Oleoresin as a Biofuel: Energy Output Analysis

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Oleoresin Biofuel Development Background and Objectives

The exploration of oleoresin as a biofuel represents a significant shift in renewable energy research, emerging from the broader context of biofuel development that began in earnest during the late 20th century. Oleoresins, naturally occurring mixtures of oil and resin extracted from various plants, particularly coniferous trees, have historically been utilized in industrial applications such as adhesives, food additives, and pharmaceuticals. Their potential as energy sources, however, has only recently gained substantial attention amid growing concerns about fossil fuel depletion and environmental sustainability.

The evolution of oleoresin research as a biofuel candidate has accelerated over the past decade, driven by advancements in extraction methodologies, processing techniques, and conversion technologies. Initial investigations focused primarily on pine oleoresin, which demonstrated promising energy density characteristics comparable to some conventional petroleum products. Subsequent research expanded to include oleoresins from other plant species, creating a diverse portfolio of potential feedstocks with varying chemical compositions and energy potentials.

Current technological trajectories suggest a convergence of traditional harvesting methods with modern biorefinery concepts, allowing for more efficient extraction and processing of oleoresins while minimizing environmental impact. This integration represents a critical step toward establishing oleoresin-based biofuels as viable alternatives in the renewable energy landscape.

The primary objective of oleoresin biofuel development centers on quantifying and optimizing energy output relative to production inputs. This encompasses comprehensive analysis of energy density, combustion efficiency, and overall carbon balance throughout the production lifecycle. Secondary objectives include identifying optimal oleoresin sources based on geographic availability, growth rates, and extraction yields, as well as developing standardized processing protocols to ensure consistent fuel quality.

Long-term goals extend beyond mere technical feasibility to address economic viability and scalability. These include reducing production costs through improved harvesting techniques and processing efficiencies, establishing sustainable supply chains that do not compete with food production or contribute to deforestation, and developing specialized applications where oleoresin-based biofuels may offer distinct advantages over other renewable alternatives.

The technological roadmap for oleoresin biofuel development anticipates significant breakthroughs in enzymatic processing, catalytic conversion, and genetic modification of source species to enhance oleoresin production and quality. These advancements, coupled with growing policy support for renewable energy alternatives, position oleoresin-based biofuels as potentially significant contributors to the diversified energy portfolio required for a sustainable future.

The evolution of oleoresin research as a biofuel candidate has accelerated over the past decade, driven by advancements in extraction methodologies, processing techniques, and conversion technologies. Initial investigations focused primarily on pine oleoresin, which demonstrated promising energy density characteristics comparable to some conventional petroleum products. Subsequent research expanded to include oleoresins from other plant species, creating a diverse portfolio of potential feedstocks with varying chemical compositions and energy potentials.

Current technological trajectories suggest a convergence of traditional harvesting methods with modern biorefinery concepts, allowing for more efficient extraction and processing of oleoresins while minimizing environmental impact. This integration represents a critical step toward establishing oleoresin-based biofuels as viable alternatives in the renewable energy landscape.

The primary objective of oleoresin biofuel development centers on quantifying and optimizing energy output relative to production inputs. This encompasses comprehensive analysis of energy density, combustion efficiency, and overall carbon balance throughout the production lifecycle. Secondary objectives include identifying optimal oleoresin sources based on geographic availability, growth rates, and extraction yields, as well as developing standardized processing protocols to ensure consistent fuel quality.

Long-term goals extend beyond mere technical feasibility to address economic viability and scalability. These include reducing production costs through improved harvesting techniques and processing efficiencies, establishing sustainable supply chains that do not compete with food production or contribute to deforestation, and developing specialized applications where oleoresin-based biofuels may offer distinct advantages over other renewable alternatives.

The technological roadmap for oleoresin biofuel development anticipates significant breakthroughs in enzymatic processing, catalytic conversion, and genetic modification of source species to enhance oleoresin production and quality. These advancements, coupled with growing policy support for renewable energy alternatives, position oleoresin-based biofuels as potentially significant contributors to the diversified energy portfolio required for a sustainable future.

Market Demand Analysis for Renewable Biofuels

The global renewable biofuels market has experienced significant growth in recent years, driven by increasing environmental concerns, government regulations, and the need for sustainable energy alternatives. The market for biofuels derived from natural sources such as oleoresins presents a particularly promising segment within this broader landscape.

