Optimize Oleoresin Extraction for Improved Solvent Efficiency

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Oleoresin Extraction Technology Background and Objectives

Oleoresin extraction represents a critical process in various industries, including pharmaceuticals, food additives, and natural product chemistry. The technology has evolved significantly since its inception in the early 20th century, transitioning from rudimentary mechanical pressing methods to sophisticated solvent-based extraction techniques. This evolution has been driven by increasing demands for higher purity extracts, improved yield rates, and more environmentally sustainable processes.

The fundamental principle behind oleoresin extraction involves separating essential oils and resins from plant materials through various physical and chemical mechanisms. Traditional methods relied heavily on petroleum-based solvents, which, while effective, presented significant environmental and safety concerns. The industry has since witnessed a paradigm shift toward greener alternatives and more efficient extraction methodologies.

Recent technological advancements have introduced supercritical fluid extraction, ultrasonic-assisted extraction, and microwave-assisted extraction, each offering unique advantages in terms of extraction efficiency and product quality. These innovations have expanded the application scope of oleoresins across multiple sectors, from culinary applications to pharmaceutical formulations.

The global market for oleoresin products has experienced steady growth, with a compound annual growth rate exceeding 4% over the past decade. This growth trajectory is expected to continue as consumer preference shifts toward natural ingredients and clean-label products. Consequently, the demand for more efficient extraction technologies has intensified, placing solvent efficiency at the forefront of research priorities.

Current extraction processes face several challenges, including high solvent consumption, extended processing times, and variable extract quality. These inefficiencies translate to increased operational costs and environmental impact, creating a compelling case for optimization efforts. Industry benchmarks suggest that solvent recovery rates typically range between 70-85%, indicating substantial room for improvement.

The primary objectives of optimizing oleoresin extraction for improved solvent efficiency encompass multiple dimensions: reducing solvent consumption by at least 20%, increasing solvent recovery rates to exceed 95%, minimizing energy requirements during the extraction process, and maintaining or enhancing extract quality parameters. These objectives align with broader industry trends toward sustainable manufacturing practices and cost optimization.

Achieving these objectives requires a multidisciplinary approach, combining principles from chemical engineering, materials science, and process optimization. The potential benefits extend beyond immediate economic gains to include reduced environmental footprint, enhanced product consistency, and improved operational safety profiles.

The fundamental principle behind oleoresin extraction involves separating essential oils and resins from plant materials through various physical and chemical mechanisms. Traditional methods relied heavily on petroleum-based solvents, which, while effective, presented significant environmental and safety concerns. The industry has since witnessed a paradigm shift toward greener alternatives and more efficient extraction methodologies.

Recent technological advancements have introduced supercritical fluid extraction, ultrasonic-assisted extraction, and microwave-assisted extraction, each offering unique advantages in terms of extraction efficiency and product quality. These innovations have expanded the application scope of oleoresins across multiple sectors, from culinary applications to pharmaceutical formulations.

The global market for oleoresin products has experienced steady growth, with a compound annual growth rate exceeding 4% over the past decade. This growth trajectory is expected to continue as consumer preference shifts toward natural ingredients and clean-label products. Consequently, the demand for more efficient extraction technologies has intensified, placing solvent efficiency at the forefront of research priorities.

Current extraction processes face several challenges, including high solvent consumption, extended processing times, and variable extract quality. These inefficiencies translate to increased operational costs and environmental impact, creating a compelling case for optimization efforts. Industry benchmarks suggest that solvent recovery rates typically range between 70-85%, indicating substantial room for improvement.

The primary objectives of optimizing oleoresin extraction for improved solvent efficiency encompass multiple dimensions: reducing solvent consumption by at least 20%, increasing solvent recovery rates to exceed 95%, minimizing energy requirements during the extraction process, and maintaining or enhancing extract quality parameters. These objectives align with broader industry trends toward sustainable manufacturing practices and cost optimization.

