Comparing Low vs High-Temperature Oleoresin Curing

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Oleoresin Curing Technology Background and Objectives

Oleoresin curing technology has evolved significantly over the past several decades, transitioning from traditional methods to more sophisticated processes that enhance product quality and efficiency. The fundamental distinction between low and high-temperature curing represents a critical technological divergence that has shaped the industry's development trajectory. Low-temperature curing, typically conducted below 150°C, emerged in the early 1960s as the standard approach for processing pine and other coniferous tree resins into usable industrial materials.

The evolution toward high-temperature curing processes began in the late 1980s, driven by increasing demands for faster production cycles and improved product characteristics. High-temperature curing, generally performed at 150-250°C, represented a paradigm shift in oleoresin processing technology, enabling significant reductions in curing time while potentially altering the chemical composition and properties of the final products.

Current technological trends indicate a growing interest in hybrid curing systems that combine elements of both temperature ranges to optimize specific product attributes. The industry is witnessing increased research into precision temperature control mechanisms that allow for programmed temperature profiles throughout the curing process, enabling manufacturers to target specific molecular transformations at different stages.

The primary objective of comparing low versus high-temperature oleoresin curing is to establish comprehensive performance metrics across multiple dimensions: energy efficiency, product quality consistency, throughput capacity, and environmental impact. This comparison aims to identify optimal processing parameters for different oleoresin types and end-product applications, recognizing that temperature selection significantly influences chemical reactions, volatile compound retention, and polymerization processes.

Secondary objectives include quantifying the relationship between curing temperature and key product characteristics such as color stability, adhesion properties, viscosity, and resistance to environmental degradation. Understanding these correlations will enable more precise process control and product customization to meet diverse market requirements.

Long-term technological goals in this field include developing intelligent curing systems with real-time monitoring capabilities that can dynamically adjust temperature profiles based on feedback from in-process measurements. Additionally, the industry seeks to establish standardized testing methodologies for comparing products processed at different temperature ranges, facilitating more objective quality assessment and regulatory compliance.

The advancement of oleoresin curing technology intersects with broader sustainability initiatives, creating additional objectives around reducing energy consumption, minimizing emissions, and exploring bio-based alternatives to traditional curing catalysts and additives. These environmental considerations are increasingly influencing technological development pathways in the industry.

The evolution toward high-temperature curing processes began in the late 1980s, driven by increasing demands for faster production cycles and improved product characteristics. High-temperature curing, generally performed at 150-250°C, represented a paradigm shift in oleoresin processing technology, enabling significant reductions in curing time while potentially altering the chemical composition and properties of the final products.

Current technological trends indicate a growing interest in hybrid curing systems that combine elements of both temperature ranges to optimize specific product attributes. The industry is witnessing increased research into precision temperature control mechanisms that allow for programmed temperature profiles throughout the curing process, enabling manufacturers to target specific molecular transformations at different stages.

The primary objective of comparing low versus high-temperature oleoresin curing is to establish comprehensive performance metrics across multiple dimensions: energy efficiency, product quality consistency, throughput capacity, and environmental impact. This comparison aims to identify optimal processing parameters for different oleoresin types and end-product applications, recognizing that temperature selection significantly influences chemical reactions, volatile compound retention, and polymerization processes.

Secondary objectives include quantifying the relationship between curing temperature and key product characteristics such as color stability, adhesion properties, viscosity, and resistance to environmental degradation. Understanding these correlations will enable more precise process control and product customization to meet diverse market requirements.

Long-term technological goals in this field include developing intelligent curing systems with real-time monitoring capabilities that can dynamically adjust temperature profiles based on feedback from in-process measurements. Additionally, the industry seeks to establish standardized testing methodologies for comparing products processed at different temperature ranges, facilitating more objective quality assessment and regulatory compliance.

The advancement of oleoresin curing technology intersects with broader sustainability initiatives, creating additional objectives around reducing energy consumption, minimizing emissions, and exploring bio-based alternatives to traditional curing catalysts and additives. These environmental considerations are increasingly influencing technological development pathways in the industry.

