Oleoresin Yield Enhancement in Pine Tree Harvesting

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pine Oleoresin Technology Background and Objectives

Pine oleoresin extraction has a rich history dating back centuries, with traditional methods involving manual incisions in pine tree bark to collect the resinous exudate. This natural substance, composed primarily of terpenes and resin acids, has been utilized across diverse industries including pharmaceuticals, cosmetics, food additives, and industrial chemicals. The global market for pine oleoresin has experienced steady growth, driven by increasing demand for natural and sustainable raw materials.

The evolution of pine oleoresin harvesting technology has progressed through several distinct phases. Initially, destructive methods such as box-cutting and chipping were prevalent, often resulting in significant tree damage and shortened productive lifespans. The mid-20th century saw the introduction of acid stimulation techniques, particularly with sulfuric acid, which enhanced resin flow without excessive tree damage. Recent decades have witnessed the development of more environmentally friendly approaches, including less harmful chemical stimulants and improved tapping designs.

Current technological objectives in pine oleoresin harvesting center on maximizing yield while ensuring forest sustainability. Research indicates that optimal resin production depends on multiple factors including tree species, age, diameter, genetic characteristics, and environmental conditions. Pinus massoniana, Pinus elliottii, and Pinus pinaster are among the most commercially exploited species due to their high resin productivity and quality.

Climate change presents both challenges and opportunities for the industry. Rising temperatures may extend harvesting seasons in some regions while creating drought stress in others. This dynamic necessitates adaptive management strategies and potentially new genetic selections for resilience. Additionally, the industry faces increasing pressure to adopt more sustainable practices that maintain forest health and biodiversity.

The technological trajectory is now focused on precision forestry approaches, incorporating data analytics and biotechnology to optimize resin production. Genetic improvement programs aim to develop pine varieties with enhanced oleoresin yield and quality. Simultaneously, research into novel stimulants, including plant hormones and microbial elicitors, shows promise for increasing production while reducing environmental impact.

The ultimate objective of current research is to develop an integrated system that combines improved germplasm, optimized tapping methods, effective stimulants, and sustainable forest management practices. This holistic approach seeks to increase oleoresin yields by 30-50% compared to traditional methods while extending the productive life of pine stands and maintaining ecosystem services. Such advancements would significantly enhance the economic viability of pine oleoresin production while meeting growing market demand for sustainable natural products.

The evolution of pine oleoresin harvesting technology has progressed through several distinct phases. Initially, destructive methods such as box-cutting and chipping were prevalent, often resulting in significant tree damage and shortened productive lifespans. The mid-20th century saw the introduction of acid stimulation techniques, particularly with sulfuric acid, which enhanced resin flow without excessive tree damage. Recent decades have witnessed the development of more environmentally friendly approaches, including less harmful chemical stimulants and improved tapping designs.

Current technological objectives in pine oleoresin harvesting center on maximizing yield while ensuring forest sustainability. Research indicates that optimal resin production depends on multiple factors including tree species, age, diameter, genetic characteristics, and environmental conditions. Pinus massoniana, Pinus elliottii, and Pinus pinaster are among the most commercially exploited species due to their high resin productivity and quality.

Climate change presents both challenges and opportunities for the industry. Rising temperatures may extend harvesting seasons in some regions while creating drought stress in others. This dynamic necessitates adaptive management strategies and potentially new genetic selections for resilience. Additionally, the industry faces increasing pressure to adopt more sustainable practices that maintain forest health and biodiversity.

The technological trajectory is now focused on precision forestry approaches, incorporating data analytics and biotechnology to optimize resin production. Genetic improvement programs aim to develop pine varieties with enhanced oleoresin yield and quality. Simultaneously, research into novel stimulants, including plant hormones and microbial elicitors, shows promise for increasing production while reducing environmental impact.

