How to Reduce Oleoresin Acidity in Paint Applications

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Oleoresin Acidity Reduction Background and Objectives

Oleoresin, a natural substance derived from pine trees, has been utilized in paint formulations for centuries due to its excellent binding properties and water resistance. However, the inherent acidity of oleoresins presents significant challenges in paint applications, including reduced shelf life, corrosion of metal containers, and degradation of color stability. The evolution of oleoresin usage in paints has seen a transition from traditional methods of extraction and processing to more sophisticated techniques aimed at mitigating these acidic properties.

The technical landscape of oleoresin acidity management has progressed through several distinct phases. Initially, basic neutralization methods using alkaline compounds were employed, followed by the development of modified extraction processes in the mid-20th century. Recent decades have witnessed the emergence of advanced chemical modification techniques and nanotechnology applications designed to address acidity at the molecular level.

Current industry trends indicate a growing demand for environmentally friendly paint formulations with extended durability and performance characteristics. This shift has intensified research into oleoresin acidity reduction, as manufacturers seek to maintain the beneficial properties of these natural resins while eliminating their detrimental acidic components. The global push toward sustainable materials further emphasizes the importance of developing effective acidity reduction methods for natural resins like oleoresin.

The primary technical objective of this research is to identify and evaluate innovative approaches to reduce oleoresin acidity in paint applications without compromising the beneficial properties that make oleoresins valuable components in paint formulations. Specifically, we aim to achieve a reduction in acid value below 10 mg KOH/g while maintaining adhesion strength, water resistance, and compatibility with modern paint systems.

Secondary objectives include developing cost-effective implementation strategies for identified solutions, ensuring scalability for industrial production, and maintaining compliance with increasingly stringent environmental regulations governing paint manufacturing and application. Additionally, we seek to establish standardized testing protocols for evaluating the effectiveness of acidity reduction methods across different oleoresin types and paint formulations.

This research is positioned within the broader context of sustainable materials science and green chemistry, reflecting the industry's movement toward bio-based alternatives to petrochemical products. By addressing the fundamental challenge of oleoresin acidity, this work aims to expand the practical applications of these renewable resources in modern coating technologies, potentially opening new market opportunities while reducing environmental impact.

The technical landscape of oleoresin acidity management has progressed through several distinct phases. Initially, basic neutralization methods using alkaline compounds were employed, followed by the development of modified extraction processes in the mid-20th century. Recent decades have witnessed the emergence of advanced chemical modification techniques and nanotechnology applications designed to address acidity at the molecular level.

Current industry trends indicate a growing demand for environmentally friendly paint formulations with extended durability and performance characteristics. This shift has intensified research into oleoresin acidity reduction, as manufacturers seek to maintain the beneficial properties of these natural resins while eliminating their detrimental acidic components. The global push toward sustainable materials further emphasizes the importance of developing effective acidity reduction methods for natural resins like oleoresin.

The primary technical objective of this research is to identify and evaluate innovative approaches to reduce oleoresin acidity in paint applications without compromising the beneficial properties that make oleoresins valuable components in paint formulations. Specifically, we aim to achieve a reduction in acid value below 10 mg KOH/g while maintaining adhesion strength, water resistance, and compatibility with modern paint systems.

Secondary objectives include developing cost-effective implementation strategies for identified solutions, ensuring scalability for industrial production, and maintaining compliance with increasingly stringent environmental regulations governing paint manufacturing and application. Additionally, we seek to establish standardized testing protocols for evaluating the effectiveness of acidity reduction methods across different oleoresin types and paint formulations.

This research is positioned within the broader context of sustainable materials science and green chemistry, reflecting the industry's movement toward bio-based alternatives to petrochemical products. By addressing the fundamental challenge of oleoresin acidity, this work aims to expand the practical applications of these renewable resources in modern coating technologies, potentially opening new market opportunities while reducing environmental impact.

Market Analysis for Low-Acidity Paint Solutions

The global market for low-acidity paint solutions has experienced significant growth in recent years, driven primarily by increasing awareness of environmental concerns and health impacts associated with traditional paint formulations. The market size for eco-friendly paints, including those with reduced oleoresin acidity, reached approximately $38 billion in 2022 and is projected to grow at a compound annual growth rate of 6.2% through 2028.

