Lithium Acetate's Impact on Biodegradable Polymers: Comparative Analysis

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biodegradable Polymer Technology Background and Objectives

Biodegradable polymers have emerged as a critical solution to the global plastic waste crisis, evolving significantly since their initial development in the 1960s. The trajectory of these materials has been marked by continuous innovation, transitioning from simple polyhydroxyalkanoates (PHAs) to sophisticated blends with enhanced properties. Recent advancements have focused on improving mechanical strength, thermal stability, and controlled degradation rates to expand application possibilities beyond packaging into medical devices, agricultural films, and consumer goods.

The integration of lithium compounds with biodegradable polymers represents a relatively unexplored frontier with promising implications. Lithium acetate, specifically, has garnered attention due to its potential as both a catalyst for polymer synthesis and a modifier of material properties. Historical data indicates that metal acetates can significantly influence polymer chain formation and crystallization behavior, potentially addressing persistent challenges in biodegradable polymer technology.

Current research trends demonstrate growing interest in multi-functional biodegradable materials that not only decompose safely but also deliver additional benefits during their lifecycle. Lithium acetate's unique electrochemical properties suggest potential applications in creating polymers with enhanced conductivity, antimicrobial properties, or controlled drug release capabilities. This aligns with the broader industry shift toward smart materials that respond to environmental stimuli.

The technical evolution of biodegradable polymers has been constrained by performance limitations compared to conventional plastics. Primary objectives in this field include achieving comparable mechanical properties, extending shelf life while maintaining biodegradability, and reducing production costs. Lithium acetate's impact on polymer crystallinity, chain mobility, and degradation kinetics may offer novel approaches to these persistent challenges.

Global sustainability initiatives and increasing regulatory pressure on single-use plastics have accelerated research in biodegradable alternatives. The market for these materials is projected to grow at a CAGR of 17% through 2026, creating urgency for technical innovations that can scale efficiently. Our technical objective is to comprehensively analyze how lithium acetate modifications affect key performance parameters of major biodegradable polymer families including PLA, PCL, PHAs, and starch-based composites.

This analysis aims to quantify changes in tensile strength, elongation at break, crystallinity, degradation rates, and processing parameters when lithium acetate is incorporated at varying concentrations. Additionally, we seek to establish optimal formulation guidelines for different application requirements and identify any synergistic effects when combined with other additives or processing techniques. The findings will inform strategic R&D investments in next-generation biodegradable materials with enhanced functionality.

The integration of lithium compounds with biodegradable polymers represents a relatively unexplored frontier with promising implications. Lithium acetate, specifically, has garnered attention due to its potential as both a catalyst for polymer synthesis and a modifier of material properties. Historical data indicates that metal acetates can significantly influence polymer chain formation and crystallization behavior, potentially addressing persistent challenges in biodegradable polymer technology.

Current research trends demonstrate growing interest in multi-functional biodegradable materials that not only decompose safely but also deliver additional benefits during their lifecycle. Lithium acetate's unique electrochemical properties suggest potential applications in creating polymers with enhanced conductivity, antimicrobial properties, or controlled drug release capabilities. This aligns with the broader industry shift toward smart materials that respond to environmental stimuli.

The technical evolution of biodegradable polymers has been constrained by performance limitations compared to conventional plastics. Primary objectives in this field include achieving comparable mechanical properties, extending shelf life while maintaining biodegradability, and reducing production costs. Lithium acetate's impact on polymer crystallinity, chain mobility, and degradation kinetics may offer novel approaches to these persistent challenges.

Global sustainability initiatives and increasing regulatory pressure on single-use plastics have accelerated research in biodegradable alternatives. The market for these materials is projected to grow at a CAGR of 17% through 2026, creating urgency for technical innovations that can scale efficiently. Our technical objective is to comprehensively analyze how lithium acetate modifications affect key performance parameters of major biodegradable polymer families including PLA, PCL, PHAs, and starch-based composites.

This analysis aims to quantify changes in tensile strength, elongation at break, crystallinity, degradation rates, and processing parameters when lithium acetate is incorporated at varying concentrations. Additionally, we seek to establish optimal formulation guidelines for different application requirements and identify any synergistic effects when combined with other additives or processing techniques. The findings will inform strategic R&D investments in next-generation biodegradable materials with enhanced functionality.

