How to Extract Oleoresin Efficiently for Maximum Yields

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Oleoresin Extraction Technology Background and Objectives

Oleoresin extraction represents a critical process in various industries including pharmaceuticals, food additives, cosmetics, and natural product manufacturing. The history of oleoresin extraction dates back centuries, with traditional methods involving simple pressing and solvent extraction techniques. Over time, these methods have evolved significantly, incorporating advanced technologies to enhance efficiency and yield.

The global oleoresin market has witnessed substantial growth, driven by increasing consumer preference for natural ingredients and growing applications across multiple sectors. Traditional extraction methods, while effective to some extent, often result in lower yields, inconsistent quality, and potential degradation of bioactive compounds. This has necessitated continuous innovation in extraction technologies to meet the growing market demands.

Recent technological advancements have focused on optimizing extraction parameters such as temperature, pressure, solvent selection, and process duration. Supercritical fluid extraction (SFE), particularly using CO2, has emerged as a promising technique due to its ability to operate at lower temperatures, thereby preserving heat-sensitive compounds. Microwave-assisted extraction (MAE) and ultrasound-assisted extraction (UAE) have also gained prominence for their reduced processing times and enhanced extraction efficiency.

The primary objective of modern oleoresin extraction research is to develop methods that maximize yield while maintaining the quality and bioactivity of extracted compounds. This involves optimizing extraction conditions to enhance solubility and mass transfer rates, designing equipment that improves contact between solvent and plant material, and implementing process controls that ensure consistency across production batches.

Environmental sustainability has become an increasingly important consideration in extraction technology development. Research efforts are now directed toward reducing solvent consumption, minimizing energy requirements, and developing green extraction techniques that utilize renewable resources and generate less waste.

The technological trajectory indicates a shift toward hybrid extraction systems that combine multiple techniques to leverage their respective advantages. Integration of artificial intelligence and machine learning for process optimization represents the cutting edge of extraction technology, enabling real-time adjustments based on feedback mechanisms to maximize yields.

The ultimate goal of oleoresin extraction technology advancement is to establish scalable, cost-effective processes that consistently deliver high-quality extracts with maximum yield and minimal environmental impact. This requires interdisciplinary approaches combining principles from chemical engineering, plant science, analytical chemistry, and process automation to overcome existing limitations and push the boundaries of extraction efficiency.

The global oleoresin market has witnessed substantial growth, driven by increasing consumer preference for natural ingredients and growing applications across multiple sectors. Traditional extraction methods, while effective to some extent, often result in lower yields, inconsistent quality, and potential degradation of bioactive compounds. This has necessitated continuous innovation in extraction technologies to meet the growing market demands.

Recent technological advancements have focused on optimizing extraction parameters such as temperature, pressure, solvent selection, and process duration. Supercritical fluid extraction (SFE), particularly using CO2, has emerged as a promising technique due to its ability to operate at lower temperatures, thereby preserving heat-sensitive compounds. Microwave-assisted extraction (MAE) and ultrasound-assisted extraction (UAE) have also gained prominence for their reduced processing times and enhanced extraction efficiency.

The primary objective of modern oleoresin extraction research is to develop methods that maximize yield while maintaining the quality and bioactivity of extracted compounds. This involves optimizing extraction conditions to enhance solubility and mass transfer rates, designing equipment that improves contact between solvent and plant material, and implementing process controls that ensure consistency across production batches.

Environmental sustainability has become an increasingly important consideration in extraction technology development. Research efforts are now directed toward reducing solvent consumption, minimizing energy requirements, and developing green extraction techniques that utilize renewable resources and generate less waste.

The technological trajectory indicates a shift toward hybrid extraction systems that combine multiple techniques to leverage their respective advantages. Integration of artificial intelligence and machine learning for process optimization represents the cutting edge of extraction technology, enabling real-time adjustments based on feedback mechanisms to maximize yields.

