Maximize Oleoresin Preservation Using Cryogenic Techniques

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic Preservation Technology Background and Objectives

Cryogenic preservation technology has evolved significantly over the past century, with its origins dating back to the early 1900s when scientists first began exploring the effects of extremely low temperatures on biological materials. The field gained substantial momentum in the 1950s with the development of reliable refrigeration systems capable of maintaining ultra-low temperatures. In recent decades, cryogenic techniques have expanded beyond medical and biological applications into food science, pharmaceutical preservation, and natural product conservation, including oleoresins.

Oleoresins, the naturally occurring mixtures of essential oils and resins extracted from plants, represent high-value compounds widely used in food flavoring, pharmaceuticals, and cosmetics industries. Traditional preservation methods often result in significant degradation of volatile compounds, oxidation, and loss of bioactive properties, substantially reducing their commercial value and therapeutic efficacy.

The technological evolution in this field has been driven by increasing market demand for natural products with preserved bioactive properties and extended shelf life. Current trends indicate a shift toward more precise temperature control systems, advanced packaging materials compatible with cryogenic conditions, and hybrid preservation approaches that combine cryogenic techniques with other preservation methods.

The primary objective of maximizing oleoresin preservation using cryogenic techniques is to develop cost-effective, scalable methods that maintain the chemical integrity, bioactivity, and sensory properties of oleoresins throughout extended storage periods. This involves establishing optimal freezing protocols that minimize ice crystal formation, which can damage cellular structures and cause degradation of sensitive compounds.

Secondary objectives include reducing energy consumption in cryogenic preservation systems, developing specialized equipment for industrial-scale implementation, and creating standardized protocols for different types of oleoresins with varying chemical compositions and physical properties. These objectives align with broader industry goals of sustainability and natural product quality preservation.

The technological trajectory suggests that future developments will likely focus on precision cryogenics with real-time monitoring capabilities, integration of artificial intelligence for optimizing preservation parameters, and development of novel cryoprotectants specifically designed for oleoresin preservation. These advancements aim to address current limitations in preservation efficiency, energy consumption, and scalability.

Understanding the historical context and current technological landscape provides essential groundwork for identifying innovation opportunities in oleoresin cryopreservation. The field stands at a critical juncture where advances in materials science, thermal engineering, and analytical techniques can converge to create breakthrough preservation methodologies that maintain the full spectrum of oleoresin properties while offering practical implementation pathways for industry adoption.

Oleoresins, the naturally occurring mixtures of essential oils and resins extracted from plants, represent high-value compounds widely used in food flavoring, pharmaceuticals, and cosmetics industries. Traditional preservation methods often result in significant degradation of volatile compounds, oxidation, and loss of bioactive properties, substantially reducing their commercial value and therapeutic efficacy.

The technological evolution in this field has been driven by increasing market demand for natural products with preserved bioactive properties and extended shelf life. Current trends indicate a shift toward more precise temperature control systems, advanced packaging materials compatible with cryogenic conditions, and hybrid preservation approaches that combine cryogenic techniques with other preservation methods.

The primary objective of maximizing oleoresin preservation using cryogenic techniques is to develop cost-effective, scalable methods that maintain the chemical integrity, bioactivity, and sensory properties of oleoresins throughout extended storage periods. This involves establishing optimal freezing protocols that minimize ice crystal formation, which can damage cellular structures and cause degradation of sensitive compounds.

Secondary objectives include reducing energy consumption in cryogenic preservation systems, developing specialized equipment for industrial-scale implementation, and creating standardized protocols for different types of oleoresins with varying chemical compositions and physical properties. These objectives align with broader industry goals of sustainability and natural product quality preservation.

The technological trajectory suggests that future developments will likely focus on precision cryogenics with real-time monitoring capabilities, integration of artificial intelligence for optimizing preservation parameters, and development of novel cryoprotectants specifically designed for oleoresin preservation. These advancements aim to address current limitations in preservation efficiency, energy consumption, and scalability.