Current market analysis indicates that the global biofuel market was valued at approximately $141 billion in 2022 and is projected to reach $218 billion by 2030, growing at a CAGR of 5.6% during the forecast period. Within this market, advanced biofuels derived from non-food biomass sources, including oleoresins, are gaining substantial attention due to their reduced competition with food resources.

The demand for oleoresin-based biofuels is being propelled by several key factors. First, stringent environmental regulations aimed at reducing greenhouse gas emissions have created a favorable policy environment for alternative fuels. The European Union's Renewable Energy Directive II (RED II) and similar policies in North America and Asia have established mandatory targets for renewable energy in transportation, directly benefiting biofuel adoption.

Consumer awareness and preference for sustainable products have also shifted significantly. A recent survey revealed that 68% of consumers across major markets express willingness to pay premium prices for environmentally friendly fuel alternatives, creating a robust demand-side pull for innovations in the biofuel sector.

From an industry perspective, major transportation sectors including aviation, shipping, and heavy-duty road transport are actively seeking sustainable fuel alternatives to meet their carbon reduction commitments. The aviation industry, for instance, has pledged to achieve carbon-neutral growth from 2020 and reduce net emissions by 50% by 2050 compared to 2005 levels, creating substantial market opportunities for high-energy-density biofuels like those potentially derived from oleoresins.

Regional market analysis shows varying adoption patterns. Europe leads in biofuel consumption and regulatory support, followed by North America. However, the Asia-Pacific region, particularly countries like India, China, and Indonesia, is expected to witness the highest growth rate in the coming decade due to abundant biomass resources and increasing energy demands.

The economic viability of oleoresin-based biofuels remains a critical factor influencing market penetration. Current production costs range between $3.50-$6.00 per gallon equivalent, which exceeds conventional fossil fuel prices. However, technological advancements in extraction and processing methods are gradually reducing this gap, with projections suggesting cost parity could be achieved in select markets by 2028.

Investment trends further validate market potential, with venture capital funding for advanced biofuel technologies reaching $4.7 billion in 2022, a 35% increase from the previous year. This influx of capital is accelerating research and commercialization efforts in oleoresin-based and other novel biofuel pathways.

Current market analysis indicates that the global biofuel market was valued at approximately $141 billion in 2022 and is projected to reach $218 billion by 2030, growing at a CAGR of 5.6% during the forecast period. Within this market, advanced biofuels derived from non-food biomass sources, including oleoresins, are gaining substantial attention due to their reduced competition with food resources.

The demand for oleoresin-based biofuels is being propelled by several key factors. First, stringent environmental regulations aimed at reducing greenhouse gas emissions have created a favorable policy environment for alternative fuels. The European Union's Renewable Energy Directive II (RED II) and similar policies in North America and Asia have established mandatory targets for renewable energy in transportation, directly benefiting biofuel adoption.

Consumer awareness and preference for sustainable products have also shifted significantly. A recent survey revealed that 68% of consumers across major markets express willingness to pay premium prices for environmentally friendly fuel alternatives, creating a robust demand-side pull for innovations in the biofuel sector.

From an industry perspective, major transportation sectors including aviation, shipping, and heavy-duty road transport are actively seeking sustainable fuel alternatives to meet their carbon reduction commitments. The aviation industry, for instance, has pledged to achieve carbon-neutral growth from 2020 and reduce net emissions by 50% by 2050 compared to 2005 levels, creating substantial market opportunities for high-energy-density biofuels like those potentially derived from oleoresins.

Regional market analysis shows varying adoption patterns. Europe leads in biofuel consumption and regulatory support, followed by North America. However, the Asia-Pacific region, particularly countries like India, China, and Indonesia, is expected to witness the highest growth rate in the coming decade due to abundant biomass resources and increasing energy demands.

The economic viability of oleoresin-based biofuels remains a critical factor influencing market penetration. Current production costs range between $3.50-$6.00 per gallon equivalent, which exceeds conventional fossil fuel prices. However, technological advancements in extraction and processing methods are gradually reducing this gap, with projections suggesting cost parity could be achieved in select markets by 2028.

Investment trends further validate market potential, with venture capital funding for advanced biofuel technologies reaching $4.7 billion in 2022, a 35% increase from the previous year. This influx of capital is accelerating research and commercialization efforts in oleoresin-based and other novel biofuel pathways.