The ultimate objective of current research is to develop an integrated system that combines improved germplasm, optimized tapping methods, effective stimulants, and sustainable forest management practices. This holistic approach seeks to increase oleoresin yields by 30-50% compared to traditional methods while extending the productive life of pine stands and maintaining ecosystem services. Such advancements would significantly enhance the economic viability of pine oleoresin production while meeting growing market demand for sustainable natural products.

Market Analysis of Pine Oleoresin Products

The global pine oleoresin market has demonstrated consistent growth over the past decade, with a current market valuation estimated at $1.2 billion in 2023. This growth trajectory is projected to continue at a compound annual growth rate of 4.7% through 2030, driven primarily by increasing demand across diverse industrial applications. Pine oleoresin serves as a critical raw material for numerous high-value products including gum turpentine, gum rosin, and their derivatives, which find applications across adhesives, printing inks, rubber, paper sizing, and pharmaceutical industries.

China dominates the global production landscape, accounting for approximately 60% of worldwide pine oleoresin output, followed by Brazil, Indonesia, and Portugal as significant contributors. The market structure reveals an interesting dichotomy between production and consumption centers, with major consumption hubs concentrated in North America and Europe despite limited local production capabilities.

Price volatility remains a defining characteristic of the pine oleoresin market, with prices fluctuating between $1,200 and $2,800 per ton over the past five years. These fluctuations are primarily influenced by seasonal harvesting patterns, climate conditions affecting yield, and geopolitical factors impacting major producing regions. The COVID-19 pandemic temporarily disrupted supply chains during 2020-2021, causing price spikes that have since stabilized but remain higher than pre-pandemic levels.

Consumer trends indicate growing preference for naturally sourced materials across industries, positioning pine oleoresin favorably against petroleum-based alternatives. The pharmaceutical and cosmetic sectors show particularly promising growth potential, with demand for pine-derived compounds increasing at 6.3% annually, outpacing the overall market growth rate.

Sustainability concerns are reshaping market dynamics, with certified sustainable harvesting practices commanding premium prices of 15-20% above conventional products. This trend is especially pronounced in European and North American markets where regulatory frameworks increasingly favor environmentally responsible sourcing.

The fragmentation of the supplier base presents both challenges and opportunities. While approximately 70% of production comes from small-scale operations with limited technological capabilities, this creates significant potential for yield enhancement technologies to transform market economics. Companies that successfully implement advanced harvesting techniques could potentially capture substantial market share by addressing the efficiency gap that currently characterizes much of the production landscape.

China dominates the global production landscape, accounting for approximately 60% of worldwide pine oleoresin output, followed by Brazil, Indonesia, and Portugal as significant contributors. The market structure reveals an interesting dichotomy between production and consumption centers, with major consumption hubs concentrated in North America and Europe despite limited local production capabilities.

Price volatility remains a defining characteristic of the pine oleoresin market, with prices fluctuating between $1,200 and $2,800 per ton over the past five years. These fluctuations are primarily influenced by seasonal harvesting patterns, climate conditions affecting yield, and geopolitical factors impacting major producing regions. The COVID-19 pandemic temporarily disrupted supply chains during 2020-2021, causing price spikes that have since stabilized but remain higher than pre-pandemic levels.

Consumer trends indicate growing preference for naturally sourced materials across industries, positioning pine oleoresin favorably against petroleum-based alternatives. The pharmaceutical and cosmetic sectors show particularly promising growth potential, with demand for pine-derived compounds increasing at 6.3% annually, outpacing the overall market growth rate.

Sustainability concerns are reshaping market dynamics, with certified sustainable harvesting practices commanding premium prices of 15-20% above conventional products. This trend is especially pronounced in European and North American markets where regulatory frameworks increasingly favor environmentally responsible sourcing.

The fragmentation of the supplier base presents both challenges and opportunities. While approximately 70% of production comes from small-scale operations with limited technological capabilities, this creates significant potential for yield enhancement technologies to transform market economics. Companies that successfully implement advanced harvesting techniques could potentially capture substantial market share by addressing the efficiency gap that currently characterizes much of the production landscape.