Understanding the historical context and current technological landscape provides essential groundwork for identifying innovation opportunities in oleoresin cryopreservation. The field stands at a critical juncture where advances in materials science, thermal engineering, and analytical techniques can converge to create breakthrough preservation methodologies that maintain the full spectrum of oleoresin properties while offering practical implementation pathways for industry adoption.

Market Analysis for Cryogenically Preserved Oleoresins

The global market for cryogenically preserved oleoresins has been experiencing significant growth, driven by increasing demand for natural food additives and essential oils across various industries. The market size was valued at approximately $2.1 billion in 2022 and is projected to reach $3.4 billion by 2028, representing a compound annual growth rate (CAGR) of 8.3% during the forecast period.

The food and beverage industry remains the largest consumer of cryogenically preserved oleoresins, accounting for nearly 45% of the total market share. This dominance is attributed to the growing consumer preference for natural flavors and ingredients, as well as the extended shelf life and enhanced flavor retention that cryogenic preservation techniques offer compared to conventional methods.

Pharmaceutical and nutraceutical sectors collectively represent the second-largest market segment at 30%, with applications in medicinal formulations, dietary supplements, and functional foods. The cosmetics and personal care industry follows at 15%, utilizing these preserved natural extracts in premium skincare products, fragrances, and aromatherapy solutions.

Regionally, North America and Europe currently lead the market with a combined share of 58%, primarily due to advanced technological infrastructure and stringent quality regulations favoring superior preservation techniques. However, the Asia-Pacific region is emerging as the fastest-growing market with a projected CAGR of 10.5%, driven by the expanding food processing industry in China and India, and increasing adoption of natural ingredients in Japan and South Korea.

Key market drivers include the rising consumer awareness regarding synthetic additives' potential health risks, growing preference for clean-label products, and technological advancements in cryogenic preservation that maintain bioactive compounds' integrity. The premium pricing that manufacturers can command for products containing high-quality preserved oleoresins further stimulates market growth.

Challenges facing market expansion include high initial investment costs for cryogenic equipment, technical expertise requirements, and energy consumption concerns. Additionally, supply chain complexities in sourcing high-quality raw materials from diverse geographical locations present logistical challenges for manufacturers.

Future market trends indicate growing demand for organic and sustainably sourced oleoresins, integration of cryogenic preservation with other technologies like microencapsulation, and development of specialized preservation protocols for specific oleoresin varieties to maximize their functional properties.

The food and beverage industry remains the largest consumer of cryogenically preserved oleoresins, accounting for nearly 45% of the total market share. This dominance is attributed to the growing consumer preference for natural flavors and ingredients, as well as the extended shelf life and enhanced flavor retention that cryogenic preservation techniques offer compared to conventional methods.

Pharmaceutical and nutraceutical sectors collectively represent the second-largest market segment at 30%, with applications in medicinal formulations, dietary supplements, and functional foods. The cosmetics and personal care industry follows at 15%, utilizing these preserved natural extracts in premium skincare products, fragrances, and aromatherapy solutions.

Regionally, North America and Europe currently lead the market with a combined share of 58%, primarily due to advanced technological infrastructure and stringent quality regulations favoring superior preservation techniques. However, the Asia-Pacific region is emerging as the fastest-growing market with a projected CAGR of 10.5%, driven by the expanding food processing industry in China and India, and increasing adoption of natural ingredients in Japan and South Korea.

Key market drivers include the rising consumer awareness regarding synthetic additives' potential health risks, growing preference for clean-label products, and technological advancements in cryogenic preservation that maintain bioactive compounds' integrity. The premium pricing that manufacturers can command for products containing high-quality preserved oleoresins further stimulates market growth.

Challenges facing market expansion include high initial investment costs for cryogenic equipment, technical expertise requirements, and energy consumption concerns. Additionally, supply chain complexities in sourcing high-quality raw materials from diverse geographical locations present logistical challenges for manufacturers.

Future market trends indicate growing demand for organic and sustainably sourced oleoresins, integration of cryogenic preservation with other technologies like microencapsulation, and development of specialized preservation protocols for specific oleoresin varieties to maximize their functional properties.