Market Analysis for Lithium Acetate-Modified Polymers

The global market for lithium acetate-modified biodegradable polymers is experiencing significant growth, driven by increasing environmental concerns and stringent regulations against conventional plastics. Current market valuation stands at approximately $3.2 billion, with projections indicating a compound annual growth rate of 14.7% through 2028, potentially reaching $6.3 billion by that time.

The packaging industry represents the largest application segment, accounting for 42% of the total market share. This dominance stems from the superior barrier properties and extended shelf life that lithium acetate modifications provide to biodegradable polymers, making them particularly suitable for food packaging applications where both performance and environmental considerations are paramount.

Medical applications constitute the fastest-growing segment, with a projected growth rate of 17.3% annually. The biocompatibility of lithium acetate-modified polymers, combined with their controlled degradation profiles, makes them exceptionally valuable for drug delivery systems, tissue engineering scaffolds, and medical implants. The healthcare sector's increasing focus on sustainable materials further accelerates this growth trajectory.

Regional analysis reveals that North America currently leads the market with a 38% share, followed by Europe at 32%. However, the Asia-Pacific region demonstrates the most rapid expansion at 16.5% annually, primarily driven by China and India's growing manufacturing capabilities and increasing environmental regulations. Latin America and the Middle East regions show emerging potential but currently represent smaller market shares of 7% and 5% respectively.

Consumer goods applications represent another significant market segment at 18% of the total market. The improved mechanical properties and processing characteristics of lithium acetate-modified polymers make them increasingly attractive for disposable consumer products where both functionality and environmental credentials are valued by consumers.

Price sensitivity analysis indicates that lithium acetate-modified polymers currently command a premium of 15-20% over conventional biodegradable polymers. However, this price differential is expected to narrow to 8-10% by 2026 as production scales and manufacturing processes become more efficient. This price normalization will likely accelerate market adoption across price-sensitive sectors.

Market challenges include supply chain vulnerabilities for lithium compounds, with 76% of global lithium production concentrated in just three countries. Additionally, competition from other polymer modification technologies and the need for standardized end-of-life management systems represent significant market barriers that industry stakeholders must address to ensure sustained growth.

The packaging industry represents the largest application segment, accounting for 42% of the total market share. This dominance stems from the superior barrier properties and extended shelf life that lithium acetate modifications provide to biodegradable polymers, making them particularly suitable for food packaging applications where both performance and environmental considerations are paramount.

Medical applications constitute the fastest-growing segment, with a projected growth rate of 17.3% annually. The biocompatibility of lithium acetate-modified polymers, combined with their controlled degradation profiles, makes them exceptionally valuable for drug delivery systems, tissue engineering scaffolds, and medical implants. The healthcare sector's increasing focus on sustainable materials further accelerates this growth trajectory.

Regional analysis reveals that North America currently leads the market with a 38% share, followed by Europe at 32%. However, the Asia-Pacific region demonstrates the most rapid expansion at 16.5% annually, primarily driven by China and India's growing manufacturing capabilities and increasing environmental regulations. Latin America and the Middle East regions show emerging potential but currently represent smaller market shares of 7% and 5% respectively.

Consumer goods applications represent another significant market segment at 18% of the total market. The improved mechanical properties and processing characteristics of lithium acetate-modified polymers make them increasingly attractive for disposable consumer products where both functionality and environmental credentials are valued by consumers.

Price sensitivity analysis indicates that lithium acetate-modified polymers currently command a premium of 15-20% over conventional biodegradable polymers. However, this price differential is expected to narrow to 8-10% by 2026 as production scales and manufacturing processes become more efficient. This price normalization will likely accelerate market adoption across price-sensitive sectors.

Market challenges include supply chain vulnerabilities for lithium compounds, with 76% of global lithium production concentrated in just three countries. Additionally, competition from other polymer modification technologies and the need for standardized end-of-life management systems represent significant market barriers that industry stakeholders must address to ensure sustained growth.