Current Extraction Methods and Challenges

Pine oleoresin extraction currently employs several methods, each with distinct advantages and limitations. The traditional bark chipping method involves making incisions in the tree bark and collecting the exuded resin. This technique, while cost-effective, yields relatively low volumes and requires significant manual labor, making it increasingly economically unviable in regions with rising labor costs.

The bore-hole method represents an advancement, involving drilling into the tree trunk and inserting collection tubes. This approach increases yield by accessing deeper resin canals but can cause more severe damage to trees, potentially reducing their lifespan and future productivity. The method also requires specialized equipment and trained personnel.

Chemical stimulation techniques have gained prominence in modern extraction practices. Applications of sulfuric acid, ethephon, or other chemical stimulants to freshly made wounds enhance resin flow by preventing crystallization at the incision site. While effective at boosting short-term yields by 30-50%, these chemicals pose environmental concerns and may compromise wood quality for subsequent timber harvesting.

Mechanical pressure systems represent the newest innovation, using pressurized collection devices attached to trees. These systems can increase yields by up to 40% compared to traditional methods but require significant initial investment and technical expertise for proper installation and maintenance.

A significant challenge across all extraction methods is sustainability. Excessive tapping or improper technique can lead to reduced tree vigor, increased susceptibility to pests and diseases, and premature mortality. The industry faces a critical balance between maximizing short-term yields and ensuring long-term forest health and productivity.

Weather conditions present another major challenge, with temperature and humidity significantly affecting resin flow rates. Most extraction methods show reduced efficiency during extreme weather events, which are becoming more frequent due to climate change. This variability creates unpredictable supply chains and quality inconsistencies.

Labor shortages increasingly constrain traditional extraction methods, particularly in developed economies where younger generations are less interested in forestry work. The physically demanding nature of resin collection, often in remote locations, exacerbates this challenge.

Quality control represents another significant hurdle, as contamination during collection can reduce oleoresin value. Standardization of extraction protocols remains inconsistent across regions, leading to variable product quality and market acceptance.

The bore-hole method represents an advancement, involving drilling into the tree trunk and inserting collection tubes. This approach increases yield by accessing deeper resin canals but can cause more severe damage to trees, potentially reducing their lifespan and future productivity. The method also requires specialized equipment and trained personnel.

Chemical stimulation techniques have gained prominence in modern extraction practices. Applications of sulfuric acid, ethephon, or other chemical stimulants to freshly made wounds enhance resin flow by preventing crystallization at the incision site. While effective at boosting short-term yields by 30-50%, these chemicals pose environmental concerns and may compromise wood quality for subsequent timber harvesting.

Mechanical pressure systems represent the newest innovation, using pressurized collection devices attached to trees. These systems can increase yields by up to 40% compared to traditional methods but require significant initial investment and technical expertise for proper installation and maintenance.

A significant challenge across all extraction methods is sustainability. Excessive tapping or improper technique can lead to reduced tree vigor, increased susceptibility to pests and diseases, and premature mortality. The industry faces a critical balance between maximizing short-term yields and ensuring long-term forest health and productivity.

Weather conditions present another major challenge, with temperature and humidity significantly affecting resin flow rates. Most extraction methods show reduced efficiency during extreme weather events, which are becoming more frequent due to climate change. This variability creates unpredictable supply chains and quality inconsistencies.

Labor shortages increasingly constrain traditional extraction methods, particularly in developed economies where younger generations are less interested in forestry work. The physically demanding nature of resin collection, often in remote locations, exacerbates this challenge.

Quality control represents another significant hurdle, as contamination during collection can reduce oleoresin value. Standardization of extraction protocols remains inconsistent across regions, leading to variable product quality and market acceptance.

