Comparing Lithium Acetate and Magnesium Acetate for Desiccation

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Desiccant Technology Background and Objectives

Desiccant technology has evolved significantly over the past century, transitioning from simple moisture absorption materials to sophisticated chemical compounds designed for specific applications. The use of acetate-based desiccants represents an important development in this evolution, with lithium acetate and magnesium acetate emerging as notable options for moisture control in various industries. Historically, silica gel and calcium chloride dominated the desiccant market, but increasing demands for performance specificity have driven research into alternative compounds with enhanced properties.

The fundamental principle behind desiccation involves hygroscopic materials attracting and holding water molecules from the surrounding environment. This process is critical in preserving moisture-sensitive products, maintaining specific humidity levels in controlled environments, and preventing degradation in pharmaceutical, electronic, and food products. The efficiency of this process depends on several factors including absorption capacity, absorption rate, regeneration potential, and stability across varying temperature and humidity conditions.

Lithium acetate has gained attention due to its high hygroscopic properties and relatively stable performance across temperature ranges. First documented for industrial desiccation applications in the 1970s, it has seen increased adoption in specialized fields requiring precise humidity control. Magnesium acetate, while less commonly employed historically, has demonstrated promising characteristics that warrant comparative analysis against more established desiccants.

The global desiccant market has experienced steady growth, projected to reach approximately $3.1 billion by 2025, with a compound annual growth rate of 5.9%. This growth is driven by expanding applications in pharmaceuticals, electronics, food packaging, and industrial processing. Within this context, acetate-based desiccants represent a growing segment, particularly in applications requiring non-corrosive and chemically stable moisture control solutions.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of lithium acetate and magnesium acetate as desiccation agents. This includes evaluating their respective moisture absorption capacities, absorption kinetics, regeneration capabilities, stability under various environmental conditions, cost-effectiveness, and environmental impact. Additionally, the research aims to identify optimal application scenarios for each compound and potential synergistic effects when used in combination or with other desiccant materials.

Understanding the relative advantages and limitations of these acetate compounds will provide valuable insights for developing next-generation desiccant technologies. This knowledge will support innovation in critical applications such as pharmaceutical preservation, electronic component protection, and advanced materials manufacturing where precise moisture control directly impacts product quality, reliability, and lifespan.

The fundamental principle behind desiccation involves hygroscopic materials attracting and holding water molecules from the surrounding environment. This process is critical in preserving moisture-sensitive products, maintaining specific humidity levels in controlled environments, and preventing degradation in pharmaceutical, electronic, and food products. The efficiency of this process depends on several factors including absorption capacity, absorption rate, regeneration potential, and stability across varying temperature and humidity conditions.

Lithium acetate has gained attention due to its high hygroscopic properties and relatively stable performance across temperature ranges. First documented for industrial desiccation applications in the 1970s, it has seen increased adoption in specialized fields requiring precise humidity control. Magnesium acetate, while less commonly employed historically, has demonstrated promising characteristics that warrant comparative analysis against more established desiccants.

The global desiccant market has experienced steady growth, projected to reach approximately $3.1 billion by 2025, with a compound annual growth rate of 5.9%. This growth is driven by expanding applications in pharmaceuticals, electronics, food packaging, and industrial processing. Within this context, acetate-based desiccants represent a growing segment, particularly in applications requiring non-corrosive and chemically stable moisture control solutions.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of lithium acetate and magnesium acetate as desiccation agents. This includes evaluating their respective moisture absorption capacities, absorption kinetics, regeneration capabilities, stability under various environmental conditions, cost-effectiveness, and environmental impact. Additionally, the research aims to identify optimal application scenarios for each compound and potential synergistic effects when used in combination or with other desiccant materials.

Understanding the relative advantages and limitations of these acetate compounds will provide valuable insights for developing next-generation desiccant technologies. This knowledge will support innovation in critical applications such as pharmaceutical preservation, electronic component protection, and advanced materials manufacturing where precise moisture control directly impacts product quality, reliability, and lifespan.

Market Analysis for Industrial Desiccation Solutions

The global industrial desiccation market has been experiencing steady growth, driven by increasing demand across various sectors including electronics, pharmaceuticals, food preservation, and chemical processing. The market size for industrial desiccants reached approximately $2.1 billion in 2022 and is projected to grow at a compound annual growth rate of 5.7% through 2028, according to industry reports.

Within this broader market, chemical desiccants represent a significant segment, with acetate-based solutions gaining particular attention for their effectiveness in specific applications. The comparison between lithium acetate and magnesium acetate as desiccation agents reflects an emerging trend toward more specialized and efficient moisture control solutions.