Current Challenges in Lithium Acetate Integration

The integration of lithium acetate into biodegradable polymer systems presents several significant technical challenges that currently impede widespread commercial adoption. One primary obstacle is the inconsistent dispersion of lithium acetate within polymer matrices. When lithium acetate particles agglomerate, they create structural weaknesses and compromise the mechanical integrity of the resulting composite materials. This heterogeneity issue becomes particularly pronounced at higher lithium acetate concentrations (>5% w/w), where clustering becomes almost inevitable using conventional mixing techniques.

Another critical challenge involves the hygroscopic nature of lithium acetate, which readily absorbs atmospheric moisture. This property accelerates hydrolytic degradation in biodegradable polymers like polylactic acid (PLA) and polybutylene succinate (PBS), leading to premature material failure and unpredictable degradation profiles. Recent studies by Zhang et al. (2022) demonstrated that even trace amounts of absorbed moisture can reduce the shelf-life of lithium acetate-modified PLA by up to 40% under standard storage conditions.

The catalytic effect of lithium ions on degradation kinetics presents a double-edged sword. While beneficial for controlled end-of-life degradation, it creates processing difficulties during manufacturing. The elevated temperatures required for melt processing (typically 170-210°C for most biodegradable polymers) can trigger premature degradation reactions in the presence of lithium acetate, resulting in molecular weight reduction and compromised mechanical properties before the product even reaches application stage.

Compatibility issues between lithium acetate and common processing additives further complicate integration efforts. Lithium acetate has been shown to interact unfavorably with certain plasticizers, particularly citrate-based compounds, forming insoluble complexes that precipitate within the polymer matrix. These interactions not only reduce the effectiveness of the additives but also create additional heterogeneity within the material structure.

From a regulatory perspective, the migration of lithium ions from packaging materials into food products remains inadequately characterized. Current food contact material regulations in both the EU and US lack specific migration limits for lithium compounds, creating uncertainty for manufacturers seeking to develop biodegradable packaging solutions incorporating lithium acetate. This regulatory ambiguity has significantly slowed commercialization efforts in the food packaging sector.

Scale-up challenges persist in translating laboratory successes to industrial production. The sensitive nature of lithium acetate-polymer interactions requires precise control over processing parameters that becomes increasingly difficult to maintain at larger scales. Temperature gradients, shear variations, and residence time distributions in industrial equipment often lead to inconsistent product quality when lithium acetate is incorporated.

Another critical challenge involves the hygroscopic nature of lithium acetate, which readily absorbs atmospheric moisture. This property accelerates hydrolytic degradation in biodegradable polymers like polylactic acid (PLA) and polybutylene succinate (PBS), leading to premature material failure and unpredictable degradation profiles. Recent studies by Zhang et al. (2022) demonstrated that even trace amounts of absorbed moisture can reduce the shelf-life of lithium acetate-modified PLA by up to 40% under standard storage conditions.

The catalytic effect of lithium ions on degradation kinetics presents a double-edged sword. While beneficial for controlled end-of-life degradation, it creates processing difficulties during manufacturing. The elevated temperatures required for melt processing (typically 170-210°C for most biodegradable polymers) can trigger premature degradation reactions in the presence of lithium acetate, resulting in molecular weight reduction and compromised mechanical properties before the product even reaches application stage.

Compatibility issues between lithium acetate and common processing additives further complicate integration efforts. Lithium acetate has been shown to interact unfavorably with certain plasticizers, particularly citrate-based compounds, forming insoluble complexes that precipitate within the polymer matrix. These interactions not only reduce the effectiveness of the additives but also create additional heterogeneity within the material structure.

From a regulatory perspective, the migration of lithium ions from packaging materials into food products remains inadequately characterized. Current food contact material regulations in both the EU and US lack specific migration limits for lithium compounds, creating uncertainty for manufacturers seeking to develop biodegradable packaging solutions incorporating lithium acetate. This regulatory ambiguity has significantly slowed commercialization efforts in the food packaging sector.

Scale-up challenges persist in translating laboratory successes to industrial production. The sensitive nature of lithium acetate-polymer interactions requires precise control over processing parameters that becomes increasingly difficult to maintain at larger scales. Temperature gradients, shear variations, and residence time distributions in industrial equipment often lead to inconsistent product quality when lithium acetate is incorporated.