The ultimate goal of oleoresin extraction technology advancement is to establish scalable, cost-effective processes that consistently deliver high-quality extracts with maximum yield and minimal environmental impact. This requires interdisciplinary approaches combining principles from chemical engineering, plant science, analytical chemistry, and process automation to overcome existing limitations and push the boundaries of extraction efficiency.

Market Demand Analysis for High-Yield Oleoresin Products

The global oleoresin market has been experiencing robust growth, with a market value reaching $1.7 billion in 2022 and projected to expand at a CAGR of 6.8% through 2030. This growth is primarily driven by increasing demand across multiple industries including food and beverages, pharmaceuticals, cosmetics, and aromatherapy. The shift toward natural ingredients in consumer products has significantly boosted the demand for high-yield oleoresin products.

In the food industry, which accounts for approximately 45% of oleoresin consumption, manufacturers are increasingly replacing synthetic flavors and colors with natural oleoresin alternatives. This trend is particularly evident in processed foods, beverages, and confectionery products where clean label initiatives have gained substantial traction. Market research indicates that 78% of global consumers now prefer products with natural ingredients, creating a sustained demand for high-quality oleoresins.

The pharmaceutical sector represents another significant market segment, with oleoresins being utilized in various medicinal formulations due to their therapeutic properties. The global herbal medicine market, valued at $107 billion in 2022, heavily relies on efficient extraction of oleoresins from medicinal plants. Companies investing in advanced extraction technologies can potentially capture a larger share of this growing market.

Regional analysis reveals that Asia Pacific dominates the oleoresin market with a 38% share, followed by Europe (27%) and North America (22%). India and China are the largest producers and exporters of oleoresins globally, while developed markets in North America and Europe represent the highest value consumption regions due to premium pricing of natural ingredients.

Consumer willingness to pay premium prices for natural products has created a favorable economic environment for high-yield oleoresin production. Market surveys indicate that consumers are willing to pay 15-30% more for products containing natural ingredients compared to synthetic alternatives. This price premium directly translates to higher profit margins for companies that can efficiently extract maximum yields from raw materials.

Supply chain challenges present both obstacles and opportunities in the oleoresin market. Fluctuations in raw material availability due to climate change, agricultural practices, and geopolitical factors have created volatility in pricing. Companies that can develop efficient extraction technologies to maximize yields from available raw materials stand to gain significant competitive advantages by mitigating these supply chain risks.

Sustainability considerations are increasingly influencing market dynamics, with 67% of global consumers considering environmental impact when making purchasing decisions. Extraction methods that maximize yields while minimizing waste and environmental footprint are positioned to capture growing market share in environmentally conscious consumer segments.

In the food industry, which accounts for approximately 45% of oleoresin consumption, manufacturers are increasingly replacing synthetic flavors and colors with natural oleoresin alternatives. This trend is particularly evident in processed foods, beverages, and confectionery products where clean label initiatives have gained substantial traction. Market research indicates that 78% of global consumers now prefer products with natural ingredients, creating a sustained demand for high-quality oleoresins.

The pharmaceutical sector represents another significant market segment, with oleoresins being utilized in various medicinal formulations due to their therapeutic properties. The global herbal medicine market, valued at $107 billion in 2022, heavily relies on efficient extraction of oleoresins from medicinal plants. Companies investing in advanced extraction technologies can potentially capture a larger share of this growing market.

Regional analysis reveals that Asia Pacific dominates the oleoresin market with a 38% share, followed by Europe (27%) and North America (22%). India and China are the largest producers and exporters of oleoresins globally, while developed markets in North America and Europe represent the highest value consumption regions due to premium pricing of natural ingredients.

Consumer willingness to pay premium prices for natural products has created a favorable economic environment for high-yield oleoresin production. Market surveys indicate that consumers are willing to pay 15-30% more for products containing natural ingredients compared to synthetic alternatives. This price premium directly translates to higher profit margins for companies that can efficiently extract maximum yields from raw materials.