Consumer demand for low-acidity paint solutions is particularly strong in residential applications, where health-conscious homeowners are willing to pay premium prices for products that minimize indoor air pollution and reduce potential respiratory irritants. This segment accounts for nearly 45% of the total market share, followed by commercial applications at 30% and industrial uses at 25%.

Regional analysis reveals that North America and Europe currently dominate the market for low-acidity paint solutions, collectively representing over 60% of global consumption. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and India leading the expansion due to rapid urbanization, increasing disposable incomes, and strengthening environmental regulations.

Key market drivers include stringent VOC (Volatile Organic Compound) regulations, growing consumer preference for sustainable products, and increasing adoption of green building standards. The LEED certification program, for instance, awards points for using low-emission paints, creating a significant incentive for builders to select products with reduced oleoresin acidity.

Market segmentation shows that water-based low-acidity paints currently hold the largest market share at 65%, followed by powder coatings at 20% and high-solids formulations at 15%. Within these categories, products specifically advertising reduced oleoresin acidity command price premiums of 15-30% compared to conventional alternatives.

Customer willingness to pay these premiums varies significantly by segment. Professional painters and contractors demonstrate higher price sensitivity, while end consumers in the premium residential segment show greater willingness to absorb higher costs for perceived health and environmental benefits.

Industry forecasts suggest that the market for low-acidity paint solutions will continue to expand as regulatory pressures increase and consumer awareness grows. Manufacturers who can develop cost-effective methods to reduce oleoresin acidity while maintaining performance characteristics will likely capture significant market share in this growing segment.

Consumer demand for low-acidity paint solutions is particularly strong in residential applications, where health-conscious homeowners are willing to pay premium prices for products that minimize indoor air pollution and reduce potential respiratory irritants. This segment accounts for nearly 45% of the total market share, followed by commercial applications at 30% and industrial uses at 25%.

Regional analysis reveals that North America and Europe currently dominate the market for low-acidity paint solutions, collectively representing over 60% of global consumption. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and India leading the expansion due to rapid urbanization, increasing disposable incomes, and strengthening environmental regulations.

Key market drivers include stringent VOC (Volatile Organic Compound) regulations, growing consumer preference for sustainable products, and increasing adoption of green building standards. The LEED certification program, for instance, awards points for using low-emission paints, creating a significant incentive for builders to select products with reduced oleoresin acidity.

Market segmentation shows that water-based low-acidity paints currently hold the largest market share at 65%, followed by powder coatings at 20% and high-solids formulations at 15%. Within these categories, products specifically advertising reduced oleoresin acidity command price premiums of 15-30% compared to conventional alternatives.

Customer willingness to pay these premiums varies significantly by segment. Professional painters and contractors demonstrate higher price sensitivity, while end consumers in the premium residential segment show greater willingness to absorb higher costs for perceived health and environmental benefits.

Industry forecasts suggest that the market for low-acidity paint solutions will continue to expand as regulatory pressures increase and consumer awareness grows. Manufacturers who can develop cost-effective methods to reduce oleoresin acidity while maintaining performance characteristics will likely capture significant market share in this growing segment.

Current Challenges in Oleoresin Acidity Management

The management of oleoresin acidity in paint applications presents significant challenges for manufacturers and end-users alike. Oleoresins, naturally derived from various plant sources such as pine trees, contain varying levels of acidic compounds that can adversely affect paint performance, stability, and application properties. These acidic components, primarily resin acids and fatty acids, contribute to decreased pH levels in paint formulations, leading to a cascade of technical issues throughout the product lifecycle.

One of the primary challenges is the inconsistent acid content in raw oleoresin materials. Natural variations in harvesting conditions, seasonal factors, and botanical sources create significant batch-to-batch variability, making standardization difficult for paint manufacturers. This inconsistency necessitates constant reformulation and adjustment of neutralizing agents, increasing production complexity and costs.

