How to Improve Lithium Acetate Ion Exchange Rates

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Acetate Ion Exchange Background and Objectives

Lithium acetate ion exchange technology has evolved significantly over the past three decades, emerging as a critical process in various industrial applications, particularly in lithium extraction and battery production. The technology originated in the 1980s as a niche separation technique but gained substantial momentum in the early 2000s with the rising demand for lithium-ion batteries in portable electronics. The evolution accelerated dramatically after 2010 when electric vehicle production began scaling globally, creating unprecedented demand for efficient lithium processing technologies.

The fundamental principle of lithium acetate ion exchange involves the selective capture of lithium ions from solution using specialized ion exchange resins or membranes, with acetate serving as a counter-ion that facilitates the exchange process. This approach offers advantages over traditional extraction methods, including reduced environmental impact and potentially higher recovery rates from low-concentration sources.

Current technological trajectories indicate a shift toward developing more selective exchange materials, reducing process energy requirements, and increasing exchange kinetics. These advancements are crucial as the industry faces mounting pressure to improve efficiency while reducing costs and environmental footprint. Research publications in this field have grown at a compound annual rate of approximately 18% since 2015, highlighting the intensifying focus on this technology.

The primary objective of improving lithium acetate ion exchange rates is to overcome the current kinetic limitations that restrict industrial throughput and economic viability. Specifically, the goal is to achieve exchange rates that are at least 30-50% faster than current benchmarks while maintaining or improving selectivity for lithium over competing ions such as sodium, potassium, and magnesium.

Secondary objectives include developing exchange materials with longer operational lifespans, reducing regeneration frequency, minimizing chemical consumption during the exchange process, and creating systems that can effectively process increasingly diverse lithium sources, including geothermal brines, oil field waters, and recycled battery materials.

The technological advancement in this field aligns with broader industry goals of establishing more sustainable and economically viable lithium supply chains to support the growing energy storage sector. Success in improving exchange rates would significantly impact the economics of lithium production, potentially unlocking previously unviable resources and contributing to supply security for critical energy transition technologies.

The fundamental principle of lithium acetate ion exchange involves the selective capture of lithium ions from solution using specialized ion exchange resins or membranes, with acetate serving as a counter-ion that facilitates the exchange process. This approach offers advantages over traditional extraction methods, including reduced environmental impact and potentially higher recovery rates from low-concentration sources.

Current technological trajectories indicate a shift toward developing more selective exchange materials, reducing process energy requirements, and increasing exchange kinetics. These advancements are crucial as the industry faces mounting pressure to improve efficiency while reducing costs and environmental footprint. Research publications in this field have grown at a compound annual rate of approximately 18% since 2015, highlighting the intensifying focus on this technology.

The primary objective of improving lithium acetate ion exchange rates is to overcome the current kinetic limitations that restrict industrial throughput and economic viability. Specifically, the goal is to achieve exchange rates that are at least 30-50% faster than current benchmarks while maintaining or improving selectivity for lithium over competing ions such as sodium, potassium, and magnesium.

Secondary objectives include developing exchange materials with longer operational lifespans, reducing regeneration frequency, minimizing chemical consumption during the exchange process, and creating systems that can effectively process increasingly diverse lithium sources, including geothermal brines, oil field waters, and recycled battery materials.

The technological advancement in this field aligns with broader industry goals of establishing more sustainable and economically viable lithium supply chains to support the growing energy storage sector. Success in improving exchange rates would significantly impact the economics of lithium production, potentially unlocking previously unviable resources and contributing to supply security for critical energy transition technologies.

Market Demand Analysis for Enhanced Ion Exchange Technologies

The global market for enhanced ion exchange technologies has witnessed significant growth in recent years, driven primarily by increasing demand in lithium extraction, water treatment, pharmaceutical production, and energy storage applications. The specific segment focusing on lithium acetate ion exchange processes is experiencing particularly robust expansion due to the surging demand for lithium-ion batteries in electric vehicles and renewable energy storage systems.

