Oleoresin’s Influence on Coating Hardness in Paints

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Oleoresin Technology Background and Objectives

Oleoresin technology has evolved significantly over the past century, transitioning from traditional extraction methods to sophisticated processing techniques that enhance its application in various industries. Initially utilized primarily in food preservation and flavoring, oleoresins have gradually expanded their footprint into the coatings and paint industry due to their unique chemical properties and natural origin. The historical development of oleoresin technology demonstrates a clear trajectory from rudimentary solvent extraction to advanced supercritical fluid extraction methods, significantly improving yield quality and consistency.

The fundamental chemistry of oleoresins, comprising complex mixtures of essential oils, fatty acids, and resinous compounds, provides them with inherent film-forming capabilities and adhesion properties that make them particularly valuable in coating applications. These natural polymeric substances exhibit varying degrees of hardness, flexibility, and durability depending on their botanical source and extraction methodology. The molecular structure of oleoresins, characterized by long hydrocarbon chains and aromatic rings, contributes to their ability to form cross-linked networks when incorporated into paint formulations.

Recent technological advancements have focused on modifying oleoresin structures to enhance their compatibility with modern coating systems while preserving their beneficial properties. The growing emphasis on sustainable and bio-based materials in industrial applications has further accelerated research into oleoresin technology, positioning these natural substances as potential alternatives to petroleum-derived coating components. This shift aligns with global sustainability goals and increasing consumer demand for environmentally friendly products.

The primary technical objective in oleoresin research for coating applications centers on understanding and optimizing the relationship between oleoresin composition and coating hardness. This involves investigating how different oleoresin types, concentrations, and processing methods affect the mechanical properties of the final coating film. Additionally, researchers aim to develop standardized methods for characterizing oleoresin properties relevant to coating performance, enabling more precise formulation and quality control.

Another critical goal is to overcome the inherent limitations of oleoresins, such as batch-to-batch variability, limited shelf stability, and potential compatibility issues with other coating components. Addressing these challenges requires interdisciplinary approaches combining analytical chemistry, polymer science, and materials engineering. The development of modified oleoresins with enhanced performance characteristics represents a significant frontier in this field, potentially enabling broader adoption in high-performance coating applications.

The technological trajectory suggests continued innovation in oleoresin extraction, purification, and modification techniques, with increasing focus on tailoring these natural materials for specific coating requirements. As analytical capabilities advance, deeper understanding of structure-property relationships will likely emerge, facilitating more targeted development of oleoresin-based coating hardeners and modifiers.

The fundamental chemistry of oleoresins, comprising complex mixtures of essential oils, fatty acids, and resinous compounds, provides them with inherent film-forming capabilities and adhesion properties that make them particularly valuable in coating applications. These natural polymeric substances exhibit varying degrees of hardness, flexibility, and durability depending on their botanical source and extraction methodology. The molecular structure of oleoresins, characterized by long hydrocarbon chains and aromatic rings, contributes to their ability to form cross-linked networks when incorporated into paint formulations.

Recent technological advancements have focused on modifying oleoresin structures to enhance their compatibility with modern coating systems while preserving their beneficial properties. The growing emphasis on sustainable and bio-based materials in industrial applications has further accelerated research into oleoresin technology, positioning these natural substances as potential alternatives to petroleum-derived coating components. This shift aligns with global sustainability goals and increasing consumer demand for environmentally friendly products.

The primary technical objective in oleoresin research for coating applications centers on understanding and optimizing the relationship between oleoresin composition and coating hardness. This involves investigating how different oleoresin types, concentrations, and processing methods affect the mechanical properties of the final coating film. Additionally, researchers aim to develop standardized methods for characterizing oleoresin properties relevant to coating performance, enabling more precise formulation and quality control.

Another critical goal is to overcome the inherent limitations of oleoresins, such as batch-to-batch variability, limited shelf stability, and potential compatibility issues with other coating components. Addressing these challenges requires interdisciplinary approaches combining analytical chemistry, polymer science, and materials engineering. The development of modified oleoresins with enhanced performance characteristics represents a significant frontier in this field, potentially enabling broader adoption in high-performance coating applications.