The acidic nature of oleoresins also catalyzes undesirable chemical reactions within paint formulations. These include premature polymerization, degradation of other components, and accelerated corrosion of metal packaging. Such reactions can significantly reduce shelf life and compromise product integrity before application even occurs. Manufacturers must therefore implement extensive stability testing protocols and often resort to using higher levels of preservatives and stabilizers.

During application, high oleoresin acidity can impair adhesion properties, particularly on alkaline substrates like concrete or certain metals. The acid-base reactions at the interface create weak boundary layers that compromise long-term durability. Additionally, the acidic components can interfere with the proper functioning of certain additives, including dispersants and rheology modifiers, leading to inconsistent application properties and finish quality.

Environmental and health concerns further complicate oleoresin acidity management. Volatile acidic compounds can contribute to indoor air quality issues and potential respiratory irritation for both professional applicators and consumers. Regulatory frameworks increasingly restrict the allowable levels of such emissions, forcing manufacturers to find alternative solutions while maintaining performance characteristics.

The economic impact of these challenges is substantial. Additional processing steps to reduce acidity, such as washing, neutralization, or distillation, increase production costs and energy consumption. The use of higher-grade, lower-acidity oleoresins commands premium pricing, directly affecting product margins or consumer costs. Furthermore, the specialized equipment required for proper acidity management represents significant capital investment for manufacturers.

Technical solutions to these challenges often create trade-offs in other performance attributes. For example, chemical neutralization of acids may introduce unwanted water sensitivity, while heat treatments to reduce acidity can negatively impact the color and odor profile of the final product. Finding balanced approaches that address acidity without compromising other quality parameters remains an ongoing challenge for formulation scientists.

One of the primary challenges is the inconsistent acid content in raw oleoresin materials. Natural variations in harvesting conditions, seasonal factors, and botanical sources create significant batch-to-batch variability, making standardization difficult for paint manufacturers. This inconsistency necessitates constant reformulation and adjustment of neutralizing agents, increasing production complexity and costs.

The acidic nature of oleoresins also catalyzes undesirable chemical reactions within paint formulations. These include premature polymerization, degradation of other components, and accelerated corrosion of metal packaging. Such reactions can significantly reduce shelf life and compromise product integrity before application even occurs. Manufacturers must therefore implement extensive stability testing protocols and often resort to using higher levels of preservatives and stabilizers.

During application, high oleoresin acidity can impair adhesion properties, particularly on alkaline substrates like concrete or certain metals. The acid-base reactions at the interface create weak boundary layers that compromise long-term durability. Additionally, the acidic components can interfere with the proper functioning of certain additives, including dispersants and rheology modifiers, leading to inconsistent application properties and finish quality.

Environmental and health concerns further complicate oleoresin acidity management. Volatile acidic compounds can contribute to indoor air quality issues and potential respiratory irritation for both professional applicators and consumers. Regulatory frameworks increasingly restrict the allowable levels of such emissions, forcing manufacturers to find alternative solutions while maintaining performance characteristics.

The economic impact of these challenges is substantial. Additional processing steps to reduce acidity, such as washing, neutralization, or distillation, increase production costs and energy consumption. The use of higher-grade, lower-acidity oleoresins commands premium pricing, directly affecting product margins or consumer costs. Furthermore, the specialized equipment required for proper acidity management represents significant capital investment for manufacturers.

Technical solutions to these challenges often create trade-offs in other performance attributes. For example, chemical neutralization of acids may introduce unwanted water sensitivity, while heat treatments to reduce acidity can negatively impact the color and odor profile of the final product. Finding balanced approaches that address acidity without compromising other quality parameters remains an ongoing challenge for formulation scientists.

Existing Techniques for Oleoresin Neutralization

01 Methods for reducing acidity in oleoresins

Various methods have been developed to reduce the acidity of oleoresins, which is important for improving their stability and quality. These methods include neutralization with alkaline compounds, steam distillation, and solvent extraction techniques. Reducing acidity helps extend shelf life and improves the sensory properties of oleoresin products used in food, pharmaceutical, and cosmetic applications.- Methods for measuring and controlling oleoresin acidity: Various analytical methods are employed to measure the acidity of oleoresins, which is a critical quality parameter. These methods include titration techniques, chromatography, and spectroscopic analysis. Controlling the acidity level is essential for maintaining the stability and quality of oleoresin products. Standardized procedures have been developed to ensure consistent measurement and control of oleoresin acidity across different production batches.