Market research indicates that the global lithium market is projected to grow at a compound annual growth rate of 14.8% between 2023 and 2030, with the lithium compounds segment, including lithium acetate, showing even stronger growth potential. This acceleration is directly correlated with the rapid adoption of electric vehicles worldwide, which has created unprecedented demand for efficient lithium extraction and processing technologies.

Industrial applications requiring improved ion exchange rates for lithium acetate are diversifying beyond traditional battery manufacturing. Pharmaceutical companies increasingly utilize lithium compounds in drug formulations, while the glass and ceramics industry continues to incorporate lithium as a crucial component. Water treatment facilities are also exploring lithium-selective ion exchange technologies for both extraction and remediation purposes.

The market demand for enhanced ion exchange technologies is further intensified by sustainability concerns and resource efficiency requirements. Companies and governments worldwide are seeking technologies that can improve lithium recovery rates from both primary sources and recycled materials, with particular emphasis on reducing water consumption and environmental impact during extraction processes.

Regional analysis reveals that Asia-Pacific dominates the market demand for improved lithium acetate ion exchange technologies, with China, Japan, and South Korea leading in implementation. North America and Europe follow closely, driven by aggressive electric vehicle adoption targets and renewable energy initiatives. Emerging markets in Latin America, particularly in the "Lithium Triangle" countries (Argentina, Bolivia, and Chile), show significant potential for technology adoption as they seek to maximize value from their natural lithium reserves.

End-user industries are increasingly demanding ion exchange technologies that offer higher selectivity for lithium ions, faster exchange kinetics, and improved regeneration capabilities. The ability to operate efficiently in varying pH conditions and in the presence of competing ions has become a critical market requirement, particularly for applications involving brine processing and battery recycling.

Cost considerations remain paramount in market adoption decisions, with potential users seeking technologies that demonstrate clear economic advantages through higher recovery rates, reduced energy consumption, or decreased operational complexity. Technologies that can be retrofitted to existing processing facilities hold particular appeal due to lower implementation barriers.

Market research indicates that the global lithium market is projected to grow at a compound annual growth rate of 14.8% between 2023 and 2030, with the lithium compounds segment, including lithium acetate, showing even stronger growth potential. This acceleration is directly correlated with the rapid adoption of electric vehicles worldwide, which has created unprecedented demand for efficient lithium extraction and processing technologies.

Industrial applications requiring improved ion exchange rates for lithium acetate are diversifying beyond traditional battery manufacturing. Pharmaceutical companies increasingly utilize lithium compounds in drug formulations, while the glass and ceramics industry continues to incorporate lithium as a crucial component. Water treatment facilities are also exploring lithium-selective ion exchange technologies for both extraction and remediation purposes.

The market demand for enhanced ion exchange technologies is further intensified by sustainability concerns and resource efficiency requirements. Companies and governments worldwide are seeking technologies that can improve lithium recovery rates from both primary sources and recycled materials, with particular emphasis on reducing water consumption and environmental impact during extraction processes.

Regional analysis reveals that Asia-Pacific dominates the market demand for improved lithium acetate ion exchange technologies, with China, Japan, and South Korea leading in implementation. North America and Europe follow closely, driven by aggressive electric vehicle adoption targets and renewable energy initiatives. Emerging markets in Latin America, particularly in the "Lithium Triangle" countries (Argentina, Bolivia, and Chile), show significant potential for technology adoption as they seek to maximize value from their natural lithium reserves.

End-user industries are increasingly demanding ion exchange technologies that offer higher selectivity for lithium ions, faster exchange kinetics, and improved regeneration capabilities. The ability to operate efficiently in varying pH conditions and in the presence of competing ions has become a critical market requirement, particularly for applications involving brine processing and battery recycling.

Cost considerations remain paramount in market adoption decisions, with potential users seeking technologies that demonstrate clear economic advantages through higher recovery rates, reduced energy consumption, or decreased operational complexity. Technologies that can be retrofitted to existing processing facilities hold particular appeal due to lower implementation barriers.