Market Analysis of Oleoresin Products and Applications

The global oleoresin market has been experiencing steady growth, valued at approximately $1.7 billion in 2022 and projected to reach $2.3 billion by 2028, with a compound annual growth rate of 5.2%. This growth is primarily driven by increasing demand across various industries including food and beverages, pharmaceuticals, cosmetics, and industrial applications.

The food and beverage sector remains the dominant application area, accounting for over 40% of the total market share. Within this sector, oleoresins are extensively used as natural food colorants, flavoring agents, and preservatives. The shift toward clean-label products and natural ingredients has significantly boosted the demand for oleoresins as alternatives to synthetic additives.

Pharmaceutical applications represent the fastest-growing segment, with a growth rate exceeding 6% annually. This is attributed to the increasing recognition of oleoresins' therapeutic properties and their incorporation into various medicinal formulations, particularly in traditional medicine systems and emerging nutraceutical products.

The market dynamics between low and high-temperature cured oleoresins reveal distinct application preferences. Low-temperature cured oleoresins dominate the premium food segment and pharmaceutical applications due to their superior retention of volatile compounds, better preservation of thermolabile components, and enhanced organoleptic properties. These products command premium pricing, typically 20-30% higher than their high-temperature counterparts.

High-temperature cured oleoresins, conversely, maintain strong market presence in industrial applications, mass-market food products, and certain cosmetic formulations where cost-effectiveness is prioritized over subtle quality differences. The faster production cycle of high-temperature curing also appeals to manufacturers seeking higher production volumes.

Geographically, Asia-Pacific represents the largest market for oleoresins, accounting for approximately 35% of global consumption, followed by Europe and North America. India remains the world's largest producer and exporter of oleoresins, particularly in spice oleoresins, while China leads in consumption growth rates.

Consumer trends indicate increasing preference for sustainably sourced and organically certified oleoresins, with this premium segment growing at twice the rate of conventional oleoresins. Additionally, there is rising demand for oleoresins with standardized active component concentrations, particularly in pharmaceutical and nutraceutical applications where consistency in bioactive compounds is crucial.

The food and beverage sector remains the dominant application area, accounting for over 40% of the total market share. Within this sector, oleoresins are extensively used as natural food colorants, flavoring agents, and preservatives. The shift toward clean-label products and natural ingredients has significantly boosted the demand for oleoresins as alternatives to synthetic additives.

Pharmaceutical applications represent the fastest-growing segment, with a growth rate exceeding 6% annually. This is attributed to the increasing recognition of oleoresins' therapeutic properties and their incorporation into various medicinal formulations, particularly in traditional medicine systems and emerging nutraceutical products.

The market dynamics between low and high-temperature cured oleoresins reveal distinct application preferences. Low-temperature cured oleoresins dominate the premium food segment and pharmaceutical applications due to their superior retention of volatile compounds, better preservation of thermolabile components, and enhanced organoleptic properties. These products command premium pricing, typically 20-30% higher than their high-temperature counterparts.

High-temperature cured oleoresins, conversely, maintain strong market presence in industrial applications, mass-market food products, and certain cosmetic formulations where cost-effectiveness is prioritized over subtle quality differences. The faster production cycle of high-temperature curing also appeals to manufacturers seeking higher production volumes.

Geographically, Asia-Pacific represents the largest market for oleoresins, accounting for approximately 35% of global consumption, followed by Europe and North America. India remains the world's largest producer and exporter of oleoresins, particularly in spice oleoresins, while China leads in consumption growth rates.

Consumer trends indicate increasing preference for sustainably sourced and organically certified oleoresins, with this premium segment growing at twice the rate of conventional oleoresins. Additionally, there is rising demand for oleoresins with standardized active component concentrations, particularly in pharmaceutical and nutraceutical applications where consistency in bioactive compounds is crucial.

Current State and Challenges in Oleoresin Curing Processes

The oleoresin curing process represents a critical phase in various industries, including coatings, adhesives, and composite materials manufacturing. Currently, the global market employs both low-temperature and high-temperature curing methodologies, each with distinct technological characteristics and implementation challenges. Low-temperature curing typically operates below 100°C, while high-temperature processes generally function between 120-200°C or higher depending on specific resin formulations.