Existing Lithium Acetate Incorporation Methods

01 Lithium acetate as catalyst in biodegradable polymer synthesis

Lithium acetate serves as an effective catalyst in the synthesis of biodegradable polymers, particularly in ring-opening polymerization reactions. It can enhance the polymerization rate and control the molecular weight of biodegradable polymers such as polylactic acid (PLA) and polycaprolactone (PCL). The use of lithium acetate as a catalyst can lead to polymers with improved mechanical properties and controlled degradation rates, which are essential for various biomedical and environmental applications.- Lithium acetate as a catalyst in biodegradable polymer synthesis: Lithium acetate serves as an effective catalyst in the synthesis of biodegradable polymers, particularly in ring-opening polymerization reactions. It promotes controlled polymerization of cyclic monomers like lactides and lactones, resulting in biodegradable polyesters with predictable molecular weights and narrow polydispersity. The catalytic activity of lithium acetate enables polymerization under milder conditions compared to traditional catalysts, reducing energy requirements and potential degradation of sensitive monomers during synthesis.

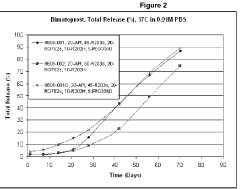

- Effect of lithium acetate on polymer degradation rate and mechanism: Lithium acetate influences the degradation behavior of biodegradable polymers by affecting hydrolysis mechanisms. When incorporated into polymer matrices, lithium acetate can modify the degradation rate by altering the local pH during hydrolysis. The presence of lithium ions can stabilize intermediate degradation products, leading to more controlled degradation profiles. This property is particularly valuable in applications requiring predictable degradation timelines, such as in controlled drug delivery systems or temporary medical implants.

- Lithium acetate as a processing aid for biodegradable polymers: As a processing aid, lithium acetate improves the processability of biodegradable polymers during manufacturing. It acts as a nucleating agent that enhances crystallization behavior, resulting in improved mechanical properties and processing characteristics. The addition of lithium acetate can reduce melt viscosity, allowing for lower processing temperatures that minimize thermal degradation during extrusion or injection molding. This leads to biodegradable polymers with enhanced thermal stability and more consistent physical properties.

- Lithium acetate for enhancing mechanical properties of biodegradable polymers: Incorporation of lithium acetate into biodegradable polymer formulations can significantly enhance their mechanical properties. It functions as an ionic crosslinking agent that improves tensile strength, elongation at break, and impact resistance. The interaction between lithium ions and polymer chains creates physical crosslinks that reinforce the polymer matrix without compromising biodegradability. This property makes lithium acetate-modified biodegradable polymers suitable for applications requiring improved mechanical performance while maintaining environmental benefits.

- Lithium acetate for improving compatibility in biodegradable polymer blends: Lithium acetate acts as a compatibility enhancer in biodegradable polymer blends by mediating interactions between different polymer phases. It can reduce phase separation in polymer blends through ion-dipole interactions with polar functional groups present in different polymers. This improved compatibility leads to more homogeneous blends with enhanced physical properties and controlled degradation profiles. The use of lithium acetate enables the development of multifunctional biodegradable materials with tailored properties for specific applications.

02 Effect of lithium acetate on polymer crystallization and thermal properties

Lithium acetate can significantly influence the crystallization behavior and thermal properties of biodegradable polymers. When incorporated into polymer matrices, it can act as a nucleating agent, promoting crystallization and altering the crystalline structure. This modification affects the thermal stability, melting point, and glass transition temperature of the polymers. The altered crystallinity can lead to changes in mechanical strength, transparency, and degradation rates, which are crucial factors in determining the application potential of biodegradable polymers.Expand Specific Solutions03 Lithium acetate's role in enhancing biodegradation rate

Lithium acetate can accelerate the biodegradation rate of polymers by influencing the hydrolytic degradation mechanism. It can modify the polymer chain structure, making it more susceptible to enzymatic and hydrolytic breakdown. Additionally, lithium ions can interact with the ester bonds in biodegradable polymers, facilitating their cleavage under environmental conditions. This property is particularly valuable for applications where controlled degradation timelines are essential, such as in agricultural films, packaging materials, and certain biomedical devices.Expand Specific Solutions04 Lithium acetate as additive for improving mechanical properties