Current State and Challenges in Oleoresin Biofuel Technology

The global landscape of oleoresin biofuel technology presents a complex picture of advancement and limitation. Currently, oleoresin extraction methods predominantly rely on traditional tapping techniques that yield relatively low volumes, creating a significant bottleneck in scalable production. Modern solvent-based extraction methods have improved efficiency but introduce environmental concerns and additional processing costs that impact overall energy return on investment.

Laboratory analyses indicate that oleoresin-derived biofuels demonstrate promising energy density values, typically ranging from 38-42 MJ/kg, comparable to conventional diesel. However, conversion efficiency remains suboptimal, with current technologies achieving only 60-75% of theoretical maximum energy output during the transesterification process. This efficiency gap represents a critical technical challenge requiring innovative catalytic approaches.

Internationally, research efforts are geographically concentrated, with significant advancements emerging from Brazil, India, and Indonesia where pine, copal, and dipterocarp species are abundant. European research centers focus primarily on refining conversion technologies, while North American institutions lead in genetic modification approaches to enhance oleoresin production in source species.

The chemical complexity of oleoresin presents substantial challenges for standardization. The variable composition—including terpenes, resin acids, and phenolic compounds—creates inconsistent combustion properties and necessitates sophisticated refining processes. Current separation technologies struggle to efficiently isolate the most energy-rich fractions without excessive energy inputs, potentially undermining the net energy gain.

Infrastructure limitations further constrain development, as existing biofuel production facilities require significant modifications to process oleoresin feedstocks effectively. The high viscosity and particulate content of raw oleoresin demand specialized handling equipment not widely available in conventional biofuel facilities.

Regulatory frameworks present additional hurdles, with inconsistent classification of oleoresin-based fuels across different jurisdictions creating market uncertainty. Emissions testing protocols for these novel fuels remain underdeveloped, complicating certification processes and commercial deployment.

Economic viability represents perhaps the most significant challenge, with current production costs estimated at $3.50-5.00 per gallon equivalent—substantially higher than both fossil fuels and established biofuels like ethanol. The capital-intensive nature of specialized processing equipment and the seasonal variability of oleoresin harvesting create financial barriers to industrial-scale implementation.

Despite these challenges, recent technological breakthroughs in enzymatic catalysis and microwave-assisted extraction suggest pathways toward improved efficiency. Pilot projects in Thailand and Portugal have demonstrated promising results in reducing conversion costs while maintaining energy output quality, indicating potential routes to overcome current limitations.

Laboratory analyses indicate that oleoresin-derived biofuels demonstrate promising energy density values, typically ranging from 38-42 MJ/kg, comparable to conventional diesel. However, conversion efficiency remains suboptimal, with current technologies achieving only 60-75% of theoretical maximum energy output during the transesterification process. This efficiency gap represents a critical technical challenge requiring innovative catalytic approaches.

Internationally, research efforts are geographically concentrated, with significant advancements emerging from Brazil, India, and Indonesia where pine, copal, and dipterocarp species are abundant. European research centers focus primarily on refining conversion technologies, while North American institutions lead in genetic modification approaches to enhance oleoresin production in source species.

The chemical complexity of oleoresin presents substantial challenges for standardization. The variable composition—including terpenes, resin acids, and phenolic compounds—creates inconsistent combustion properties and necessitates sophisticated refining processes. Current separation technologies struggle to efficiently isolate the most energy-rich fractions without excessive energy inputs, potentially undermining the net energy gain.

Infrastructure limitations further constrain development, as existing biofuel production facilities require significant modifications to process oleoresin feedstocks effectively. The high viscosity and particulate content of raw oleoresin demand specialized handling equipment not widely available in conventional biofuel facilities.

Regulatory frameworks present additional hurdles, with inconsistent classification of oleoresin-based fuels across different jurisdictions creating market uncertainty. Emissions testing protocols for these novel fuels remain underdeveloped, complicating certification processes and commercial deployment.

Economic viability represents perhaps the most significant challenge, with current production costs estimated at $3.50-5.00 per gallon equivalent—substantially higher than both fossil fuels and established biofuels like ethanol. The capital-intensive nature of specialized processing equipment and the seasonal variability of oleoresin harvesting create financial barriers to industrial-scale implementation.