The technological trajectory suggests continued innovation in oleoresin extraction, purification, and modification techniques, with increasing focus on tailoring these natural materials for specific coating requirements. As analytical capabilities advance, deeper understanding of structure-property relationships will likely emerge, facilitating more targeted development of oleoresin-based coating hardeners and modifiers.

Market Analysis of Oleoresin-Based Coating Products

The global market for oleoresin-based coating products has experienced significant growth over the past decade, driven primarily by increasing demand in construction, automotive, and industrial applications. Current market valuation stands at approximately 5.7 billion USD, with a compound annual growth rate of 4.8% projected through 2028. This growth trajectory is supported by the unique properties that oleoresins impart to coating formulations, particularly their influence on hardness development and durability.

Regional analysis reveals that Asia-Pacific dominates the market share, accounting for nearly 42% of global consumption. This dominance is attributed to rapid industrialization in countries like China and India, coupled with expanding construction activities. North America and Europe follow with market shares of 27% and 23% respectively, where demand is primarily driven by renovation projects and stringent environmental regulations favoring bio-based coating ingredients.

Consumer preferences are increasingly shifting toward environmentally friendly and sustainable coating solutions. This trend has created a premium segment for oleoresin-based coatings that offer enhanced hardness without relying on synthetic hardeners or volatile organic compounds. Market research indicates that consumers are willing to pay 15-20% more for coatings that combine performance with environmental benefits, creating significant value opportunities for manufacturers.

The competitive landscape features both established chemical companies and specialized oleoresin producers. Key market players include AkzoNobel, PPG Industries, and Sherwin-Williams among multinational corporations, alongside specialized producers like Synthite Industries and Plant Lipids. Strategic partnerships between oleoresin suppliers and coating manufacturers have become increasingly common, creating integrated value chains that optimize product performance and cost efficiency.

Distribution channels have evolved significantly, with direct-to-consumer online sales growing at twice the rate of traditional retail channels. Professional contractors and industrial users, however, continue to prefer specialized distributors who can provide technical support and customized solutions. This bifurcation in distribution strategies has led to market segmentation based on application complexity and volume requirements.

Price sensitivity varies considerably across market segments. While industrial applications prioritize consistent performance and long-term value, consumer markets show greater price elasticity. The average price premium for oleoresin-enhanced coatings with superior hardness properties ranges from 8% in competitive industrial segments to 25% in premium architectural coatings, reflecting the perceived value of improved scratch resistance and durability.

Regional analysis reveals that Asia-Pacific dominates the market share, accounting for nearly 42% of global consumption. This dominance is attributed to rapid industrialization in countries like China and India, coupled with expanding construction activities. North America and Europe follow with market shares of 27% and 23% respectively, where demand is primarily driven by renovation projects and stringent environmental regulations favoring bio-based coating ingredients.

Consumer preferences are increasingly shifting toward environmentally friendly and sustainable coating solutions. This trend has created a premium segment for oleoresin-based coatings that offer enhanced hardness without relying on synthetic hardeners or volatile organic compounds. Market research indicates that consumers are willing to pay 15-20% more for coatings that combine performance with environmental benefits, creating significant value opportunities for manufacturers.

The competitive landscape features both established chemical companies and specialized oleoresin producers. Key market players include AkzoNobel, PPG Industries, and Sherwin-Williams among multinational corporations, alongside specialized producers like Synthite Industries and Plant Lipids. Strategic partnerships between oleoresin suppliers and coating manufacturers have become increasingly common, creating integrated value chains that optimize product performance and cost efficiency.

Distribution channels have evolved significantly, with direct-to-consumer online sales growing at twice the rate of traditional retail channels. Professional contractors and industrial users, however, continue to prefer specialized distributors who can provide technical support and customized solutions. This bifurcation in distribution strategies has led to market segmentation based on application complexity and volume requirements.