Achieving these objectives requires a multidisciplinary approach, combining principles from chemical engineering, materials science, and process optimization. The potential benefits extend beyond immediate economic gains to include reduced environmental footprint, enhanced product consistency, and improved operational safety profiles.

Market Demand Analysis for Efficient Oleoresin Products

The global oleoresin market has witnessed substantial growth in recent years, driven by increasing demand across various industries including food and beverages, pharmaceuticals, cosmetics, and aromatherapy. Current market valuations place the global oleoresin market at approximately 1.7 billion USD in 2023, with projections indicating a compound annual growth rate of 6.8% through 2030.

Consumer preferences are shifting dramatically toward natural ingredients and clean-label products, creating significant market pull for efficiently extracted oleoresins. This trend is particularly pronounced in the food industry, where synthetic additives are increasingly being replaced by natural alternatives. Market research indicates that over 65% of global consumers now actively seek products with natural ingredient claims, directly benefiting the oleoresin sector.

The pharmaceutical industry represents another major demand driver, with oleoresins being utilized in various medicinal formulations due to their therapeutic properties. The market for plant-based pharmaceuticals has expanded at nearly twice the rate of conventional pharmaceuticals over the past five years, creating substantial opportunities for optimized oleoresin extraction technologies.

Sustainability concerns are reshaping market dynamics, with both industrial buyers and end consumers demonstrating willingness to pay premium prices for products manufactured using environmentally responsible processes. Solvent efficiency improvements directly address this market need, as they reduce chemical usage, minimize waste generation, and lower energy consumption during production.

Regional analysis reveals that Asia Pacific currently dominates the oleoresin market, accounting for approximately 40% of global demand, followed by Europe and North America. However, the fastest growth is being observed in emerging economies where rising disposable incomes are fueling demand for premium food products and natural medicines containing oleoresins.

Supply chain considerations are increasingly important to market participants. The volatility in raw material availability and pricing has created strong incentives for extraction process optimization. Companies capable of achieving higher yields through improved solvent efficiency gain significant competitive advantages through cost reduction and supply security.

Industry forecasts suggest that the market segment specifically for efficiently extracted oleoresins will grow at a rate approximately 2.5 percentage points higher than the overall oleoresin market. This premium growth trajectory reflects the convergence of economic benefits (reduced production costs) and sustainability advantages (lower environmental impact) that optimized extraction processes deliver.

Consumer preferences are shifting dramatically toward natural ingredients and clean-label products, creating significant market pull for efficiently extracted oleoresins. This trend is particularly pronounced in the food industry, where synthetic additives are increasingly being replaced by natural alternatives. Market research indicates that over 65% of global consumers now actively seek products with natural ingredient claims, directly benefiting the oleoresin sector.

The pharmaceutical industry represents another major demand driver, with oleoresins being utilized in various medicinal formulations due to their therapeutic properties. The market for plant-based pharmaceuticals has expanded at nearly twice the rate of conventional pharmaceuticals over the past five years, creating substantial opportunities for optimized oleoresin extraction technologies.

Sustainability concerns are reshaping market dynamics, with both industrial buyers and end consumers demonstrating willingness to pay premium prices for products manufactured using environmentally responsible processes. Solvent efficiency improvements directly address this market need, as they reduce chemical usage, minimize waste generation, and lower energy consumption during production.

Regional analysis reveals that Asia Pacific currently dominates the oleoresin market, accounting for approximately 40% of global demand, followed by Europe and North America. However, the fastest growth is being observed in emerging economies where rising disposable incomes are fueling demand for premium food products and natural medicines containing oleoresins.

Supply chain considerations are increasingly important to market participants. The volatility in raw material availability and pricing has created strong incentives for extraction process optimization. Companies capable of achieving higher yields through improved solvent efficiency gain significant competitive advantages through cost reduction and supply security.