Demand drivers for these specific acetate-based desiccants include the growing electronics industry, where moisture control is critical for product integrity, and the pharmaceutical sector, where precise humidity regulation is essential for drug stability and shelf life. The Asia-Pacific region currently leads market consumption, accounting for approximately 38% of global demand, followed by North America at 29% and Europe at 24%.

Customer requirements are increasingly focused on performance efficiency, environmental impact, and cost-effectiveness. Lithium acetate commands premium pricing due to limited lithium resources and high extraction costs, while magnesium acetate offers a more economical alternative with different performance characteristics. The average price differential between these two solutions stands at 30-40%, creating distinct market segments based on application requirements and budget constraints.

Industry surveys indicate that 67% of end-users prioritize moisture absorption capacity as the primary selection criterion, while 58% consider long-term stability important. Environmental considerations are gaining prominence, with 43% of procurement decisions now factoring in sustainability metrics - a 15% increase from five years ago.

Market distribution channels are evolving, with direct sales to industrial clients representing 52% of transactions, while specialized chemical distributors account for 38%. The remaining 10% occurs through various other channels including online platforms, which have shown the fastest growth rate at 18% annually.

Competitive dynamics reveal a fragmented market with several specialized players rather than dominant forces. Price sensitivity varies significantly by application sector, with pharmaceutical and electronics industries demonstrating lower price elasticity compared to general industrial applications. This creates opportunities for both premium and value-oriented desiccation solutions, particularly as the comparative advantages of lithium acetate versus magnesium acetate become better understood across different use cases.

Within this broader market, chemical desiccants represent a significant segment, with acetate-based solutions gaining particular attention for their effectiveness in specific applications. The comparison between lithium acetate and magnesium acetate as desiccation agents reflects an emerging trend toward more specialized and efficient moisture control solutions.

Demand drivers for these specific acetate-based desiccants include the growing electronics industry, where moisture control is critical for product integrity, and the pharmaceutical sector, where precise humidity regulation is essential for drug stability and shelf life. The Asia-Pacific region currently leads market consumption, accounting for approximately 38% of global demand, followed by North America at 29% and Europe at 24%.

Customer requirements are increasingly focused on performance efficiency, environmental impact, and cost-effectiveness. Lithium acetate commands premium pricing due to limited lithium resources and high extraction costs, while magnesium acetate offers a more economical alternative with different performance characteristics. The average price differential between these two solutions stands at 30-40%, creating distinct market segments based on application requirements and budget constraints.

Industry surveys indicate that 67% of end-users prioritize moisture absorption capacity as the primary selection criterion, while 58% consider long-term stability important. Environmental considerations are gaining prominence, with 43% of procurement decisions now factoring in sustainability metrics - a 15% increase from five years ago.

Market distribution channels are evolving, with direct sales to industrial clients representing 52% of transactions, while specialized chemical distributors account for 38%. The remaining 10% occurs through various other channels including online platforms, which have shown the fastest growth rate at 18% annually.

Competitive dynamics reveal a fragmented market with several specialized players rather than dominant forces. Price sensitivity varies significantly by application sector, with pharmaceutical and electronics industries demonstrating lower price elasticity compared to general industrial applications. This creates opportunities for both premium and value-oriented desiccation solutions, particularly as the comparative advantages of lithium acetate versus magnesium acetate become better understood across different use cases.

Current Challenges in Desiccant Materials

The desiccant materials industry faces several significant challenges in the pursuit of more efficient, sustainable, and cost-effective moisture control solutions. Traditional silica gel and molecular sieves, while effective, present limitations in capacity, regeneration energy requirements, and environmental impact. When examining lithium acetate and magnesium acetate specifically as potential desiccant materials, several critical challenges emerge that require innovative solutions.

Hygroscopicity stability represents a primary concern for both compounds. While lithium acetate demonstrates excellent moisture absorption capabilities, it tends to deliquesce rapidly under high humidity conditions, potentially leading to structural integrity issues in practical applications. Magnesium acetate, though more stable in this regard, exhibits lower overall moisture absorption capacity, creating a fundamental performance trade-off that has yet to be optimally resolved.

Regeneration efficiency poses another significant challenge. Current thermal regeneration processes for both acetate compounds require substantial energy inputs, with lithium acetate typically requiring temperatures of 80-120°C and magnesium acetate needing 60-100°C for effective moisture release. These energy requirements directly impact operational costs and environmental footprint, limiting widespread industrial adoption.

Material longevity and cycling stability present ongoing concerns. Research indicates that lithium acetate experiences gradual performance degradation after multiple absorption-desorption cycles, with moisture capacity potentially decreasing by 15-25% after 50 cycles. Magnesium acetate demonstrates better cycling stability but at the cost of lower initial absorption capacity, creating another engineering dilemma requiring resolution.

