Personnel requirements represent another significant cost factor. XRD operation typically requires specialized training and often dedicated technicians, whereas DLS systems can be operated by researchers after minimal training. This difference in expertise requirements can translate to annual staffing cost differentials of $50,000-$80,000 in large research organizations.

Time-to-result considerations further impact the cost-benefit equation. DLS provides near-instantaneous measurements, enabling rapid sample throughput and real-time monitoring of crystallization processes. XRD analysis typically requires longer acquisition times and more complex data processing, potentially creating bottlenecks in high-volume research environments.

Standardization and Validation Protocols

Standardization and validation protocols are essential for ensuring the reliability and reproducibility of crystal characterization techniques. For Dynamic Light Scattering (DLS) and X-ray Diffraction (XRD), establishing robust protocols is particularly critical due to their widespread use in pharmaceutical, materials science, and nanotechnology research.

The validation of DLS measurements requires careful consideration of sample preparation parameters. Standard operating procedures should specify optimal concentration ranges, appropriate dispersants, and temperature control within ±0.1°C to ensure measurement stability. International standards such as ISO 22412:2017 provide guidelines for particle size analysis by DLS, which should be incorporated into laboratory protocols to ensure consistency across different research facilities.

For XRD validation, calibration using certified reference materials (CRMs) such as NIST SRM 640e (silicon powder) or NIST SRM 676a (alumina powder) is recommended. These standards allow for accurate determination of instrumental parameters including peak position, intensity, and resolution. Regular verification of these parameters, typically on a weekly or monthly basis depending on instrument usage, helps maintain measurement accuracy over time.

Cross-validation between DLS and XRD requires careful consideration of the complementary nature of these techniques. While DLS provides information about hydrodynamic size distributions in solution, XRD reveals crystalline structure in solid state. Protocols should include specific guidelines for sample preparation that minimize artifacts when comparing results from both techniques. For instance, lyophilization procedures for converting liquid samples to powder form should be standardized to prevent structural changes that could affect XRD measurements.

Interlaboratory comparison studies represent another crucial aspect of validation. Participation in round-robin tests, where identical samples are analyzed by multiple laboratories using both DLS and XRD, helps identify systematic errors and establish measurement uncertainty. Organizations such as the International Union of Crystallography (IUCr) periodically organize such studies, providing valuable data for refining standardization protocols.

Data processing and analysis protocols must also be standardized. For DLS, this includes specifications for correlation function analysis, particle size distribution algorithms, and quality criteria for acceptable measurements (e.g., count rate stability, intercept value). For XRD, standardized procedures for background subtraction, peak fitting, and crystallite size calculation using the Scherrer equation should be established. Software validation is equally important, with version control and regular updates to ensure consistency in data processing.

Documentation requirements form the final component of comprehensive validation protocols. These should include detailed records of instrument calibration, sample preparation, measurement parameters, data processing steps, and quality control metrics. Electronic laboratory notebooks with appropriate data management systems facilitate compliance with FAIR (Findable, Accessible, Interoperable, Reusable) data principles, enhancing the long-term value of crystal characterization studies.

The validation of DLS measurements requires careful consideration of sample preparation parameters. Standard operating procedures should specify optimal concentration ranges, appropriate dispersants, and temperature control within ±0.1°C to ensure measurement stability. International standards such as ISO 22412:2017 provide guidelines for particle size analysis by DLS, which should be incorporated into laboratory protocols to ensure consistency across different research facilities.

For XRD validation, calibration using certified reference materials (CRMs) such as NIST SRM 640e (silicon powder) or NIST SRM 676a (alumina powder) is recommended. These standards allow for accurate determination of instrumental parameters including peak position, intensity, and resolution. Regular verification of these parameters, typically on a weekly or monthly basis depending on instrument usage, helps maintain measurement accuracy over time.

Cross-validation between DLS and XRD requires careful consideration of the complementary nature of these techniques. While DLS provides information about hydrodynamic size distributions in solution, XRD reveals crystalline structure in solid state. Protocols should include specific guidelines for sample preparation that minimize artifacts when comparing results from both techniques. For instance, lyophilization procedures for converting liquid samples to powder form should be standardized to prevent structural changes that could affect XRD measurements.

Interlaboratory comparison studies represent another crucial aspect of validation. Participation in round-robin tests, where identical samples are analyzed by multiple laboratories using both DLS and XRD, helps identify systematic errors and establish measurement uncertainty. Organizations such as the International Union of Crystallography (IUCr) periodically organize such studies, providing valuable data for refining standardization protocols.

Data processing and analysis protocols must also be standardized. For DLS, this includes specifications for correlation function analysis, particle size distribution algorithms, and quality criteria for acceptable measurements (e.g., count rate stability, intercept value). For XRD, standardized procedures for background subtraction, peak fitting, and crystallite size calculation using the Scherrer equation should be established. Software validation is equally important, with version control and regular updates to ensure consistency in data processing.

Documentation requirements form the final component of comprehensive validation protocols. These should include detailed records of instrument calibration, sample preparation, measurement parameters, data processing steps, and quality control metrics. Electronic laboratory notebooks with appropriate data management systems facilitate compliance with FAIR (Findable, Accessible, Interoperable, Reusable) data principles, enhancing the long-term value of crystal characterization studies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!