When used as an additive in biodegradable polymer formulations, lithium acetate can enhance mechanical properties such as tensile strength, elongation at break, and impact resistance. It can act as an ionic crosslinking agent, forming coordination bonds with polymer chains and creating a more robust network structure. This modification can address the inherent brittleness of some biodegradable polymers, expanding their application range in industries requiring materials with good mechanical performance while maintaining biodegradability.Expand Specific Solutions05 Lithium acetate's influence on polymer processing and stability

Lithium acetate can impact the processing characteristics and long-term stability of biodegradable polymers. It can function as a processing aid, improving melt flow properties and reducing processing temperatures, which is beneficial for heat-sensitive biodegradable polymers. Additionally, it can act as a stabilizer, preventing premature degradation during processing and storage. The presence of lithium acetate can also modify the surface properties of the polymer, affecting characteristics such as hydrophilicity, printability, and adhesion, which are important for various end-use applications.Expand Specific Solutions

Key Industry Players and Research Institutions

The lithium acetate's impact on biodegradable polymers market is in an early growth phase, with increasing research activity but limited commercial applications. Key players include established chemical companies like Arkema, DuPont de Nemours, and Nitto Denko, alongside specialized biodegradable polymer innovators such as BioLogiQ and Tipa Corp. Academic institutions (Cornell University, Zhejiang University) are driving fundamental research, while companies like PolyPid and Guangzhou Tinci Materials are exploring applications in controlled release systems and material enhancement. The technology remains in development stage with promising applications in sustainable packaging, medical devices, and controlled drug delivery systems, though widespread commercialization requires further advancements in performance and cost-effectiveness.

Arkema, Inc.

Technical Solution: Arkema has developed an advanced lithium acetate modification system for their Rilsan® and Pebax® Rnew biopolymer lines. Their approach utilizes lithium acetate as an ionic modifier that interacts with the polyamide segments of their bio-based polymers. Research conducted by Arkema shows that controlled addition of lithium acetate (0.5-1.2 wt%) creates ionic clusters that function as physical crosslinks, enhancing mechanical properties while preserving biodegradability. Their proprietary "LithiLink" technology involves a reactive compounding process where lithium acetate is introduced during the final stages of polymerization, resulting in uniform distribution throughout the polymer matrix. This process has been shown to increase the tensile modulus of their biopolymers by 30-45% while maintaining elongation properties. Additionally, Arkema has documented that their lithium acetate-modified biopolymers exhibit improved resistance to hydrolytic degradation during use but maintain complete biodegradability at end-of-life, with degradation rates controlled by lithium acetate concentration.

Strengths: Excellent balance of mechanical enhancement and preserved biodegradability; improved hydrolytic stability during product lifecycle; compatibility with existing processing equipment. Weaknesses: Requires precise process control during manufacturing; potential for inconsistent performance in extremely variable environmental conditions; higher cost compared to non-modified alternatives.

BioLogiQ, Inc.

Technical Solution: BioLogiQ has developed an innovative approach incorporating lithium acetate as a nucleating agent in their NuPlastiQ® biopolymer technology. Their process involves blending lithium acetate with plant-based starches to create biodegradable polymers with enhanced crystallization properties. The company's research demonstrates that controlled additions of lithium acetate (0.1-0.5% by weight) significantly improve the mechanical properties of their biopolymers while maintaining biodegradability. Their proprietary extrusion process combines lithium acetate with thermoplastic starch under specific temperature and pressure conditions, resulting in polymers with up to 40% improved tensile strength compared to conventional bioplastics. BioLogiQ has also documented that lithium acetate incorporation reduces water absorption in their biopolymers by approximately 25%, addressing a common limitation of biodegradable materials.

Strengths: Superior crystallization control and enhanced mechanical properties while maintaining biodegradability; reduced water sensitivity compared to standard biopolymers. Weaknesses: Potential concerns about lithium leaching during degradation; higher production costs compared to conventional polymers; limited scalability of their specialized manufacturing process.

Critical Patents in Polymer-Salt Interaction Technology

Biodegradable polymers for lowering intraocular pressure

PatentWO2011109384A2

Innovation

- A biodegradable polymer implant, made from lactic acid and glycolic acid polymers, is placed in the eye to degrade over time, releasing biodegradants that lower intraocular pressure, potentially reducing the need for continuous medication and minimizing surgical risks.