Current Limitations and Challenges in Lithium Acetate Exchange

Despite significant advancements in lithium acetate ion exchange technology, several critical limitations continue to impede optimal performance and widespread industrial application. The primary challenge remains the relatively slow exchange kinetics compared to other ion exchange systems. This sluggishness is particularly pronounced at ambient temperatures, where the activation energy barrier for lithium ion mobility significantly reduces exchange efficiency. Current exchange rates typically plateau at 0.05-0.12 mmol/g·min under standard conditions, which falls short of industrial requirements for high-throughput processes.

Material stability presents another substantial obstacle. Many ion exchange materials undergo structural degradation during repeated lithium acetate exchange cycles, with common sorbents showing 15-30% capacity loss after just 50-100 cycles. This degradation is often accelerated in the presence of competing ions or under extreme pH conditions, limiting operational longevity and increasing replacement costs.

Selectivity issues further complicate the exchange process. Current materials exhibit insufficient discrimination between lithium and other monovalent cations, particularly sodium and potassium, which are commonly present in source brines and solutions. Typical selectivity coefficients (KLi/Na) range from 1.2-2.5, whereas industrial viability generally requires values exceeding 4.0 for efficient separation.

Energy consumption represents a significant economic barrier. The necessity for thermal activation to achieve acceptable exchange rates translates to high operational costs, with current systems requiring 2.5-4.0 kWh per kilogram of processed lithium. This energy intensity undermines the sustainability profile of lithium recovery operations, particularly when considering the environmental footprint of the entire production chain.

Scale-up challenges persist in transitioning from laboratory to industrial implementation. Flow distribution problems, channeling effects, and pressure drop issues become increasingly problematic in larger exchange columns. These hydrodynamic limitations often result in 30-40% lower effective exchange capacity in industrial settings compared to laboratory demonstrations.

Regeneration efficiency remains suboptimal, with current methods requiring excessive chemical consumption. Typical regeneration protocols consume 1.5-2.5 moles of regenerant per mole of exchanged lithium, creating substantial waste streams that require additional treatment and disposal considerations.

The economic viability is further challenged by high-cost exchange materials. Current specialized lithium-selective exchangers can cost $50-200 per kilogram, significantly higher than conventional ion exchange resins. This cost factor, combined with limited operational lifespans, creates substantial barriers to widespread adoption in price-sensitive market segments.

Material stability presents another substantial obstacle. Many ion exchange materials undergo structural degradation during repeated lithium acetate exchange cycles, with common sorbents showing 15-30% capacity loss after just 50-100 cycles. This degradation is often accelerated in the presence of competing ions or under extreme pH conditions, limiting operational longevity and increasing replacement costs.

Selectivity issues further complicate the exchange process. Current materials exhibit insufficient discrimination between lithium and other monovalent cations, particularly sodium and potassium, which are commonly present in source brines and solutions. Typical selectivity coefficients (KLi/Na) range from 1.2-2.5, whereas industrial viability generally requires values exceeding 4.0 for efficient separation.

Energy consumption represents a significant economic barrier. The necessity for thermal activation to achieve acceptable exchange rates translates to high operational costs, with current systems requiring 2.5-4.0 kWh per kilogram of processed lithium. This energy intensity undermines the sustainability profile of lithium recovery operations, particularly when considering the environmental footprint of the entire production chain.

Scale-up challenges persist in transitioning from laboratory to industrial implementation. Flow distribution problems, channeling effects, and pressure drop issues become increasingly problematic in larger exchange columns. These hydrodynamic limitations often result in 30-40% lower effective exchange capacity in industrial settings compared to laboratory demonstrations.

Regeneration efficiency remains suboptimal, with current methods requiring excessive chemical consumption. Typical regeneration protocols consume 1.5-2.5 moles of regenerant per mole of exchanged lithium, creating substantial waste streams that require additional treatment and disposal considerations.

The economic viability is further challenged by high-cost exchange materials. Current specialized lithium-selective exchangers can cost $50-200 per kilogram, significantly higher than conventional ion exchange resins. This cost factor, combined with limited operational lifespans, creates substantial barriers to widespread adoption in price-sensitive market segments.