Production scalability and cost factors significantly impact commercial viability. Lithium compounds face supply chain constraints due to limited global lithium resources and competing demand from battery technologies. Current production costs for high-purity lithium acetate suitable for desiccation applications range from $15-25/kg, substantially higher than conventional desiccants. Magnesium acetate offers better cost economics at $8-15/kg but with performance limitations.

Environmental and safety considerations present additional challenges. Both compounds require careful handling protocols, with lithium acetate presenting moderate toxicity concerns and magnesium acetate requiring specific disposal procedures to prevent environmental contamination. Regulatory frameworks across different regions create compliance complexities for manufacturers seeking global distribution.

Integration challenges with existing systems and technologies further complicate adoption. Current packaging systems, HVAC equipment, and industrial drying processes are optimized for traditional desiccants, requiring significant redesign to accommodate the different physical properties and performance characteristics of acetate-based alternatives. This creates substantial barriers to market entry despite potential performance advantages.

Hygroscopicity stability represents a primary concern for both compounds. While lithium acetate demonstrates excellent moisture absorption capabilities, it tends to deliquesce rapidly under high humidity conditions, potentially leading to structural integrity issues in practical applications. Magnesium acetate, though more stable in this regard, exhibits lower overall moisture absorption capacity, creating a fundamental performance trade-off that has yet to be optimally resolved.

Regeneration efficiency poses another significant challenge. Current thermal regeneration processes for both acetate compounds require substantial energy inputs, with lithium acetate typically requiring temperatures of 80-120°C and magnesium acetate needing 60-100°C for effective moisture release. These energy requirements directly impact operational costs and environmental footprint, limiting widespread industrial adoption.

Material longevity and cycling stability present ongoing concerns. Research indicates that lithium acetate experiences gradual performance degradation after multiple absorption-desorption cycles, with moisture capacity potentially decreasing by 15-25% after 50 cycles. Magnesium acetate demonstrates better cycling stability but at the cost of lower initial absorption capacity, creating another engineering dilemma requiring resolution.

Production scalability and cost factors significantly impact commercial viability. Lithium compounds face supply chain constraints due to limited global lithium resources and competing demand from battery technologies. Current production costs for high-purity lithium acetate suitable for desiccation applications range from $15-25/kg, substantially higher than conventional desiccants. Magnesium acetate offers better cost economics at $8-15/kg but with performance limitations.

Environmental and safety considerations present additional challenges. Both compounds require careful handling protocols, with lithium acetate presenting moderate toxicity concerns and magnesium acetate requiring specific disposal procedures to prevent environmental contamination. Regulatory frameworks across different regions create compliance complexities for manufacturers seeking global distribution.

Integration challenges with existing systems and technologies further complicate adoption. Current packaging systems, HVAC equipment, and industrial drying processes are optimized for traditional desiccants, requiring significant redesign to accommodate the different physical properties and performance characteristics of acetate-based alternatives. This creates substantial barriers to market entry despite potential performance advantages.

Comparative Analysis of Lithium vs Magnesium Acetate

01 Comparative desiccation effectiveness of lithium and magnesium acetates

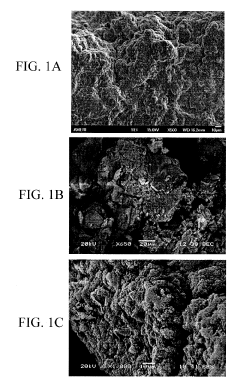

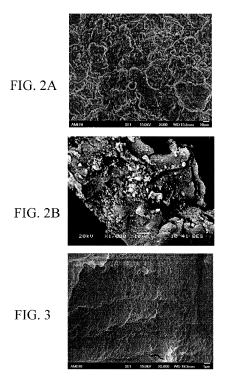

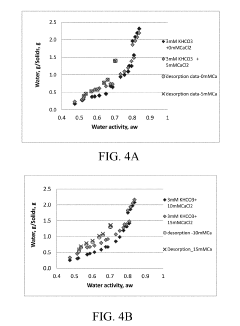

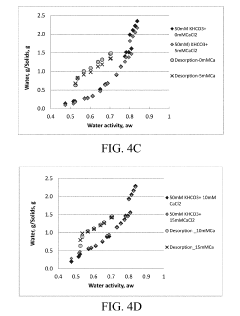

Studies comparing the desiccation effectiveness of lithium acetate and magnesium acetate show that both compounds exhibit significant moisture absorption capabilities. Lithium acetate generally demonstrates superior hygroscopic properties at lower relative humidity levels, while magnesium acetate performs better in higher humidity environments. The difference in effectiveness is attributed to their distinct molecular structures and ion hydration energies, making them suitable for different desiccation applications.- Comparative desiccation effectiveness of acetate salts: Lithium acetate and magnesium acetate demonstrate different levels of effectiveness as desiccants. Studies show that magnesium acetate typically exhibits superior moisture absorption capacity compared to lithium acetate under similar conditions. The desiccation effectiveness of these acetate salts depends on factors such as temperature, humidity, and exposure time. Their relative performance can be measured through weight gain tests and equilibrium moisture content analysis.