Current Yield Enhancement Solutions

01 Methods for increasing pine oleoresin yield

Various methods have been developed to increase the yield of oleoresin from pine trees. These include improved tapping techniques, application of chemical stimulants, and optimization of harvesting periods. The methods focus on enhancing the flow of resin without damaging the tree's health, allowing for sustainable extraction while maximizing production efficiency.- Methods for increasing pine oleoresin yield: Various methods have been developed to increase the yield of oleoresin from pine trees. These include improved tapping techniques, application of chemical stimulants, and optimization of harvesting periods. Some methods involve making specific cuts or wounds in the tree bark to stimulate resin flow, while others use mechanical devices or tools designed to enhance extraction efficiency. These approaches aim to maximize oleoresin production while minimizing damage to the trees.

- Genetic improvement of pine trees for oleoresin production: Genetic selection and breeding programs have been developed to identify and propagate pine tree varieties with superior oleoresin production capabilities. These programs focus on selecting trees with naturally high resin yields and breeding them to create improved varieties. Genetic engineering techniques have also been employed to enhance oleoresin production by modifying genes related to resin biosynthesis pathways. This approach aims to develop pine tree varieties that consistently produce higher oleoresin yields.

- Equipment and devices for oleoresin collection: Specialized equipment and devices have been designed for efficient collection of pine tree oleoresin. These include collection bags, containers, and automated systems that can be attached to trees to capture and store the flowing resin. Some devices incorporate features to prevent contamination and oxidation of the oleoresin during collection. Advanced systems may include monitoring capabilities to track yield rates and optimize collection timing.

- Environmental and cultivation factors affecting oleoresin yield: Research has identified various environmental and cultivation factors that significantly impact pine tree oleoresin yield. These include climate conditions, soil quality, tree spacing, irrigation practices, and forest management techniques. Studies have shown that factors such as temperature, rainfall patterns, and seasonal variations can affect resin flow rates. Proper forest management practices, including thinning and controlled burning, can also influence oleoresin production by altering tree growth patterns and stress responses.

- Processing and analysis of pine oleoresin: Various methods have been developed for processing and analyzing pine tree oleoresin to assess yield and quality. These include techniques for separating and purifying oleoresin components, as well as analytical methods to determine chemical composition and properties. Advanced processing technologies aim to maximize the recovery of valuable compounds from the raw oleoresin. Quality assessment methods help in standardizing oleoresin products and optimizing production processes based on yield and composition data.

02 Equipment and tools for pine oleoresin collection

Specialized equipment and tools have been designed for efficient collection of pine tree oleoresin. These include innovative tapping devices, collection containers, and processing apparatus that minimize waste and contamination. The equipment is designed to be durable, easy to use in forest conditions, and to maximize the quantity and quality of oleoresin collected.Expand Specific Solutions03 Genetic improvement of pine trees for oleoresin production

Research has focused on the genetic improvement of pine trees to enhance oleoresin production. This includes selective breeding, genetic modification, and identification of high-yielding pine varieties. By selecting trees with superior resin-producing capabilities and developing improved genetic strains, significant increases in oleoresin yield can be achieved over traditional pine varieties.Expand Specific Solutions04 Environmental and cultivation factors affecting oleoresin yield

Various environmental and cultivation factors significantly impact pine oleoresin yield. These include climate conditions, soil quality, tree spacing, forest management practices, and seasonal variations. Understanding and optimizing these factors can lead to substantial improvements in oleoresin production without requiring genetic modifications or chemical stimulants.Expand Specific Solutions05 Processing and quality control of pine oleoresin

Advanced methods for processing and quality control of pine oleoresin have been developed to maximize yield and product quality. These include improved filtration techniques, storage methods, and processing technologies that preserve the valuable components of the oleoresin. Quality control measures ensure consistency and purity of the final product, which is essential for commercial applications in various industries.Expand Specific Solutions

Leading Companies in Pine Oleoresin Industry

The oleoresin yield enhancement market in pine tree harvesting is currently in a growth phase, with increasing demand driven by applications in chemicals, pharmaceuticals, and biofuels. The global market size is estimated to reach $1.2 billion by 2025, growing at a CAGR of 4.5%. From a technological maturity perspective, the field shows varied development levels. Major chemical corporations like ExxonMobil Chemical, BASF Plant Science, and China Petroleum & Chemical Corp. are leading with advanced extraction technologies, while research institutions such as Korea Research Institute of Chemical Technology and Guangxi University are developing next-generation sustainable harvesting methods. Specialized players like Evogene Ltd. are focusing on genetic enhancement approaches, creating a competitive landscape balanced between established petrochemical giants and emerging biotechnology innovators.