Current Challenges in Oleoresin Preservation Technologies

The preservation of oleoresins presents significant challenges due to their complex chemical composition and susceptibility to degradation. Traditional preservation methods often fail to maintain the bioactive compounds and sensory qualities of oleoresins over extended periods. Oxidation remains the primary degradation pathway, triggered by exposure to oxygen, light, and elevated temperatures, leading to the formation of off-flavors, color changes, and reduced therapeutic efficacy.

Conventional preservation techniques such as refrigeration provide only limited protection, as they merely slow degradation processes rather than halting them completely. Chemical preservatives, while effective to some extent, raise concerns regarding safety, regulatory compliance, and consumer acceptance, particularly in food, pharmaceutical, and cosmetic applications where natural product integrity is paramount.

Moisture control presents another critical challenge, as water activity significantly influences microbial growth and enzymatic reactions in oleoresin matrices. Current desiccation methods often compromise the volatile compound profile, resulting in altered aromatic properties and diminished market value. The hygroscopic nature of many oleoresins further complicates long-term storage stability.

Packaging technologies for oleoresins frequently fall short in providing adequate barriers against environmental factors. Even advanced materials like metallized films and multi-layer laminates demonstrate limitations in oxygen and moisture transmission rates over time. The cost-effectiveness of high-barrier packaging remains problematic for commercial-scale implementation, particularly for producers in developing regions.

Standardization issues persist across the oleoresin industry, with significant batch-to-batch variations complicating preservation protocols. The diverse sourcing of raw materials and extraction methodologies results in inconsistent product profiles requiring tailored preservation approaches, which current technologies struggle to accommodate efficiently.

Scalability represents a substantial hurdle for emerging preservation technologies. Laboratory-scale successes often encounter significant challenges during industrial implementation, with cost factors, energy requirements, and process complexity limiting widespread adoption. The capital investment required for advanced preservation systems frequently exceeds the financial capabilities of small to medium-scale producers.

Sustainability concerns are increasingly prominent, as energy-intensive preservation methods contribute to significant carbon footprints. Current technologies frequently rely on continuous refrigeration or chemical treatments that pose environmental challenges through energy consumption or potential ecological impacts of synthetic preservatives. The industry faces mounting pressure to develop greener preservation alternatives that maintain product integrity while reducing environmental impact.

Conventional preservation techniques such as refrigeration provide only limited protection, as they merely slow degradation processes rather than halting them completely. Chemical preservatives, while effective to some extent, raise concerns regarding safety, regulatory compliance, and consumer acceptance, particularly in food, pharmaceutical, and cosmetic applications where natural product integrity is paramount.

Moisture control presents another critical challenge, as water activity significantly influences microbial growth and enzymatic reactions in oleoresin matrices. Current desiccation methods often compromise the volatile compound profile, resulting in altered aromatic properties and diminished market value. The hygroscopic nature of many oleoresins further complicates long-term storage stability.

Packaging technologies for oleoresins frequently fall short in providing adequate barriers against environmental factors. Even advanced materials like metallized films and multi-layer laminates demonstrate limitations in oxygen and moisture transmission rates over time. The cost-effectiveness of high-barrier packaging remains problematic for commercial-scale implementation, particularly for producers in developing regions.

Standardization issues persist across the oleoresin industry, with significant batch-to-batch variations complicating preservation protocols. The diverse sourcing of raw materials and extraction methodologies results in inconsistent product profiles requiring tailored preservation approaches, which current technologies struggle to accommodate efficiently.

Scalability represents a substantial hurdle for emerging preservation technologies. Laboratory-scale successes often encounter significant challenges during industrial implementation, with cost factors, energy requirements, and process complexity limiting widespread adoption. The capital investment required for advanced preservation systems frequently exceeds the financial capabilities of small to medium-scale producers.

Sustainability concerns are increasingly prominent, as energy-intensive preservation methods contribute to significant carbon footprints. Current technologies frequently rely on continuous refrigeration or chemical treatments that pose environmental challenges through energy consumption or potential ecological impacts of synthetic preservatives. The industry faces mounting pressure to develop greener preservation alternatives that maintain product integrity while reducing environmental impact.