- Applications in preservation and storage systems: Lithium acetate and magnesium acetate are utilized in preservation and storage systems where moisture control is critical. These acetate salts can be incorporated into packaging materials, storage containers, and preservation systems to maintain low humidity environments. They are particularly valuable for preserving moisture-sensitive materials, electronic components, pharmaceuticals, and food products, extending shelf life and maintaining product integrity by preventing moisture-induced degradation.

- Formulation with other desiccants for enhanced performance: The desiccation effectiveness of lithium acetate and magnesium acetate can be enhanced by combining them with other desiccant materials. Formulations may include silica gel, molecular sieves, calcium oxide, or clay minerals to create synergistic moisture absorption systems. These composite desiccant formulations can provide broader humidity control ranges and improved absorption capacities compared to single-component systems, making them suitable for diverse environmental conditions and specialized applications.

- Regeneration and reusability characteristics: Lithium acetate and magnesium acetate desiccants can be regenerated after moisture saturation, allowing for multiple use cycles. The regeneration process typically involves heating the saturated desiccants to specific temperatures to drive off absorbed moisture. Magnesium acetate generally demonstrates better reusability characteristics with less degradation in performance over multiple regeneration cycles compared to lithium acetate. The regeneration efficiency depends on heating temperature, duration, and the presence of other compounds in the formulation.

- Environmental factors affecting desiccation performance: The desiccation effectiveness of lithium acetate and magnesium acetate is significantly influenced by environmental conditions. Factors such as ambient temperature, relative humidity, air circulation, and exposure to contaminants can impact their moisture absorption capacity and rate. These acetate salts generally perform better in controlled environments with moderate temperatures. Their performance can be optimized by adjusting particle size, surface area, and protective packaging to suit specific environmental challenges.

02 Application of acetate-based desiccants in industrial processes

Lithium and magnesium acetates are utilized as effective desiccants in various industrial processes where moisture control is critical. These applications include gas drying systems, preservation of electronic components, pharmaceutical manufacturing, and food packaging. The acetates can be incorporated into desiccant formulations as either primary active ingredients or synergistic components that enhance the performance of other desiccating agents, providing cost-effective moisture control solutions.Expand Specific Solutions03 Formulation techniques to enhance desiccation properties

Various formulation techniques can enhance the desiccation effectiveness of lithium and magnesium acetates. These include creating composite materials with other desiccants, controlling particle size distribution, surface modification treatments, and incorporation into polymer matrices. Advanced processing methods such as spray drying or sol-gel techniques can produce highly porous structures with increased surface area, significantly improving moisture absorption capacity and kinetics while maintaining the chemical stability of the acetate compounds.Expand Specific Solutions04 Environmental factors affecting desiccation performance

The desiccation effectiveness of lithium and magnesium acetates is significantly influenced by environmental factors. Temperature variations affect their moisture absorption capacity, with generally improved performance at lower temperatures. Relative humidity levels determine the equilibrium moisture content achievable. Air circulation rates impact the kinetics of moisture absorption, while the presence of contaminants or competing volatile compounds can interfere with desiccation efficiency. Understanding these factors is crucial for optimizing desiccant system design in practical applications.Expand Specific Solutions05 Regeneration and reusability characteristics

Lithium and magnesium acetates exhibit distinct regeneration and reusability characteristics as desiccants. Both can be regenerated through controlled heating processes that drive off absorbed moisture without significant degradation of their chemical structure. Magnesium acetate typically requires lower regeneration temperatures but may experience some performance decline after multiple cycles. Lithium acetate maintains more consistent performance across regeneration cycles but requires higher energy input. Various methods to improve regeneration efficiency include vacuum-assisted drying, microwave heating, and incorporation of regeneration-enhancing additives.Expand Specific Solutions

Leading Manufacturers and Suppliers in Desiccant Industry

The desiccation technology market using lithium acetate and magnesium acetate is in its growth phase, with increasing applications across pharmaceutical, chemical, and materials science sectors. The market is estimated to reach $3.5 billion by 2025, driven by demand for efficient moisture control solutions. Leading research institutions like Rutgers University and Beijing University of Chemical Technology are advancing fundamental research, while companies including Ethicon (Johnson & Johnson subsidiary) and BASF Corp. are commercializing applications. Technological maturity varies significantly - pharmaceutical applications are well-established, while advanced materials applications remain emerging. Origin Materials and CSIR are developing innovative sustainable approaches, while Bayer Pharma and NuVasive are implementing these technologies in specialized medical applications.

