How to Optimize Oleoresin Filtering for Industrial Use

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Oleoresin Filtration Background and Objectives

Oleoresin extraction and processing has evolved significantly over the past century, transitioning from rudimentary mechanical methods to sophisticated industrial processes. Initially developed for the food and pharmaceutical industries in the early 1900s, oleoresin filtration techniques have undergone substantial refinement to meet increasing quality standards and production demands. The trajectory of development has been characterized by a shift from basic gravity filtration to pressure-assisted systems, and more recently, to advanced membrane technologies and continuous flow processes.

The global oleoresin market, valued at approximately $1.7 billion in 2022, is projected to reach $2.3 billion by 2027, with a compound annual growth rate of 6.2%. This growth underscores the critical importance of optimizing filtration processes to meet escalating demand while maintaining product quality and operational efficiency. Current filtration technologies face significant challenges in balancing throughput with purity, particularly when processing high-viscosity oleoresins from sources such as capsicum, black pepper, and ginger.

The primary objective of oleoresin filtration optimization is to develop scalable, energy-efficient processes that effectively remove particulate matter, waxes, and other impurities while preserving the volatile compounds responsible for flavor, aroma, and bioactive properties. This requires a multidisciplinary approach integrating principles from chemical engineering, material science, and process automation.

Recent technological advancements have introduced innovations such as cross-flow microfiltration, ultrasonic-assisted filtration, and supercritical fluid extraction coupled with in-line filtration. These developments aim to address persistent challenges including membrane fouling, pressure drop issues, and the degradation of heat-sensitive compounds during processing. The integration of real-time monitoring systems and predictive maintenance protocols represents another frontier in optimization efforts.

Geographically, technological leadership in oleoresin filtration has been concentrated in Western Europe, particularly Germany and France, with emerging contributions from India, China, and Brazil—countries with substantial botanical resources and growing processing capabilities. This global distribution reflects both the historical development of the technology and the contemporary economic importance of oleoresin production in various regions.

The optimization of oleoresin filtration processes must balance multiple competing factors: production efficiency, product quality, environmental sustainability, and economic viability. As regulatory requirements become more stringent and consumer preferences shift toward natural products with minimal processing, the technical goals increasingly include reducing solvent usage, minimizing energy consumption, and developing closed-loop systems that maximize resource recovery while minimizing waste generation.

The global oleoresin market, valued at approximately $1.7 billion in 2022, is projected to reach $2.3 billion by 2027, with a compound annual growth rate of 6.2%. This growth underscores the critical importance of optimizing filtration processes to meet escalating demand while maintaining product quality and operational efficiency. Current filtration technologies face significant challenges in balancing throughput with purity, particularly when processing high-viscosity oleoresins from sources such as capsicum, black pepper, and ginger.

The primary objective of oleoresin filtration optimization is to develop scalable, energy-efficient processes that effectively remove particulate matter, waxes, and other impurities while preserving the volatile compounds responsible for flavor, aroma, and bioactive properties. This requires a multidisciplinary approach integrating principles from chemical engineering, material science, and process automation.

Recent technological advancements have introduced innovations such as cross-flow microfiltration, ultrasonic-assisted filtration, and supercritical fluid extraction coupled with in-line filtration. These developments aim to address persistent challenges including membrane fouling, pressure drop issues, and the degradation of heat-sensitive compounds during processing. The integration of real-time monitoring systems and predictive maintenance protocols represents another frontier in optimization efforts.

Geographically, technological leadership in oleoresin filtration has been concentrated in Western Europe, particularly Germany and France, with emerging contributions from India, China, and Brazil—countries with substantial botanical resources and growing processing capabilities. This global distribution reflects both the historical development of the technology and the contemporary economic importance of oleoresin production in various regions.

The optimization of oleoresin filtration processes must balance multiple competing factors: production efficiency, product quality, environmental sustainability, and economic viability. As regulatory requirements become more stringent and consumer preferences shift toward natural products with minimal processing, the technical goals increasingly include reducing solvent usage, minimizing energy consumption, and developing closed-loop systems that maximize resource recovery while minimizing waste generation.