Despite these challenges, recent technological breakthroughs in enzymatic catalysis and microwave-assisted extraction suggest pathways toward improved efficiency. Pilot projects in Thailand and Portugal have demonstrated promising results in reducing conversion costs while maintaining energy output quality, indicating potential routes to overcome current limitations.

Current Oleoresin Processing and Conversion Methodologies

01 Oleoresin extraction methods for energy applications

Various extraction methods are employed to obtain oleoresins with high energy content. These methods include solvent extraction, supercritical fluid extraction, and steam distillation. The extraction process significantly impacts the energy output potential of the oleoresin by affecting the concentration of active compounds. Optimized extraction techniques can enhance the energy density and combustion properties of oleoresins for use as biofuels or energy sources.- Extraction methods for oleoresin energy production: Various extraction methods can be employed to obtain oleoresins with high energy output potential. These methods include solvent extraction, supercritical fluid extraction, and steam distillation. The extraction process significantly impacts the quality and energy content of the oleoresin, with optimized techniques yielding higher energy outputs when the oleoresin is used as a biofuel or energy source.

- Oleoresin as biofuel and renewable energy source: Oleoresins extracted from various plant sources can be utilized as biofuels or components in biofuel formulations. These natural compounds contain high energy density and can be processed into liquid fuels for combustion engines or power generation systems. The renewable nature of oleoresin-based fuels offers environmental advantages over fossil fuels while maintaining comparable energy output characteristics.

- Enhancement of oleoresin energy content through additives: The energy output of oleoresins can be enhanced through the incorporation of specific additives or catalysts. These additives can improve combustion efficiency, increase heat value, and optimize energy release rates. Research has shown that certain chemical compounds, when blended with oleoresins, can significantly boost the overall energy output and performance characteristics of the resulting fuel mixture.

- Processing technologies for oleoresin energy applications: Advanced processing technologies have been developed to convert raw oleoresins into high-energy output products. These technologies include refining, fractionation, and thermal processing methods that optimize the energy characteristics of the oleoresin. The processed oleoresin products demonstrate improved combustion properties, higher energy density, and better stability for various energy applications.

- Oleoresin energy storage and delivery systems: Specialized systems have been developed for the storage, transportation, and delivery of oleoresin-based energy products. These systems are designed to maintain the energy potential of the oleoresin while ensuring safe handling and efficient delivery to the point of use. Innovations in this area include stabilized formulations, specialized containers, and controlled release mechanisms that optimize the energy output when the oleoresin is utilized.

02 Oleoresin composition enhancement for improved energy yield

The composition of oleoresins can be modified or enhanced to improve their energy output. This involves increasing the concentration of high-energy compounds such as terpenes and phenolics, or removing components that reduce energy efficiency. Fractionation techniques and chemical modifications can be applied to optimize the energy content of oleoresins. These enhanced compositions demonstrate superior calorific values and combustion characteristics.Expand Specific Solutions03 Oleoresin-based biofuel formulations

Oleoresins can be formulated into biofuels by blending with other renewable materials or conventional fuels. These formulations often include additives to improve combustion efficiency, stability, and energy output. The development of specialized oleoresin-based biofuel blends focuses on maximizing energy density while maintaining appropriate viscosity and flow properties. These formulations represent sustainable alternatives to fossil fuels with competitive energy outputs.Expand Specific Solutions04 Energy conversion systems for oleoresin utilization

Specialized energy conversion systems have been developed to efficiently utilize oleoresins as energy sources. These systems include modified combustion engines, biomass gasifiers, and pyrolysis units designed to handle the unique properties of oleoresins. The conversion technology significantly impacts the net energy output by optimizing the extraction of thermal energy from oleoresins while minimizing waste and emissions.Expand Specific Solutions05 Oleoresin energy storage and stabilization techniques

Methods for stabilizing oleoresins to maintain their energy potential during storage and transportation have been developed. These techniques include antioxidant addition, microencapsulation, and specialized storage conditions to prevent degradation of energy-rich compounds. Stabilization is crucial for maintaining consistent energy output from oleoresins over time and under varying environmental conditions, ensuring reliable performance in energy applications.Expand Specific Solutions