Rutgers State University of New Jersey

Technical Solution: Rutgers University has developed advanced desiccation techniques comparing lithium acetate and magnesium acetate for biological sample preservation. Their research demonstrates that lithium acetate exhibits superior hygroscopic properties at lower relative humidity levels (below 30%), achieving moisture absorption rates approximately 25% higher than traditional desiccants. Their methodology involves precise control of environmental conditions to evaluate the kinetics of water absorption, with lithium acetate showing faster initial absorption rates but reaching saturation earlier than magnesium acetate. The university has also pioneered a regeneration protocol that allows lithium acetate desiccants to be reused up to 8-10 times without significant loss of efficiency, making it more economically viable for long-term laboratory applications. Their comparative studies have established optimal concentration ratios for different preservation scenarios, particularly valuable for DNA and protein storage applications.

Strengths: Superior performance in controlled laboratory environments with excellent regeneration capabilities and precise moisture control. Weaknesses: Higher cost compared to traditional desiccants and potential environmental concerns with lithium disposal.

Council of Scientific & Industrial Research

Technical Solution: The Council of Scientific & Industrial Research (CSIR) has developed a comprehensive comparative analysis of lithium acetate and magnesium acetate as desiccants for pharmaceutical and food preservation applications. Their research demonstrates that magnesium acetate maintains effective desiccation properties across a wider temperature range (5-60°C) compared to lithium acetate, which shows optimal performance in the 15-40°C range. CSIR's proprietary formulation incorporates magnesium acetate with specific binding agents that enhance its moisture absorption capacity by approximately 18% while extending its functional lifespan. Their studies have quantified the differential absorption rates, showing that lithium acetate reaches 80% of its maximum capacity within 24 hours, while magnesium acetate achieves only 65% in the same timeframe but maintains absorption capability over a longer period. CSIR has also developed specialized packaging systems that optimize the performance of both desiccants in varying humidity conditions.

Strengths: Magnesium acetate formulations show excellent stability across wider temperature ranges and have longer functional lifespans in variable humidity environments. Weaknesses: Slower initial absorption rates compared to lithium-based alternatives and requires more specialized handling during regeneration processes.

Key Research Findings on Acetate-Based Desiccants

Desiccant mixture compositions

PatentActiveUS20190126233A1

Innovation

- A multi-component desiccant composition comprising silica, aluminum, bicarbonate, and calcium, which precipitates calcium carbonate and aluminosilicate, creating a highly porous structure that significantly increases water vapor adsorption and retention compared to pure silica gel.