Recent technological assessments indicate that low-temperature curing processes have gained significant traction due to energy efficiency considerations and compatibility with temperature-sensitive substrates. However, these systems frequently encounter challenges related to extended curing times, which can range from several hours to days, creating production bottlenecks and increasing manufacturing cycle times. Additionally, low-temperature cured oleoresins often exhibit inferior mechanical properties and chemical resistance compared to their high-temperature counterparts.

High-temperature curing technologies, while more energy-intensive, deliver substantially accelerated curing rates—often reducing processing times by 60-80% compared to low-temperature alternatives. These systems typically achieve superior cross-linking density, resulting in enhanced mechanical strength, chemical resistance, and thermal stability. Nevertheless, the elevated temperature requirements present significant challenges, including higher energy consumption, specialized equipment needs, and potential thermal degradation of certain components.

A notable technical constraint across both methodologies involves achieving uniform curing throughout the material matrix, particularly in thick sections or complex geometries. Temperature gradients can lead to differential curing rates, resulting in internal stresses, warping, and compromised mechanical integrity. This challenge is especially pronounced in high-temperature systems where rapid curing can exacerbate these effects.

Geographically, advanced oleoresin curing technologies are predominantly concentrated in North America, Western Europe, and East Asia, with significant research clusters in Germany, Japan, and the United States. Emerging research centers in China and India are rapidly closing technological gaps through substantial R&D investments and industrial partnerships.

Environmental and regulatory pressures represent another significant challenge, particularly regarding volatile organic compound (VOC) emissions during curing processes. This has accelerated research into water-based formulations and UV-curable systems that can operate at lower temperatures while maintaining performance characteristics.

The integration of digital monitoring and control systems represents a recent technological advancement addressing curing uniformity challenges. Real-time cure monitoring technologies utilizing dielectric analysis, ultrasonic sensing, and infrared spectroscopy are being implemented to optimize curing parameters dynamically, though their widespread adoption remains limited by implementation costs and technical complexity.

Recent technological assessments indicate that low-temperature curing processes have gained significant traction due to energy efficiency considerations and compatibility with temperature-sensitive substrates. However, these systems frequently encounter challenges related to extended curing times, which can range from several hours to days, creating production bottlenecks and increasing manufacturing cycle times. Additionally, low-temperature cured oleoresins often exhibit inferior mechanical properties and chemical resistance compared to their high-temperature counterparts.

High-temperature curing technologies, while more energy-intensive, deliver substantially accelerated curing rates—often reducing processing times by 60-80% compared to low-temperature alternatives. These systems typically achieve superior cross-linking density, resulting in enhanced mechanical strength, chemical resistance, and thermal stability. Nevertheless, the elevated temperature requirements present significant challenges, including higher energy consumption, specialized equipment needs, and potential thermal degradation of certain components.

A notable technical constraint across both methodologies involves achieving uniform curing throughout the material matrix, particularly in thick sections or complex geometries. Temperature gradients can lead to differential curing rates, resulting in internal stresses, warping, and compromised mechanical integrity. This challenge is especially pronounced in high-temperature systems where rapid curing can exacerbate these effects.

Geographically, advanced oleoresin curing technologies are predominantly concentrated in North America, Western Europe, and East Asia, with significant research clusters in Germany, Japan, and the United States. Emerging research centers in China and India are rapidly closing technological gaps through substantial R&D investments and industrial partnerships.

Environmental and regulatory pressures represent another significant challenge, particularly regarding volatile organic compound (VOC) emissions during curing processes. This has accelerated research into water-based formulations and UV-curable systems that can operate at lower temperatures while maintaining performance characteristics.

The integration of digital monitoring and control systems represents a recent technological advancement addressing curing uniformity challenges. Real-time cure monitoring technologies utilizing dielectric analysis, ultrasonic sensing, and infrared spectroscopy are being implemented to optimize curing parameters dynamically, though their widespread adoption remains limited by implementation costs and technical complexity.