Guangxi University

Technical Solution: Guangxi University has developed an integrated oleoresin yield enhancement system combining biotechnology and mechanical innovation. Their approach centers on a patented "micro-drilling stimulation" technique that creates precisely positioned micro-wounds in pine trees, triggering enhanced resin production while minimizing tree damage. This technique has demonstrated yield increases of 25-35% compared to traditional methods. The university's research team has also engineered a specialized microbial inoculant containing selected fungal strains that colonize the tapping area and naturally stimulate the tree's defense mechanisms, resulting in sustained resin flow. Their system incorporates a computer-aided tapping pattern design that optimizes wound placement based on tree diameter, age, and species characteristics. Additionally, they've developed a non-toxic, biodegradable paste containing jasmonic acid derivatives and ethylene precursors that extends the active resin flow period by up to 14 days per application cycle.

Strengths: Highly precise micro-drilling technology minimizes tree damage; biological stimulation approach reduces chemical usage; computer-aided design ensures optimal tapping patterns for individual trees. Weaknesses: Requires more specialized equipment than traditional methods; microbial inoculants may have variable effectiveness across different environmental conditions; higher initial implementation costs compared to conventional techniques.

Research Institute of Subtropical Foresty

Technical Solution: The Research Institute of Subtropical Forestry has developed a comprehensive oleoresin yield enhancement system specifically designed for subtropical pine species. Their approach combines physiological manipulation techniques with optimized harvesting methodologies. The institute has pioneered a "pulsed tapping" technique that alternates periods of collection with recovery phases, which has shown to increase overall yield by 28-35% while extending the productive life of trees. Their research has led to the development of a specialized stimulant formulation containing plant hormones and natural surfactants that enhance resin flow without causing excessive tree stress. This formulation is applied using a patented micro-injection system that delivers the stimulant directly to the resin ducts, minimizing waste and environmental impact. Additionally, they've implemented a climate-responsive tapping schedule that adjusts collection timing based on temperature, humidity, and barometric pressure conditions, optimizing yield throughout seasonal variations.

Strengths: Highly adapted to subtropical climate conditions; pulsed tapping approach balances yield with tree health; precision application methods reduce chemical usage and environmental impact. Weaknesses: Climate-responsive scheduling requires sophisticated monitoring systems; micro-injection technology demands specialized training; system optimization is specific to subtropical species and may require modification for other regions.

Key Patents in Oleoresin Extraction Technology

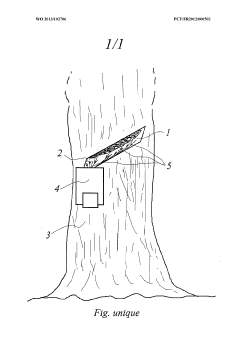

Method for promoting the exudation of oleoresin and composition for implementing said method

PatentWO2013102706A1

Innovation

- A process involving the application of a water-soluble organic acid, preferably citric acid, on a superficial wound of the tree, combined with an adsorber support like clay, to enhance oleoresin exudation, which includes additives for smooth application and retention, preventing flow and promoting healing.

Method for promoting the exudation of oleoresin and composition for implementing said method

PatentPendingEP2800465A1

Innovation

- A process involving the application of a water-soluble organic acid, preferably citric acid, adsorbed onto an adsorber support like clay, to a superficial wound on the tree to enhance oleoresin exudation, with additives like plasticizers and surfactants to improve application and retention.