Industry forecasts suggest that the market segment specifically for efficiently extracted oleoresins will grow at a rate approximately 2.5 percentage points higher than the overall oleoresin market. This premium growth trajectory reflects the convergence of economic benefits (reduced production costs) and sustainability advantages (lower environmental impact) that optimized extraction processes deliver.

Current Extraction Methods and Technical Challenges

Oleoresin extraction currently employs several established methods, each with distinct advantages and limitations. Conventional solvent extraction remains the most widely utilized approach, with hexane being the predominant solvent due to its high extraction efficiency and relatively low cost. However, this method faces significant challenges including high solvent consumption, environmental concerns due to volatile organic compound emissions, and potential solvent residues in final products that necessitate additional purification steps.

Supercritical fluid extraction (SFE), particularly using CO2, has emerged as a promising alternative that addresses many conventional method limitations. SFE operates by manipulating pressure and temperature to achieve supercritical conditions where CO2 exhibits both liquid-like solvating properties and gas-like diffusion capabilities. While this technique offers superior selectivity and minimal environmental impact, its widespread industrial adoption remains constrained by high capital investment requirements and operational complexities.

Ultrasound-assisted extraction (UAE) and microwave-assisted extraction (MAE) represent newer technological approaches that enhance extraction efficiency through mechanical and thermal effects respectively. UAE employs acoustic cavitation to disrupt cell walls, while MAE utilizes electromagnetic radiation to rapidly heat intracellular moisture. Both methods demonstrate reduced extraction times and solvent consumption compared to conventional techniques, but face challenges in scale-up and process standardization.

The primary technical challenges across all extraction methods center on solvent efficiency optimization. Current processes typically require solvent-to-material ratios ranging from 5:1 to 20:1, representing significant operational costs and environmental burdens. Recovery and recycling of solvents remain inefficient, with typical recovery rates between 85-95%, resulting in substantial solvent losses during industrial-scale operations.

Energy consumption presents another critical challenge, particularly for methods requiring heating or pressurization. Conventional extraction systems often operate at thermal efficiencies below 60%, while advanced technologies like SFE demand considerable energy for pressure maintenance. This energy intensity directly impacts operational costs and carbon footprint.

Selectivity limitations constitute a persistent technical obstacle, as current methods often co-extract undesired compounds alongside target oleoresins, necessitating additional downstream purification. This challenge is particularly pronounced when extracting from complex biological matrices containing diverse phytochemical profiles.

Recent technological innovations have focused on hybrid extraction systems that combine multiple techniques to overcome individual limitations. These include ultrasound-assisted supercritical fluid extraction and microwave-integrated solvent extraction systems. While promising at laboratory scale, these hybrid approaches require further development to address engineering challenges related to process integration and control systems before achieving commercial viability.

Supercritical fluid extraction (SFE), particularly using CO2, has emerged as a promising alternative that addresses many conventional method limitations. SFE operates by manipulating pressure and temperature to achieve supercritical conditions where CO2 exhibits both liquid-like solvating properties and gas-like diffusion capabilities. While this technique offers superior selectivity and minimal environmental impact, its widespread industrial adoption remains constrained by high capital investment requirements and operational complexities.

Ultrasound-assisted extraction (UAE) and microwave-assisted extraction (MAE) represent newer technological approaches that enhance extraction efficiency through mechanical and thermal effects respectively. UAE employs acoustic cavitation to disrupt cell walls, while MAE utilizes electromagnetic radiation to rapidly heat intracellular moisture. Both methods demonstrate reduced extraction times and solvent consumption compared to conventional techniques, but face challenges in scale-up and process standardization.

The primary technical challenges across all extraction methods center on solvent efficiency optimization. Current processes typically require solvent-to-material ratios ranging from 5:1 to 20:1, representing significant operational costs and environmental burdens. Recovery and recycling of solvents remain inefficient, with typical recovery rates between 85-95%, resulting in substantial solvent losses during industrial-scale operations.

