Measuring Solvent Retention in Oleoresin Extraction

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Oleoresin Extraction Solvent Retention Background and Objectives

Oleoresin extraction represents a critical process in various industries, including food, pharmaceuticals, and cosmetics. The technique involves the separation of essential oils and resins from plant materials using solvents. This extraction method has evolved significantly over the past century, transitioning from rudimentary processes to sophisticated techniques that maximize yield while minimizing environmental impact.

The historical development of oleoresin extraction began with traditional methods using organic solvents such as hexane, petroleum ether, and acetone. These conventional approaches, while effective for extraction, presented significant challenges regarding solvent retention in the final product. The presence of residual solvents in oleoresins has been a persistent concern due to potential health risks, regulatory compliance issues, and impacts on product quality and stability.

Recent technological advancements have introduced more efficient extraction methodologies, including supercritical fluid extraction (SFE), pressurized liquid extraction (PLE), and microwave-assisted extraction (MAE). Despite these innovations, the fundamental challenge of solvent retention remains a critical area requiring precise measurement and control methodologies.

The evolution of analytical techniques for measuring solvent retention has paralleled the development of extraction technologies. Early methods relied on simple distillation and gravimetric analysis, which have gradually been replaced by more sophisticated approaches such as gas chromatography (GC), high-performance liquid chromatography (HPLC), and mass spectrometry (MS). These advanced techniques offer improved sensitivity, specificity, and reliability in quantifying residual solvents.

Current industry trends indicate a growing emphasis on "green" extraction technologies that utilize environmentally friendly solvents and processes. This shift is driven by increasing regulatory scrutiny, consumer demand for natural products, and corporate sustainability initiatives. The measurement of solvent retention has become increasingly important in this context, as it directly impacts product safety, quality, and regulatory compliance.

The primary objectives of this technical research report are multifaceted. First, we aim to comprehensively evaluate current methodologies for measuring solvent retention in oleoresin extraction processes. Second, we seek to identify technological gaps and challenges in existing measurement techniques. Third, we intend to explore emerging technologies and approaches that could potentially enhance the accuracy, efficiency, and cost-effectiveness of solvent retention analysis. Finally, we will assess the regulatory landscape governing solvent residues in oleoresin products across different markets and applications.

By addressing these objectives, this report will provide valuable insights for research and development teams, quality control departments, regulatory affairs specialists, and strategic decision-makers in industries utilizing oleoresin extraction processes.

The historical development of oleoresin extraction began with traditional methods using organic solvents such as hexane, petroleum ether, and acetone. These conventional approaches, while effective for extraction, presented significant challenges regarding solvent retention in the final product. The presence of residual solvents in oleoresins has been a persistent concern due to potential health risks, regulatory compliance issues, and impacts on product quality and stability.

Recent technological advancements have introduced more efficient extraction methodologies, including supercritical fluid extraction (SFE), pressurized liquid extraction (PLE), and microwave-assisted extraction (MAE). Despite these innovations, the fundamental challenge of solvent retention remains a critical area requiring precise measurement and control methodologies.

The evolution of analytical techniques for measuring solvent retention has paralleled the development of extraction technologies. Early methods relied on simple distillation and gravimetric analysis, which have gradually been replaced by more sophisticated approaches such as gas chromatography (GC), high-performance liquid chromatography (HPLC), and mass spectrometry (MS). These advanced techniques offer improved sensitivity, specificity, and reliability in quantifying residual solvents.

Current industry trends indicate a growing emphasis on "green" extraction technologies that utilize environmentally friendly solvents and processes. This shift is driven by increasing regulatory scrutiny, consumer demand for natural products, and corporate sustainability initiatives. The measurement of solvent retention has become increasingly important in this context, as it directly impacts product safety, quality, and regulatory compliance.

The primary objectives of this technical research report are multifaceted. First, we aim to comprehensively evaluate current methodologies for measuring solvent retention in oleoresin extraction processes. Second, we seek to identify technological gaps and challenges in existing measurement techniques. Third, we intend to explore emerging technologies and approaches that could potentially enhance the accuracy, efficiency, and cost-effectiveness of solvent retention analysis. Finally, we will assess the regulatory landscape governing solvent residues in oleoresin products across different markets and applications.