- Reduction of acidity in oleoresins through processing techniques: Various processing techniques have been developed to reduce the acidity of oleoresins. These include neutralization with alkaline compounds, steam distillation, molecular distillation, and solvent extraction methods. Reducing acidity improves the stability, flavor profile, and shelf life of oleoresin products. These techniques can be optimized for different types of oleoresins based on their specific chemical compositions and intended applications.

- Impact of extraction methods on oleoresin acidity: The extraction method significantly influences the acidity level of the resulting oleoresin. Supercritical fluid extraction, solvent extraction, and cold pressing yield oleoresins with different acidity profiles. Parameters such as temperature, pressure, solvent type, and extraction time can be optimized to minimize acid formation during extraction. Proper selection of extraction methods based on the source material can help maintain desired acidity levels in the final oleoresin product.

- Formulations to stabilize oleoresins with high acidity: Specialized formulations have been developed to stabilize oleoresins that naturally have high acidity levels. These formulations may include antioxidants, chelating agents, and pH buffers that prevent further acid formation and oxidative degradation. Encapsulation technologies and emulsion systems can also be employed to protect acidic oleoresins from environmental factors that accelerate degradation. These stabilization approaches extend the shelf life and maintain the functional properties of oleoresin products.

- Applications of oleoresins with controlled acidity levels: Oleoresins with precisely controlled acidity levels find applications in various industries including food, pharmaceuticals, and cosmetics. Low-acidity oleoresins are preferred in food applications for better flavor profiles and stability. In pharmaceutical applications, controlled acidity is crucial for bioavailability and therapeutic efficacy. The cosmetic industry utilizes oleoresins with specific acidity levels for improved skin compatibility and product stability. Understanding the relationship between acidity and functional properties enables the development of tailored oleoresin products for specific applications.

02 Measurement and analysis of oleoresin acidity

Techniques for measuring and analyzing the acidity of oleoresins are essential for quality control and standardization. These include titration methods, chromatographic analysis, and spectroscopic techniques that quantify free fatty acids and other acidic components. Accurate measurement of acidity is crucial for ensuring consistent product quality and meeting industry specifications for oleoresin products.Expand Specific Solutions03 Formulations to stabilize oleoresins with high acidity

Specialized formulations have been developed to stabilize oleoresins that naturally have high acidity levels. These formulations may include antioxidants, emulsifiers, and encapsulation technologies that protect the oleoresin from oxidation and degradation. Such stabilization techniques are particularly important for oleoresins used in food products and nutritional supplements where shelf stability is critical.Expand Specific Solutions04 Extraction processes affecting oleoresin acidity

The extraction method used to obtain oleoresins significantly impacts their acidity profile. Supercritical fluid extraction, cold pressing, and solvent-based extraction techniques each yield oleoresins with different acidity characteristics. Process parameters such as temperature, pressure, and extraction time can be optimized to minimize acid formation during extraction, resulting in higher quality oleoresin products.Expand Specific Solutions05 Applications of oleoresins with controlled acidity

Oleoresins with carefully controlled acidity have specific applications across various industries. In food products, low-acidity oleoresins provide flavor without contributing sourness. In pharmaceuticals, controlled acidity oleoresins ensure better bioavailability and stability of active compounds. Cosmetic applications benefit from oleoresins with balanced acidity that maintain skin compatibility while delivering beneficial properties.Expand Specific Solutions

Leading Companies in Paint Formulation Technology

The oleoresin acidity reduction market in paint applications is currently in a growth phase, with increasing demand driven by stricter environmental regulations and consumer preferences for eco-friendly products. The market size is expanding steadily, estimated to reach significant value as paint manufacturers seek solutions to improve product stability and performance. Technologically, the field shows moderate maturity with established players like Sherwin-Williams, PPG Industries, and Kansai Paint leading innovation through proprietary formulations. Japanese companies including Nippon Paint and DIC Corp demonstrate strong technical capabilities, while specialty chemical manufacturers such as Arkema and Mitsui Chemicals contribute advanced solutions. European and American companies generally focus on premium solutions, while Asian manufacturers like Jiangsu Champion Technology are rapidly advancing with cost-effective alternatives, creating a competitive global landscape.