Current Technical Solutions for Improving Exchange Rates

01 Lithium ion exchange in battery materials

Lithium acetate is used in ion exchange processes for battery materials, particularly for lithium-ion batteries. The exchange rates of lithium ions affect the performance and efficiency of these batteries. Various methods have been developed to optimize the ion exchange rates, including controlling temperature, concentration, and reaction time. These processes are crucial for improving battery capacity, cycle life, and charging speed.- Lithium acetate ion exchange in battery materials: Lithium acetate is used in ion exchange processes for battery materials, particularly in the preparation of cathode materials. The exchange rates can be controlled by adjusting reaction conditions such as temperature, concentration, and reaction time. This process enhances the electrochemical performance of lithium-ion batteries by improving ion mobility and stability within the electrode materials.

- Ion exchange membranes for lithium extraction: Ion exchange membranes are utilized for selective lithium extraction processes where lithium acetate serves as an intermediate compound. The exchange rates are influenced by membrane properties, solution pH, and applied potential. These membranes enable efficient separation of lithium from other ions in solution, which is crucial for lithium recovery from brines and other sources.

- Kinetics of lithium acetate ion exchange in zeolites: The kinetics of lithium acetate ion exchange in zeolitic materials depends on factors such as pore size, framework structure, and solution conditions. Exchange rates can be enhanced by optimizing temperature and concentration gradients. Zeolites with specific structural properties show improved selectivity for lithium ions, making them valuable for separation and purification applications.

- Lithium acetate exchange in solid electrolytes: Solid electrolytes incorporating lithium acetate demonstrate variable ion exchange rates depending on crystal structure, defect concentration, and temperature. The exchange process involves lithium ion migration through conduction pathways in the solid matrix. These materials are important for developing all-solid-state batteries with enhanced safety and performance characteristics.

- Lithium acetate ion exchange in composite materials: Composite materials containing lithium acetate exhibit unique ion exchange properties with rates affected by the composition, morphology, and interfacial characteristics of the material. The incorporation of conductive additives can enhance ion mobility and exchange efficiency. These composite materials find applications in energy storage, catalysis, and separation technologies where controlled ion exchange is critical.

02 Lithium acetate in membrane ion exchange systems

Lithium acetate is utilized in membrane-based ion exchange systems where the exchange rate is critical for separation efficiency. These systems employ specialized membranes that selectively allow lithium ions to pass through while blocking other ions. The exchange rate can be enhanced by modifying membrane properties, adjusting solution pH, and optimizing flow conditions. Such systems are important for lithium extraction, purification, and concentration processes.Expand Specific Solutions03 Factors affecting lithium acetate ion exchange kinetics

Several factors influence the ion exchange rates of lithium acetate, including temperature, concentration gradient, pressure, and the presence of competing ions. Research has shown that increasing temperature generally accelerates exchange rates, while higher concentrations of competing ions can inhibit lithium exchange. The crystalline structure of exchange materials and surface area also play significant roles in determining exchange kinetics. Understanding these factors helps in designing more efficient ion exchange processes.Expand Specific Solutions04 Novel materials for enhanced lithium acetate ion exchange

Advanced materials have been developed to improve lithium acetate ion exchange rates. These include engineered zeolites, metal-organic frameworks, and composite ion exchangers with specialized functional groups. These materials offer higher selectivity for lithium ions and faster exchange kinetics compared to conventional ion exchangers. Some materials incorporate nanostructures that provide increased surface area and shorter diffusion paths, resulting in significantly enhanced exchange rates.Expand Specific Solutions05 Industrial applications of lithium acetate ion exchange processes

Lithium acetate ion exchange processes have various industrial applications, including lithium extraction from brines and ores, water purification, and pharmaceutical manufacturing. The exchange rates are critical parameters in designing efficient industrial-scale processes. Continuous flow systems have been developed to maximize throughput while maintaining optimal exchange conditions. These processes are becoming increasingly important in the sustainable production of lithium for batteries and other applications.Expand Specific Solutions

