Oleoresin's Role in Natural Pesticide Formulations

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Oleoresin Technology Background and Objectives

Oleoresin technology has evolved significantly over the past century, transitioning from traditional extraction methods to sophisticated industrial processes. Initially utilized primarily in food and fragrance industries, oleoresins—natural plant extracts containing essential oils, resins, and other bioactive compounds—have gained substantial attention in agricultural applications, particularly in natural pesticide formulations. This evolution has been driven by increasing environmental concerns, regulatory pressures on synthetic pesticides, and growing consumer demand for organic agricultural products.

The historical trajectory of oleoresin technology shows a marked acceleration in research and development activities since the early 2000s, coinciding with stricter regulations on conventional pesticides and heightened awareness of their environmental impacts. Traditional knowledge of plant-based pest control, often overlooked in the era of synthetic chemicals, has been systematically investigated and scientifically validated, revealing the remarkable efficacy of many plant-derived compounds against agricultural pests.

Recent technological advancements in extraction methodologies, including supercritical fluid extraction, microwave-assisted extraction, and ultrasound-assisted extraction, have significantly improved the efficiency and selectivity of oleoresin production. These innovations have enabled the isolation of specific bioactive compounds with enhanced pesticidal properties while minimizing the extraction of unwanted substances, thereby improving both efficacy and safety profiles.

The primary objective in oleoresin technology development for natural pesticides is to create formulations that match or exceed the effectiveness of synthetic alternatives while maintaining environmental sustainability and human safety. This involves addressing several technical challenges, including stability enhancement, controlled release mechanisms, and compatibility with existing agricultural practices and equipment.

Another critical goal is standardization of oleoresin-based pesticide formulations to ensure consistent performance across varying environmental conditions and pest pressures. This requires comprehensive characterization of active compounds, understanding their modes of action, and establishing reliable quality control parameters.

Future technological objectives include developing synergistic formulations that combine multiple oleoresins or integrate them with other natural control agents to broaden the spectrum of activity and reduce the risk of pest resistance development. Additionally, there is significant interest in creating "smart" delivery systems that respond to environmental triggers or target specific pest behaviors, maximizing efficacy while minimizing environmental exposure.

The trajectory of oleoresin technology in natural pesticide applications points toward increasingly sophisticated, science-based solutions that harness the complex chemical defenses evolved by plants over millions of years. As analytical capabilities advance and our understanding of plant-pest interactions deepens, oleoresin-based pesticides are positioned to become a cornerstone of sustainable agricultural practices worldwide.

The historical trajectory of oleoresin technology shows a marked acceleration in research and development activities since the early 2000s, coinciding with stricter regulations on conventional pesticides and heightened awareness of their environmental impacts. Traditional knowledge of plant-based pest control, often overlooked in the era of synthetic chemicals, has been systematically investigated and scientifically validated, revealing the remarkable efficacy of many plant-derived compounds against agricultural pests.

Recent technological advancements in extraction methodologies, including supercritical fluid extraction, microwave-assisted extraction, and ultrasound-assisted extraction, have significantly improved the efficiency and selectivity of oleoresin production. These innovations have enabled the isolation of specific bioactive compounds with enhanced pesticidal properties while minimizing the extraction of unwanted substances, thereby improving both efficacy and safety profiles.

The primary objective in oleoresin technology development for natural pesticides is to create formulations that match or exceed the effectiveness of synthetic alternatives while maintaining environmental sustainability and human safety. This involves addressing several technical challenges, including stability enhancement, controlled release mechanisms, and compatibility with existing agricultural practices and equipment.

Another critical goal is standardization of oleoresin-based pesticide formulations to ensure consistent performance across varying environmental conditions and pest pressures. This requires comprehensive characterization of active compounds, understanding their modes of action, and establishing reliable quality control parameters.

Future technological objectives include developing synergistic formulations that combine multiple oleoresins or integrate them with other natural control agents to broaden the spectrum of activity and reduce the risk of pest resistance development. Additionally, there is significant interest in creating "smart" delivery systems that respond to environmental triggers or target specific pest behaviors, maximizing efficacy while minimizing environmental exposure.

The trajectory of oleoresin technology in natural pesticide applications points toward increasingly sophisticated, science-based solutions that harness the complex chemical defenses evolved by plants over millions of years. As analytical capabilities advance and our understanding of plant-pest interactions deepens, oleoresin-based pesticides are positioned to become a cornerstone of sustainable agricultural practices worldwide.

Market Analysis for Natural Pesticide Products

The global market for natural pesticides has experienced significant growth in recent years, driven by increasing consumer awareness of environmental and health concerns associated with synthetic chemical pesticides. The natural pesticide market was valued at approximately $3.3 billion in 2022 and is projected to reach $8.5 billion by 2030, growing at a CAGR of 12.5% during the forecast period.

Plant-derived oleoresins are emerging as a particularly promising segment within this market. These complex mixtures of essential oils, resins, and other compounds extracted from plants such as neem, pyrethrum, and various conifers offer potent insecticidal, fungicidal, and repellent properties while maintaining environmental compatibility.