By addressing these objectives, this report will provide valuable insights for research and development teams, quality control departments, regulatory affairs specialists, and strategic decision-makers in industries utilizing oleoresin extraction processes.

Market Demand Analysis for Solvent-Free Oleoresin Products

The global market for oleoresin products has been experiencing significant growth, driven by increasing consumer preference for natural ingredients in food, pharmaceuticals, and cosmetics. The demand for solvent-free oleoresin products specifically has surged over the past five years, with the market value reaching $2.3 billion in 2022 and projected to grow at a CAGR of 7.8% through 2028.

This growth is primarily fueled by heightened consumer awareness regarding health implications of chemical residues in food products. Regulatory bodies worldwide, including the FDA and EFSA, have implemented stricter guidelines on solvent residue limits in food ingredients, compelling manufacturers to adopt cleaner extraction technologies. The European market has been particularly responsive, with solvent-free products commanding premium prices up to 40% higher than conventional alternatives.

Food and beverage industry represents the largest application segment, accounting for approximately 65% of the total oleoresin market. Within this segment, natural food coloring applications have shown the most robust growth at 9.2% annually, as major food manufacturers reformulate products to meet clean label demands. The pharmaceutical and nutraceutical sectors follow closely, driven by increasing research validating the therapeutic properties of pure plant extracts.

Regional analysis indicates that North America and Europe currently dominate the market for premium solvent-free oleoresins, while Asia-Pacific represents the fastest-growing region with 11.3% annual growth. This is attributed to the expanding middle class in countries like China and India, coupled with increasing adoption of Western dietary preferences and health consciousness.

Consumer surveys indicate that 78% of respondents express concern about chemical residues in food products, with 63% willing to pay more for guaranteed solvent-free alternatives. This trend is particularly pronounced among millennial consumers, who demonstrate the highest awareness of extraction methods and their implications.

The B2B market segment shows equally strong demand signals, with 82% of food manufacturers reporting plans to increase their sourcing of solvent-free ingredients within the next three years. This is reinforced by sustainability commitments from major multinational corporations, many of whom have published roadmaps for transitioning to cleaner ingredient profiles by 2025.

Market forecasts suggest that technologies enabling accurate measurement and certification of zero solvent retention will create significant competitive advantage, potentially commanding market premiums of 25-35% over conventional products. This represents a clear commercial incentive for investment in advanced analytical methods for solvent detection and certification.

This growth is primarily fueled by heightened consumer awareness regarding health implications of chemical residues in food products. Regulatory bodies worldwide, including the FDA and EFSA, have implemented stricter guidelines on solvent residue limits in food ingredients, compelling manufacturers to adopt cleaner extraction technologies. The European market has been particularly responsive, with solvent-free products commanding premium prices up to 40% higher than conventional alternatives.

Food and beverage industry represents the largest application segment, accounting for approximately 65% of the total oleoresin market. Within this segment, natural food coloring applications have shown the most robust growth at 9.2% annually, as major food manufacturers reformulate products to meet clean label demands. The pharmaceutical and nutraceutical sectors follow closely, driven by increasing research validating the therapeutic properties of pure plant extracts.

Regional analysis indicates that North America and Europe currently dominate the market for premium solvent-free oleoresins, while Asia-Pacific represents the fastest-growing region with 11.3% annual growth. This is attributed to the expanding middle class in countries like China and India, coupled with increasing adoption of Western dietary preferences and health consciousness.

Consumer surveys indicate that 78% of respondents express concern about chemical residues in food products, with 63% willing to pay more for guaranteed solvent-free alternatives. This trend is particularly pronounced among millennial consumers, who demonstrate the highest awareness of extraction methods and their implications.

The B2B market segment shows equally strong demand signals, with 82% of food manufacturers reporting plans to increase their sourcing of solvent-free ingredients within the next three years. This is reinforced by sustainability commitments from major multinational corporations, many of whom have published roadmaps for transitioning to cleaner ingredient profiles by 2025.

Market forecasts suggest that technologies enabling accurate measurement and certification of zero solvent retention will create significant competitive advantage, potentially commanding market premiums of 25-35% over conventional products. This represents a clear commercial incentive for investment in advanced analytical methods for solvent detection and certification.