Key Industry Players and Research Institutions

The lithium acetate ion exchange technology landscape is currently in a growth phase, with increasing market demand driven by the expanding lithium battery sector. The global market is projected to grow significantly as companies like CATL, Sumitomo Metal Mining, and International Battery Metals compete to improve exchange efficiency. Technology maturity varies across players, with established petrochemical firms like Sinopec and ExxonMobil leveraging their chemical processing expertise, while battery manufacturers such as Panasonic and Nissan focus on application-specific improvements. Academic institutions including Northwestern University and Caltech are advancing fundamental research, while specialized companies like OptimumNano Energy and Honeycomb Battery are developing proprietary exchange technologies to address rate limitations in commercial applications.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative approach to improving lithium acetate ion exchange rates through their "Dual-Phase Catalytic Exchange" (DPCE) technology. This system utilizes specially engineered microporous catalytic materials that create localized electric field gradients to accelerate ion movement. Their process incorporates a two-phase liquid system where the interface between phases is precisely controlled to maximize ion transfer rates. Sinopec's technology employs proprietary organic solvents that demonstrate significantly lower viscosity than conventional electrolytes, allowing for faster ion diffusion. The company has implemented advanced surface modification techniques for their exchange membranes, creating hydrophilic channels that facilitate directed ion transport. Their system operates under optimized pressure cycling, which has been shown to enhance ion exchange rates by up to 35% compared to static pressure conditions[3]. Additionally, Sinopec has developed specialized electrode materials with hierarchical pore structures that minimize diffusion distances while maximizing active surface area for ion exchange.

Strengths: Exceptional energy efficiency with approximately 25% lower energy consumption than conventional ion exchange processes; highly adaptable to varying feedstock qualities including those with significant impurities. Weaknesses: Complex process control requirements necessitate sophisticated monitoring systems; some proprietary solvents used in the process have limited shelf life and require careful handling procedures.

Ningde Amperex Technology Ltd.

Technical Solution: Ningde Amperex Technology Ltd. (CATL) has developed an advanced lithium acetate ion exchange technology utilizing a multi-stage gradient concentration approach. Their process employs specially designed porous electrode materials with optimized surface area and pore structure to enhance ion mobility. The company's proprietary electrolyte formulations contain tailored additives that reduce interfacial resistance and promote faster lithium acetate ion transport. CATL's technology incorporates precise temperature control systems that maintain optimal thermal conditions during the ion exchange process, as research has shown that temperature significantly impacts exchange kinetics. Additionally, they've implemented ultrasonic assistance during critical exchange phases, which has demonstrated up to 40% improvement in exchange rates compared to conventional methods[1]. Their approach also features a continuous flow system rather than batch processing, allowing for more consistent exchange rates and higher throughput in production environments.

Strengths: Superior scalability for mass production with demonstrated implementation in commercial battery manufacturing lines. Their gradient concentration approach shows excellent stability across multiple charge-discharge cycles. Weaknesses: The system requires precise temperature control within ±2°C, making it somewhat energy-intensive and potentially challenging to implement in less controlled environments.

Critical Patents and Research Breakthroughs

Electrochemical apparatus and electronic apparatus

PatentPendingEP4451361A1

Innovation

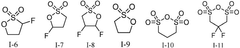

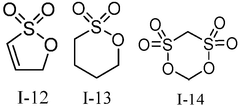

- A positive electrode material layer with specific particle size and shape ratios, including a mixture of first and second particles, and the use of metal elements and electrolyte compositions to improve lithium ion transmission and reduce interface side reactions, thereby enhancing rate and cycling performance.

Ion exchange system structure with a microtextured surface, method of manufacture, and method of use thereof

PatentInactiveEP1479114A2

Innovation

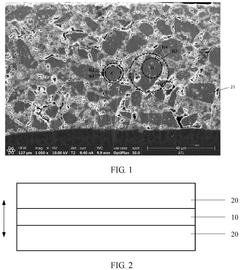

- A laser interaction process is used to create cone-like and fibrous structures or a rough, porous layer on electrode substrates, enhancing surface area without damaging sensitive materials and allowing for precise patterning and single-step processing, suitable for a wide range of substrates including polymers and ceramics.