Kansai Paint Co., Ltd.

Technical Solution: Kansai Paint has developed an advanced acid mitigation system for oleoresin-containing coatings called ACIDLESS technology. Their approach utilizes a multi-stage treatment process beginning with selective hydrogenation of unsaturated acid groups in natural resins, significantly reducing their oxidative degradation potential. This is followed by controlled reaction with epoxy-functional modifiers that convert remaining carboxylic acid groups to more stable ester linkages. The company has also pioneered the use of specialized zirconium-based coordination complexes that selectively bind to acidic sites without negatively impacting film formation or adhesion properties. Their research demonstrates that this combined approach can reduce total acid number by up to 75% while improving resistance to alkaline substrates. Kansai has successfully implemented this technology in their architectural and industrial maintenance coating lines, showing particular effectiveness in high-temperature applications where acid-catalyzed degradation is typically accelerated.

Strengths: Excellent thermal stability of treated resins; improved adhesion to alkaline substrates like concrete; reduced interaction with metal pigments and driers. Weaknesses: Multi-stage process increases production complexity; higher cost compared to conventional neutralization; some formulations may require additional stabilizers in exterior applications.

PPG Industries Ohio, Inc.

Technical Solution: PPG has pioneered an innovative approach to oleoresin acidity reduction through their INNOVEL technology platform. Their method employs specialized carboxylic acid scavengers that selectively target and neutralize acidic components in natural and modified resins. The company utilizes a proprietary pre-treatment process where oleoresins undergo controlled esterification reactions with polyhydric alcohols under specific temperature and catalyst conditions, effectively converting acidic groups to neutral ester linkages. This process reduces total acid number (TAN) by approximately 70-85% in treated resins. Additionally, PPG has developed nano-encapsulation techniques for acid-sensitive pigments and additives, creating a protective barrier against residual acidity in the paint matrix. Their research demonstrates that these treated resins exhibit significantly improved compatibility with alkaline substrates and reduced corrosion potential.

Strengths: Advanced analytical capabilities for precise acid number control; patented esterification catalysts that operate at lower temperatures; excellent long-term stability in architectural applications. Weaknesses: Process requires specialized equipment for large-scale implementation; higher raw material costs; some formulations may experience reduced flexibility compared to untreated alternatives.

Key Patents in Acidity Reduction Chemistry

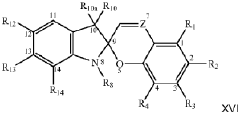

Antiskinning compound and compositions containing them

PatentInactiveEP1778777B1

Innovation

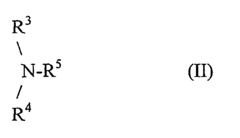

- A combination of organic or inorganic oxygen scavengers with alkyl amines and alkyl alkanolamines is used to inhibit skin formation in alkyd resin coatings, balancing rapid drying with effective oxidative control at the air-resin interface, thereby preventing skin formation without compromising drying properties.

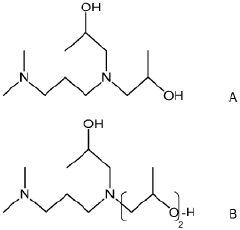

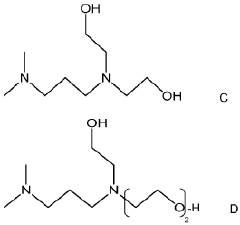

Amine-imino dialcohol neutralizing agents for low volatile compound aqueous organic coating compositions and methods for using same

PatentWO2016111718A1

Innovation

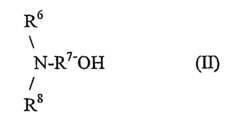

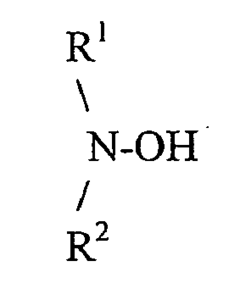

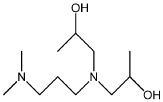

- The use of [(dimethylamino)alkyl]-imino-dialcohols as neutralizing agents in aqueous coating formulations, which reduce VOC content, provide low odor, and improve pigment dispersion, thereby enhancing the properties of the paint while maintaining low VOC levels.