Current Challenges in Solvent Retention Measurement Technologies

Despite significant advancements in oleoresin extraction technologies, the measurement of solvent retention remains a persistent challenge for industry practitioners and researchers alike. Current methodologies exhibit considerable limitations in accuracy, efficiency, and applicability across diverse extraction scenarios. Traditional gravimetric methods, while straightforward, suffer from inherent imprecision when dealing with volatile compounds and complex oleoresin matrices, often resulting in measurement errors exceeding acceptable thresholds for quality control purposes.

Gas chromatography (GC) techniques, though widely employed, face challenges related to sample preparation complexity and the potential for thermal degradation of sensitive compounds during analysis. This is particularly problematic when analyzing thermolabile components in plant-derived oleoresins. Additionally, GC methods typically require extensive calibration procedures and specialized equipment, limiting their accessibility for routine quality control in smaller production facilities.

Spectroscopic methods such as FTIR and NIR offer non-destructive alternatives but struggle with specificity when multiple solvents are present in the extraction matrix. The overlapping spectral signatures of different organic solvents often necessitate complex chemometric models for accurate quantification, requiring substantial expertise and reference datasets that may not be readily available across all industry segments.

Real-time monitoring systems represent another technological gap in the field. Current technologies predominantly rely on offline sampling and analysis, creating significant delays between production and quality verification. This temporal disconnect impedes process optimization and increases the risk of producing non-compliant batches, particularly in continuous extraction operations where rapid feedback is essential for parameter adjustment.

Miniaturization and field-deployable solutions remain underdeveloped, with most precise measurement technologies confined to laboratory settings. This centralization creates logistical challenges for distributed production facilities and limits the implementation of quality control measures at critical points throughout the supply chain, from extraction sites to processing facilities.

Regulatory considerations further complicate the technological landscape, as different regions maintain varying standards for acceptable solvent residue levels in final products. This regulatory heterogeneity necessitates measurement technologies with adjustable sensitivity thresholds and validation protocols that can satisfy diverse compliance requirements, a capability not fully realized in current systems.

Cost-effectiveness represents another significant barrier, particularly for small and medium-sized enterprises. High-precision analytical equipment often requires substantial capital investment and specialized technical expertise, creating an accessibility gap that hampers industry-wide adoption of rigorous solvent retention measurement practices.

Gas chromatography (GC) techniques, though widely employed, face challenges related to sample preparation complexity and the potential for thermal degradation of sensitive compounds during analysis. This is particularly problematic when analyzing thermolabile components in plant-derived oleoresins. Additionally, GC methods typically require extensive calibration procedures and specialized equipment, limiting their accessibility for routine quality control in smaller production facilities.

Spectroscopic methods such as FTIR and NIR offer non-destructive alternatives but struggle with specificity when multiple solvents are present in the extraction matrix. The overlapping spectral signatures of different organic solvents often necessitate complex chemometric models for accurate quantification, requiring substantial expertise and reference datasets that may not be readily available across all industry segments.

Real-time monitoring systems represent another technological gap in the field. Current technologies predominantly rely on offline sampling and analysis, creating significant delays between production and quality verification. This temporal disconnect impedes process optimization and increases the risk of producing non-compliant batches, particularly in continuous extraction operations where rapid feedback is essential for parameter adjustment.

Miniaturization and field-deployable solutions remain underdeveloped, with most precise measurement technologies confined to laboratory settings. This centralization creates logistical challenges for distributed production facilities and limits the implementation of quality control measures at critical points throughout the supply chain, from extraction sites to processing facilities.

Regulatory considerations further complicate the technological landscape, as different regions maintain varying standards for acceptable solvent residue levels in final products. This regulatory heterogeneity necessitates measurement technologies with adjustable sensitivity thresholds and validation protocols that can satisfy diverse compliance requirements, a capability not fully realized in current systems.

Cost-effectiveness represents another significant barrier, particularly for small and medium-sized enterprises. High-precision analytical equipment often requires substantial capital investment and specialized technical expertise, creating an accessibility gap that hampers industry-wide adoption of rigorous solvent retention measurement practices.