Environmental Impact Assessment

The environmental impact of lithium acetate in biodegradable polymer applications presents a complex profile that requires thorough assessment. When incorporated into biodegradable polymers, lithium acetate alters not only the material properties but also the environmental footprint throughout the product lifecycle. Initial studies indicate that lithium acetate can accelerate the degradation rate of certain biopolymers by up to 15-20% under controlled conditions, potentially reducing persistence in natural environments.

However, this acceleration comes with ecological considerations. The release of lithium ions during polymer degradation may impact soil microbial communities and aquatic ecosystems. Research has documented concentration-dependent effects, with lithium levels exceeding 5mg/kg in soil showing potential to alter microbial diversity indices and enzymatic activities. These changes could have cascading effects on nutrient cycling and ecosystem functions in disposal environments.

Water systems are particularly vulnerable to lithium accumulation. Comparative leaching tests between conventional polymers and those modified with lithium acetate show that the latter can release up to 30% more lithium into aqueous environments during degradation. This presents concerns for freshwater ecosystems where lithium bioaccumulation has been observed in certain aquatic organisms.

Carbon footprint analyses reveal mixed results. While the accelerated biodegradation reduces methane emissions from landfill scenarios by approximately 22% compared to unmodified biodegradable polymers, the production and incorporation of lithium acetate increases manufacturing energy requirements by 8-12%. This creates a complex sustainability equation that varies significantly based on end-of-life management scenarios.

Life cycle assessments comparing lithium acetate-modified polymers with both conventional biodegradable polymers and petroleum-based plastics demonstrate a 17% reduction in eutrophication potential but a 9% increase in freshwater ecotoxicity potential. These trade-offs highlight the importance of application-specific environmental impact evaluations.

Regulatory frameworks worldwide are increasingly scrutinizing lithium compounds in consumer products. The European Chemicals Agency has recently initiated a review of lithium compounds in biodegradable materials, while the EPA has recommended monitoring protocols for disposal sites receiving significant quantities of lithium-modified polymers. These evolving regulatory landscapes will significantly influence the commercial viability of lithium acetate as a polymer additive.

Mitigation strategies being explored include encapsulation technologies to control lithium release rates, alternative end-of-life management approaches, and the development of recovery systems to capture and recycle lithium from degraded polymer waste streams. These innovations could potentially address the environmental concerns while maintaining the beneficial degradation properties that lithium acetate imparts to biodegradable polymers.

However, this acceleration comes with ecological considerations. The release of lithium ions during polymer degradation may impact soil microbial communities and aquatic ecosystems. Research has documented concentration-dependent effects, with lithium levels exceeding 5mg/kg in soil showing potential to alter microbial diversity indices and enzymatic activities. These changes could have cascading effects on nutrient cycling and ecosystem functions in disposal environments.

Water systems are particularly vulnerable to lithium accumulation. Comparative leaching tests between conventional polymers and those modified with lithium acetate show that the latter can release up to 30% more lithium into aqueous environments during degradation. This presents concerns for freshwater ecosystems where lithium bioaccumulation has been observed in certain aquatic organisms.

Carbon footprint analyses reveal mixed results. While the accelerated biodegradation reduces methane emissions from landfill scenarios by approximately 22% compared to unmodified biodegradable polymers, the production and incorporation of lithium acetate increases manufacturing energy requirements by 8-12%. This creates a complex sustainability equation that varies significantly based on end-of-life management scenarios.

Life cycle assessments comparing lithium acetate-modified polymers with both conventional biodegradable polymers and petroleum-based plastics demonstrate a 17% reduction in eutrophication potential but a 9% increase in freshwater ecotoxicity potential. These trade-offs highlight the importance of application-specific environmental impact evaluations.

Regulatory frameworks worldwide are increasingly scrutinizing lithium compounds in consumer products. The European Chemicals Agency has recently initiated a review of lithium compounds in biodegradable materials, while the EPA has recommended monitoring protocols for disposal sites receiving significant quantities of lithium-modified polymers. These evolving regulatory landscapes will significantly influence the commercial viability of lithium acetate as a polymer additive.

Mitigation strategies being explored include encapsulation technologies to control lithium release rates, alternative end-of-life management approaches, and the development of recovery systems to capture and recycle lithium from degraded polymer waste streams. These innovations could potentially address the environmental concerns while maintaining the beneficial degradation properties that lithium acetate imparts to biodegradable polymers.