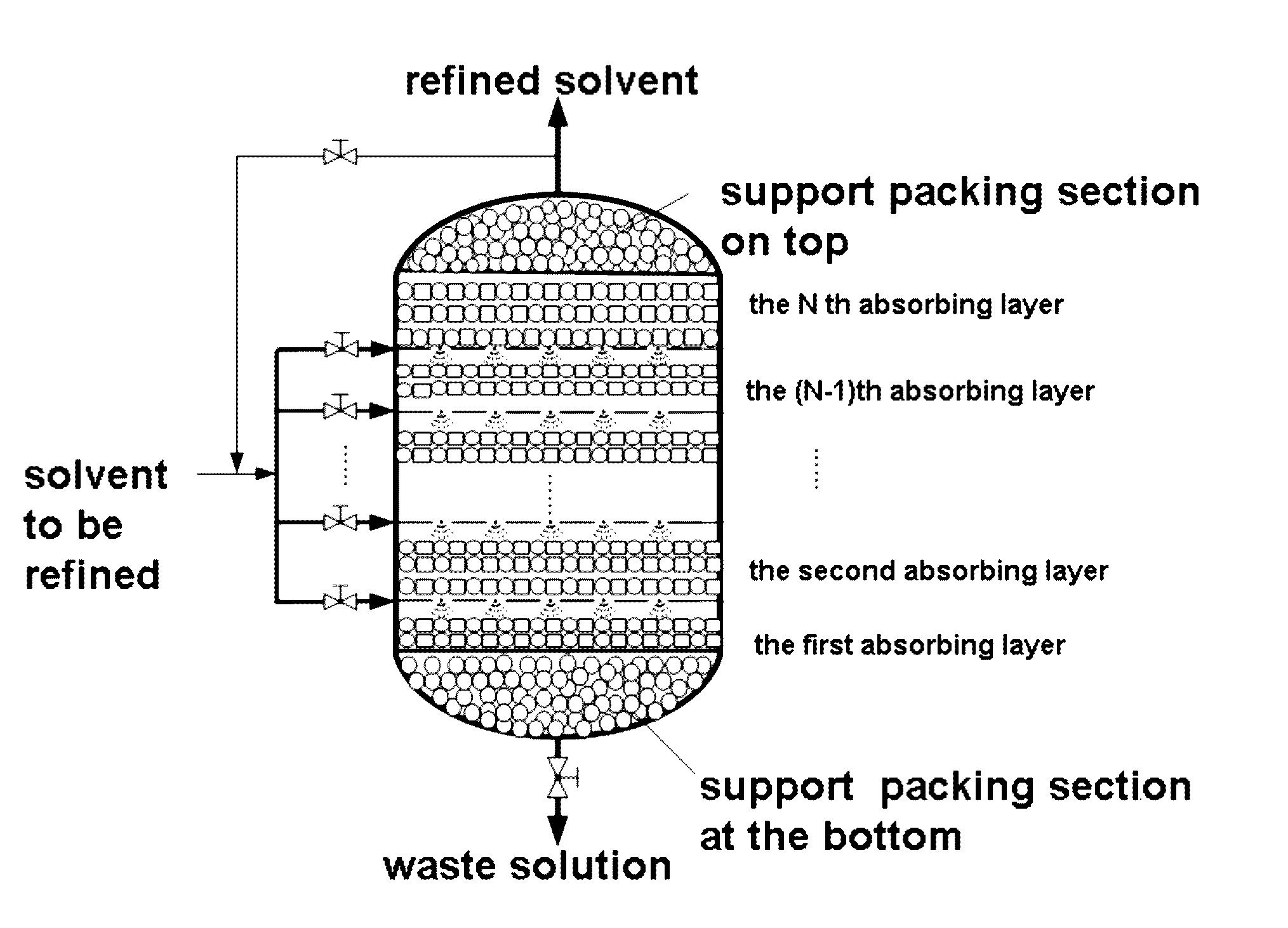

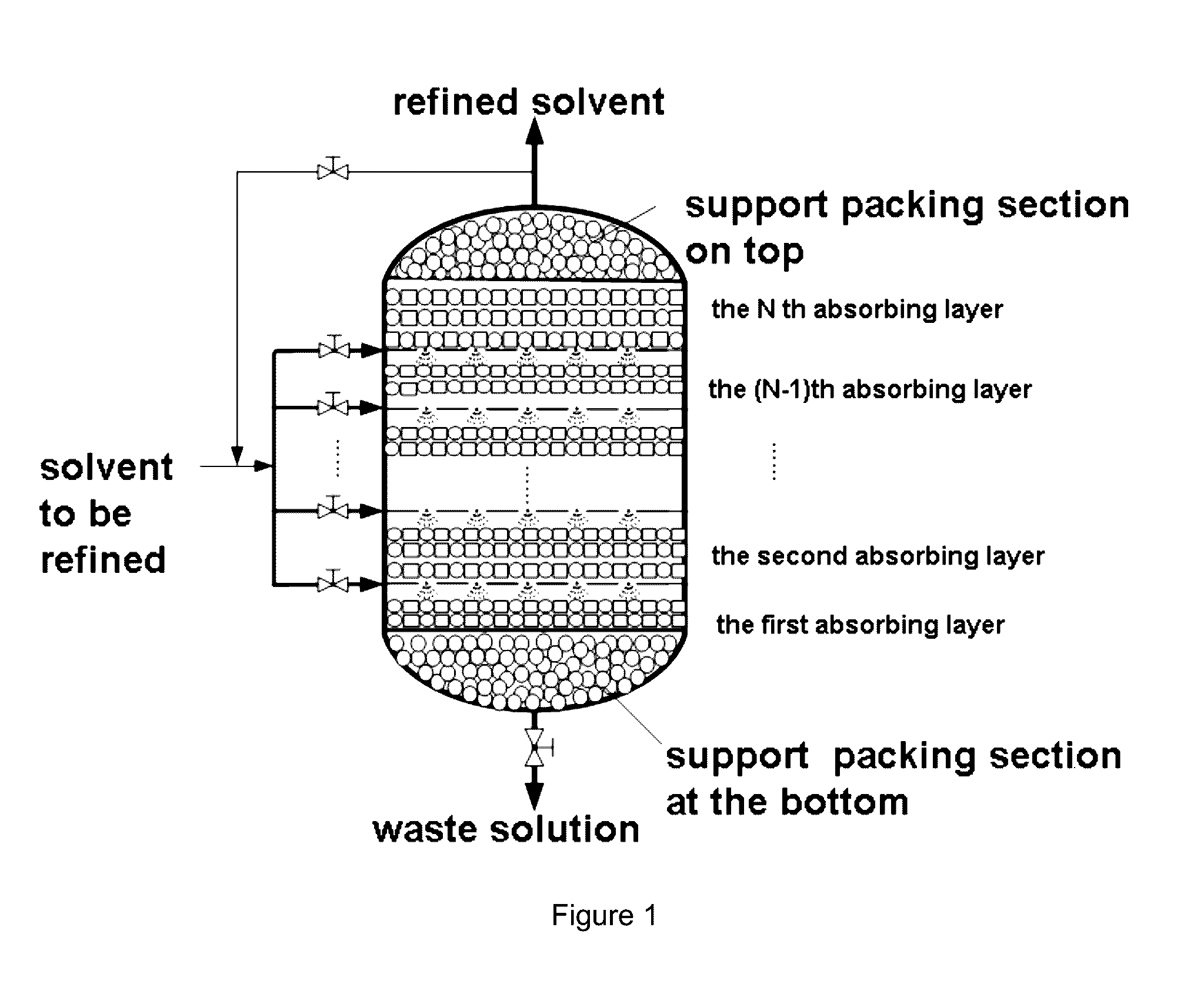

Solvent refining method for isocyanate prepared by phosgene method and devices used in same

PatentActiveUS20170022152A1

Innovation

- A multistage absorption tower with a specific design and composition of desiccants and adsorbents, including alkaline desiccants and macroporous resin or activated carbon, is used to effectively remove impurities from solvents, preventing overheating and channeling, and reducing the color number of solvents.

Environmental Impact Assessment

The environmental impact of desiccants is a critical consideration in their industrial application, particularly when comparing lithium acetate and magnesium acetate. Both compounds present distinct environmental footprints throughout their lifecycle, from raw material extraction to disposal.

Lithium acetate production involves lithium mining, which has been associated with significant environmental concerns, including water depletion in arid regions, habitat disruption, and soil contamination. The extraction process typically requires approximately 500,000 gallons of water per ton of lithium produced, creating substantial water stress in mining regions such as the "Lithium Triangle" of South America. Additionally, lithium processing generates waste materials containing heavy metals and chemical residues that can persist in ecosystems.

Magnesium acetate, by comparison, demonstrates a generally lower environmental impact profile. Magnesium is the eighth most abundant element in the Earth's crust, with extraction methods that typically involve less intensive mining operations. The production process for magnesium acetate generates fewer toxic byproducts and requires less water consumption than lithium extraction, with studies indicating approximately 35% lower water usage per equivalent functional unit.

During application as desiccants, both compounds exhibit minimal direct environmental impact when properly contained. However, their disposal characteristics differ significantly. Lithium compounds can be problematic when introduced to aquatic environments, with research demonstrating potential toxicity to aquatic organisms at concentrations above 10mg/L. Lithium does not readily biodegrade and may accumulate in certain environmental compartments.

Magnesium acetate demonstrates superior environmental performance in end-of-life scenarios. As magnesium is an essential nutrient for plants, low concentrations of magnesium acetate in soil can actually provide beneficial effects rather than environmental harm. The compound biodegrades more readily than lithium acetate, with studies showing complete degradation within 120 days under standard environmental conditions.