Existing Methodologies for Measuring Residual Solvents

01 Solvent selection for oleoresin extraction

The choice of solvent significantly impacts the efficiency of oleoresin extraction and subsequent solvent retention. Various solvents including ethanol, hexane, acetone, and supercritical CO2 are used based on their selectivity, extraction efficiency, and ease of removal. The polarity and boiling point of the solvent affect both the extraction yield and the difficulty of complete removal from the final oleoresin product.- Solvent selection for oleoresin extraction: The choice of solvent significantly impacts the efficiency of oleoresin extraction and subsequent solvent retention. Various solvents including ethanol, hexane, acetone, and supercritical CO2 are used based on their selectivity, extraction efficiency, and ease of removal. The polarity and boiling point of the solvent affect both the extraction yield and the difficulty of complete solvent removal from the final oleoresin product.

- Advanced extraction techniques to minimize solvent retention: Modern extraction methods such as supercritical fluid extraction, microwave-assisted extraction, and ultrasonic extraction can significantly reduce solvent retention in oleoresins. These techniques often operate at lower temperatures or use solvents that are easier to remove completely. The controlled process parameters in these methods help achieve higher quality oleoresins with minimal residual solvent content.

- Post-extraction processing for solvent removal: Various post-extraction techniques are employed to minimize solvent retention in oleoresins, including vacuum distillation, thin-film evaporation, and steam stripping. These processes are designed to efficiently remove residual solvents while preserving the volatile compounds and active ingredients in the oleoresin. The temperature, pressure, and duration of these processes are critical factors affecting the final solvent content.

- Quality control and analytical methods for solvent retention: Analytical techniques such as gas chromatography, mass spectrometry, and headspace analysis are used to monitor and quantify residual solvent levels in oleoresins. These methods help ensure compliance with regulatory limits for solvent residues in food, pharmaceutical, and cosmetic applications. Standardized testing protocols have been developed to verify that oleoresin products meet safety requirements regarding solvent retention.

- Solvent-free and reduced-solvent extraction methods: Innovative approaches to oleoresin extraction that eliminate or significantly reduce the use of conventional solvents include mechanical expression, enzyme-assisted extraction, and pulsed electric field technology. These methods address solvent retention concerns by minimizing or eliminating solvent use from the beginning of the process. They are particularly valuable for applications requiring extremely low or zero solvent residues in the final oleoresin product.

02 Solvent removal techniques to minimize retention

Various techniques are employed to minimize solvent retention in oleoresin products. These include vacuum distillation, steam stripping, thin film evaporation, and molecular distillation. Advanced processes combine multiple stages of solvent removal under controlled temperature and pressure conditions to achieve lower solvent residues while preserving the volatile compounds in the oleoresin.Expand Specific Solutions03 Novel extraction methods for reduced solvent retention

Innovative extraction methods have been developed to address solvent retention issues. These include pulsed electric field-assisted extraction, ultrasound-assisted extraction, microwave-assisted extraction, and enzyme-assisted extraction. These technologies can enhance extraction efficiency while operating at milder conditions, thereby reducing the amount of solvent needed and facilitating easier removal of residual solvents from the final oleoresin product.Expand Specific Solutions04 Quality control and analytical methods for solvent residues

Analytical techniques for monitoring and controlling solvent residues in oleoresin products are essential for quality assurance. Methods such as gas chromatography, headspace analysis, and mass spectrometry are employed to quantify residual solvents. Standardized testing protocols and acceptance criteria have been established to ensure that solvent retention levels comply with regulatory requirements for food, pharmaceutical, and cosmetic applications.Expand Specific Solutions05 Green solvents and sustainable extraction processes

Environmental concerns have driven the development of green solvents and sustainable extraction processes for oleoresins. Bio-based solvents derived from renewable resources, water-based extraction systems, and solvent recycling technologies are being implemented to reduce environmental impact. These approaches not only address ecological concerns but often result in lower solvent retention in the final product due to the inherent properties of these alternative solvents.Expand Specific Solutions

Key Industry Players in Oleoresin Extraction and Analysis

The oleoresin extraction solvent retention measurement market is in a growth phase, with increasing demand driven by quality control requirements in pharmaceutical, food, and chemical industries. Market size is expanding as natural product extraction gains popularity for sustainable applications. Technology maturity varies across players, with established companies like ExxonMobil Technology & Engineering and Agilent Technologies leading with advanced analytical solutions. Mid-tier competitors including Nippon Shokubai, AGC, and Riken Vitamin focus on specialized extraction technologies, while PetroChina and Saudi Arabian Oil Co. contribute significant R&D resources to improve extraction efficiency. Emerging players like Turatti and W.D. Von Gonten Laboratories are developing niche solutions, creating a competitive landscape balanced between established analytical expertise and industry-specific innovation.