Energy consumption presents another critical challenge, particularly for methods requiring heating or pressurization. Conventional extraction systems often operate at thermal efficiencies below 60%, while advanced technologies like SFE demand considerable energy for pressure maintenance. This energy intensity directly impacts operational costs and carbon footprint.

Selectivity limitations constitute a persistent technical obstacle, as current methods often co-extract undesired compounds alongside target oleoresins, necessitating additional downstream purification. This challenge is particularly pronounced when extracting from complex biological matrices containing diverse phytochemical profiles.

Recent technological innovations have focused on hybrid extraction systems that combine multiple techniques to overcome individual limitations. These include ultrasound-assisted supercritical fluid extraction and microwave-integrated solvent extraction systems. While promising at laboratory scale, these hybrid approaches require further development to address engineering challenges related to process integration and control systems before achieving commercial viability.

Current Solvent Efficiency Optimization Approaches

01 Supercritical fluid extraction for oleoresins

Supercritical fluid extraction, particularly using CO2, has emerged as an efficient method for extracting oleoresins from plant materials. This solvent-free technique operates at specific temperature and pressure conditions to extract valuable compounds while avoiding residual solvent issues. The method provides high extraction efficiency, preserves heat-sensitive compounds, and yields purer extracts compared to conventional solvent extraction methods.- Supercritical fluid extraction for oleoresins: Supercritical fluid extraction, particularly using CO2, has emerged as an efficient method for extracting oleoresins from plant materials. This technique operates at critical temperature and pressure conditions, allowing for selective extraction of compounds without leaving solvent residues. The method provides higher yields, better quality extracts, and is environmentally friendly compared to conventional solvent extraction methods. The process parameters can be optimized for specific oleoresin types to enhance extraction efficiency.

- Green solvents for oleoresin extraction: Environmentally friendly solvents such as ethanol, isopropanol, and other bio-based solvents are increasingly being used for oleoresin extraction. These green solvents offer reduced toxicity, lower environmental impact, and better safety profiles compared to traditional petroleum-based solvents. They can effectively extract various oleoresins while meeting sustainability requirements and regulatory standards. The extraction efficiency can be enhanced by optimizing solvent concentration, temperature, and extraction time.

- Hydrocarbon solvent extraction techniques: Hydrocarbon solvents like hexane, petroleum ether, and benzene have been traditionally used for oleoresin extraction due to their high efficiency in dissolving non-polar compounds. These techniques often involve Soxhlet extraction, maceration, or percolation methods. The extraction parameters such as solvent-to-material ratio, extraction time, and temperature significantly influence the yield and quality of oleoresins. Multiple extraction cycles and solvent recovery systems are employed to maximize efficiency and reduce environmental impact.

- Combined and sequential solvent extraction methods: Combined and sequential extraction methods using multiple solvents of varying polarities can significantly improve oleoresin extraction efficiency. These approaches allow for the selective extraction of different compounds based on their solubility characteristics. The process typically begins with non-polar solvents followed by increasingly polar solvents, or uses solvent mixtures with optimized ratios. This methodology maximizes the yield and diversity of extracted compounds while improving the overall extraction efficiency.

- Novel extraction equipment and process innovations: Technological advancements in extraction equipment and process innovations have significantly improved oleoresin extraction efficiency. These include ultrasonic-assisted extraction, microwave-assisted extraction, pulsed electric field extraction, and specialized extraction vessels with enhanced heat and mass transfer capabilities. Automated systems with precise control over extraction parameters such as temperature, pressure, and flow rate have been developed. These innovations reduce extraction time, increase yield, improve extract quality, and enhance energy efficiency of the overall process.