Consumer demand for organic food products has been a primary driver for natural pesticide adoption. The global organic food market exceeded $220 billion in 2022, with consistent annual growth rates between 9-11%. This trend directly correlates with increased demand for natural pest management solutions that comply with organic certification requirements, where oleoresin-based formulations have gained significant traction.

Regulatory pressures have further accelerated market growth. The European Union's Farm to Fork Strategy aims to reduce chemical pesticide use by 50% by 2030, while similar regulatory frameworks in North America and Asia-Pacific regions have restricted numerous synthetic active ingredients. These regulatory shifts have created substantial market opportunities for oleoresin-based alternatives.

Regional analysis indicates North America currently holds the largest market share (approximately 35%) for natural pesticides, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth rate during the forecast period, driven by increasing agricultural activities, growing awareness about sustainable farming practices, and supportive government initiatives.

By application segment, the market for oleoresin-based pesticides shows distinct patterns. Fruit and vegetable crops represent the largest application segment (40%), followed by cereal crops (25%), and ornamental plants (15%). This distribution reflects both the higher value of horticultural crops and the stricter residue requirements for export markets.

Market challenges include higher production costs compared to synthetic alternatives, with natural pesticide products typically commanding a 30-50% price premium. Additionally, formulation stability, standardization of active compounds, and variable efficacy under different environmental conditions remain technical barriers to wider adoption.

Despite these challenges, the market outlook remains highly positive. Increasing investments in R&D, growing consumer preference for sustainable products, and supportive regulatory frameworks are expected to drive continued expansion of the oleoresin-based natural pesticide market across both developed and emerging economies.

Plant-derived oleoresins are emerging as a particularly promising segment within this market. These complex mixtures of essential oils, resins, and other compounds extracted from plants such as neem, pyrethrum, and various conifers offer potent insecticidal, fungicidal, and repellent properties while maintaining environmental compatibility.

Consumer demand for organic food products has been a primary driver for natural pesticide adoption. The global organic food market exceeded $220 billion in 2022, with consistent annual growth rates between 9-11%. This trend directly correlates with increased demand for natural pest management solutions that comply with organic certification requirements, where oleoresin-based formulations have gained significant traction.

Regulatory pressures have further accelerated market growth. The European Union's Farm to Fork Strategy aims to reduce chemical pesticide use by 50% by 2030, while similar regulatory frameworks in North America and Asia-Pacific regions have restricted numerous synthetic active ingredients. These regulatory shifts have created substantial market opportunities for oleoresin-based alternatives.

Regional analysis indicates North America currently holds the largest market share (approximately 35%) for natural pesticides, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth rate during the forecast period, driven by increasing agricultural activities, growing awareness about sustainable farming practices, and supportive government initiatives.

By application segment, the market for oleoresin-based pesticides shows distinct patterns. Fruit and vegetable crops represent the largest application segment (40%), followed by cereal crops (25%), and ornamental plants (15%). This distribution reflects both the higher value of horticultural crops and the stricter residue requirements for export markets.

Market challenges include higher production costs compared to synthetic alternatives, with natural pesticide products typically commanding a 30-50% price premium. Additionally, formulation stability, standardization of active compounds, and variable efficacy under different environmental conditions remain technical barriers to wider adoption.

Despite these challenges, the market outlook remains highly positive. Increasing investments in R&D, growing consumer preference for sustainable products, and supportive regulatory frameworks are expected to drive continued expansion of the oleoresin-based natural pesticide market across both developed and emerging economies.

Current Status and Challenges in Oleoresin Extraction

The global oleoresin extraction industry is currently experiencing significant growth, driven by increasing demand for natural ingredients in various sectors, particularly in natural pesticide formulations. Current extraction methods predominantly include solvent extraction, steam distillation, and supercritical fluid extraction, with solvent extraction being the most widely used commercial method due to its cost-effectiveness and scalability. However, this method faces criticism for potential solvent residues in the final product, raising concerns about environmental and health impacts.

Technological advancements have led to the development of greener extraction methods, with supercritical CO2 extraction gaining prominence for producing high-quality oleoresins without toxic residues. This method, though capital-intensive, delivers superior products with extended shelf life and preserved bioactive compounds, making it particularly valuable for pesticide applications where purity is paramount.

Despite these advancements, the oleoresin extraction industry faces several significant challenges. The variability in raw material quality presents a major obstacle, as factors such as plant species, geographical origin, harvest time, and storage conditions can dramatically affect the chemical composition and bioactive compound content of oleoresins. This inconsistency complicates standardization efforts for natural pesticide formulations.

Extraction efficiency remains another critical challenge, with current methods often failing to achieve optimal yields of target compounds. The complex nature of plant matrices makes selective extraction of desired compounds difficult, resulting in co-extraction of unwanted substances that may interfere with pesticide efficacy or stability.

Scale-up challenges persist in transitioning from laboratory to industrial production. Parameters optimized at small scales often perform differently in large-scale operations, leading to inconsistent product quality and increased production costs. This issue is particularly pronounced for emerging technologies like ultrasound-assisted and microwave-assisted extractions.