Environmental Impact of Acidity Reduction Methods

The environmental implications of oleoresin acidity reduction methods in paint applications represent a critical consideration for sustainable manufacturing practices. Traditional acidity reduction techniques often involve chemical neutralization processes that generate significant waste streams containing heavy metals and other environmentally harmful compounds. These methods typically require substantial water usage for processing and cleaning, contributing to industrial wastewater contamination when not properly managed.

Chemical neutralization using alkaline substances such as calcium carbonate or sodium hydroxide, while effective at reducing acidity, can create sludge byproducts that require specialized disposal procedures. The environmental footprint extends beyond waste generation to include energy consumption during processing, as many conventional methods require elevated temperatures maintained over extended periods.

More recent advancements in molecular sieves and selective adsorption technologies demonstrate improved environmental profiles. These approaches reduce chemical waste generation by physically removing acidic components rather than chemically neutralizing them. Studies indicate that adsorption-based methods can decrease hazardous waste production by 40-65% compared to traditional neutralization techniques, while simultaneously reducing water consumption by approximately 30%.

Enzymatic treatment methods represent another environmentally favorable approach, operating at ambient temperatures and neutral pH conditions. These biological catalysts selectively target acidic compounds without generating significant chemical byproducts. Research indicates that enzyme-based processes can reduce the carbon footprint of acidity reduction by up to 50% compared to conventional thermal-chemical methods.

Life cycle assessments of various acidity reduction technologies reveal that membrane filtration systems, despite higher initial implementation costs, offer substantial environmental benefits through operational efficiency. These systems typically consume 25-40% less energy than conventional methods while producing minimal waste streams that can often be further processed for resource recovery.

Regulatory frameworks increasingly emphasize the importance of environmental considerations in manufacturing processes. The European Union's REACH regulations and similar frameworks in North America and Asia have established stringent guidelines for chemical usage and waste management in coating industries, driving innovation toward greener acidity reduction technologies. Companies adopting environmentally responsible acidity reduction methods often gain competitive advantages through regulatory compliance, reduced waste management costs, and enhanced brand reputation among environmentally conscious consumers.

Chemical neutralization using alkaline substances such as calcium carbonate or sodium hydroxide, while effective at reducing acidity, can create sludge byproducts that require specialized disposal procedures. The environmental footprint extends beyond waste generation to include energy consumption during processing, as many conventional methods require elevated temperatures maintained over extended periods.

More recent advancements in molecular sieves and selective adsorption technologies demonstrate improved environmental profiles. These approaches reduce chemical waste generation by physically removing acidic components rather than chemically neutralizing them. Studies indicate that adsorption-based methods can decrease hazardous waste production by 40-65% compared to traditional neutralization techniques, while simultaneously reducing water consumption by approximately 30%.

Enzymatic treatment methods represent another environmentally favorable approach, operating at ambient temperatures and neutral pH conditions. These biological catalysts selectively target acidic compounds without generating significant chemical byproducts. Research indicates that enzyme-based processes can reduce the carbon footprint of acidity reduction by up to 50% compared to conventional thermal-chemical methods.

Life cycle assessments of various acidity reduction technologies reveal that membrane filtration systems, despite higher initial implementation costs, offer substantial environmental benefits through operational efficiency. These systems typically consume 25-40% less energy than conventional methods while producing minimal waste streams that can often be further processed for resource recovery.