02 Green solvents for sustainable oleoresin extraction

Environmentally friendly solvents such as ethanol, isopropanol, and other bio-based solvents are increasingly used for oleoresin extraction. These green alternatives reduce environmental impact while maintaining extraction efficiency. The use of these solvents aligns with sustainable practices in the natural products industry and often results in extracts with fewer toxic residues compared to traditional petroleum-based solvents.Expand Specific Solutions03 Solvent polarity optimization techniques

The efficiency of oleoresin extraction is significantly influenced by solvent polarity. By optimizing solvent polarity through the use of specific solvents or solvent mixtures, extraction yield and selectivity can be enhanced. Techniques include using solvent combinations with varying polarities, sequential extraction with solvents of increasing polarity, and modifying extraction conditions to target specific oleoresin components.Expand Specific Solutions04 Novel extraction equipment and processes

Innovative extraction equipment and processes have been developed to improve oleoresin extraction efficiency. These include ultrasonic-assisted extraction, microwave-assisted extraction, pulsed electric field extraction, and specialized extraction vessels designed to optimize solvent contact with plant material. These technologies can reduce extraction time, lower solvent consumption, and increase yield compared to traditional methods.Expand Specific Solutions05 Solvent recovery and recycling systems

Efficient solvent recovery and recycling systems are crucial for economic and environmental sustainability in oleoresin extraction. These systems typically involve distillation, condensation, and purification steps to recover solvents for reuse. Advanced technologies incorporate energy recovery mechanisms to reduce operational costs and minimize environmental impact while maintaining the quality of recovered solvents for subsequent extraction cycles.Expand Specific Solutions

Key Industry Players in Oleoresin Extraction

The oleoresin extraction technology market is currently in a growth phase, characterized by increasing demand for more efficient solvent-based extraction methods across pharmaceutical, food, and chemical industries. The global market size is estimated at $1.2-1.5 billion, with projected annual growth of 5-7% driven by rising applications in natural products. Technologically, the field is moderately mature but evolving rapidly toward greener processes. Leading players include major petrochemical corporations (Saudi Aramco, PetroChina, Sinopec, Shell) focusing on solvent optimization, while specialized chemical companies (Evonik, Rhodia, Riken Vitamin) are developing novel extraction technologies. Research institutions like CSIR and universities (Nanjing, Southeast) are advancing fundamental extraction science, creating a competitive landscape balanced between established industrial players and innovative research-driven entities.

Council of Scientific & Industrial Research

Technical Solution: CSIR has developed advanced supercritical fluid extraction (SFE) technology for oleoresin extraction, utilizing CO2 as a green solvent. Their process operates at optimized pressure (200-350 bar) and temperature (40-60°C) conditions to maximize yield while minimizing solvent consumption. The technology incorporates a multi-stage fractionation system that allows for selective extraction of different components based on their solubility parameters. CSIR has also pioneered the use of co-solvents (5-15% ethanol) to enhance extraction efficiency for polar compounds in oleoresins. Their continuous flow system design reduces processing time by approximately 40% compared to conventional batch extraction methods, while achieving solvent recovery rates exceeding 95%.

Strengths: Environmentally friendly process using non-toxic solvents; high selectivity for target compounds; excellent solvent recovery rates. Weaknesses: Higher initial capital investment compared to conventional methods; requires precise pressure and temperature control systems; energy requirements for maintaining supercritical conditions.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a proprietary solvent optimization system for oleoresin extraction that utilizes a combination of hydrocarbon solvents with precisely controlled polarity profiles. Their technology employs a multi-stage counter-current extraction process with solvent-to-feed ratios optimized at 3:1 to 5:1 depending on feedstock characteristics. The system incorporates advanced heat integration, reducing energy consumption by approximately 30% compared to conventional methods. Sinopec's process features proprietary solvent recovery technology with vacuum distillation operating at reduced temperatures (40-60°C) to prevent degradation of heat-sensitive compounds while achieving solvent recovery rates of 98-99%. Their extraction units are equipped with real-time monitoring systems that adjust solvent composition based on feedstock variations to maintain optimal extraction efficiency.