Supply chain challenges present both obstacles and opportunities in the oleoresin market. Fluctuations in raw material availability due to climate change, agricultural practices, and geopolitical factors have created volatility in pricing. Companies that can develop efficient extraction technologies to maximize yields from available raw materials stand to gain significant competitive advantages by mitigating these supply chain risks.

Sustainability considerations are increasingly influencing market dynamics, with 67% of global consumers considering environmental impact when making purchasing decisions. Extraction methods that maximize yields while minimizing waste and environmental footprint are positioned to capture growing market share in environmentally conscious consumer segments.

Current Extraction Methods and Technical Challenges

Oleoresin extraction currently employs several established methods, each with distinct advantages and limitations. Conventional solvent extraction remains the most widely used technique, utilizing organic solvents such as hexane, ethanol, and acetone to dissolve and separate oleoresins from plant materials. While this method achieves relatively high yields, it faces significant challenges including solvent residue concerns, environmental hazards, and high energy consumption during solvent recovery processes.

Steam distillation represents another traditional approach, particularly suitable for heat-stable compounds. This method uses steam to volatilize essential oils within the oleoresin, followed by condensation and separation. Though environmentally friendlier than solvent extraction, steam distillation typically yields lower recovery rates and may cause thermal degradation of heat-sensitive compounds, resulting in altered organoleptic properties of the final product.

Supercritical fluid extraction (SFE), particularly using CO2, has emerged as a premium extraction technology. Operating at supercritical conditions (typically 31°C and 74 bar for CO2), this method offers excellent selectivity and produces solvent-free extracts. However, widespread industrial adoption remains limited due to high initial capital investment requirements and operational complexity, restricting its use primarily to high-value products.

Ultrasound-assisted extraction (UAE) and microwave-assisted extraction (MAE) represent newer technologies gaining traction. These methods enhance extraction efficiency through acoustic cavitation or dielectric heating mechanisms, respectively. Both technologies significantly reduce processing time and solvent consumption while improving yields. Technical challenges include equipment scaling limitations and potential degradation of thermolabile compounds during processing.

Cold pressing, though simple and preserving natural characteristics, delivers substantially lower yields compared to other methods and is applicable only to certain oleoresin sources with sufficient oil content. The technique also struggles with standardization and consistency across batches.

Key technical challenges across all extraction methods include achieving complete extraction while maintaining compound integrity, reducing energy consumption, minimizing environmental impact, and ensuring cost-effectiveness at industrial scale. Selective extraction of target compounds while leaving undesirable components behind remains particularly challenging.

Recent research focuses on hybrid technologies combining multiple extraction principles, process intensification through novel equipment designs, and green chemistry approaches using bio-based solvents. Continuous extraction systems that reduce batch-to-batch variation while increasing throughput represent another significant development area, though engineering challenges in maintaining consistent extraction conditions throughout the process remain substantial.

Steam distillation represents another traditional approach, particularly suitable for heat-stable compounds. This method uses steam to volatilize essential oils within the oleoresin, followed by condensation and separation. Though environmentally friendlier than solvent extraction, steam distillation typically yields lower recovery rates and may cause thermal degradation of heat-sensitive compounds, resulting in altered organoleptic properties of the final product.

Supercritical fluid extraction (SFE), particularly using CO2, has emerged as a premium extraction technology. Operating at supercritical conditions (typically 31°C and 74 bar for CO2), this method offers excellent selectivity and produces solvent-free extracts. However, widespread industrial adoption remains limited due to high initial capital investment requirements and operational complexity, restricting its use primarily to high-value products.

Ultrasound-assisted extraction (UAE) and microwave-assisted extraction (MAE) represent newer technologies gaining traction. These methods enhance extraction efficiency through acoustic cavitation or dielectric heating mechanisms, respectively. Both technologies significantly reduce processing time and solvent consumption while improving yields. Technical challenges include equipment scaling limitations and potential degradation of thermolabile compounds during processing.

Cold pressing, though simple and preserving natural characteristics, delivers substantially lower yields compared to other methods and is applicable only to certain oleoresin sources with sufficient oil content. The technique also struggles with standardization and consistency across batches.