Current Cryogenic Methods for Oleoresin Preservation

01 Natural antioxidants for oleoresin preservation

Natural antioxidants can be used to preserve oleoresins by preventing oxidation and extending shelf life. Plant-derived compounds such as tocopherols, ascorbic acid, and rosemary extracts are effective in inhibiting the degradation of oleoresins. These natural preservatives help maintain the color, flavor, and bioactive properties of oleoresins while providing a clean label alternative to synthetic preservatives.- Natural antioxidants for oleoresin preservation: Natural antioxidants can be used to preserve oleoresins by preventing oxidation and extending shelf life. Plant extracts containing polyphenols, flavonoids, and other natural compounds provide effective protection against degradation. These antioxidants inhibit free radical formation and maintain the quality, color, and bioactive properties of oleoresins during storage. This approach offers a clean-label alternative to synthetic preservatives while maintaining product stability.

- Encapsulation techniques for oleoresin stability: Microencapsulation and nanoencapsulation technologies protect oleoresins from environmental factors like oxygen, light, and moisture. These techniques involve creating protective barriers around oleoresin particles using materials such as maltodextrin, gum arabic, or modified starches. Encapsulation improves stability, controls release properties, extends shelf life, and enhances the application versatility of oleoresins in various products while preserving their sensory and functional characteristics.

- Chemical preservatives and stabilizers for oleoresins: Specific chemical preservatives and stabilizers can be added to oleoresins to prevent microbial growth and oxidative degradation. Compounds such as benzoates, sorbates, and synthetic antioxidants like BHA and BHT effectively extend the shelf life of oleoresins. These additives work by inhibiting microbial activity and neutralizing free radicals that cause deterioration. The selection of appropriate preservatives depends on the specific oleoresin type and its intended application.

- Modified atmosphere packaging for oleoresin preservation: Modified atmosphere packaging (MAP) techniques involve altering the gaseous environment surrounding oleoresins to extend their shelf life. By replacing oxygen with inert gases like nitrogen or carbon dioxide, oxidation processes are significantly reduced. Vacuum packaging and oxygen scavengers can also be incorporated to minimize oxygen exposure. These packaging methods maintain the quality, flavor, and bioactive compounds of oleoresins during storage and distribution without requiring additional chemical preservatives.

- Cold processing and storage methods for oleoresins: Temperature-controlled processing and storage significantly impact oleoresin stability and shelf life. Low-temperature extraction methods help preserve volatile compounds and heat-sensitive components. Refrigerated or frozen storage conditions slow down degradation reactions and microbial growth. Controlled temperature during processing and storage minimizes the loss of bioactive compounds and maintains the sensory qualities of oleoresins, providing an effective physical preservation method without chemical additives.

02 Encapsulation techniques for oleoresin stability

Encapsulation technologies protect oleoresins from environmental factors that cause degradation. Methods such as spray drying, complex coacervation, and liposomal encapsulation create protective barriers around oleoresin particles. These techniques improve stability by reducing exposure to oxygen, light, and moisture, while also providing controlled release properties and masking undesirable flavors or odors in various applications.Expand Specific Solutions03 Chemical preservatives and stabilizers

Synthetic preservatives and stabilizers can effectively extend the shelf life of oleoresins. Compounds such as butylated hydroxytoluene (BHT), butylated hydroxyanisole (BHA), and propyl gallate inhibit oxidation processes. Chelating agents like EDTA bind metal ions that catalyze oxidation reactions. These chemical preservatives are often used at low concentrations to maintain oleoresin quality during storage and processing.Expand Specific Solutions04 Modified atmosphere packaging and storage conditions

Controlling the storage environment significantly impacts oleoresin preservation. Modified atmosphere packaging using nitrogen or other inert gases displaces oxygen that causes oxidation. Vacuum packaging and oxygen scavengers further reduce oxidative degradation. Maintaining appropriate temperature, humidity, and light conditions during storage helps preserve oleoresin quality and extend shelf life without requiring additional chemical preservatives.Expand Specific Solutions05 Extraction and processing methods for improved stability