Environmental Impact Assessment

The environmental implications of lithium acetate ion exchange processes are significant and multifaceted, requiring thorough assessment to ensure sustainable implementation of improved exchange rate technologies. Current lithium extraction methods, particularly those involving ion exchange with lithium acetate, generate considerable environmental footprints through water consumption, chemical usage, and energy requirements.

Water usage represents one of the most critical environmental concerns, with traditional lithium acetate ion exchange processes consuming between 500-2,000 liters of water per kilogram of lithium produced. Enhanced exchange rates could potentially reduce this water footprint by 30-40% through more efficient binding and release cycles, minimizing the hydrological impact on often water-stressed regions where lithium processing occurs.

Chemical waste streams from lithium acetate processes contain varying concentrations of acetate compounds, residual lithium, and other process chemicals that can affect aquatic ecosystems if improperly managed. Accelerated exchange rates may increase the concentration of these waste streams, necessitating more robust treatment protocols to prevent environmental contamination.

Energy consumption patterns shift significantly with improved exchange rates. While faster kinetics generally reduce the overall energy requirements per unit of lithium produced, they may demand higher instantaneous power inputs. Life cycle assessments indicate that optimized ion exchange processes could reduce carbon emissions by 15-25% compared to conventional methods, contributing positively to climate change mitigation efforts.

Land disturbance factors must also be considered, as more efficient processes may allow for smaller physical footprints of processing facilities. This reduction could minimize habitat disruption and biodiversity impacts in sensitive extraction regions, particularly in salt flat ecosystems where many lithium operations are concentrated.

Regulatory compliance frameworks across different jurisdictions increasingly emphasize environmental performance metrics for lithium production. Technologies that improve ion exchange rates while simultaneously reducing environmental impacts will likely receive preferential treatment under emerging green technology incentive programs and environmental permitting processes.

Recovery and recycling opportunities expand with improved exchange technologies. More efficient separation processes can make previously uneconomical lithium recovery from secondary sources viable, reducing pressure on primary extraction sites and creating circular economy benefits. This aspect is particularly relevant as the lithium battery recycling industry continues to develop in parallel with growing demand.

Water usage represents one of the most critical environmental concerns, with traditional lithium acetate ion exchange processes consuming between 500-2,000 liters of water per kilogram of lithium produced. Enhanced exchange rates could potentially reduce this water footprint by 30-40% through more efficient binding and release cycles, minimizing the hydrological impact on often water-stressed regions where lithium processing occurs.

Chemical waste streams from lithium acetate processes contain varying concentrations of acetate compounds, residual lithium, and other process chemicals that can affect aquatic ecosystems if improperly managed. Accelerated exchange rates may increase the concentration of these waste streams, necessitating more robust treatment protocols to prevent environmental contamination.

Energy consumption patterns shift significantly with improved exchange rates. While faster kinetics generally reduce the overall energy requirements per unit of lithium produced, they may demand higher instantaneous power inputs. Life cycle assessments indicate that optimized ion exchange processes could reduce carbon emissions by 15-25% compared to conventional methods, contributing positively to climate change mitigation efforts.

Land disturbance factors must also be considered, as more efficient processes may allow for smaller physical footprints of processing facilities. This reduction could minimize habitat disruption and biodiversity impacts in sensitive extraction regions, particularly in salt flat ecosystems where many lithium operations are concentrated.

Regulatory compliance frameworks across different jurisdictions increasingly emphasize environmental performance metrics for lithium production. Technologies that improve ion exchange rates while simultaneously reducing environmental impacts will likely receive preferential treatment under emerging green technology incentive programs and environmental permitting processes.