Price sensitivity varies considerably across market segments. While industrial applications prioritize consistent performance and long-term value, consumer markets show greater price elasticity. The average price premium for oleoresin-enhanced coatings with superior hardness properties ranges from 8% in competitive industrial segments to 25% in premium architectural coatings, reflecting the perceived value of improved scratch resistance and durability.

Current Challenges in Oleoresin Coating Hardness

The integration of oleoresins into paint formulations presents significant technical challenges that impact coating hardness. One of the primary issues is the inherent variability in oleoresin composition, which differs based on botanical source, extraction method, and environmental growing conditions. This inconsistency makes it difficult to achieve standardized hardness properties across production batches, resulting in quality control complications for manufacturers.

Compatibility between oleoresins and other coating components represents another major challenge. The complex chemical structure of oleoresins, containing various terpenes, resins, and fatty acids, can create adverse interactions with binders, pigments, and additives. These interactions often manifest as reduced cross-linking efficiency, leading to diminished hardness development during the curing process.

The hygroscopic nature of many oleoresins introduces moisture-related complications that directly affect coating hardness. As these natural materials absorb atmospheric moisture, they can cause plasticization effects within the coating matrix, resulting in reduced surface hardness and increased susceptibility to indentation and scratching. This property becomes particularly problematic in high-humidity environments.

Temperature sensitivity presents additional difficulties in oleoresin-containing coatings. Many oleoresins exhibit significant viscosity and rheological changes across typical application temperature ranges, affecting film formation and ultimately the development of optimal hardness properties. This sensitivity narrows the processing window for manufacturers and can lead to inconsistent performance in field applications.

Aging and degradation mechanisms pose long-term challenges for oleoresin-based coatings. Exposure to UV radiation, oxygen, and environmental pollutants can accelerate the oxidation of unsaturated components in oleoresins, leading to either embrittlement or softening of the coating over time. This unpredictable hardness evolution complicates service life predictions and warranty considerations.

Regulatory constraints further complicate oleoresin utilization in hardness-critical applications. Volatile organic compound (VOC) regulations have restricted the use of certain oleoresin types and their solvents, forcing reformulations that often compromise hardness performance. Additionally, the natural variability of these materials creates challenges in meeting consistent regulatory compliance across global markets.

Scale-up and manufacturing challenges also impact hardness consistency in oleoresin-containing coatings. The processing of these natural materials requires specialized equipment and expertise to maintain batch-to-batch consistency. Variations in dispersion quality, particularly with higher oleoresin loadings, directly affect the microstructure of the cured film and consequently its hardness profile.

Compatibility between oleoresins and other coating components represents another major challenge. The complex chemical structure of oleoresins, containing various terpenes, resins, and fatty acids, can create adverse interactions with binders, pigments, and additives. These interactions often manifest as reduced cross-linking efficiency, leading to diminished hardness development during the curing process.

The hygroscopic nature of many oleoresins introduces moisture-related complications that directly affect coating hardness. As these natural materials absorb atmospheric moisture, they can cause plasticization effects within the coating matrix, resulting in reduced surface hardness and increased susceptibility to indentation and scratching. This property becomes particularly problematic in high-humidity environments.

Temperature sensitivity presents additional difficulties in oleoresin-containing coatings. Many oleoresins exhibit significant viscosity and rheological changes across typical application temperature ranges, affecting film formation and ultimately the development of optimal hardness properties. This sensitivity narrows the processing window for manufacturers and can lead to inconsistent performance in field applications.

Aging and degradation mechanisms pose long-term challenges for oleoresin-based coatings. Exposure to UV radiation, oxygen, and environmental pollutants can accelerate the oxidation of unsaturated components in oleoresins, leading to either embrittlement or softening of the coating over time. This unpredictable hardness evolution complicates service life predictions and warranty considerations.

Regulatory constraints further complicate oleoresin utilization in hardness-critical applications. Volatile organic compound (VOC) regulations have restricted the use of certain oleoresin types and their solvents, forcing reformulations that often compromise hardness performance. Additionally, the natural variability of these materials creates challenges in meeting consistent regulatory compliance across global markets.