Turatti Srl

Technical Solution: Turatti Srl has pioneered an integrated solvent retention measurement system specifically designed for industrial-scale oleoresin extraction operations. Their technology combines gravimetric analysis with thermal desorption techniques to quantify residual solvents in extracted oleoresins. The system features a proprietary sample preparation module that homogenizes oleoresin samples prior to analysis, ensuring representative measurements even with heterogeneous materials. Turatti's approach incorporates a controlled heating chamber that gradually increases temperature while continuously monitoring mass loss, creating a desorption profile that distinguishes between different solvents based on their volatility characteristics. The data is processed through their proprietary algorithms that can differentiate between solvent loss and other volatile compounds naturally present in the oleoresin. Their technology includes automated sampling systems that can be integrated directly into production lines, allowing for continuous monitoring without disrupting the extraction process.

Strengths: The system's integration capability with production lines enables real-time quality control and process optimization. The differentiation between solvent residues and natural volatiles improves measurement accuracy. Weaknesses: The thermal desorption approach may alter some heat-sensitive compounds in the oleoresin, potentially affecting subsequent product quality. The system requires regular calibration with reference standards specific to each oleoresin type.

Agilent Technologies, Inc.

Technical Solution: Agilent Technologies has developed a comprehensive analytical platform for measuring solvent retention in oleoresin extraction processes. Their solution centers on headspace gas chromatography coupled with flame ionization detection (HS-GC-FID), optimized specifically for oleoresin matrices. The system features a specialized sample introduction system that minimizes matrix interference while maximizing sensitivity for common extraction solvents including hexane, ethanol, and supercritical CO2 residues. Agilent's technology incorporates automated calibration routines using internal standards with similar chemical properties to target solvents, ensuring accurate quantification across varying oleoresin compositions. Their software platform includes dedicated algorithms for peak deconvolution that can resolve complex chromatograms typical of natural product extracts, allowing for accurate identification and quantification of multiple solvents simultaneously. The system also features a database of retention times and response factors for common extraction solvents under standardized conditions, facilitating method development and validation.

Strengths: Exceptional sensitivity and specificity for a wide range of extraction solvents, with detection limits in the sub-ppm range. The automated workflows reduce operator variability and increase throughput for routine analysis. Weaknesses: Requires significant laboratory infrastructure and cannot be easily deployed for in-line process monitoring. Sample preparation remains a critical step that can introduce variability if not carefully controlled.

Critical Technologies for Trace Solvent Detection in Oleoresins

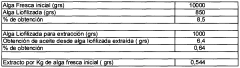

Method for the preparation of an oleoresin originating from a red alga that maintains the capacity to induce the transcriptional activity of the nuclear receptor PPAR-Γ

PatentWO2014186913A1

Innovation

- A five-stage process involving low-temperature algae extraction, mincing, freeze-drying, discontinuous solid-liquid extraction, and solvent elimination is developed to preserve the PPARγ-activating capacity of red algae oleoresin, ensuring high transcriptional activity and oral bioavailability.

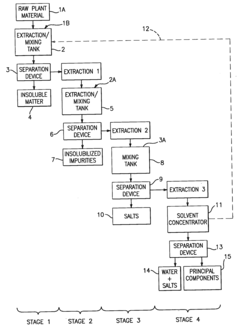

Low temperature process for extracting principal components from plants or plant materials and plant extracts produced thereby

PatentInactiveUS20060008561A1

Innovation

- A low temperature process involving the use of an organic polar solvent, pH adjustment with a base to precipitate impurities, and subsequent acid neutralization to isolate high-quality plant extracts, maintaining the natural aroma, color, and flavor.