Strengths: Highly efficient solvent recovery system minimizing operational costs; adaptable to various oleoresin types; reduced energy consumption through heat integration. Weaknesses: Relies on hydrocarbon solvents with potential environmental concerns; complex control systems requiring specialized technical expertise; higher initial capital investment than traditional methods.

Critical Patents and Innovations in Extraction Technology

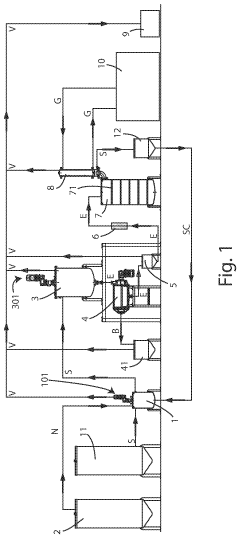

Procedure for selective extraction of active principled and/or oleoresins from vegetable material and related system

PatentInactiveUS20220132895A1

Innovation

- A process using low-pressure, low-temperature solvent extraction with controlled conditions, minimizing unwanted chlorophyll and wax extraction, and eliminating complex filtration steps, involving a refrigerated storage tank, maceration tank, evaporator, vacuum system, and solvent recovery system, with a solvent-to-material ratio of 1:5 to 1:10 and temperatures between -60°C and -100°C.

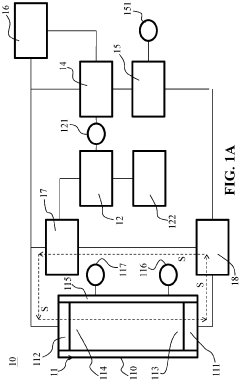

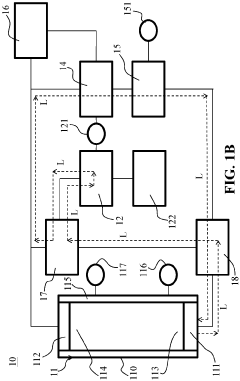

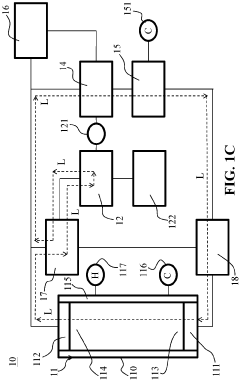

Improved extraction apparatus and method thereof

PatentActiveEP4166211A1

Innovation

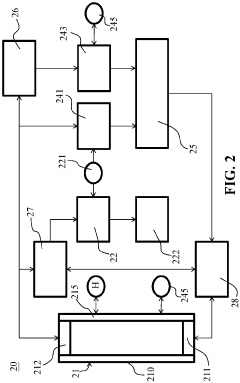

- A system comprising a circulation pump, discharge pump, extraction module, reservoir, evaporators, and condensers using C1 to C4 fluorinated hydrocarbons, which operates in short and long loop circulation modes to efficiently extract active components from plant materials, with the option of additional vapor and heat pumps for enhanced vaporization and liquefaction.

Environmental Impact Assessment of Extraction Processes

The environmental impact of oleoresin extraction processes represents a critical consideration in the optimization of solvent efficiency. Traditional extraction methods often employ organic solvents such as hexane, acetone, and ethanol, which pose significant environmental concerns due to their volatile nature and potential for atmospheric emissions. These emissions contribute to air pollution, photochemical smog formation, and may have adverse effects on local ecosystems and human health in surrounding communities.

Water consumption presents another substantial environmental challenge in extraction processes. Conventional methods typically require large volumes of water for cooling, cleaning, and processing, placing strain on local water resources. In regions facing water scarcity, this intensive usage can exacerbate environmental stress and compete with agricultural and community needs.