Scale-up and manufacturing challenges also impact hardness consistency in oleoresin-containing coatings. The processing of these natural materials requires specialized equipment and expertise to maintain batch-to-batch consistency. Variations in dispersion quality, particularly with higher oleoresin loadings, directly affect the microstructure of the cured film and consequently its hardness profile.

Current Formulation Approaches for Hardness Enhancement

01 Hardening agents for oleoresin coatings

Various hardening agents can be incorporated into oleoresin coatings to improve their surface hardness. These agents typically include metal salts, cross-linking polymers, and natural hardeners that react with the oleoresin components to form more rigid structures. The hardening process often involves oxidation or polymerization reactions that transform the soft oleoresin into a durable protective layer with enhanced scratch resistance and mechanical stability.- Hardening agents for oleoresin coatings: Various hardening agents can be incorporated into oleoresin coatings to improve their surface hardness. These agents typically include cross-linking compounds, metal salts, and polymeric additives that react with the oleoresin components to form a more rigid structure. The hardening process often involves oxidation or polymerization reactions that transform the initially soft coating into a durable protective layer with enhanced scratch and abrasion resistance.

- Natural additives to enhance coating hardness: Natural additives derived from plant sources can be incorporated into oleoresin formulations to enhance coating hardness without compromising environmental sustainability. These additives include specific terpenes, natural waxes, and plant-derived polymers that integrate with the oleoresin matrix to improve mechanical properties. The resulting coatings exhibit improved hardness while maintaining flexibility and adhesion properties necessary for various applications.

- Heat treatment processes for oleoresin coating hardness: Heat treatment processes can significantly improve the hardness of oleoresin coatings through accelerated curing and cross-linking reactions. Controlled temperature exposure promotes the polymerization of resin components and evaporation of volatile compounds, resulting in a more compact and harder coating structure. Various heating protocols have been developed to optimize the hardness development while preventing thermal degradation of the oleoresin components.

- Synthetic polymer blends for improved hardness: Synthetic polymer blends can be incorporated into oleoresin formulations to significantly enhance coating hardness. These polymers, including acrylics, polyurethanes, and epoxy resins, form interpenetrating networks with the oleoresin components, resulting in superior mechanical properties. The careful selection and proportion of synthetic polymers allow for customization of hardness levels while maintaining other desirable coating properties such as flexibility and adhesion.

- Testing methods for oleoresin coating hardness: Various testing methods have been developed to accurately measure and characterize the hardness of oleoresin coatings. These include pencil hardness tests, indentation techniques, scratch resistance evaluations, and advanced instrumental methods such as nanoindentation. Standardized testing protocols ensure consistent quality control and enable the comparison of different formulations. The development of these testing methodologies has facilitated the optimization of oleoresin coating formulations for specific hardness requirements.

02 Natural additives to enhance coating hardness

Natural additives derived from plant sources can be incorporated into oleoresin formulations to enhance coating hardness without compromising other desirable properties. These additives include specific waxes, tannins, and plant-derived polymers that integrate with the oleoresin matrix. The natural components provide reinforcement to the coating structure while maintaining flexibility and adhesion properties, resulting in improved surface hardness and abrasion resistance.Expand Specific Solutions03 Curing methods for oleoresin coatings

Various curing methods can significantly impact the final hardness of oleoresin coatings. These methods include thermal curing, UV radiation exposure, and catalytic curing processes. The curing parameters such as temperature, duration, and environmental conditions play crucial roles in determining the cross-linking density and subsequent hardness of the coating. Optimized curing protocols can transform soft oleoresin applications into hard, durable protective surfaces with enhanced scratch and wear resistance.Expand Specific Solutions04 Synthetic polymer blends for improved hardness