Regulatory frameworks increasingly emphasize the importance of environmental considerations in manufacturing processes. The European Union's REACH regulations and similar frameworks in North America and Asia have established stringent guidelines for chemical usage and waste management in coating industries, driving innovation toward greener acidity reduction technologies. Companies adopting environmentally responsible acidity reduction methods often gain competitive advantages through regulatory compliance, reduced waste management costs, and enhanced brand reputation among environmentally conscious consumers.

Regulatory Framework for Paint Chemical Composition

The regulatory landscape governing paint chemical composition has evolved significantly in response to growing environmental and health concerns. Regulations specifically addressing oleoresin acidity in paint formulations exist across multiple jurisdictions, with varying degrees of stringency. The European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation establishes comprehensive frameworks for controlling chemical substances in various products, including paints containing oleoresins. These regulations mandate maximum permissible acidity levels, typically measured in terms of acid value or pH, to ensure product safety and environmental compatibility.

In the United States, the Environmental Protection Agency (EPA) under the Toxic Substances Control Act (TSCA) regulates chemical substances in paint formulations. Additionally, the American Society for Testing and Materials (ASTM) has established standard test methods for determining acid values in resins and paint materials, providing industry benchmarks for compliance. These standards typically specify acid value limits ranging from 5 to 15 mg KOH/g depending on application type.

Regulatory bodies in Asia, particularly China and Japan, have implemented similar frameworks with the Chinese GB standards and Japanese Industrial Standards (JIS) specifying acceptable acidity parameters for paint components. These regulations often include specific provisions for volatile organic compounds (VOCs) that can be exacerbated by high acidity levels in oleoresins.

Industry-specific regulations further refine these requirements. For marine coatings, the International Maritime Organization (IMO) has established guidelines that indirectly address oleoresin acidity through restrictions on biocides and anti-fouling agents. Similarly, regulations for architectural paints often include more stringent acidity controls due to potential exposure to consumers and environmental leaching concerns.

Compliance certification systems have emerged as critical components of the regulatory framework. Third-party certification bodies verify adherence to acidity standards through standardized testing protocols. These certifications often serve as prerequisites for market access in regulated territories and provide competitive advantages in environmentally conscious markets.

Recent regulatory trends indicate a movement toward stricter limitations on acidic components in paint formulations. The EU's Green Deal and similar initiatives worldwide are driving regulatory evolution toward more environmentally friendly paint formulations with lower acidity profiles. Manufacturers must increasingly demonstrate not only compliance with current standards but also adaptability to anticipated regulatory changes that may further restrict oleoresin acidity in paint applications.

In the United States, the Environmental Protection Agency (EPA) under the Toxic Substances Control Act (TSCA) regulates chemical substances in paint formulations. Additionally, the American Society for Testing and Materials (ASTM) has established standard test methods for determining acid values in resins and paint materials, providing industry benchmarks for compliance. These standards typically specify acid value limits ranging from 5 to 15 mg KOH/g depending on application type.

Regulatory bodies in Asia, particularly China and Japan, have implemented similar frameworks with the Chinese GB standards and Japanese Industrial Standards (JIS) specifying acceptable acidity parameters for paint components. These regulations often include specific provisions for volatile organic compounds (VOCs) that can be exacerbated by high acidity levels in oleoresins.

Industry-specific regulations further refine these requirements. For marine coatings, the International Maritime Organization (IMO) has established guidelines that indirectly address oleoresin acidity through restrictions on biocides and anti-fouling agents. Similarly, regulations for architectural paints often include more stringent acidity controls due to potential exposure to consumers and environmental leaching concerns.

Compliance certification systems have emerged as critical components of the regulatory framework. Third-party certification bodies verify adherence to acidity standards through standardized testing protocols. These certifications often serve as prerequisites for market access in regulated territories and provide competitive advantages in environmentally conscious markets.

Recent regulatory trends indicate a movement toward stricter limitations on acidic components in paint formulations. The EU's Green Deal and similar initiatives worldwide are driving regulatory evolution toward more environmentally friendly paint formulations with lower acidity profiles. Manufacturers must increasingly demonstrate not only compliance with current standards but also adaptability to anticipated regulatory changes that may further restrict oleoresin acidity in paint applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!