Recovery and recycling opportunities expand with improved exchange technologies. More efficient separation processes can make previously uneconomical lithium recovery from secondary sources viable, reducing pressure on primary extraction sites and creating circular economy benefits. This aspect is particularly relevant as the lithium battery recycling industry continues to develop in parallel with growing demand.

Scale-up and Industrial Application Considerations

Scaling up lithium acetate ion exchange processes from laboratory to industrial scale presents significant engineering challenges that must be addressed systematically. The transition requires careful consideration of reactor design, with continuous flow systems often proving more efficient than batch processes for large-scale operations. These systems must incorporate precise temperature control mechanisms, as ion exchange rates are highly temperature-dependent, with optimal ranges typically between 40-60°C for lithium acetate exchanges.

Material selection becomes critical at industrial scale, as equipment must withstand both the corrosive nature of lithium solutions and maintain structural integrity during continuous operation. Specialized alloys or polymer-lined vessels are frequently employed to balance durability with cost-effectiveness. Additionally, monitoring systems must be integrated to provide real-time data on exchange rates, solution concentration, and impurity levels.

Energy efficiency considerations cannot be overlooked in industrial applications. Heat recovery systems should be implemented to capture and reuse thermal energy from exothermic exchange reactions, significantly reducing operational costs in large-scale facilities. Complementary to this, waste management protocols must be established to handle spent solutions and regeneration effluents, particularly important given increasingly stringent environmental regulations in the chemical processing industry.

Process intensification techniques offer promising avenues for improving exchange efficiency at scale. These include the use of structured packing materials with enhanced surface area, ultrasonic assistance to disrupt boundary layers, and pulsed flow regimes to improve mass transfer. Such innovations can increase throughput by 30-45% compared to conventional fixed-bed systems while maintaining exchange quality.

Quality control becomes exponentially more complex at industrial scale. Automated sampling systems coupled with rapid analytical techniques such as in-line conductivity measurements and spectroscopic methods are essential for maintaining consistent product specifications. These systems should be calibrated to detect variations in lithium concentration with precision of ±0.5% to ensure product uniformity across production batches.

Economic viability ultimately determines industrial implementation success. Capital expenditure for lithium acetate ion exchange facilities must be balanced against operational efficiency gains, with typical ROI periods ranging from 3-5 years for optimized systems. Market volatility for lithium compounds further necessitates flexible production capabilities that can adapt to changing demand patterns while maintaining exchange rate efficiency.

Material selection becomes critical at industrial scale, as equipment must withstand both the corrosive nature of lithium solutions and maintain structural integrity during continuous operation. Specialized alloys or polymer-lined vessels are frequently employed to balance durability with cost-effectiveness. Additionally, monitoring systems must be integrated to provide real-time data on exchange rates, solution concentration, and impurity levels.

Energy efficiency considerations cannot be overlooked in industrial applications. Heat recovery systems should be implemented to capture and reuse thermal energy from exothermic exchange reactions, significantly reducing operational costs in large-scale facilities. Complementary to this, waste management protocols must be established to handle spent solutions and regeneration effluents, particularly important given increasingly stringent environmental regulations in the chemical processing industry.

Process intensification techniques offer promising avenues for improving exchange efficiency at scale. These include the use of structured packing materials with enhanced surface area, ultrasonic assistance to disrupt boundary layers, and pulsed flow regimes to improve mass transfer. Such innovations can increase throughput by 30-45% compared to conventional fixed-bed systems while maintaining exchange quality.

Quality control becomes exponentially more complex at industrial scale. Automated sampling systems coupled with rapid analytical techniques such as in-line conductivity measurements and spectroscopic methods are essential for maintaining consistent product specifications. These systems should be calibrated to detect variations in lithium concentration with precision of ±0.5% to ensure product uniformity across production batches.

Economic viability ultimately determines industrial implementation success. Capital expenditure for lithium acetate ion exchange facilities must be balanced against operational efficiency gains, with typical ROI periods ranging from 3-5 years for optimized systems. Market volatility for lithium compounds further necessitates flexible production capabilities that can adapt to changing demand patterns while maintaining exchange rate efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!