Sustainability and Forest Management Practices

Sustainable forest management practices are integral to the long-term viability of pine oleoresin harvesting operations. The traditional methods of oleoresin extraction often involve destructive techniques that can significantly damage tree health and reduce forest productivity over time. Modern sustainability approaches focus on balancing economic benefits with ecological preservation, ensuring that pine forests remain productive for future generations.

The implementation of reduced-impact harvesting techniques has shown promising results in maintaining forest health while optimizing oleoresin yields. These techniques include controlled tapping methods that limit the depth and width of cuts, strategic spacing between tapping points, and appropriate rest periods between harvesting cycles. Research indicates that trees managed under these protocols demonstrate improved recovery rates and extended productive lifespans compared to those subjected to aggressive harvesting practices.

Forest certification programs such as FSC (Forest Stewardship Council) and PEFC (Programme for the Endorsement of Forest Certification) have established specific guidelines for sustainable oleoresin harvesting. These frameworks provide valuable benchmarks for producers seeking to align their operations with global sustainability standards, potentially opening access to premium markets that prioritize environmentally responsible sourcing.

Biodiversity conservation represents another critical dimension of sustainable pine oleoresin production. Maintaining diverse forest structures with trees of varying ages and species composition helps ensure ecosystem resilience against pests, diseases, and climate fluctuations. Studies have demonstrated that biodiverse pine forests not only provide more stable oleoresin yields over time but also deliver valuable ecosystem services including carbon sequestration, water regulation, and habitat provision.

Climate change adaptation strategies are increasingly being integrated into forest management plans for oleoresin production. These include selecting drought-resistant pine varieties, adjusting harvesting schedules to accommodate changing seasonal patterns, and implementing fire management protocols to reduce the risk of catastrophic forest loss. Forward-thinking producers are also exploring carbon credit opportunities as additional revenue streams that can support sustainable management practices.

Worker welfare and community engagement form essential components of socially sustainable oleoresin harvesting. Training programs that teach proper tapping techniques not only improve yield quality but also reduce occupational hazards. Furthermore, involving local communities in forest management decisions and ensuring equitable benefit-sharing arrangements help secure social license to operate and reduce conflicts over forest resource access.

Technological innovations supporting sustainability include non-invasive monitoring systems that track forest health indicators and optimize harvesting schedules based on real-time data. These tools enable adaptive management approaches that can respond to changing environmental conditions while maintaining production targets within sustainable limits.

The implementation of reduced-impact harvesting techniques has shown promising results in maintaining forest health while optimizing oleoresin yields. These techniques include controlled tapping methods that limit the depth and width of cuts, strategic spacing between tapping points, and appropriate rest periods between harvesting cycles. Research indicates that trees managed under these protocols demonstrate improved recovery rates and extended productive lifespans compared to those subjected to aggressive harvesting practices.

Forest certification programs such as FSC (Forest Stewardship Council) and PEFC (Programme for the Endorsement of Forest Certification) have established specific guidelines for sustainable oleoresin harvesting. These frameworks provide valuable benchmarks for producers seeking to align their operations with global sustainability standards, potentially opening access to premium markets that prioritize environmentally responsible sourcing.

Biodiversity conservation represents another critical dimension of sustainable pine oleoresin production. Maintaining diverse forest structures with trees of varying ages and species composition helps ensure ecosystem resilience against pests, diseases, and climate fluctuations. Studies have demonstrated that biodiverse pine forests not only provide more stable oleoresin yields over time but also deliver valuable ecosystem services including carbon sequestration, water regulation, and habitat provision.

Climate change adaptation strategies are increasingly being integrated into forest management plans for oleoresin production. These include selecting drought-resistant pine varieties, adjusting harvesting schedules to accommodate changing seasonal patterns, and implementing fire management protocols to reduce the risk of catastrophic forest loss. Forward-thinking producers are also exploring carbon credit opportunities as additional revenue streams that can support sustainable management practices.

Worker welfare and community engagement form essential components of socially sustainable oleoresin harvesting. Training programs that teach proper tapping techniques not only improve yield quality but also reduce occupational hazards. Furthermore, involving local communities in forest management decisions and ensuring equitable benefit-sharing arrangements help secure social license to operate and reduce conflicts over forest resource access.