Market Demand Analysis for Industrial Oleoresin Products

The global oleoresin market has been experiencing steady growth, with a market value reaching approximately $1.7 billion in 2022 and projected to expand at a compound annual growth rate of 4.8% through 2030. This growth is primarily driven by increasing demand across various industrial sectors including food and beverages, pharmaceuticals, cosmetics, and flavors and fragrances. The food industry remains the largest consumer of oleoresins, accounting for nearly 45% of the total market share, as manufacturers increasingly replace synthetic additives with natural alternatives.

Industrial applications of oleoresins have seen particularly robust growth due to their superior properties compared to essential oils, including higher concentration, better stability, and longer shelf life. The pharmaceutical sector's demand has increased significantly, with oleoresins being utilized in various medicinal formulations due to their therapeutic properties. This sector is expected to witness the fastest growth rate in oleoresin consumption over the next five years.

Regionally, Asia-Pacific dominates the market, accounting for approximately 40% of global consumption, followed by North America and Europe. India and China are the largest producers and exporters of oleoresins, while developed markets in North America and Europe represent significant consumption hubs due to the growing preference for natural ingredients in consumer products.

The demand for high-quality filtered oleoresins has intensified as end-users require products with consistent quality, purity, and performance characteristics. Industries are increasingly willing to pay premium prices for oleoresins that meet stringent quality standards, particularly those free from contaminants and with standardized active compound content. This trend has created a substantial market opportunity for advanced filtering technologies that can deliver superior product quality while maintaining cost-effectiveness.

Supply chain challenges, including raw material availability fluctuations and quality inconsistencies, have further emphasized the need for efficient filtering processes that can handle variable input quality. Market research indicates that approximately 30% of oleoresin processors cite filtering optimization as a critical factor affecting their production costs and product marketability.

Consumer trends toward clean label products and natural ingredients have also bolstered demand for minimally processed oleoresins that retain their natural properties while meeting safety standards. This has created a growing niche for filtering technologies that can remove impurities without affecting the beneficial compounds or natural characteristics of the oleoresins.

The industrial oleoresin market is also witnessing increased demand for customized solutions, with end-users seeking specific viscosity, color, and concentration profiles tailored to their application requirements. This customization trend necessitates flexible and adaptable filtering systems that can be optimized for different oleoresin types and desired output specifications.

Industrial applications of oleoresins have seen particularly robust growth due to their superior properties compared to essential oils, including higher concentration, better stability, and longer shelf life. The pharmaceutical sector's demand has increased significantly, with oleoresins being utilized in various medicinal formulations due to their therapeutic properties. This sector is expected to witness the fastest growth rate in oleoresin consumption over the next five years.

Regionally, Asia-Pacific dominates the market, accounting for approximately 40% of global consumption, followed by North America and Europe. India and China are the largest producers and exporters of oleoresins, while developed markets in North America and Europe represent significant consumption hubs due to the growing preference for natural ingredients in consumer products.

The demand for high-quality filtered oleoresins has intensified as end-users require products with consistent quality, purity, and performance characteristics. Industries are increasingly willing to pay premium prices for oleoresins that meet stringent quality standards, particularly those free from contaminants and with standardized active compound content. This trend has created a substantial market opportunity for advanced filtering technologies that can deliver superior product quality while maintaining cost-effectiveness.

Supply chain challenges, including raw material availability fluctuations and quality inconsistencies, have further emphasized the need for efficient filtering processes that can handle variable input quality. Market research indicates that approximately 30% of oleoresin processors cite filtering optimization as a critical factor affecting their production costs and product marketability.

Consumer trends toward clean label products and natural ingredients have also bolstered demand for minimally processed oleoresins that retain their natural properties while meeting safety standards. This has created a growing niche for filtering technologies that can remove impurities without affecting the beneficial compounds or natural characteristics of the oleoresins.

The industrial oleoresin market is also witnessing increased demand for customized solutions, with end-users seeking specific viscosity, color, and concentration profiles tailored to their application requirements. This customization trend necessitates flexible and adaptable filtering systems that can be optimized for different oleoresin types and desired output specifications.