Regulatory Standards for Solvent Residues in Food and Pharmaceutical Products

Regulatory frameworks governing solvent residues in food and pharmaceutical products have become increasingly stringent worldwide, reflecting growing concerns about consumer safety and product quality. The FDA in the United States and the European Medicines Agency (EMA) have established comprehensive guidelines that specifically address acceptable limits for residual solvents in oleoresin extracts. These regulations categorize solvents into different classes based on their toxicity profiles, with Class 1 solvents (e.g., benzene) being strictly prohibited, Class 2 solvents (e.g., hexane) having defined concentration limits, and Class 3 solvents (e.g., ethanol) considered less toxic with higher permissible daily exposure limits.

The International Conference on Harmonisation (ICH) Q3C guideline serves as a global benchmark, providing harmonized approaches for controlling residual solvents in pharmaceuticals. This guideline has been adopted by regulatory bodies across North America, Europe, and Asia, establishing permitted daily exposure (PDE) values for common extraction solvents. For food applications, the Joint FAO/WHO Expert Committee on Food Additives (JECFA) has established acceptable daily intake (ADI) values for various solvents used in oleoresin extraction.

Industry-specific standards further refine these regulatory requirements. The United States Pharmacopeia (USP) and European Pharmacopoeia (Ph. Eur.) provide detailed analytical methods for measuring solvent residues, including gas chromatography techniques optimized for oleoresin matrices. These pharmacopoeial methods often serve as reference standards for compliance testing and quality control in both food and pharmaceutical industries.

Recent regulatory trends indicate a shift toward more comprehensive risk assessment approaches. The Global Food Safety Initiative (GFSI) benchmarked standards now incorporate specific requirements for solvent management systems, including validation of extraction processes and verification of residue levels. Similarly, pharmaceutical Good Manufacturing Practice (GMP) guidelines increasingly emphasize process analytical technology (PAT) for real-time monitoring of solvent residues during oleoresin processing.

Compliance challenges vary significantly across different regions. While the EU maintains some of the strictest limits for hexane residues in food-grade oleoresins (typically 5-10 ppm), regulations in emerging markets may permit higher levels or have less developed enforcement mechanisms. This regulatory divergence creates complexity for global manufacturers who must navigate multiple compliance frameworks simultaneously.

The economic impact of these regulations is substantial, with companies investing significantly in analytical capabilities, process optimization, and alternative solvent technologies. Industry estimates suggest that regulatory compliance costs related to solvent residue testing can represent 3-5% of production costs for high-value oleoresin products, driving innovation in both extraction methodologies and analytical techniques.

The International Conference on Harmonisation (ICH) Q3C guideline serves as a global benchmark, providing harmonized approaches for controlling residual solvents in pharmaceuticals. This guideline has been adopted by regulatory bodies across North America, Europe, and Asia, establishing permitted daily exposure (PDE) values for common extraction solvents. For food applications, the Joint FAO/WHO Expert Committee on Food Additives (JECFA) has established acceptable daily intake (ADI) values for various solvents used in oleoresin extraction.

Industry-specific standards further refine these regulatory requirements. The United States Pharmacopeia (USP) and European Pharmacopoeia (Ph. Eur.) provide detailed analytical methods for measuring solvent residues, including gas chromatography techniques optimized for oleoresin matrices. These pharmacopoeial methods often serve as reference standards for compliance testing and quality control in both food and pharmaceutical industries.

Recent regulatory trends indicate a shift toward more comprehensive risk assessment approaches. The Global Food Safety Initiative (GFSI) benchmarked standards now incorporate specific requirements for solvent management systems, including validation of extraction processes and verification of residue levels. Similarly, pharmaceutical Good Manufacturing Practice (GMP) guidelines increasingly emphasize process analytical technology (PAT) for real-time monitoring of solvent residues during oleoresin processing.

Compliance challenges vary significantly across different regions. While the EU maintains some of the strictest limits for hexane residues in food-grade oleoresins (typically 5-10 ppm), regulations in emerging markets may permit higher levels or have less developed enforcement mechanisms. This regulatory divergence creates complexity for global manufacturers who must navigate multiple compliance frameworks simultaneously.

The economic impact of these regulations is substantial, with companies investing significantly in analytical capabilities, process optimization, and alternative solvent technologies. Industry estimates suggest that regulatory compliance costs related to solvent residue testing can represent 3-5% of production costs for high-value oleoresin products, driving innovation in both extraction methodologies and analytical techniques.