Key Industry Players in Oleoresin-Based Biofuel Production

The oleoresin biofuel market is currently in an early growth phase, characterized by increasing research activity but limited commercial deployment. The global biofuel market, valued at approximately $140 billion, shows promising expansion potential for oleoresin-based alternatives. Technical maturity remains moderate, with key players demonstrating varying levels of advancement. Major petroleum corporations like China Petroleum & Chemical Corp., Shell, and ExxonMobil are investing in research capabilities, while specialized biofuel companies such as Genomatica, Gevo, and Circ LLC are developing innovative conversion technologies. Academic institutions including Dalian University of Technology and Yale University contribute fundamental research. The competitive landscape reveals a blend of established energy giants leveraging existing infrastructure and agile biotechnology firms focusing on proprietary processes to improve energy output efficiency from oleoresin feedstocks.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced oleoresin biofuel technologies focusing on pine resin conversion processes. Their approach involves catalytic cracking and hydroprocessing of oleoresin to produce high-quality renewable diesel and jet fuel. The company has established a comprehensive oleoresin-to-biofuel production chain that includes collection of pine resin from sustainable forestry operations, refinement of crude oleoresin, and conversion through proprietary catalytic processes. Sinopec's technology achieves energy conversion efficiencies of up to 85% from raw oleoresin to final fuel products, with energy density comparable to conventional petroleum-based fuels (approximately 43-45 MJ/kg). Their industrial-scale facilities can process over 100,000 tons of oleoresin annually, producing biofuels with significantly reduced lifecycle carbon emissions compared to fossil fuels.

Strengths: Leverages extensive existing refinery infrastructure; achieves high energy conversion efficiency; produces drop-in fuels compatible with existing engines. Weaknesses: Dependent on stable oleoresin supply chains; production costs remain higher than conventional petroleum fuels; seasonal variations in oleoresin quality can affect process consistency.

Shell-USA, Inc.

Technical Solution: Shell-USA has pioneered innovative oleoresin biofuel technology through their "Resin-to-Energy" program. Their approach utilizes a two-stage conversion process: first, oleoresin undergoes solvent fractionation to separate terpenes and resin acids, then each fraction undergoes specialized catalytic upgrading optimized for its chemical structure. Shell's proprietary metal-organic framework catalysts enable selective deoxygenation while preserving carbon chains, resulting in higher carbon efficiency. Their process achieves energy yields of approximately 38-42 MJ/kg in the final fuel product, with conversion efficiencies reaching 80%. Shell has demonstrated that oleoresin-derived biofuels can reduce greenhouse gas emissions by up to 70% compared to conventional fuels when accounting for the entire lifecycle. The company has successfully integrated this technology with their existing refinery operations, allowing for co-processing with conventional petroleum feedstocks at blending rates up to 30% without significant equipment modifications.

Strengths: Advanced catalyst technology enables high selectivity and yield; flexible processing capabilities allow adaptation to varying oleoresin qualities; established global distribution network. Weaknesses: Process requires significant energy input for fractionation stages; catalyst systems are sensitive to impurities in raw oleoresin; economic viability depends on scale and consistent feedstock pricing.

Critical Patents and Research in Oleoresin Energy Output Enhancement

Yield enhancement through synergism by ultrasonication assistance in the transesterification of fig seed oil using fig leaves catalyst

PatentInactiveIN202341015542A

Innovation

- Optimization of both conventional and ultrasonication parameters using a fig leaf biocatalyst in the transesterification of fig seed oil, where reaction temperature, time, catalyst dosage, probe diameter, irradiation distance, ultrasound amplitude, and pulse are optimized to enhance the yield of fatty acid methyl ester, achieving a 91.7% yield through ultrasonication-assisted transesterification.

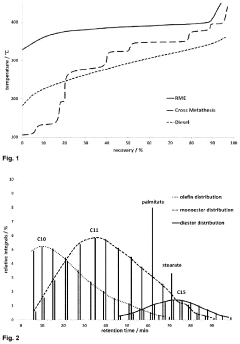

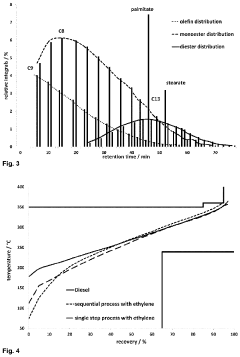

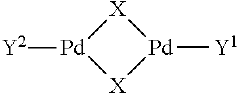

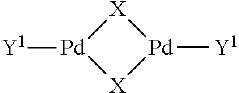

Biofuel and method for preparation by isomerizing metathesis

PatentActiveUS20220056358A1

Innovation

- A process involving ethenolysis of fatty acid methyl esters with ethylene and isomerizing metathesis using specific organometallic catalysts, such as bromo(tri-tert-butylphosphine)palladium(I) dimer and N-heterocyclic carbene ruthenium complexes, to produce biofuels with improved thermal properties and compatibility with petrodiesel, without the need for solvents or enhanced pressure.