Current Filtration Technologies and Challenges

The industrial filtration of oleoresins currently employs several established technologies, each with specific advantages and limitations. Conventional methods include pressure filtration, vacuum filtration, and centrifugation. Pressure filtration systems force oleoresin through filter media using positive pressure, while vacuum filtration draws the material through filters using negative pressure. Centrifugation separates components based on density differences, which is particularly useful for removing particulate matter from oleoresins.

Filter media technology has evolved significantly, with options ranging from traditional cloth filters to advanced ceramic membranes. Diatomaceous earth and activated carbon are commonly used as filter aids to enhance filtration efficiency by creating a porous cake that traps fine particles. Polymeric membranes with controlled pore sizes have gained popularity for their ability to achieve consistent filtration results across batches.

Despite these advancements, the industry faces persistent challenges in oleoresin filtration. The high viscosity of oleoresins, particularly at lower temperatures, significantly reduces flow rates and increases processing time. This viscosity issue often necessitates heating the oleoresin, which can potentially degrade heat-sensitive compounds and alter the product's chemical profile.

Fouling represents another major challenge, as resinous materials tend to accumulate on filter surfaces, rapidly decreasing filtration efficiency and necessitating frequent cleaning or replacement of filter media. This leads to increased downtime and operational costs. The heterogeneous nature of oleoresins, containing particles of varying sizes and compositions, further complicates the selection of optimal filtration parameters.

Energy consumption remains a significant concern, particularly for pressure-based systems that require substantial power to maintain adequate flow rates through clogged filters. The trade-off between filtration speed and quality often forces manufacturers to compromise, resulting in either lower throughput or reduced product purity.

Scale-up challenges persist when transitioning from laboratory to industrial production. Filtration systems that perform well at small scales often encounter unexpected issues when processing larger volumes, including channeling, uneven cake formation, and pressure distribution problems.

Environmental considerations have become increasingly important, with traditional filtration methods generating substantial waste in the form of spent filter media and filter aids. The disposal of these materials, often contaminated with organic compounds, presents both environmental and regulatory challenges for manufacturers.

Recent technological innovations are addressing these challenges through the development of cross-flow filtration systems, self-cleaning filters, and hybrid approaches combining multiple separation techniques. However, implementation costs and technical complexity have limited widespread adoption of these advanced solutions in the oleoresin industry.

Filter media technology has evolved significantly, with options ranging from traditional cloth filters to advanced ceramic membranes. Diatomaceous earth and activated carbon are commonly used as filter aids to enhance filtration efficiency by creating a porous cake that traps fine particles. Polymeric membranes with controlled pore sizes have gained popularity for their ability to achieve consistent filtration results across batches.

Despite these advancements, the industry faces persistent challenges in oleoresin filtration. The high viscosity of oleoresins, particularly at lower temperatures, significantly reduces flow rates and increases processing time. This viscosity issue often necessitates heating the oleoresin, which can potentially degrade heat-sensitive compounds and alter the product's chemical profile.

Fouling represents another major challenge, as resinous materials tend to accumulate on filter surfaces, rapidly decreasing filtration efficiency and necessitating frequent cleaning or replacement of filter media. This leads to increased downtime and operational costs. The heterogeneous nature of oleoresins, containing particles of varying sizes and compositions, further complicates the selection of optimal filtration parameters.

Energy consumption remains a significant concern, particularly for pressure-based systems that require substantial power to maintain adequate flow rates through clogged filters. The trade-off between filtration speed and quality often forces manufacturers to compromise, resulting in either lower throughput or reduced product purity.

Scale-up challenges persist when transitioning from laboratory to industrial production. Filtration systems that perform well at small scales often encounter unexpected issues when processing larger volumes, including channeling, uneven cake formation, and pressure distribution problems.

Environmental considerations have become increasingly important, with traditional filtration methods generating substantial waste in the form of spent filter media and filter aids. The disposal of these materials, often contaminated with organic compounds, presents both environmental and regulatory challenges for manufacturers.

Recent technological innovations are addressing these challenges through the development of cross-flow filtration systems, self-cleaning filters, and hybrid approaches combining multiple separation techniques. However, implementation costs and technical complexity have limited widespread adoption of these advanced solutions in the oleoresin industry.