Energy utilization across the extraction lifecycle significantly influences the carbon footprint of oleoresin production. From solvent heating and cooling to distillation and recovery processes, energy-intensive operations contribute to greenhouse gas emissions when powered by fossil fuel sources. Quantitative life cycle assessments indicate that solvent recovery and purification phases often account for 40-60% of the total energy consumption in extraction operations.

Waste generation and management present ongoing challenges, particularly regarding spent plant material and partially degraded solvents. These waste streams may contain residual chemicals that require specialized treatment before disposal to prevent soil and groundwater contamination. Advanced extraction facilities increasingly implement closed-loop systems that minimize waste generation through improved solvent recovery rates exceeding 95%.

Recent technological innovations have demonstrated promising pathways toward more environmentally sustainable extraction processes. Supercritical CO2 extraction, while initially more energy-intensive, offers significant environmental advantages through the elimination of toxic organic solvents and reduced waste generation. Similarly, ultrasound-assisted and microwave-assisted extraction techniques can reduce solvent requirements by 30-50% while simultaneously decreasing processing time and energy consumption.

Regulatory frameworks worldwide are increasingly emphasizing environmental performance metrics for industrial processes. The European Union's Industrial Emissions Directive and similar regulations in North America establish stringent standards for volatile organic compound emissions, wastewater quality, and waste management practices. Companies optimizing oleoresin extraction must navigate these evolving compliance requirements while balancing efficiency and environmental responsibility.

Future environmental optimization strategies should focus on integrated approaches combining solvent selection, process intensification, and renewable energy integration to minimize the ecological footprint of extraction operations while maintaining or improving yield and quality parameters.

Water consumption presents another substantial environmental challenge in extraction processes. Conventional methods typically require large volumes of water for cooling, cleaning, and processing, placing strain on local water resources. In regions facing water scarcity, this intensive usage can exacerbate environmental stress and compete with agricultural and community needs.

Energy utilization across the extraction lifecycle significantly influences the carbon footprint of oleoresin production. From solvent heating and cooling to distillation and recovery processes, energy-intensive operations contribute to greenhouse gas emissions when powered by fossil fuel sources. Quantitative life cycle assessments indicate that solvent recovery and purification phases often account for 40-60% of the total energy consumption in extraction operations.

Waste generation and management present ongoing challenges, particularly regarding spent plant material and partially degraded solvents. These waste streams may contain residual chemicals that require specialized treatment before disposal to prevent soil and groundwater contamination. Advanced extraction facilities increasingly implement closed-loop systems that minimize waste generation through improved solvent recovery rates exceeding 95%.

Recent technological innovations have demonstrated promising pathways toward more environmentally sustainable extraction processes. Supercritical CO2 extraction, while initially more energy-intensive, offers significant environmental advantages through the elimination of toxic organic solvents and reduced waste generation. Similarly, ultrasound-assisted and microwave-assisted extraction techniques can reduce solvent requirements by 30-50% while simultaneously decreasing processing time and energy consumption.

Regulatory frameworks worldwide are increasingly emphasizing environmental performance metrics for industrial processes. The European Union's Industrial Emissions Directive and similar regulations in North America establish stringent standards for volatile organic compound emissions, wastewater quality, and waste management practices. Companies optimizing oleoresin extraction must navigate these evolving compliance requirements while balancing efficiency and environmental responsibility.

Future environmental optimization strategies should focus on integrated approaches combining solvent selection, process intensification, and renewable energy integration to minimize the ecological footprint of extraction operations while maintaining or improving yield and quality parameters.

Regulatory Compliance for Oleoresin Production

Regulatory compliance represents a critical dimension in the optimization of oleoresin extraction processes, particularly when focusing on solvent efficiency improvements. The oleoresin industry operates under stringent regulatory frameworks that vary significantly across global markets, creating a complex compliance landscape that manufacturers must navigate effectively.