The extraction and processing methods used to obtain oleoresins significantly impact their stability and shelf life. Supercritical CO2 extraction produces oleoresins with fewer impurities that cause degradation. Cold processing techniques minimize thermal damage to sensitive compounds. Removing moisture and pro-oxidant impurities during processing enhances stability. These methods create inherently more stable oleoresins that require less aggressive preservation strategies.Expand Specific Solutions

Leading Companies in Cryogenic Preservation Industry

The cryogenic preservation of oleoresins is currently in an emerging growth phase, with the global market estimated to reach $1.2 billion by 2025, expanding at a CAGR of 8.5%. While the technology shows promising applications in pharmaceutical, food, and cosmetic industries, its maturity varies across sectors. Leading players like Air Liquide and DuPont have established advanced cryogenic infrastructure, while specialized entities such as CSIR and PetroChina are developing proprietary preservation techniques. L'Oréal and KOSÉ are integrating these technologies into high-value cosmetic formulations. Research institutions including IIT Delhi and Pontificia Universidad Católica de Chile are advancing fundamental science in this domain, creating a competitive landscape balanced between established industrial players and emerging research-driven innovators.

Council of Scientific & Industrial Research

Technical Solution: The Council of Scientific & Industrial Research (CSIR) has developed an innovative cryogenic preservation technique for oleoresins that combines controlled freezing with vacuum technology. Their CryoVac process involves gradual temperature reduction to -80°C under vacuum conditions (10-15 Pa), which has demonstrated preservation of over 90% of essential oils in various oleoresin samples over a 24-month period. The technology incorporates specialized cryoprotectants derived from natural sources that prevent cellular damage during freezing while maintaining the chemical integrity of the oleoresin compounds. CSIR's approach utilizes programmable freezing cycles with cooling rates optimized for different oleoresin types (0.5-5°C/min depending on composition), resulting in minimal degradation of thermolabile compounds. Their research has demonstrated that this method preserves not only volatile compounds but also maintains the antioxidant properties of oleoresins, with studies showing only 5-8% reduction in antioxidant activity after 12 months of storage.

Strengths: Extensive research background in natural product preservation; cost-effective solutions suitable for developing markets; strong focus on maintaining bioactive properties. Weaknesses: Less commercialized than some competitors; technology requires longer processing times; limited scalability for very large industrial applications.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive cryogenic preservation system for oleoresins extracted during petroleum processing operations. Their technology utilizes a cascade refrigeration system that achieves temperatures as low as -150°C without requiring expensive liquid nitrogen, making it more economically viable for large-scale operations. Sinopec's approach incorporates proprietary anti-crystallization agents that prevent the formation of ice crystals during the freezing process, which typically damage cellular structures and lead to quality degradation. Their system features automated pressure-controlled chambers that maintain optimal conditions for different oleoresin types, with pressure ranges from 0.1-1.0 MPa depending on the specific compound being preserved. The technology includes specialized stainless steel storage vessels with multi-layer vacuum insulation that reduces energy consumption by approximately 40% compared to conventional preservation methods while extending preservation periods to 36+ months with minimal quality loss.

Strengths: Extensive industrial-scale implementation experience; integrated approach from extraction to preservation; lower operational costs for large-scale applications. Weaknesses: Systems primarily optimized for petroleum-derived oleoresins; less flexible for small-batch processing; higher initial capital investment requirements.

Key Patents and Innovations in Cryogenic Preservation

Method for the preparation of an oleoresin originating from a red alga that maintains the capacity to induce the transcriptional activity of the nuclear receptor PPAR-Γ

PatentWO2014186913A1

Innovation

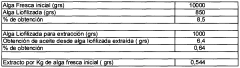

- A five-stage process involving low-temperature algae extraction, mincing, freeze-drying, discontinuous solid-liquid extraction, and solvent elimination is developed to preserve the PPARγ-activating capacity of red algae oleoresin, ensuring high transcriptional activity and oral bioavailability.

Anti-freezing composition

PatentWO2016195273A1

Innovation

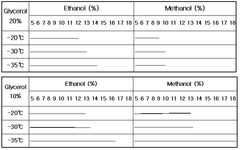

- A cryoprotectant composition using a combination of ethanol and glycerol, which maintains biomaterials in a non-frozen state at temperatures below -20°C without affecting their activity, allowing for stable storage and increased usability by minimizing the need for frequent thawing and freezing.