Comparative Analysis of Low vs High-Temperature Curing Methods

01 Low temperature curing for oleoresins

Low temperature curing processes for oleoresins help preserve volatile compounds and sensitive bioactive ingredients. This approach typically involves curing at temperatures below 50°C, which minimizes thermal degradation and maintains the natural aroma profiles. Low temperature curing often requires longer processing times but results in higher quality oleoresins with better retention of essential oils and flavor components.- Low temperature curing for oleoresins: Low temperature curing processes for oleoresins help preserve volatile compounds and sensitive bioactive ingredients. This approach typically involves temperatures below 50°C and longer curing times, resulting in better retention of aromatic compounds and essential oils. Low temperature curing is particularly beneficial for oleoresins derived from spices and herbs where flavor profile preservation is critical.

- High temperature curing techniques: High temperature curing of oleoresins accelerates the process and can be advantageous for certain applications. Temperatures typically range from 60-120°C, significantly reducing curing time while promoting polymerization and cross-linking reactions. This method is often employed in industrial settings where processing efficiency is prioritized over preserving volatile compounds, and can result in more stable end products with longer shelf life.

- Temperature-controlled staged curing processes: Staged curing processes involve multiple temperature phases to optimize oleoresin properties. These methods typically begin with lower temperatures to preserve volatile compounds, followed by controlled temperature increases to promote specific chemical reactions. This approach allows for customization of the final product characteristics while balancing preservation of sensitive compounds with desired curing outcomes.

- Effect of curing temperature on oleoresin quality: The curing temperature significantly impacts the quality attributes of oleoresins including color, viscosity, and bioactive compound concentration. Lower temperatures generally preserve more natural characteristics but may result in higher moisture content, while higher temperatures can enhance certain functional properties but potentially degrade heat-sensitive compounds. The optimal curing temperature depends on the specific oleoresin source and intended application.

- Innovative curing technologies for oleoresins: Novel technologies are being developed to improve oleoresin curing processes, including microwave-assisted curing, ultrasonic treatment, and vacuum-based methods. These approaches aim to reduce energy consumption, processing time, and potential degradation of valuable compounds. Some innovations combine temperature control with other parameters such as pressure or electromagnetic fields to achieve superior curing results compared to conventional temperature-only methods.

02 High temperature curing techniques

High temperature curing of oleoresins typically involves temperatures above 70°C, which accelerates the curing process and reduces processing time. This method is often used in industrial applications where throughput is prioritized. While high temperature curing can increase production efficiency, it may lead to some loss of volatile compounds and potential changes in the organoleptic properties of the final oleoresin product.Expand Specific Solutions03 Temperature-controlled curing equipment

Specialized equipment for precise temperature control during oleoresin curing processes enables manufacturers to optimize curing conditions. These systems often include programmable temperature profiles, humidity control, and air circulation features. Advanced curing chambers with multi-zone temperature control allow for gradual temperature transitions, which can be particularly beneficial for heat-sensitive oleoresins and can improve the consistency of the final product.Expand Specific Solutions04 Effect of curing temperature on oleoresin quality

The curing temperature significantly impacts the quality attributes of oleoresins, including color, viscosity, and bioactive compound content. Lower curing temperatures generally preserve more heat-sensitive compounds and result in lighter-colored products with higher bioactivity. Higher temperatures may increase extraction efficiency but can lead to degradation of certain compounds. The optimal curing temperature depends on the specific oleoresin source and the desired characteristics of the final product.Expand Specific Solutions05 Hybrid and staged temperature curing approaches

Hybrid curing methods combine different temperature regimes to optimize both efficiency and quality. These approaches often involve initial low-temperature phases to preserve volatile compounds, followed by controlled higher temperature stages to complete the curing process. Staged temperature profiles can be customized based on the specific oleoresin type and desired end-product characteristics. This balanced approach aims to achieve optimal extraction yields while maintaining the integrity of temperature-sensitive compounds.Expand Specific Solutions

Key Industry Players in Oleoresin Processing

The oleoresin curing technology market is currently in a growth phase, with increasing demand for high-performance coatings across automotive, electronics, and construction sectors. The competition between low and high-temperature curing processes reflects the industry's evolution toward more energy-efficient and environmentally sustainable solutions. Major players like PPG Industries, BASF, and 3M lead innovation in traditional curing methods, while companies such as LG Chem, Kaneka, and Sekisui Chemical are advancing high-temperature technologies offering superior durability and chemical resistance. Asian manufacturers, particularly from Japan and China (Guangdong Komo, FUJIFILM), are rapidly gaining market share by developing proprietary formulations that balance performance with processing efficiency, challenging Western incumbents in this approximately $5 billion global market.