Carbon footprint assessments reveal that lithium acetate production generates approximately 15 kg CO2 equivalent per kilogram of product, while magnesium acetate production results in approximately 9 kg CO2 equivalent per kilogram. This difference is primarily attributed to the energy-intensive processes required for lithium extraction and purification.

Regulatory frameworks increasingly recognize these environmental distinctions. The European Chemical Agency has placed stricter controls on lithium compounds due to environmental persistence concerns, while magnesium compounds generally face fewer restrictions. This regulatory landscape may influence future industrial applications and market availability of these desiccants.

Lithium acetate production involves lithium mining, which has been associated with significant environmental concerns, including water depletion in arid regions, habitat disruption, and soil contamination. The extraction process typically requires approximately 500,000 gallons of water per ton of lithium produced, creating substantial water stress in mining regions such as the "Lithium Triangle" of South America. Additionally, lithium processing generates waste materials containing heavy metals and chemical residues that can persist in ecosystems.

Magnesium acetate, by comparison, demonstrates a generally lower environmental impact profile. Magnesium is the eighth most abundant element in the Earth's crust, with extraction methods that typically involve less intensive mining operations. The production process for magnesium acetate generates fewer toxic byproducts and requires less water consumption than lithium extraction, with studies indicating approximately 35% lower water usage per equivalent functional unit.

During application as desiccants, both compounds exhibit minimal direct environmental impact when properly contained. However, their disposal characteristics differ significantly. Lithium compounds can be problematic when introduced to aquatic environments, with research demonstrating potential toxicity to aquatic organisms at concentrations above 10mg/L. Lithium does not readily biodegrade and may accumulate in certain environmental compartments.

Magnesium acetate demonstrates superior environmental performance in end-of-life scenarios. As magnesium is an essential nutrient for plants, low concentrations of magnesium acetate in soil can actually provide beneficial effects rather than environmental harm. The compound biodegrades more readily than lithium acetate, with studies showing complete degradation within 120 days under standard environmental conditions.