Environmental Impact Assessment of Extraction Solvents

The environmental impact of solvents used in oleoresin extraction processes represents a critical consideration for sustainable industrial practices. Conventional extraction solvents such as hexane, acetone, and ethanol each carry distinct environmental footprints throughout their lifecycle, from production to disposal. These impacts manifest in various forms including greenhouse gas emissions, water pollution, soil contamination, and potential ecosystem disruption.

Solvent retention in extracted oleoresins directly correlates with environmental risk factors. Higher retention levels increase the potential for solvent release into the environment during subsequent processing or product use. Studies indicate that hexane, commonly used for its extraction efficiency, poses significant environmental concerns due to its volatile organic compound (VOC) status, contributing to photochemical smog formation and air quality degradation when released.

Quantitative lifecycle assessment (LCA) data reveals that solvent production and recovery processes account for approximately 60-70% of the total environmental impact in oleoresin extraction operations. Energy consumption during solvent recovery particularly contributes to carbon emissions, with estimates suggesting 2-4 kg CO2 equivalent per kilogram of oleoresin produced using conventional methods.

Water ecosystems face particular vulnerability from improper solvent management. Trace amounts of extraction solvents entering waterways can affect aquatic organisms at concentrations as low as 10-50 parts per million, depending on the specific solvent and species sensitivity. Bioaccumulation potential varies significantly among solvents, with more lipophilic compounds presenting higher ecological risks.

Regulatory frameworks worldwide increasingly address these environmental concerns. The European Union's REACH regulations, the United States EPA guidelines, and similar frameworks in Asia-Pacific regions have established progressively stringent thresholds for acceptable solvent residues and emissions. These regulations have driven innovation toward greener extraction technologies and more precise retention measurement methodologies.

Alternative "green solvents" derived from renewable resources demonstrate promising environmental profiles. Supercritical CO2, for instance, offers a substantially reduced environmental footprint with minimal persistence in the environment. Similarly, bio-based solvents like d-limonene and ethyl lactate show 40-60% lower ecotoxicity scores compared to petroleum-derived counterparts, though their production scalability remains challenging.

Measurement precision in solvent retention analysis directly impacts environmental risk assessment accuracy. Advanced analytical techniques such as headspace gas chromatography coupled with mass spectrometry enable detection of solvent residues at parts-per-billion levels, allowing for more precise environmental impact predictions and mitigation strategies in oleoresin production facilities.

Solvent retention in extracted oleoresins directly correlates with environmental risk factors. Higher retention levels increase the potential for solvent release into the environment during subsequent processing or product use. Studies indicate that hexane, commonly used for its extraction efficiency, poses significant environmental concerns due to its volatile organic compound (VOC) status, contributing to photochemical smog formation and air quality degradation when released.

Quantitative lifecycle assessment (LCA) data reveals that solvent production and recovery processes account for approximately 60-70% of the total environmental impact in oleoresin extraction operations. Energy consumption during solvent recovery particularly contributes to carbon emissions, with estimates suggesting 2-4 kg CO2 equivalent per kilogram of oleoresin produced using conventional methods.

Water ecosystems face particular vulnerability from improper solvent management. Trace amounts of extraction solvents entering waterways can affect aquatic organisms at concentrations as low as 10-50 parts per million, depending on the specific solvent and species sensitivity. Bioaccumulation potential varies significantly among solvents, with more lipophilic compounds presenting higher ecological risks.

Regulatory frameworks worldwide increasingly address these environmental concerns. The European Union's REACH regulations, the United States EPA guidelines, and similar frameworks in Asia-Pacific regions have established progressively stringent thresholds for acceptable solvent residues and emissions. These regulations have driven innovation toward greener extraction technologies and more precise retention measurement methodologies.

Alternative "green solvents" derived from renewable resources demonstrate promising environmental profiles. Supercritical CO2, for instance, offers a substantially reduced environmental footprint with minimal persistence in the environment. Similarly, bio-based solvents like d-limonene and ethyl lactate show 40-60% lower ecotoxicity scores compared to petroleum-derived counterparts, though their production scalability remains challenging.

Measurement precision in solvent retention analysis directly impacts environmental risk assessment accuracy. Advanced analytical techniques such as headspace gas chromatography coupled with mass spectrometry enable detection of solvent residues at parts-per-billion levels, allowing for more precise environmental impact predictions and mitigation strategies in oleoresin production facilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!