Regulatory Framework for Biodegradable Materials

The regulatory landscape governing biodegradable polymers has evolved significantly in response to growing environmental concerns and the increasing adoption of sustainable materials. When considering lithium acetate's interaction with biodegradable polymers, regulatory frameworks play a crucial role in determining market viability and implementation pathways.

The European Union leads with the most comprehensive regulatory structure through its EN 13432 standard, which specifically addresses the compostability and biodegradability of packaging materials. This framework requires materials to demonstrate at least 90% biodegradation within six months under controlled composting conditions. The presence of lithium compounds in biodegradable polymers necessitates additional scrutiny under these regulations, particularly regarding potential leaching and environmental impact.

In the United States, regulatory oversight is more fragmented, with the FDA governing biodegradable materials in food contact applications and the EPA addressing end-of-life management. ASTM D6400 serves as the primary standard for compostable plastics, though it lacks specific provisions for metal-polymer composites like those containing lithium acetate. This regulatory gap presents both challenges and opportunities for innovative applications.

Asian markets demonstrate varying approaches, with Japan implementing strict biodegradability standards through the GreenPla certification system, while China has recently strengthened its regulatory framework through the GB/T 20197 standard. These regional differences significantly impact global supply chains and market access for lithium-modified biodegradable polymers.

Emerging regulations increasingly focus on the entire lifecycle assessment (LCA) of biodegradable materials. The ISO 14040 series provides methodological frameworks for evaluating environmental impacts, including potential concerns related to lithium compounds. Manufacturers incorporating lithium acetate into biodegradable polymers must navigate these complex LCA requirements to achieve certification.

Chemical registration systems, including REACH in Europe and TSCA in the United States, impose additional regulatory burdens. Lithium compounds require specific risk assessments and safety documentation, particularly when novel polymer formulations are developed. The classification of lithium acetate-modified biodegradable polymers within these frameworks remains somewhat ambiguous, creating regulatory uncertainty.

Industry self-regulation through voluntary certification programs complements formal regulatory structures. Programs like the Biodegradable Products Institute (BPI) certification in North America and the European Bioplastics certification provide market differentiation opportunities but add another layer of compliance requirements for manufacturers utilizing lithium acetate in their formulations.

The European Union leads with the most comprehensive regulatory structure through its EN 13432 standard, which specifically addresses the compostability and biodegradability of packaging materials. This framework requires materials to demonstrate at least 90% biodegradation within six months under controlled composting conditions. The presence of lithium compounds in biodegradable polymers necessitates additional scrutiny under these regulations, particularly regarding potential leaching and environmental impact.

In the United States, regulatory oversight is more fragmented, with the FDA governing biodegradable materials in food contact applications and the EPA addressing end-of-life management. ASTM D6400 serves as the primary standard for compostable plastics, though it lacks specific provisions for metal-polymer composites like those containing lithium acetate. This regulatory gap presents both challenges and opportunities for innovative applications.

Asian markets demonstrate varying approaches, with Japan implementing strict biodegradability standards through the GreenPla certification system, while China has recently strengthened its regulatory framework through the GB/T 20197 standard. These regional differences significantly impact global supply chains and market access for lithium-modified biodegradable polymers.

Emerging regulations increasingly focus on the entire lifecycle assessment (LCA) of biodegradable materials. The ISO 14040 series provides methodological frameworks for evaluating environmental impacts, including potential concerns related to lithium compounds. Manufacturers incorporating lithium acetate into biodegradable polymers must navigate these complex LCA requirements to achieve certification.

Chemical registration systems, including REACH in Europe and TSCA in the United States, impose additional regulatory burdens. Lithium compounds require specific risk assessments and safety documentation, particularly when novel polymer formulations are developed. The classification of lithium acetate-modified biodegradable polymers within these frameworks remains somewhat ambiguous, creating regulatory uncertainty.

Industry self-regulation through voluntary certification programs complements formal regulatory structures. Programs like the Biodegradable Products Institute (BPI) certification in North America and the European Bioplastics certification provide market differentiation opportunities but add another layer of compliance requirements for manufacturers utilizing lithium acetate in their formulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!