Current Industrial Filtration Solutions

01 Filtration equipment and apparatus design

Specialized equipment and apparatus designs can significantly improve oleoresin filtration efficiency. These include innovative filter press configurations, continuous filtration systems, and automated filtering equipment that optimize the separation of solid impurities from oleoresin extracts. Advanced designs incorporate features like adjustable pressure control, multi-stage filtration, and specialized filter media holders to enhance throughput and filtration quality.- Filtration equipment and apparatus design: Specialized equipment and apparatus designs can significantly improve oleoresin filtration efficiency. These designs include multi-stage filtration systems, pressure-assisted filtration units, and automated filtering equipment with precise control mechanisms. Advanced filtration apparatus may incorporate features such as adjustable pressure controls, temperature regulation systems, and specialized filter media holders to optimize the separation of oleoresin components from impurities.

- Filter media selection and optimization: The selection of appropriate filter media is crucial for oleoresin filtration optimization. Different filter materials such as diatomaceous earth, activated carbon, cellulose, and synthetic membranes offer varying degrees of filtration efficiency depending on the oleoresin type and desired purity level. Optimization involves selecting the appropriate pore size, material compatibility, and filter arrangement to maximize throughput while maintaining product quality. Multi-layer filtration using different media in sequence can effectively remove particles of various sizes.

- Process parameter optimization: Optimizing process parameters such as temperature, pressure, flow rate, and residence time significantly impacts oleoresin filtration efficiency. Higher temperatures generally reduce viscosity and improve flow characteristics, while controlled pressure differentials can enhance filtration rates without compromising quality. The optimization of these parameters must be tailored to specific oleoresin types, as different botanical sources require different processing conditions to maintain bioactive compound integrity while maximizing yield.

- Pre-treatment and clarification methods: Pre-treatment processes before main filtration significantly improve overall filtration efficiency for oleoresins. Techniques include centrifugation to remove coarse particles, enzymatic treatment to break down complex molecules, and clarification using flocculants or coagulants to aggregate fine particles. These pre-treatment steps reduce the burden on the main filtration system, extend filter life, improve throughput rates, and enhance the purity of the final oleoresin product.

- Novel extraction and filtration technologies: Innovative technologies are being developed to enhance oleoresin filtration, including membrane filtration, ultrafiltration, and supercritical fluid extraction combined with integrated filtration systems. These advanced methods offer advantages such as higher selectivity, reduced solvent usage, lower processing temperatures, and improved retention of volatile compounds. Some novel approaches incorporate nanotechnology-based filter materials or utilize electromagnetic fields to enhance separation efficiency while maintaining the bioactive properties of oleoresin compounds.

02 Filter media selection and optimization

The choice of filter media significantly impacts oleoresin filtration efficiency. Various materials such as diatomaceous earth, activated carbon, cellulose, and synthetic membranes offer different advantages in terms of particle retention, flow rate, and capacity. Optimizing filter media combinations, pore sizes, and layering techniques can enhance filtration performance while minimizing product loss and maintaining the desired oleoresin characteristics.Expand Specific Solutions03 Process parameter optimization

Optimizing process parameters such as temperature, pressure, flow rate, and residence time is crucial for efficient oleoresin filtration. Controlled heating can reduce viscosity and improve flow characteristics, while optimized pressure gradients enhance filtration rates without compromising quality. Systematic adjustment of these parameters based on the specific oleoresin type and desired end-product specifications can significantly improve filtration efficiency and yield.Expand Specific Solutions04 Pre-treatment and clarification methods

Various pre-treatment methods can enhance subsequent filtration of oleoresins. These include settling, centrifugation, flocculation, and preliminary clarification steps that remove larger particles and reduce the load on the main filtration system. Chemical treatments to modify the physical properties of impurities or the addition of filter aids can also significantly improve filtration efficiency and extend filter life.Expand Specific Solutions05 Novel extraction and purification techniques

Innovative extraction and purification approaches can improve the overall quality of oleoresins and simplify subsequent filtration steps. These include supercritical fluid extraction, membrane filtration technologies, and integrated extraction-filtration systems. Advanced techniques like ultrasonic-assisted filtration, pulsed electric field treatment, and enzymatic processing can break down complex impurities and enhance the filterability of oleoresin products.Expand Specific Solutions