The FDA in the United States and the European Food Safety Authority (EFSA) in Europe have established comprehensive guidelines regarding solvent selection for oleoresin extraction. These regulations specifically limit residual solvent levels in final products, with particular emphasis on hexane, acetone, and ethanol—the most commonly used solvents in industrial extraction processes. Maximum residual limits typically range from 25-50 ppm depending on the specific solvent and intended product application.

Environmental protection agencies worldwide impose additional regulatory requirements concerning solvent emissions, waste disposal, and workplace exposure limits. The EPA's Clean Air Act regulations in the US mandate specific control technologies for facilities using volatile organic compounds (VOCs) in extraction processes, while the EU's Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation imposes strict documentation and risk management protocols for solvent usage.

Recent regulatory trends indicate a progressive tightening of standards, with increasing preference for greener extraction technologies. The International Organization for Standardization (ISO) has developed specific standards (ISO 22000 and ISO 14001) that address food safety management systems and environmental management aspects relevant to oleoresin production facilities seeking to optimize solvent efficiency while maintaining compliance.

Certification requirements present another layer of regulatory complexity. Organic certification bodies impose particularly stringent limitations on acceptable solvents, often restricting options to water, ethanol, and supercritical CO2. These certification standards significantly influence extraction method selection for manufacturers targeting premium market segments.

Compliance documentation requirements have also expanded substantially, with manufacturers now expected to maintain detailed records of solvent selection justifications, usage quantities, recovery rates, and disposal methods. Regulatory authorities increasingly require demonstration of continuous improvement in solvent efficiency metrics as part of periodic facility inspections and permit renewals.

Forward-looking regulatory compliance strategies for oleoresin producers should incorporate regular monitoring of evolving global standards, investment in analytical capabilities for precise solvent residue testing, and proactive engagement with regulatory bodies during process optimization initiatives. Companies that successfully integrate regulatory compliance considerations into their solvent efficiency optimization efforts gain significant competitive advantages through reduced compliance costs, enhanced market access, and strengthened brand reputation.

The FDA in the United States and the European Food Safety Authority (EFSA) in Europe have established comprehensive guidelines regarding solvent selection for oleoresin extraction. These regulations specifically limit residual solvent levels in final products, with particular emphasis on hexane, acetone, and ethanol—the most commonly used solvents in industrial extraction processes. Maximum residual limits typically range from 25-50 ppm depending on the specific solvent and intended product application.

Environmental protection agencies worldwide impose additional regulatory requirements concerning solvent emissions, waste disposal, and workplace exposure limits. The EPA's Clean Air Act regulations in the US mandate specific control technologies for facilities using volatile organic compounds (VOCs) in extraction processes, while the EU's Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation imposes strict documentation and risk management protocols for solvent usage.

Recent regulatory trends indicate a progressive tightening of standards, with increasing preference for greener extraction technologies. The International Organization for Standardization (ISO) has developed specific standards (ISO 22000 and ISO 14001) that address food safety management systems and environmental management aspects relevant to oleoresin production facilities seeking to optimize solvent efficiency while maintaining compliance.

Certification requirements present another layer of regulatory complexity. Organic certification bodies impose particularly stringent limitations on acceptable solvents, often restricting options to water, ethanol, and supercritical CO2. These certification standards significantly influence extraction method selection for manufacturers targeting premium market segments.

Compliance documentation requirements have also expanded substantially, with manufacturers now expected to maintain detailed records of solvent selection justifications, usage quantities, recovery rates, and disposal methods. Regulatory authorities increasingly require demonstration of continuous improvement in solvent efficiency metrics as part of periodic facility inspections and permit renewals.

Forward-looking regulatory compliance strategies for oleoresin producers should incorporate regular monitoring of evolving global standards, investment in analytical capabilities for precise solvent residue testing, and proactive engagement with regulatory bodies during process optimization initiatives. Companies that successfully integrate regulatory compliance considerations into their solvent efficiency optimization efforts gain significant competitive advantages through reduced compliance costs, enhanced market access, and strengthened brand reputation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!