Quality Control Standards for Preserved Oleoresins

Quality control standards for preserved oleoresins using cryogenic techniques must be comprehensive and rigorous to ensure product integrity throughout the preservation process. These standards should encompass multiple dimensions of quality assessment, beginning with raw material evaluation prior to cryogenic treatment. Incoming oleoresins must be tested for purity, volatile compound content, viscosity, and contamination levels to establish baseline characteristics.

During the cryogenic preservation process, critical control points must be established with precise temperature monitoring protocols. Temperature fluctuations beyond ±2°C can significantly impact oleoresin quality, necessitating continuous monitoring systems with automated alerts. The cooling rate should be standardized based on the specific oleoresin type, with documentation of temperature curves throughout the preservation cycle.

Post-preservation quality assessment should include organoleptic evaluation, comparing sensory properties before and after cryogenic treatment. This includes color stability, aroma profile analysis using gas chromatography-mass spectrometry (GC-MS), and flavor compound retention rates. Industry standards typically require at least 90% retention of key volatile compounds to meet premium quality specifications.

Microbiological standards must be established with clear acceptable limits for total plate count, yeast, mold, and specific pathogens. Cryogenic preservation typically reduces microbial load, but verification testing remains essential. Regular sampling protocols should be implemented at defined intervals during storage to monitor stability and detect any quality degradation over time.

Chemical stability indicators should be monitored, including peroxide value, acid value, and antioxidant activity. These parameters provide objective measures of oxidative stability and potential shelf-life extension achieved through cryogenic preservation. Maximum acceptable thresholds should be established based on industry benchmarks and product-specific requirements.

Packaging integrity testing represents another critical quality control standard, as improper packaging can negate the benefits of cryogenic preservation. Oxygen transmission rate, moisture vapor transmission rate, and seal integrity tests should be conducted on all packaging materials used for preserved oleoresins.

Documentation and traceability systems form the foundation of effective quality control, enabling batch-specific monitoring from raw material receipt through processing and distribution. Each preserved oleoresin batch should receive a unique identifier linked to its complete quality profile, processing parameters, and storage conditions.

During the cryogenic preservation process, critical control points must be established with precise temperature monitoring protocols. Temperature fluctuations beyond ±2°C can significantly impact oleoresin quality, necessitating continuous monitoring systems with automated alerts. The cooling rate should be standardized based on the specific oleoresin type, with documentation of temperature curves throughout the preservation cycle.

Post-preservation quality assessment should include organoleptic evaluation, comparing sensory properties before and after cryogenic treatment. This includes color stability, aroma profile analysis using gas chromatography-mass spectrometry (GC-MS), and flavor compound retention rates. Industry standards typically require at least 90% retention of key volatile compounds to meet premium quality specifications.

Microbiological standards must be established with clear acceptable limits for total plate count, yeast, mold, and specific pathogens. Cryogenic preservation typically reduces microbial load, but verification testing remains essential. Regular sampling protocols should be implemented at defined intervals during storage to monitor stability and detect any quality degradation over time.

Chemical stability indicators should be monitored, including peroxide value, acid value, and antioxidant activity. These parameters provide objective measures of oxidative stability and potential shelf-life extension achieved through cryogenic preservation. Maximum acceptable thresholds should be established based on industry benchmarks and product-specific requirements.

Packaging integrity testing represents another critical quality control standard, as improper packaging can negate the benefits of cryogenic preservation. Oxygen transmission rate, moisture vapor transmission rate, and seal integrity tests should be conducted on all packaging materials used for preserved oleoresins.

Documentation and traceability systems form the foundation of effective quality control, enabling batch-specific monitoring from raw material receipt through processing and distribution. Each preserved oleoresin batch should receive a unique identifier linked to its complete quality profile, processing parameters, and storage conditions.