PPG Industries Ohio, Inc.

Technical Solution: PPG Industries has developed a comprehensive oleoresin curing technology that differentiates between low and high-temperature processes. Their low-temperature curing system operates between 80-120°C and utilizes proprietary catalysts to achieve complete crosslinking without thermal degradation. This approach incorporates specialized additives that accelerate polymerization while maintaining resin stability. For high-temperature applications (150-200°C), PPG employs thermally-activated hardeners with controlled reaction kinetics to prevent exothermic runaway. Their dual-cure technology combines UV-initiated and thermal curing mechanisms, allowing for initial network formation at ambient temperatures followed by complete property development during thermal post-cure. This system is particularly valuable for complex composite structures where uniform heat distribution is challenging.

Strengths: Superior control over curing kinetics across temperature ranges; reduced energy consumption for low-temperature systems; excellent adhesion properties in both temperature regimes. Weaknesses: Low-temperature systems typically require longer cure times; specialized catalysts increase formulation costs; some high-temperature formulations may have limited shelf stability.

3M Innovative Properties Co.

Technical Solution: 3M has pioneered a multi-stage oleoresin curing approach that optimizes performance across temperature spectrums. Their low-temperature technology utilizes proprietary latent catalysts that remain dormant until activated at specific threshold temperatures (typically 70-110°C). This enables extended working time followed by rapid cure without requiring high temperatures. The system incorporates phase-change materials that absorb excess exothermic heat, preventing thermal spikes during curing. For high-temperature applications (160-220°C), 3M employs thermally-stable resins with engineered crosslinking agents that achieve optimal network density and mechanical properties. Their hybrid curing technology combines chemical and thermal activation mechanisms, allowing for staged curing processes that minimize internal stresses. 3M's approach includes specialized surface treatments that enhance adhesion regardless of cure temperature, making it particularly suitable for bonding dissimilar materials in electronics and aerospace applications.

Strengths: Exceptional control over cure progression; superior thermal stability of cured products; excellent adhesion to difficult substrates; versatility across multiple application methods. Weaknesses: Complex formulations require precise handling; some low-temperature systems show reduced chemical resistance; higher material costs compared to conventional systems.

Technical Innovations in Oleoresin Curing Patents

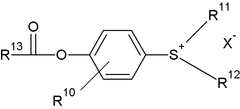

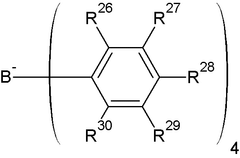

Low temperature curing composition, cured film formed therefrom, and electronic device having cured film

PatentWO2017039159A1

Innovation

- A low-temperature curable composition comprising an epoxy group-containing siloxane compound with specific molecular weight ranges and an epoxy ring-opening reaction cationic thermal initiator, which allows for curing at temperatures below 100°C, providing high mechanical strength, high transmittance, and excellent chemical resistance, and minimizing outgassing and haze.

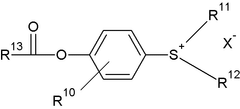

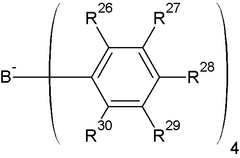

Low-cure powder coatings, related coating method and coated substrates

PatentInactiveEP1792961A1

Innovation

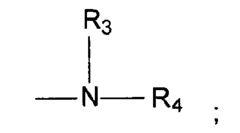

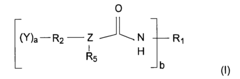

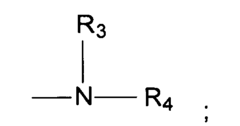

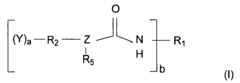

- The use of tertiary aminourea and aminourethane compounds in combination with epoxy-containing or siloxane-containing resins allows for low-temperature curing without the need for crosslinkers or accelerators, enhancing stability and enabling storage at room temperature.