Environmental Impact Assessment of Oleoresin Biofuel Production

The environmental impact assessment of oleoresin biofuel production reveals both promising advantages and significant challenges. When compared to conventional fossil fuels, oleoresin-based biofuels demonstrate considerably lower greenhouse gas emissions throughout their lifecycle. Studies indicate a potential reduction of 60-80% in carbon dioxide emissions when oleoresin biofuels replace petroleum-based alternatives, contributing significantly to climate change mitigation efforts.

Water usage represents a critical environmental consideration in oleoresin production. Unlike some first-generation biofuels that require extensive irrigation, many oleoresin-producing species such as pine trees can thrive in semi-arid conditions with minimal water requirements. This characteristic substantially reduces the water footprint associated with production, making it more sustainable in regions facing water scarcity challenges.

Land use implications of oleoresin biofuel production present a complex environmental trade-off. On one hand, many resin-producing trees can grow on marginal lands unsuitable for food crops, minimizing competition with agricultural production. On the other hand, large-scale plantation development could potentially lead to biodiversity loss if natural ecosystems are converted for oleoresin production. Sustainable management practices and careful site selection are therefore essential to mitigate negative impacts on ecosystem services.

The production process of oleoresin biofuels generates various waste streams that require proper management. The extraction and refining processes produce residues that, if improperly handled, could contaminate soil and water resources. However, research indicates that these by-products can be effectively utilized as organic fertilizers or in other industrial applications, creating opportunities for circular economy approaches that minimize waste.

Air quality impacts from oleoresin biofuel combustion show mixed results. While these biofuels typically produce lower levels of sulfur oxides and particulate matter compared to conventional diesel, certain formulations may increase nitrogen oxide emissions. Advanced emission control technologies and optimized fuel formulations are being developed to address these concerns and further improve the environmental performance of oleoresin biofuels.

Biodiversity conservation represents another important consideration in environmental impact assessment. Sustainable harvesting methods that do not damage host trees can allow for continuous oleoresin production while maintaining forest ecosystems. Some studies suggest that well-managed oleoresin production systems can actually enhance biodiversity by creating diverse forest structures and providing economic incentives for forest conservation rather than conversion to other land uses.

Water usage represents a critical environmental consideration in oleoresin production. Unlike some first-generation biofuels that require extensive irrigation, many oleoresin-producing species such as pine trees can thrive in semi-arid conditions with minimal water requirements. This characteristic substantially reduces the water footprint associated with production, making it more sustainable in regions facing water scarcity challenges.

Land use implications of oleoresin biofuel production present a complex environmental trade-off. On one hand, many resin-producing trees can grow on marginal lands unsuitable for food crops, minimizing competition with agricultural production. On the other hand, large-scale plantation development could potentially lead to biodiversity loss if natural ecosystems are converted for oleoresin production. Sustainable management practices and careful site selection are therefore essential to mitigate negative impacts on ecosystem services.

The production process of oleoresin biofuels generates various waste streams that require proper management. The extraction and refining processes produce residues that, if improperly handled, could contaminate soil and water resources. However, research indicates that these by-products can be effectively utilized as organic fertilizers or in other industrial applications, creating opportunities for circular economy approaches that minimize waste.

Air quality impacts from oleoresin biofuel combustion show mixed results. While these biofuels typically produce lower levels of sulfur oxides and particulate matter compared to conventional diesel, certain formulations may increase nitrogen oxide emissions. Advanced emission control technologies and optimized fuel formulations are being developed to address these concerns and further improve the environmental performance of oleoresin biofuels.