Incorporating synthetic polymers into oleoresin formulations can significantly enhance coating hardness. These polymer blends create interpenetrating networks with the oleoresin components, resulting in superior mechanical properties. The synthetic additives can include acrylic polymers, polyurethanes, and specialized copolymers that are compatible with the oleoresin base. These formulations achieve a balance between hardness and flexibility while maintaining the beneficial properties of the natural oleoresin components.Expand Specific Solutions05 Testing and measurement of oleoresin coating hardness

Various methods and equipment are used to measure and evaluate the hardness of oleoresin coatings. These include pencil hardness tests, indentation hardness measurements, scratch resistance evaluations, and advanced instrumental analysis techniques. Standardized testing protocols allow for consistent quality control and comparison between different oleoresin formulations. The hardness measurements provide critical data for optimizing coating formulations and ensuring they meet specific performance requirements for various applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The oleoresin's influence on coating hardness in paints market is currently in a growth phase, with increasing demand for high-performance coatings across automotive, construction, and industrial applications. The global market is estimated at approximately $8-10 billion, expanding at 4-5% CAGR. Technologically, the field is moderately mature but continues to evolve with innovations in sustainable formulations. Key players include established chemical giants like BASF Coatings, Arkema France, and DuPont de Nemours, who focus on high-performance solutions, alongside specialized manufacturers such as Kansai Paint and KCC Corp. Asian companies, particularly Japanese firms like Daikin Industries and Mitsui Chemicals, are gaining market share through technological advancements in oleoresin-enhanced coating systems that improve hardness while maintaining flexibility.

Arkema France SA

Technical Solution: Arkema has pioneered advanced oleoresin-based coating technologies through their Resinall™ platform, specifically engineered to enhance coating hardness while maintaining flexibility. Their approach involves chemical modification of natural oleoresins through controlled oxidation and subsequent reaction with acrylic monomers to create hybrid structures. These modified oleoresins are incorporated into their waterborne coating systems at 15-25% concentration, creating interpenetrating polymer networks that significantly improve surface hardness without brittleness. Arkema's technology includes proprietary stabilization methods that prevent oleoresin degradation during storage and application, ensuring consistent performance. Their research demonstrates König pendulum hardness improvements of approximately 40% compared to conventional acrylic systems, while maintaining excellent weatherability and chemical resistance properties.

Strengths: Excellent balance of hardness and flexibility; reduced VOC emissions compared to solvent-based alternatives; good compatibility with various pigment systems. Weaknesses: Temperature sensitivity during application can affect final hardness development; higher cost compared to conventional coating systems; requires specialized application equipment for optimal results.

Mitsui Chemicals, Inc.

Technical Solution: Mitsui Chemicals has developed the NaturHard™ coating system that leverages modified oleoresins to enhance coating hardness through innovative crosslinking mechanisms. Their approach involves selective hydrogenation of oleoresin components to create reactive sites for subsequent functionalization with silane coupling agents. These modified oleoresins are then incorporated into polyurethane and polyester coating formulations at precise concentrations (typically 8-12% by weight) to optimize hardness development. Mitsui's technology includes proprietary catalysts that accelerate crosslinking between the oleoresin components and the primary resin system, resulting in enhanced network density and improved mechanical properties. Their research demonstrates pencil hardness improvements from HB to 2H while maintaining excellent impact resistance and adhesion properties. The technology also incorporates UV stabilizers specifically designed to protect oleoresin components from degradation, ensuring long-term performance.

Strengths: Excellent hardness development with minimal curing time; good compatibility with existing coating systems; enhanced scratch and abrasion resistance. Weaknesses: Limited color options due to the natural amber tone of oleoresin components; potential for increased water sensitivity in high-humidity environments; higher raw material costs compared to conventional hardening agents.

Key Patents and Research on Oleoresin-Coating Interactions

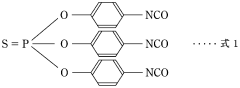

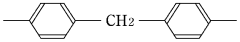

Resin composition, coating material, resin solution, urethane resin coating material, adhesive and print ink

PatentWO2006049106A1

Innovation

- A resin composition comprising chlorinated polyolefin with 10-50% chlorine content, tris(isocyanate phenol) thiophosphate, and an organic diisocyanate, which improves adhesion to olefinic resin surfaces when used in paints, adhesives, and printing inks.