Environmental Impact Assessment of Curing Temperatures

The environmental impact of oleoresin curing temperatures represents a critical consideration in sustainable manufacturing practices. Low-temperature curing processes (typically below 150°C) demonstrate significantly reduced energy consumption compared to high-temperature alternatives (above 200°C), with energy savings potentially reaching 30-45% depending on specific process parameters and equipment efficiency. This energy reduction directly translates to lower greenhouse gas emissions, with studies indicating that high-temperature curing can produce up to 2.5 times more carbon dioxide equivalent emissions per production unit.

Water consumption patterns also differ markedly between these approaches. High-temperature curing typically requires additional cooling systems to manage excess heat, increasing water usage by approximately 20-35% compared to low-temperature alternatives. Furthermore, water discharge from high-temperature processes often contains elevated thermal pollution, potentially disrupting aquatic ecosystems when released into natural water bodies without proper treatment.

Air quality impacts present another environmental dimension worth examining. High-temperature curing generates increased volatile organic compound (VOC) emissions—approximately 15-25% higher than low-temperature processes—due to accelerated chemical reactions and material degradation at elevated temperatures. These emissions contribute to photochemical smog formation and may pose respiratory health risks in manufacturing environments and surrounding communities.

Waste generation profiles differ substantially between the two approaches. High-temperature processes typically experience 10-18% higher material rejection rates due to thermal stress-induced defects, resulting in increased solid waste production. Additionally, the accelerated degradation of equipment components under high-temperature conditions leads to more frequent replacement cycles, generating additional industrial waste streams.

Life cycle assessment (LCA) studies comparing these processes reveal that low-temperature curing generally demonstrates superior environmental performance across multiple impact categories, including global warming potential, acidification potential, and resource depletion. However, these advantages must be balanced against potential trade-offs in curing time and certain performance characteristics of the final product.

Regulatory compliance considerations increasingly favor low-temperature processes as environmental standards become more stringent worldwide. Many jurisdictions have implemented carbon pricing mechanisms, emissions caps, and energy efficiency requirements that economically disadvantage high-temperature manufacturing processes. Forward-thinking manufacturers are proactively transitioning to lower-temperature alternatives to mitigate regulatory risks and position themselves advantageously in increasingly environmentally conscious markets.

Water consumption patterns also differ markedly between these approaches. High-temperature curing typically requires additional cooling systems to manage excess heat, increasing water usage by approximately 20-35% compared to low-temperature alternatives. Furthermore, water discharge from high-temperature processes often contains elevated thermal pollution, potentially disrupting aquatic ecosystems when released into natural water bodies without proper treatment.

Air quality impacts present another environmental dimension worth examining. High-temperature curing generates increased volatile organic compound (VOC) emissions—approximately 15-25% higher than low-temperature processes—due to accelerated chemical reactions and material degradation at elevated temperatures. These emissions contribute to photochemical smog formation and may pose respiratory health risks in manufacturing environments and surrounding communities.

Waste generation profiles differ substantially between the two approaches. High-temperature processes typically experience 10-18% higher material rejection rates due to thermal stress-induced defects, resulting in increased solid waste production. Additionally, the accelerated degradation of equipment components under high-temperature conditions leads to more frequent replacement cycles, generating additional industrial waste streams.

Life cycle assessment (LCA) studies comparing these processes reveal that low-temperature curing generally demonstrates superior environmental performance across multiple impact categories, including global warming potential, acidification potential, and resource depletion. However, these advantages must be balanced against potential trade-offs in curing time and certain performance characteristics of the final product.

Regulatory compliance considerations increasingly favor low-temperature processes as environmental standards become more stringent worldwide. Many jurisdictions have implemented carbon pricing mechanisms, emissions caps, and energy efficiency requirements that economically disadvantage high-temperature manufacturing processes. Forward-thinking manufacturers are proactively transitioning to lower-temperature alternatives to mitigate regulatory risks and position themselves advantageously in increasingly environmentally conscious markets.