Key technical challenges across all extraction methods include achieving complete extraction while maintaining compound integrity, reducing energy consumption, minimizing environmental impact, and ensuring cost-effectiveness at industrial scale. Selective extraction of target compounds while leaving undesirable components behind remains particularly challenging.

Recent research focuses on hybrid technologies combining multiple extraction principles, process intensification through novel equipment designs, and green chemistry approaches using bio-based solvents. Continuous extraction systems that reduce batch-to-batch variation while increasing throughput represent another significant development area, though engineering challenges in maintaining consistent extraction conditions throughout the process remain substantial.

Current High-Efficiency Extraction Solutions

01 Extraction methods for improving oleoresin yield

Various extraction methods can significantly impact oleoresin yield. These include supercritical fluid extraction, solvent extraction, and steam distillation. Each method offers different advantages in terms of extraction efficiency, with some providing higher yields depending on the plant material. The extraction parameters such as temperature, pressure, and duration also play crucial roles in maximizing the oleoresin yield.- Extraction methods for improving oleoresin yield: Various extraction methods can significantly impact oleoresin yield. These include supercritical fluid extraction, solvent extraction, and steam distillation. Each method offers different advantages in terms of extraction efficiency, with some providing higher yields while preserving the quality of the oleoresin. The choice of extraction method depends on the source material and desired end product characteristics.

- Optimization of extraction parameters: Optimizing extraction parameters such as temperature, pressure, time, and solvent-to-material ratio can significantly enhance oleoresin yield. Research indicates that controlling these parameters precisely leads to maximum extraction efficiency. For instance, higher temperatures may increase yield up to a certain point, after which degradation of compounds may occur, reducing the quality and quantity of extracted oleoresin.

- Pre-treatment techniques for raw materials: Pre-treatment of raw materials before extraction can substantially improve oleoresin yield. Techniques such as grinding, drying, enzyme treatment, and ultrasonic pre-treatment help break down cell walls and increase the accessibility of oleoresins. These pre-treatments enhance the contact between solvents and the target compounds, resulting in higher extraction yields.

- Novel equipment and apparatus designs: Innovative equipment and apparatus designs can significantly improve oleoresin extraction yield. These include specialized extractors with enhanced mixing capabilities, continuous extraction systems, and equipment with precise temperature and pressure control. Such technological advancements allow for more efficient extraction processes, reducing solvent consumption while maximizing oleoresin yield.

- Use of co-solvents and additives: The addition of co-solvents and other additives during extraction can enhance oleoresin yield. Certain co-solvents can improve the solubility of target compounds, while additives like antioxidants can prevent degradation during the extraction process. Research shows that carefully selected combinations of solvents and additives can significantly increase extraction efficiency and improve the quality of the final oleoresin product.

02 Plant material preparation techniques

The preparation of plant material before extraction significantly affects oleoresin yield. Techniques such as drying, grinding, and particle size reduction can enhance the extraction efficiency. Proper drying methods preserve the active compounds while grinding increases the surface area, allowing better solvent penetration. The moisture content of the plant material and the degree of comminution are critical factors that influence the final oleoresin yield.Expand Specific Solutions03 Solvent selection and optimization

The choice of solvent significantly impacts oleoresin extraction yield. Different solvents have varying abilities to extract specific compounds from plant materials. Organic solvents like ethanol, hexane, and acetone are commonly used, while green solvents are gaining popularity for environmental reasons. The polarity, selectivity, and safety profile of the solvent must be considered. Optimizing solvent ratios and using solvent mixtures can enhance extraction efficiency and improve oleoresin yield.Expand Specific Solutions04 Novel extraction technologies

Innovative extraction technologies have been developed to improve oleoresin yield. These include ultrasound-assisted extraction, microwave-assisted extraction, and pulsed electric field extraction. These technologies can reduce extraction time, lower solvent consumption, and increase yield compared to conventional methods. They work by disrupting cell walls more effectively, allowing better release of bioactive compounds from the plant matrix.Expand Specific Solutions05 Post-extraction processing for yield enhancement