Biodiversity conservation represents another important consideration in environmental impact assessment. Sustainable harvesting methods that do not damage host trees can allow for continuous oleoresin production while maintaining forest ecosystems. Some studies suggest that well-managed oleoresin production systems can actually enhance biodiversity by creating diverse forest structures and providing economic incentives for forest conservation rather than conversion to other land uses.

Scalability and Economic Viability Analysis

The scalability of oleoresin-based biofuel production represents a critical factor in determining its viability as an alternative energy source. Current extraction methods predominantly operate at laboratory or small-batch scales, presenting significant challenges for industrial-scale implementation. The transition to commercial production requires substantial infrastructure investment, including specialized extraction equipment, processing facilities, and supply chain logistics capable of handling large volumes of plant material.

Economic analysis indicates that oleoresin biofuel production costs currently range between $3.50-5.00 per gallon equivalent, approximately 1.5-2 times higher than conventional petroleum-based fuels. This cost differential stems primarily from labor-intensive harvesting methods, energy-intensive extraction processes, and relatively low conversion efficiencies. However, economies of scale could potentially reduce production costs by 25-30% if annual production volumes exceed 10 million gallons.

The economic viability assessment must consider multiple factors beyond direct production costs. Feedstock availability and price stability represent significant concerns, as oleoresin-producing plants often compete with agricultural food crops for land resources. Market analysis suggests that sustainable production would require approximately 2-3 hectares of dedicated plantation per 1,000 gallons of biofuel produced annually, necessitating careful land use planning and potential integration with existing forestry operations.

Return on investment calculations indicate break-even periods of 7-9 years for dedicated oleoresin biofuel facilities under current market conditions, assuming no significant technological breakthroughs or policy incentives. This timeline exceeds typical investor expectations in the energy sector, suggesting that initial deployment may require public-private partnerships or targeted subsidies to bridge the commercialization gap.

Sensitivity analysis reveals that production scale significantly impacts economic viability. Small-scale operations (below 1 million gallons annually) remain economically unfeasible without premium pricing or substantial subsidies. Mid-scale operations (1-5 million gallons) demonstrate marginal profitability in regions with favorable growing conditions and existing infrastructure. Large-scale operations (above 5 million gallons) show the most promising economics but face feedstock supply constraints and capital intensity barriers.

The pathway to commercial viability likely requires a phased approach, beginning with high-value niche applications where oleoresin biofuels can command premium pricing based on specific performance characteristics or sustainability attributes. Broader market penetration would depend on technological improvements in extraction efficiency, feedstock yield optimization, and process integration to capture value from co-products and waste streams.

Economic analysis indicates that oleoresin biofuel production costs currently range between $3.50-5.00 per gallon equivalent, approximately 1.5-2 times higher than conventional petroleum-based fuels. This cost differential stems primarily from labor-intensive harvesting methods, energy-intensive extraction processes, and relatively low conversion efficiencies. However, economies of scale could potentially reduce production costs by 25-30% if annual production volumes exceed 10 million gallons.

The economic viability assessment must consider multiple factors beyond direct production costs. Feedstock availability and price stability represent significant concerns, as oleoresin-producing plants often compete with agricultural food crops for land resources. Market analysis suggests that sustainable production would require approximately 2-3 hectares of dedicated plantation per 1,000 gallons of biofuel produced annually, necessitating careful land use planning and potential integration with existing forestry operations.

Return on investment calculations indicate break-even periods of 7-9 years for dedicated oleoresin biofuel facilities under current market conditions, assuming no significant technological breakthroughs or policy incentives. This timeline exceeds typical investor expectations in the energy sector, suggesting that initial deployment may require public-private partnerships or targeted subsidies to bridge the commercialization gap.

Sensitivity analysis reveals that production scale significantly impacts economic viability. Small-scale operations (below 1 million gallons annually) remain economically unfeasible without premium pricing or substantial subsidies. Mid-scale operations (1-5 million gallons) demonstrate marginal profitability in regions with favorable growing conditions and existing infrastructure. Large-scale operations (above 5 million gallons) show the most promising economics but face feedstock supply constraints and capital intensity barriers.

The pathway to commercial viability likely requires a phased approach, beginning with high-value niche applications where oleoresin biofuels can command premium pricing based on specific performance characteristics or sustainability attributes. Broader market penetration would depend on technological improvements in extraction efficiency, feedstock yield optimization, and process integration to capture value from co-products and waste streams.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!