Key Industry Players in Oleoresin Filtration

The oleoresin filtering technology market is currently in a growth phase, with increasing industrial applications driving demand for more efficient filtration solutions. The global market size is estimated to exceed $2 billion, expanding at approximately 5-7% annually due to growing applications in petrochemicals, food processing, and pharmaceuticals. Major oil companies like ExxonMobil Chemical Patents, Saudi Aramco, and Shell Internationale Research dominate the technological landscape, with specialized filtration companies such as Filtration Group GmbH and SKF Recondoil AB offering innovative solutions. Chemical giants including Dow Global Technologies, Air Liquide, and Sumitomo Chemical are advancing membrane technology and sustainable filtering processes. The technology is approaching maturity in traditional applications but continues to evolve with new developments in nano-filtration, sustainable reuse systems, and specialized applications for high-value oleoresins.

Filtration Group GmbH

Technical Solution: Filtration Group GmbH has developed advanced membrane filtration technology specifically designed for oleoresin processing. Their system employs a multi-stage filtration approach that combines ceramic membranes with specialized polymer membranes resistant to terpenes and other resinous compounds. The technology utilizes cross-flow filtration principles to prevent membrane fouling, a common challenge in oleoresin processing. Their proprietary membrane configuration allows for continuous operation with automated backwashing cycles that extend membrane life by up to 300% compared to conventional systems. The process operates at moderate temperatures (60-80°C) to maintain optimal viscosity while preserving heat-sensitive compounds in the oleoresin. Their systems incorporate real-time monitoring with adaptive pressure control that responds to changes in feed composition, ensuring consistent filtration efficiency across varying oleoresin types.

Strengths: Superior fouling resistance through proprietary membrane materials and cross-flow design; automated cleaning systems that significantly reduce downtime; modular design allowing for scalability from pilot to industrial scale. Weaknesses: Higher initial capital investment compared to conventional filtration systems; requires specialized maintenance expertise; performance can be affected by extreme variations in feed composition.

Baker Hughes Co.

Technical Solution: Baker Hughes has developed an industrial-scale oleoresin filtration technology leveraging their expertise in oil and gas separation systems. Their approach utilizes a hybrid filtration system combining centrifugal separation with advanced filter media specifically engineered for high-viscosity resinous materials. The system employs a proprietary pre-conditioning stage that modifies the rheological properties of oleoresins through controlled shear and temperature manipulation, significantly improving filtration efficiency. Their filter media incorporates nanomaterial coatings that resist fouling from sticky resin components while maintaining high flow rates. The technology operates as a continuous process with automated filter element rotation that distributes the filtration load evenly, extending operational cycles by up to 400% compared to static systems. Baker Hughes' system incorporates real-time viscosity monitoring and adaptive pressure control algorithms that optimize filtration parameters based on feed characteristics, ensuring consistent performance across varying oleoresin compositions.

Strengths: Exceptional handling of high-viscosity materials through rheological pre-conditioning; advanced anti-fouling filter media significantly extends operational cycles; robust design suitable for harsh industrial environments. Weaknesses: Higher energy consumption compared to passive filtration systems; complex control systems require specialized technical support; significant footprint requirements for full-scale implementation.

Critical Patents and Technologies in Oleoresin Processing

Device to separate olefins from paraffins and to purify olefins and use thereof

PatentWO2007111521A2

Innovation

- The use of ultramicroporous ceramic membranes functionalized with silver or copper, combined with a palladium catalyst, for selective hydrogenation of dienes and alkynes, enhancing separation selectivity and driving force by converting impurities into olefins at the permeate side.

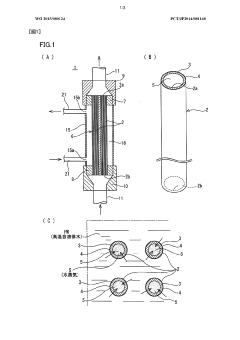

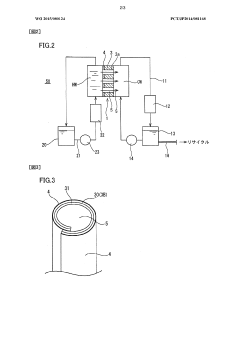

Wastewater treatment method, membrane distillation module and wastewater treatment apparatus

PatentWO2015080124A1

Innovation

- A membrane distillation method using a hydrophobic porous membrane made of fluororesin, such as PTFE, that allows only water vapor to permeate, simultaneously removing oil, salt, and organic matter, reducing the need for multiple treatment stages and desalination processes, and featuring an oil-repellent layer to prevent membrane clogging and enhance chemical resistance.