Environmental Impact of Cryogenic Preservation Methods

The implementation of cryogenic techniques for oleoresin preservation introduces significant environmental considerations that must be evaluated comprehensively. The energy consumption associated with cryogenic preservation represents one of the most substantial environmental impacts. Maintaining ultra-low temperatures requires considerable electricity usage, particularly in continuous preservation systems. This energy demand contributes to carbon emissions when sourced from non-renewable energy grids, potentially offsetting some of the sustainability benefits of improved preservation.

Refrigerant management presents another critical environmental concern. Traditional cryogenic systems often utilize gases with high global warming potential (GWP), such as hydrofluorocarbons (HFCs). Recent advancements have introduced more environmentally friendly alternatives like nitrogen and carbon dioxide-based systems, which offer significantly lower GWP values. However, even these systems require careful management to prevent leakage and minimize environmental impact.

Water usage in cryogenic cooling systems also warrants attention, particularly in regions facing water scarcity. Closed-loop cooling systems have emerged as a solution to reduce water consumption by up to 80% compared to conventional methods, though their implementation increases initial capital expenditure.

The lifecycle assessment of cryogenic preservation equipment reveals additional environmental considerations. The manufacturing of specialized cryogenic equipment involves energy-intensive processes and rare materials extraction. However, the extended shelf life of preserved oleoresins can significantly reduce waste throughout the supply chain, potentially offsetting the initial environmental costs through reduced production needs and transportation emissions.

Transportation of cryogenically preserved oleoresins offers environmental advantages through reduced spoilage rates. Studies indicate that properly preserved oleoresins can maintain quality for 3-5 times longer than conventional methods, substantially decreasing product loss during distribution. This efficiency translates to fewer required production cycles and reduced transportation emissions per usable product unit.

Waste management practices in cryogenic preservation facilities present opportunities for environmental improvement. The implementation of heat recovery systems can capture and repurpose waste cold energy, improving overall energy efficiency by 15-25%. Additionally, proper insulation technologies minimize energy loss and reduce the carbon footprint of preservation operations.

Regulatory frameworks increasingly address the environmental aspects of cryogenic preservation. The Montreal Protocol and subsequent amendments have phased out ozone-depleting refrigerants, while regional regulations like the European F-Gas Regulation continue to drive the adoption of environmentally friendly alternatives in the cryogenic preservation industry.

Refrigerant management presents another critical environmental concern. Traditional cryogenic systems often utilize gases with high global warming potential (GWP), such as hydrofluorocarbons (HFCs). Recent advancements have introduced more environmentally friendly alternatives like nitrogen and carbon dioxide-based systems, which offer significantly lower GWP values. However, even these systems require careful management to prevent leakage and minimize environmental impact.

Water usage in cryogenic cooling systems also warrants attention, particularly in regions facing water scarcity. Closed-loop cooling systems have emerged as a solution to reduce water consumption by up to 80% compared to conventional methods, though their implementation increases initial capital expenditure.

The lifecycle assessment of cryogenic preservation equipment reveals additional environmental considerations. The manufacturing of specialized cryogenic equipment involves energy-intensive processes and rare materials extraction. However, the extended shelf life of preserved oleoresins can significantly reduce waste throughout the supply chain, potentially offsetting the initial environmental costs through reduced production needs and transportation emissions.

Transportation of cryogenically preserved oleoresins offers environmental advantages through reduced spoilage rates. Studies indicate that properly preserved oleoresins can maintain quality for 3-5 times longer than conventional methods, substantially decreasing product loss during distribution. This efficiency translates to fewer required production cycles and reduced transportation emissions per usable product unit.

Waste management practices in cryogenic preservation facilities present opportunities for environmental improvement. The implementation of heat recovery systems can capture and repurpose waste cold energy, improving overall energy efficiency by 15-25%. Additionally, proper insulation technologies minimize energy loss and reduce the carbon footprint of preservation operations.

Regulatory frameworks increasingly address the environmental aspects of cryogenic preservation. The Montreal Protocol and subsequent amendments have phased out ozone-depleting refrigerants, while regional regulations like the European F-Gas Regulation continue to drive the adoption of environmentally friendly alternatives in the cryogenic preservation industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!