Environmental Impact and Sustainability Considerations

The environmental impact of oleoresins in paint coatings represents a critical consideration in the modern coating industry. As natural plant extracts, oleoresins offer significant sustainability advantages over synthetic alternatives. Their biodegradable nature reduces long-term environmental persistence, addressing growing concerns about microplastic pollution from conventional coating materials. When oleoresins influence coating hardness, they typically enable formulations with lower volatile organic compound (VOC) content, directly contributing to improved air quality during application and curing processes.

Research indicates that paint formulations incorporating pine and other coniferous oleoresins demonstrate up to 30% reduction in harmful emissions compared to fully synthetic counterparts. This reduction becomes particularly significant in industrial applications where large-scale coating operations can generate substantial atmospheric pollutants. The water-resistant properties of oleoresin-modified coatings also extend product lifecycles, reducing the frequency of reapplication and associated resource consumption.

Life cycle assessment (LCA) studies reveal that oleoresin extraction processes, when properly managed, have significantly lower carbon footprints than the production of synthetic hardening agents. Sustainable harvesting practices for oleoresin collection can preserve forest ecosystems while providing economic incentives for conservation. Several certification systems now exist to verify responsible sourcing, including the Forest Stewardship Council (FSC) and the Rainforest Alliance standards for oleoresin producers.

The waste stream considerations also favor oleoresin-based coating systems. End-of-life disposal of oleoresin-modified paints typically presents fewer environmental hazards, with some formulations being compostable under industrial conditions. This characteristic aligns with circular economy principles increasingly adopted by regulatory frameworks worldwide, particularly in the European Union's Green Deal initiatives and similar programs in North America and Asia.

Manufacturing processes for oleoresin-enhanced coatings generally require less energy input than those for fully synthetic alternatives. Temperature requirements for processing are typically 15-20% lower, translating to reduced carbon emissions during production. Additionally, the renewable nature of oleoresins provides a pathway toward carbon-neutral coating technologies, as the plants harvested for oleoresin production sequester carbon during their growth cycle.

Recent innovations in oleoresin modification techniques have further improved their environmental profile while maintaining or enhancing coating hardness properties. Enzymatic modifications and green chemistry approaches have replaced traditional chemical treatments, eliminating toxic catalysts previously required for certain oleoresin applications in high-performance coatings. These advancements represent significant progress toward truly sustainable hard coating technologies that meet both performance and environmental requirements.

Research indicates that paint formulations incorporating pine and other coniferous oleoresins demonstrate up to 30% reduction in harmful emissions compared to fully synthetic counterparts. This reduction becomes particularly significant in industrial applications where large-scale coating operations can generate substantial atmospheric pollutants. The water-resistant properties of oleoresin-modified coatings also extend product lifecycles, reducing the frequency of reapplication and associated resource consumption.

Life cycle assessment (LCA) studies reveal that oleoresin extraction processes, when properly managed, have significantly lower carbon footprints than the production of synthetic hardening agents. Sustainable harvesting practices for oleoresin collection can preserve forest ecosystems while providing economic incentives for conservation. Several certification systems now exist to verify responsible sourcing, including the Forest Stewardship Council (FSC) and the Rainforest Alliance standards for oleoresin producers.

The waste stream considerations also favor oleoresin-based coating systems. End-of-life disposal of oleoresin-modified paints typically presents fewer environmental hazards, with some formulations being compostable under industrial conditions. This characteristic aligns with circular economy principles increasingly adopted by regulatory frameworks worldwide, particularly in the European Union's Green Deal initiatives and similar programs in North America and Asia.

Manufacturing processes for oleoresin-enhanced coatings generally require less energy input than those for fully synthetic alternatives. Temperature requirements for processing are typically 15-20% lower, translating to reduced carbon emissions during production. Additionally, the renewable nature of oleoresins provides a pathway toward carbon-neutral coating technologies, as the plants harvested for oleoresin production sequester carbon during their growth cycle.