Environmental Impact and Sustainability Considerations

The industrial processing of oleoresins generates significant environmental impacts that must be addressed through sustainable practices. Traditional filtering methods often involve chemical solvents and energy-intensive processes that produce hazardous waste and contribute to greenhouse gas emissions. Recent studies indicate that the oleoresin industry's carbon footprint can be reduced by up to 30% through implementation of optimized filtering technologies that minimize resource consumption and waste generation.

Water usage represents a critical environmental concern in oleoresin processing. Conventional filtering systems may require substantial volumes of water for cleaning and maintenance operations. Advanced membrane filtration technologies have demonstrated potential to reduce water consumption by 40-60% compared to traditional methods, while simultaneously improving filtration efficiency. These systems incorporate water recycling mechanisms that capture, treat, and reuse process water, significantly reducing the overall environmental footprint.

Waste management presents another substantial challenge in oleoresin filtering operations. The spent filter media, contaminated solvents, and residual materials often contain compounds that require specialized disposal procedures. Implementing biodegradable filter media and environmentally friendly cleaning agents can substantially reduce the environmental burden. Companies pioneering these approaches have reported up to 45% reduction in hazardous waste generation while maintaining product quality standards.

Energy efficiency improvements offer significant sustainability benefits in oleoresin filtering. The transition from thermal-based separation processes to pressure-driven filtration systems can reduce energy consumption by 25-35%. Integration of renewable energy sources, such as solar thermal systems for maintaining optimal processing temperatures, further enhances the sustainability profile of industrial oleoresin operations.

Life cycle assessment (LCA) methodologies are increasingly being applied to evaluate the comprehensive environmental impact of oleoresin filtering processes. These assessments consider raw material extraction, processing, transportation, use, and end-of-life disposal. Recent LCA studies have identified filter media selection and regeneration protocols as key leverage points for environmental improvement, with potential to reduce overall ecological footprint by 20-25% through strategic material choices.

Regulatory compliance and certification standards are evolving to address environmental concerns in industrial processing. Organizations like the Sustainable Forestry Initiative and the Roundtable on Sustainable Biomaterials have developed frameworks specifically applicable to plant-derived industrial products. Adherence to these standards not only ensures environmental protection but also provides market advantages through eco-certification programs that are increasingly valued by environmentally conscious consumers and business partners.

Water usage represents a critical environmental concern in oleoresin processing. Conventional filtering systems may require substantial volumes of water for cleaning and maintenance operations. Advanced membrane filtration technologies have demonstrated potential to reduce water consumption by 40-60% compared to traditional methods, while simultaneously improving filtration efficiency. These systems incorporate water recycling mechanisms that capture, treat, and reuse process water, significantly reducing the overall environmental footprint.

Waste management presents another substantial challenge in oleoresin filtering operations. The spent filter media, contaminated solvents, and residual materials often contain compounds that require specialized disposal procedures. Implementing biodegradable filter media and environmentally friendly cleaning agents can substantially reduce the environmental burden. Companies pioneering these approaches have reported up to 45% reduction in hazardous waste generation while maintaining product quality standards.

Energy efficiency improvements offer significant sustainability benefits in oleoresin filtering. The transition from thermal-based separation processes to pressure-driven filtration systems can reduce energy consumption by 25-35%. Integration of renewable energy sources, such as solar thermal systems for maintaining optimal processing temperatures, further enhances the sustainability profile of industrial oleoresin operations.

Life cycle assessment (LCA) methodologies are increasingly being applied to evaluate the comprehensive environmental impact of oleoresin filtering processes. These assessments consider raw material extraction, processing, transportation, use, and end-of-life disposal. Recent LCA studies have identified filter media selection and regeneration protocols as key leverage points for environmental improvement, with potential to reduce overall ecological footprint by 20-25% through strategic material choices.