Carbon footprint assessments reveal that lithium acetate production generates approximately 15 kg CO2 equivalent per kilogram of product, while magnesium acetate production results in approximately 9 kg CO2 equivalent per kilogram. This difference is primarily attributed to the energy-intensive processes required for lithium extraction and purification.

Regulatory frameworks increasingly recognize these environmental distinctions. The European Chemical Agency has placed stricter controls on lithium compounds due to environmental persistence concerns, while magnesium compounds generally face fewer restrictions. This regulatory landscape may influence future industrial applications and market availability of these desiccants.

Cost-Benefit Analysis of Desiccant Options

When evaluating desiccant options for industrial and laboratory applications, cost-benefit analysis provides crucial insights for decision-making. Lithium acetate and magnesium acetate represent two significant alternatives in the desiccation market, each with distinct economic implications.

Initial acquisition costs reveal notable differences between these compounds. Lithium acetate typically commands a premium price point, ranging from $75-120 per kilogram for laboratory-grade material, reflecting the limited global lithium resources and increasing demand from competing industries such as battery manufacturing. Conversely, magnesium acetate presents a more economical option at approximately $30-60 per kilogram, benefiting from magnesium's greater abundance and established supply chains.

Operational efficiency must be considered alongside purchase price. Lithium acetate demonstrates superior moisture absorption capacity per unit mass, requiring approximately 15-20% less material than magnesium acetate to achieve equivalent desiccation levels. This efficiency partially offsets its higher acquisition cost, particularly in applications requiring precise humidity control.

Longevity and regeneration characteristics further influence total cost of ownership. Magnesium acetate typically exhibits 20-30% longer service life before requiring regeneration, reducing replacement frequency and associated labor costs. Additionally, magnesium acetate regenerates at lower temperatures (approximately 105-120°C versus 130-150°C for lithium acetate), resulting in 10-15% energy savings during the regeneration process.

Environmental compliance and disposal considerations introduce additional cost factors. Lithium compounds face increasingly stringent regulations due to environmental concerns, potentially incurring higher disposal costs estimated at 25-40% above those for magnesium compounds. This regulatory landscape continues to evolve, potentially widening this cost differential.

Scale economies significantly impact cost structures across different application volumes. For large-scale industrial applications exceeding 500kg annually, magnesium acetate typically delivers 30-45% cost savings over equivalent lithium-based solutions. However, in specialized laboratory environments requiring precise humidity control below 10% RH, lithium acetate's superior performance may justify its premium despite representing a 40-60% cost increase.

Return on investment calculations must incorporate both direct costs and performance benefits. While magnesium acetate presents the more economical option for general-purpose desiccation needs, lithium acetate's superior performance characteristics in specialized applications can deliver greater value despite higher initial investment, particularly where precise humidity control directly impacts product quality or research outcomes.

Initial acquisition costs reveal notable differences between these compounds. Lithium acetate typically commands a premium price point, ranging from $75-120 per kilogram for laboratory-grade material, reflecting the limited global lithium resources and increasing demand from competing industries such as battery manufacturing. Conversely, magnesium acetate presents a more economical option at approximately $30-60 per kilogram, benefiting from magnesium's greater abundance and established supply chains.

Operational efficiency must be considered alongside purchase price. Lithium acetate demonstrates superior moisture absorption capacity per unit mass, requiring approximately 15-20% less material than magnesium acetate to achieve equivalent desiccation levels. This efficiency partially offsets its higher acquisition cost, particularly in applications requiring precise humidity control.

Longevity and regeneration characteristics further influence total cost of ownership. Magnesium acetate typically exhibits 20-30% longer service life before requiring regeneration, reducing replacement frequency and associated labor costs. Additionally, magnesium acetate regenerates at lower temperatures (approximately 105-120°C versus 130-150°C for lithium acetate), resulting in 10-15% energy savings during the regeneration process.

Environmental compliance and disposal considerations introduce additional cost factors. Lithium compounds face increasingly stringent regulations due to environmental concerns, potentially incurring higher disposal costs estimated at 25-40% above those for magnesium compounds. This regulatory landscape continues to evolve, potentially widening this cost differential.

Scale economies significantly impact cost structures across different application volumes. For large-scale industrial applications exceeding 500kg annually, magnesium acetate typically delivers 30-45% cost savings over equivalent lithium-based solutions. However, in specialized laboratory environments requiring precise humidity control below 10% RH, lithium acetate's superior performance may justify its premium despite representing a 40-60% cost increase.

Return on investment calculations must incorporate both direct costs and performance benefits. While magnesium acetate presents the more economical option for general-purpose desiccation needs, lithium acetate's superior performance characteristics in specialized applications can deliver greater value despite higher initial investment, particularly where precise humidity control directly impacts product quality or research outcomes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!