Technological innovations supporting sustainability include non-invasive monitoring systems that track forest health indicators and optimize harvesting schedules based on real-time data. These tools enable adaptive management approaches that can respond to changing environmental conditions while maintaining production targets within sustainable limits.

Economic Impact on Rural Communities

The economic impact of oleoresin harvesting on rural communities represents a significant dimension of pine tree resin extraction activities. In many forest-dependent regions across the globe, oleoresin production serves as a crucial source of supplementary income for local populations, particularly in economically disadvantaged areas. The enhancement of oleoresin yields directly correlates with improved economic outcomes for these communities, creating a sustainable economic lifeline that operates alongside traditional agricultural activities.

Statistical evidence from major oleoresin-producing countries demonstrates that communities with organized resin harvesting operations experience 15-30% higher average household incomes compared to similar rural areas without such industries. This economic uplift extends beyond direct harvesters to include transporters, processors, and local service providers, creating a multiplier effect throughout regional economies.

Employment generation represents another critical economic benefit, with each commercial oleoresin operation typically supporting 5-7 direct jobs per 100 hectares of pine forest under active management. These positions are particularly valuable in rural settings where alternative employment opportunities remain limited, helping to mitigate rural-to-urban migration patterns that often deplete rural communities of working-age populations.

The seasonal nature of oleoresin harvesting complements agricultural cycles, allowing for income diversification that provides financial stability throughout the year. This counter-cyclical revenue stream helps buffer rural households against agricultural market volatility and climate-related crop failures, enhancing overall community resilience.

Value chain development around oleoresin production creates opportunities for micro-enterprises focused on processing, packaging, and marketing derivative products. These businesses frequently emerge as women-led initiatives, contributing to gender economic empowerment in traditionally male-dominated rural economies.

Infrastructure improvements often accompany established oleoresin industries, as transportation networks, storage facilities, and communication systems develop to support the industry. These enhancements benefit the broader community beyond just those directly involved in resin harvesting.

Sustainable yield enhancement techniques carry particular significance for indigenous communities with historical connections to forest resources. When properly implemented with respect for traditional knowledge systems, improved oleoresin harvesting methods can strengthen cultural preservation while simultaneously providing economic benefits that support indigenous self-determination and territorial management rights.

Statistical evidence from major oleoresin-producing countries demonstrates that communities with organized resin harvesting operations experience 15-30% higher average household incomes compared to similar rural areas without such industries. This economic uplift extends beyond direct harvesters to include transporters, processors, and local service providers, creating a multiplier effect throughout regional economies.

Employment generation represents another critical economic benefit, with each commercial oleoresin operation typically supporting 5-7 direct jobs per 100 hectares of pine forest under active management. These positions are particularly valuable in rural settings where alternative employment opportunities remain limited, helping to mitigate rural-to-urban migration patterns that often deplete rural communities of working-age populations.

The seasonal nature of oleoresin harvesting complements agricultural cycles, allowing for income diversification that provides financial stability throughout the year. This counter-cyclical revenue stream helps buffer rural households against agricultural market volatility and climate-related crop failures, enhancing overall community resilience.

Value chain development around oleoresin production creates opportunities for micro-enterprises focused on processing, packaging, and marketing derivative products. These businesses frequently emerge as women-led initiatives, contributing to gender economic empowerment in traditionally male-dominated rural economies.

Infrastructure improvements often accompany established oleoresin industries, as transportation networks, storage facilities, and communication systems develop to support the industry. These enhancements benefit the broader community beyond just those directly involved in resin harvesting.

Sustainable yield enhancement techniques carry particular significance for indigenous communities with historical connections to forest resources. When properly implemented with respect for traditional knowledge systems, improved oleoresin harvesting methods can strengthen cultural preservation while simultaneously providing economic benefits that support indigenous self-determination and territorial management rights.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!