Regulatory compliance and certification standards are evolving to address environmental concerns in industrial processing. Organizations like the Sustainable Forestry Initiative and the Roundtable on Sustainable Biomaterials have developed frameworks specifically applicable to plant-derived industrial products. Adherence to these standards not only ensures environmental protection but also provides market advantages through eco-certification programs that are increasingly valued by environmentally conscious consumers and business partners.

Quality Control Standards and Regulatory Compliance

Quality control standards and regulatory compliance are critical components in the optimization of oleoresin filtering for industrial applications. The oleoresin industry must adhere to stringent international standards such as ISO 22000 for food safety management systems and ISO 9001 for quality management. These frameworks establish the foundation for consistent product quality and safety across global markets.

The FDA's Current Good Manufacturing Practices (cGMPs) specifically regulate oleoresin processing in the United States, with particular emphasis on filtration processes to ensure removal of contaminants. Similarly, the European Food Safety Authority (EFSA) has established specific guidelines for plant extracts used in food applications, including detailed specifications for filtration efficiency and purity levels.

Regulatory compliance extends to environmental considerations as well. The Environmental Protection Agency (EPA) regulates waste disposal from oleoresin processing, requiring proper management of filtration byproducts and spent filter media. Companies must implement comprehensive environmental management systems to track and minimize the ecological footprint of their filtration operations.

Quality control in oleoresin filtration necessitates rigorous testing protocols at multiple stages. Standardized methods for measuring turbidity, viscosity, and particulate content have been established by organizations such as AOAC International and the American Spice Trade Association (ASTA). These methods provide quantifiable metrics for filtration effectiveness and product consistency.

Traceability requirements have become increasingly important in regulatory frameworks worldwide. Documentation systems must track oleoresin from raw material sourcing through filtration processes to final product distribution. This chain of custody documentation is essential for regulatory compliance and facilitates rapid response in case of quality concerns or product recalls.

Industry-specific certifications such as HACCP (Hazard Analysis Critical Control Points) identify filtration as a critical control point in oleoresin processing. Companies must establish monitoring procedures, critical limits, and corrective actions specifically for filtration processes to maintain certification and ensure product safety.

Emerging regulations are focusing on sustainability aspects of filtration technologies. The trend toward green chemistry principles is driving regulatory changes that favor filtration methods with reduced solvent usage, lower energy consumption, and minimized waste generation. Companies optimizing their oleoresin filtration processes must anticipate these evolving regulatory requirements to maintain compliance in the future.

The FDA's Current Good Manufacturing Practices (cGMPs) specifically regulate oleoresin processing in the United States, with particular emphasis on filtration processes to ensure removal of contaminants. Similarly, the European Food Safety Authority (EFSA) has established specific guidelines for plant extracts used in food applications, including detailed specifications for filtration efficiency and purity levels.

Regulatory compliance extends to environmental considerations as well. The Environmental Protection Agency (EPA) regulates waste disposal from oleoresin processing, requiring proper management of filtration byproducts and spent filter media. Companies must implement comprehensive environmental management systems to track and minimize the ecological footprint of their filtration operations.

Quality control in oleoresin filtration necessitates rigorous testing protocols at multiple stages. Standardized methods for measuring turbidity, viscosity, and particulate content have been established by organizations such as AOAC International and the American Spice Trade Association (ASTA). These methods provide quantifiable metrics for filtration effectiveness and product consistency.

Traceability requirements have become increasingly important in regulatory frameworks worldwide. Documentation systems must track oleoresin from raw material sourcing through filtration processes to final product distribution. This chain of custody documentation is essential for regulatory compliance and facilitates rapid response in case of quality concerns or product recalls.

Industry-specific certifications such as HACCP (Hazard Analysis Critical Control Points) identify filtration as a critical control point in oleoresin processing. Companies must establish monitoring procedures, critical limits, and corrective actions specifically for filtration processes to maintain certification and ensure product safety.

Emerging regulations are focusing on sustainability aspects of filtration technologies. The trend toward green chemistry principles is driving regulatory changes that favor filtration methods with reduced solvent usage, lower energy consumption, and minimized waste generation. Companies optimizing their oleoresin filtration processes must anticipate these evolving regulatory requirements to maintain compliance in the future.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!