Post-extraction processing techniques can significantly improve the final oleoresin yield. These include concentration methods, purification steps, and recovery processes. Techniques such as vacuum evaporation, molecular distillation, and crystallization help in removing impurities and concentrating the desired compounds. Proper handling during post-extraction processing minimizes losses and preserves the quality of the oleoresin, ultimately enhancing the overall yield.Expand Specific Solutions

Leading Companies and Research Institutions in Oleoresin Industry

The oleoresin extraction market is currently in a growth phase, with increasing demand driven by applications in food, pharmaceuticals, and cosmetics industries. The global market size is estimated to exceed $1.5 billion, expanding at a CAGR of 5-7%. Technologically, the field shows varying maturity levels, with established players like DSM IP Assets BV and China Petroleum & Chemical Corp. leading conventional extraction methods, while research institutions such as Korea Research Institute of Chemical Technology and University of Granada are advancing novel techniques. Saudi Arabian Oil Co. and Sumitomo Chemical are investing in scalable industrial applications, while specialized firms like Lummus Technology LLC focus on process optimization. The competitive landscape features both petrochemical giants and specialized extraction technology providers competing for efficiency improvements and yield maximization.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive supercritical CO2 extraction technology for oleoresin extraction. Their approach utilizes supercritical fluid extraction (SFE) with carbon dioxide as the solvent at pressures between 100-400 bar and temperatures of 35-60°C. The process incorporates a multi-stage separation system that allows for fractional precipitation of different oleoresin components based on their solubility parameters. Sinopec's technology includes pre-treatment protocols involving particle size optimization (typically 0.5-2mm) and moisture content control (below 12%) to enhance extraction efficiency. Their industrial-scale systems feature continuous operation capabilities with automated pressure and temperature control systems, achieving extraction efficiencies up to 95% for certain plant materials. The company has also developed specialized co-solvent systems using ethanol (5-15%) to enhance extraction of polar compounds within oleoresins.

Strengths: High extraction efficiency with minimal solvent residue; environmentally friendly process using non-toxic CO2; selective extraction capability through pressure/temperature manipulation; scalable to industrial production levels. Weaknesses: High initial capital investment for pressure equipment; energy-intensive process requiring significant cooling and heating systems; technical expertise needed for operation and maintenance.

Sumitomo Chemical Co., Ltd.

Technical Solution: Sumitomo Chemical has pioneered an advanced microwave-assisted extraction (MAE) technology for oleoresin production. Their system employs precisely controlled microwave energy (typically 800-1200W) to rapidly heat plant material internally, causing cell wall disruption and enhanced mass transfer. The technology incorporates a proprietary dual-frequency microwave generator (2.45 GHz and 915 MHz) that optimizes penetration depth and energy distribution within the plant matrix. Sumitomo's process includes a pre-soaking phase with selected green solvents (typically ethanol or limonene-based) to enhance extraction efficiency. Their continuous-flow MAE system achieves extraction times of 15-30 minutes compared to conventional methods requiring hours or days, while maintaining temperature below 80°C to preserve heat-sensitive compounds. The company has also developed specialized ceramic vessels with integrated cooling systems to prevent degradation of thermolabile components during extraction.

Strengths: Significantly reduced extraction time (up to 90% faster than conventional methods); lower solvent consumption; improved extraction yields of bioactive compounds; energy efficient process. Weaknesses: Potential for localized overheating affecting certain compounds; higher complexity in process control parameters; limited batch size in current implementations; requires specialized equipment not common in traditional extraction facilities.

Key Patents and Innovations in Oleoresin Extraction

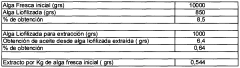

Method for the preparation of an oleoresin originating from a red alga that maintains the capacity to induce the transcriptional activity of the nuclear receptor PPAR-Γ

PatentWO2014186913A1

Innovation

- A five-stage process involving low-temperature algae extraction, mincing, freeze-drying, discontinuous solid-liquid extraction, and solvent elimination is developed to preserve the PPARγ-activating capacity of red algae oleoresin, ensuring high transcriptional activity and oral bioavailability.