Quality Control Standards for Cured Oleoresin Products

Quality control standards for cured oleoresin products must address the significant differences between low and high-temperature curing processes. The temperature regime during curing fundamentally alters the chemical composition, physical properties, and overall quality of the final product, necessitating distinct quality parameters for each method.

For low-temperature cured oleoresins (typically below 100°C), quality standards focus on moisture content (optimally below 3%), volatile compound retention (minimum 85% of original terpenes), color consistency (measured via spectrophotometric analysis), and viscosity ranges appropriate for intended applications. These products generally maintain higher levels of essential oils and aromatic compounds, requiring standards that verify these valuable components remain intact.

High-temperature cured oleoresins (above 150°C) require different quality metrics, including polymerization degree (typically 65-80%), hardness measurements (Shore D scale), thermal stability testing (resistance to degradation at elevated temperatures), and reduced volatile organic compound (VOC) emissions. The accelerated chemical reactions at higher temperatures create more stable but less aromatic products, necessitating verification of complete reaction progression.

Both curing methods require standardized testing for contaminants, with maximum allowable limits for heavy metals (lead <5ppm, arsenic <2ppm), microbial content (total plate count <1000 CFU/g), and foreign matter (<0.5% by weight). However, high-temperature cured products typically have more stringent microbial standards due to the sterilizing effect of elevated temperatures.

Shelf-life stability testing protocols differ significantly between the two product types. Low-temperature cured oleoresins require accelerated oxidation testing and monitoring of essential oil degradation over time, while high-temperature cured products focus on dimensional stability and resistance to environmental factors like UV exposure and humidity fluctuations.

Industry certification bodies including ASTM International, ISO, and the Pine Chemicals Association have established specific testing methodologies for different oleoresin applications. These standards are regularly updated to incorporate new analytical techniques such as gas chromatography-mass spectrometry (GC-MS) for volatile compound profiling and differential scanning calorimetry (DSC) for thermal property characterization.

Quality control documentation must clearly indicate the curing method employed and provide traceability throughout the production process. This includes temperature-time profiles during curing, batch identification, and complete testing records that demonstrate compliance with the appropriate standards for either low or high-temperature cured products.

For low-temperature cured oleoresins (typically below 100°C), quality standards focus on moisture content (optimally below 3%), volatile compound retention (minimum 85% of original terpenes), color consistency (measured via spectrophotometric analysis), and viscosity ranges appropriate for intended applications. These products generally maintain higher levels of essential oils and aromatic compounds, requiring standards that verify these valuable components remain intact.

High-temperature cured oleoresins (above 150°C) require different quality metrics, including polymerization degree (typically 65-80%), hardness measurements (Shore D scale), thermal stability testing (resistance to degradation at elevated temperatures), and reduced volatile organic compound (VOC) emissions. The accelerated chemical reactions at higher temperatures create more stable but less aromatic products, necessitating verification of complete reaction progression.

Both curing methods require standardized testing for contaminants, with maximum allowable limits for heavy metals (lead <5ppm, arsenic <2ppm), microbial content (total plate count <1000 CFU/g), and foreign matter (<0.5% by weight). However, high-temperature cured products typically have more stringent microbial standards due to the sterilizing effect of elevated temperatures.

Shelf-life stability testing protocols differ significantly between the two product types. Low-temperature cured oleoresins require accelerated oxidation testing and monitoring of essential oil degradation over time, while high-temperature cured products focus on dimensional stability and resistance to environmental factors like UV exposure and humidity fluctuations.

Industry certification bodies including ASTM International, ISO, and the Pine Chemicals Association have established specific testing methodologies for different oleoresin applications. These standards are regularly updated to incorporate new analytical techniques such as gas chromatography-mass spectrometry (GC-MS) for volatile compound profiling and differential scanning calorimetry (DSC) for thermal property characterization.

Quality control documentation must clearly indicate the curing method employed and provide traceability throughout the production process. This includes temperature-time profiles during curing, batch identification, and complete testing records that demonstrate compliance with the appropriate standards for either low or high-temperature cured products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!