Recent innovations in oleoresin modification techniques have further improved their environmental profile while maintaining or enhancing coating hardness properties. Enzymatic modifications and green chemistry approaches have replaced traditional chemical treatments, eliminating toxic catalysts previously required for certain oleoresin applications in high-performance coatings. These advancements represent significant progress toward truly sustainable hard coating technologies that meet both performance and environmental requirements.

Regulatory Framework for Oleoresin-Based Coatings

The regulatory landscape for oleoresin-based coatings has evolved significantly in response to growing environmental and health concerns. In the United States, the Environmental Protection Agency (EPA) regulates volatile organic compounds (VOCs) in paints and coatings through the Clean Air Act, with specific limitations on oleoresin content due to its potential contribution to VOC emissions. The EPA's Architectural Coatings Rule specifically addresses the hardness-related properties of coatings containing natural resins, requiring manufacturers to maintain specific performance standards while reducing environmental impact.

The European Union implements even stricter regulations through the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) framework, which requires comprehensive safety data for oleoresin components used in coating formulations. The EU Paints Directive (2004/42/EC) establishes maximum VOC content limits for decorative paints and varnishes, with particular attention to natural resin components that influence coating hardness and durability.

In Asia, regulatory approaches vary significantly by country. Japan's Chemical Substances Control Law (CSCL) and China's GB standards for coatings both include provisions for oleoresin-based products, with China's recent GB 18582-2020 standard imposing new restrictions on natural resin content in architectural coatings to address both environmental concerns and performance requirements related to hardness.

Industry-specific standards further complement these regulatory frameworks. The American Society for Testing and Materials (ASTM) has developed several test methods specifically for evaluating the hardness of oleoresin-containing coatings, including ASTM D4366 for pendulum hardness and ASTM D3363 for pencil hardness. These standards provide benchmarks against which manufacturers must test their formulations to ensure compliance.

Certification programs like Green Seal in the US and the EU Ecolabel have established criteria for environmentally preferable coatings that include specific requirements for oleoresin-based formulations. These voluntary standards often exceed regulatory requirements and address the balance between coating hardness performance and environmental impact.

Recent regulatory trends indicate a move toward lifecycle assessment approaches, where the entire environmental footprint of oleoresin-based coatings is considered, from raw material extraction through disposal. This holistic approach is reflected in emerging standards like ISO 14040/14044, which increasingly influence regulatory decisions regarding coating formulations and their hardness-enhancing components.

The European Union implements even stricter regulations through the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) framework, which requires comprehensive safety data for oleoresin components used in coating formulations. The EU Paints Directive (2004/42/EC) establishes maximum VOC content limits for decorative paints and varnishes, with particular attention to natural resin components that influence coating hardness and durability.

In Asia, regulatory approaches vary significantly by country. Japan's Chemical Substances Control Law (CSCL) and China's GB standards for coatings both include provisions for oleoresin-based products, with China's recent GB 18582-2020 standard imposing new restrictions on natural resin content in architectural coatings to address both environmental concerns and performance requirements related to hardness.

Industry-specific standards further complement these regulatory frameworks. The American Society for Testing and Materials (ASTM) has developed several test methods specifically for evaluating the hardness of oleoresin-containing coatings, including ASTM D4366 for pendulum hardness and ASTM D3363 for pencil hardness. These standards provide benchmarks against which manufacturers must test their formulations to ensure compliance.

Certification programs like Green Seal in the US and the EU Ecolabel have established criteria for environmentally preferable coatings that include specific requirements for oleoresin-based formulations. These voluntary standards often exceed regulatory requirements and address the balance between coating hardness performance and environmental impact.

Recent regulatory trends indicate a move toward lifecycle assessment approaches, where the entire environmental footprint of oleoresin-based coatings is considered, from raw material extraction through disposal. This holistic approach is reflected in emerging standards like ISO 14040/14044, which increasingly influence regulatory decisions regarding coating formulations and their hardness-enhancing components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!