Sustainability Considerations in Extraction Processes

Sustainability has become a critical factor in modern oleoresin extraction processes as industries face increasing pressure to reduce environmental impacts while maintaining economic viability. Traditional extraction methods often involve significant energy consumption, excessive water usage, and the application of potentially harmful solvents that can adversely affect ecosystems and human health. The shift toward sustainable extraction practices requires a holistic approach that considers the entire lifecycle of the extraction process, from raw material sourcing to waste management.

Energy efficiency represents a primary sustainability concern in oleoresin extraction. Conventional thermal extraction methods consume substantial amounts of energy, contributing to carbon emissions and operational costs. Implementing energy recovery systems, optimizing process parameters, and exploring alternative energy sources such as solar or biomass can significantly reduce the carbon footprint of extraction facilities while improving cost-effectiveness.

Water conservation strategies are equally important in sustainable extraction processes. Closed-loop water systems that recycle and reuse process water can dramatically reduce freshwater consumption. Additionally, implementing water-efficient cleaning protocols and exploring waterless or reduced-water extraction technologies can further minimize the environmental impact while preserving this increasingly scarce resource.

The selection of solvents represents another critical sustainability consideration. Traditional petroleum-based solvents pose environmental and health risks through potential contamination of air, soil, and water systems. The industry is increasingly adopting green solvents derived from renewable resources, such as bio-based alcohols, terpenes, and supercritical CO2, which offer reduced toxicity and environmental persistence while maintaining extraction efficiency.

Waste valorization has emerged as an innovative approach to sustainability in oleoresin extraction. Rather than treating spent biomass as waste, processors are developing methods to extract additional value from these materials through cascading biorefinery concepts. These approaches include extracting secondary compounds, converting biomass to bioenergy, or utilizing residues as agricultural amendments, thereby creating additional revenue streams while reducing waste.

Certification and traceability systems are becoming essential components of sustainable extraction processes. These systems ensure responsible sourcing of raw materials, fair labor practices, and compliance with environmental regulations throughout the supply chain. Implementing transparent tracking mechanisms not only supports sustainability goals but also meets the growing consumer demand for ethically produced natural products.

Energy efficiency represents a primary sustainability concern in oleoresin extraction. Conventional thermal extraction methods consume substantial amounts of energy, contributing to carbon emissions and operational costs. Implementing energy recovery systems, optimizing process parameters, and exploring alternative energy sources such as solar or biomass can significantly reduce the carbon footprint of extraction facilities while improving cost-effectiveness.

Water conservation strategies are equally important in sustainable extraction processes. Closed-loop water systems that recycle and reuse process water can dramatically reduce freshwater consumption. Additionally, implementing water-efficient cleaning protocols and exploring waterless or reduced-water extraction technologies can further minimize the environmental impact while preserving this increasingly scarce resource.

The selection of solvents represents another critical sustainability consideration. Traditional petroleum-based solvents pose environmental and health risks through potential contamination of air, soil, and water systems. The industry is increasingly adopting green solvents derived from renewable resources, such as bio-based alcohols, terpenes, and supercritical CO2, which offer reduced toxicity and environmental persistence while maintaining extraction efficiency.

Waste valorization has emerged as an innovative approach to sustainability in oleoresin extraction. Rather than treating spent biomass as waste, processors are developing methods to extract additional value from these materials through cascading biorefinery concepts. These approaches include extracting secondary compounds, converting biomass to bioenergy, or utilizing residues as agricultural amendments, thereby creating additional revenue streams while reducing waste.

Certification and traceability systems are becoming essential components of sustainable extraction processes. These systems ensure responsible sourcing of raw materials, fair labor practices, and compliance with environmental regulations throughout the supply chain. Implementing transparent tracking mechanisms not only supports sustainability goals but also meets the growing consumer demand for ethically produced natural products.

Quality Control Standards and Certification Requirements

Quality control is paramount in oleoresin extraction to ensure product consistency, safety, and market acceptance. The International Organization for Standardization (ISO) provides several relevant standards, including ISO 22000 for food safety management systems and ISO 9001 for quality management systems. These standards establish frameworks for consistent production processes, documentation requirements, and continuous improvement protocols essential for oleoresin extraction facilities.

Industry-specific standards such as the American Spice Trade Association (ASTA) cleanliness specifications and the European Spice Association (ESA) quality minima documents provide detailed parameters for oleoresin purity, color values, refractive indices, and specific gravity measurements. These standards typically require oleoresins to contain minimum levels of volatile oils and other active compounds while setting maximum allowable limits for moisture content, insoluble matter, and foreign materials.

Certification requirements vary by target market and application. For food-grade oleoresins, HACCP (Hazard Analysis Critical Control Points) certification is often mandatory, requiring producers to identify and control potential hazards throughout the extraction process. Similarly, Good Manufacturing Practices (GMP) certification ensures proper facility design, equipment maintenance, and personnel training to minimize contamination risks.

For organic certification, producers must demonstrate compliance with regulations such as the USDA National Organic Program (NOP) or the EU Organic Regulations, which restrict the use of chemical solvents and require documentation of organic raw material sourcing. These certifications typically involve annual inspections and comprehensive record-keeping of all production activities.

Testing protocols for quality assurance include chromatographic methods (GC-MS, HPLC) to verify chemical composition and active compound concentrations, spectrophotometric analysis for color consistency, and microbiological testing to ensure product safety. Many markets also require heavy metal testing and pesticide residue analysis, with maximum limits established by regulatory bodies like the FDA and EFSA.

Traceability systems represent another critical component of quality control, allowing producers to track oleoresins from raw material sourcing through processing to final distribution. Modern approaches incorporate digital solutions such as blockchain technology to enhance transparency and facilitate rapid response to quality issues.

Implementing these standards and obtaining relevant certifications not only ensures regulatory compliance but also provides significant market advantages through enhanced customer confidence and access to premium market segments where quality documentation is a prerequisite for supplier qualification.

Industry-specific standards such as the American Spice Trade Association (ASTA) cleanliness specifications and the European Spice Association (ESA) quality minima documents provide detailed parameters for oleoresin purity, color values, refractive indices, and specific gravity measurements. These standards typically require oleoresins to contain minimum levels of volatile oils and other active compounds while setting maximum allowable limits for moisture content, insoluble matter, and foreign materials.

Certification requirements vary by target market and application. For food-grade oleoresins, HACCP (Hazard Analysis Critical Control Points) certification is often mandatory, requiring producers to identify and control potential hazards throughout the extraction process. Similarly, Good Manufacturing Practices (GMP) certification ensures proper facility design, equipment maintenance, and personnel training to minimize contamination risks.

For organic certification, producers must demonstrate compliance with regulations such as the USDA National Organic Program (NOP) or the EU Organic Regulations, which restrict the use of chemical solvents and require documentation of organic raw material sourcing. These certifications typically involve annual inspections and comprehensive record-keeping of all production activities.

Testing protocols for quality assurance include chromatographic methods (GC-MS, HPLC) to verify chemical composition and active compound concentrations, spectrophotometric analysis for color consistency, and microbiological testing to ensure product safety. Many markets also require heavy metal testing and pesticide residue analysis, with maximum limits established by regulatory bodies like the FDA and EFSA.

Traceability systems represent another critical component of quality control, allowing producers to track oleoresins from raw material sourcing through processing to final distribution. Modern approaches incorporate digital solutions such as blockchain technology to enhance transparency and facilitate rapid response to quality issues.

Implementing these standards and obtaining relevant certifications not only ensures regulatory compliance but also provides significant market advantages through enhanced customer confidence and access to premium market segments where quality documentation is a prerequisite for supplier qualification.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!