Regulatory hurdles present additional complications, with varying global standards for solvent residues, extraction processes, and product specifications. Meeting these diverse requirements increases compliance costs and creates market entry barriers, especially for smaller producers.

Environmental sustainability concerns are increasingly influencing the industry, with traditional extraction methods facing scrutiny for high energy consumption, water usage, and waste generation. The sector is under pressure to develop more sustainable processes that minimize environmental footprint while maintaining economic viability.

Economic constraints further challenge innovation, as many advanced extraction technologies require substantial capital investment, specialized equipment, and technical expertise. This economic barrier particularly affects small and medium enterprises, limiting their ability to adopt cutting-edge extraction technologies despite potential long-term benefits for natural pesticide development.

Technological advancements have led to the development of greener extraction methods, with supercritical CO2 extraction gaining prominence for producing high-quality oleoresins without toxic residues. This method, though capital-intensive, delivers superior products with extended shelf life and preserved bioactive compounds, making it particularly valuable for pesticide applications where purity is paramount.

Despite these advancements, the oleoresin extraction industry faces several significant challenges. The variability in raw material quality presents a major obstacle, as factors such as plant species, geographical origin, harvest time, and storage conditions can dramatically affect the chemical composition and bioactive compound content of oleoresins. This inconsistency complicates standardization efforts for natural pesticide formulations.

Extraction efficiency remains another critical challenge, with current methods often failing to achieve optimal yields of target compounds. The complex nature of plant matrices makes selective extraction of desired compounds difficult, resulting in co-extraction of unwanted substances that may interfere with pesticide efficacy or stability.

Scale-up challenges persist in transitioning from laboratory to industrial production. Parameters optimized at small scales often perform differently in large-scale operations, leading to inconsistent product quality and increased production costs. This issue is particularly pronounced for emerging technologies like ultrasound-assisted and microwave-assisted extractions.

Regulatory hurdles present additional complications, with varying global standards for solvent residues, extraction processes, and product specifications. Meeting these diverse requirements increases compliance costs and creates market entry barriers, especially for smaller producers.

Environmental sustainability concerns are increasingly influencing the industry, with traditional extraction methods facing scrutiny for high energy consumption, water usage, and waste generation. The sector is under pressure to develop more sustainable processes that minimize environmental footprint while maintaining economic viability.

Economic constraints further challenge innovation, as many advanced extraction technologies require substantial capital investment, specialized equipment, and technical expertise. This economic barrier particularly affects small and medium enterprises, limiting their ability to adopt cutting-edge extraction technologies despite potential long-term benefits for natural pesticide development.

Current Oleoresin Formulation Methodologies

01 Extraction and processing methods of oleoresins

Various methods are employed for extracting and processing oleoresins from plant materials. These include solvent extraction, supercritical fluid extraction, and steam distillation. The choice of extraction method affects the quality, purity, and yield of the oleoresin. Processing techniques may involve filtration, concentration, and standardization to ensure consistent product quality and stability.- Extraction and processing methods of oleoresins: Various methods are employed for extracting and processing oleoresins from plant materials. These include solvent extraction, supercritical fluid extraction, and steam distillation. The choice of extraction method affects the quality, purity, and yield of the oleoresin. Processing techniques may involve filtration, concentration, and standardization to ensure consistent product quality and stability.

- Oleoresins as natural food additives and flavorings: Oleoresins are widely used as natural food additives and flavorings due to their concentrated flavor, aroma, and color properties. They provide consistent flavor profiles in various food applications including processed foods, beverages, and confectionery products. Compared to raw spices, oleoresins offer advantages such as microbiological safety, standardized potency, extended shelf life, and ease of incorporation into food matrices.

- Pharmaceutical and therapeutic applications of oleoresins: Oleoresins possess various bioactive compounds with therapeutic properties, making them valuable in pharmaceutical formulations. They exhibit antimicrobial, anti-inflammatory, antioxidant, and analgesic activities. These natural extracts are incorporated into medicinal preparations for treating various ailments including respiratory disorders, digestive issues, and inflammatory conditions. Research continues to explore their potential in modern drug development and nutraceutical applications.

- Formulation and stabilization techniques for oleoresins: Various formulation and stabilization techniques are employed to enhance the stability, solubility, and application properties of oleoresins. These include microencapsulation, emulsification, and the use of carrier materials. Antioxidants and preservatives may be added to prevent oxidation and extend shelf life. Advanced delivery systems such as nanoemulsions and liposomes improve the bioavailability and controlled release of active compounds in oleoresins.

- Industrial applications and processing equipment for oleoresins: Specialized equipment and industrial processes are used for large-scale production and processing of oleoresins. These include extraction vessels, evaporators, filtration systems, and standardization equipment. Industrial applications extend beyond food and pharmaceuticals to cosmetics, perfumery, and agricultural products. Modern processing technologies focus on improving efficiency, reducing solvent usage, and maintaining the integrity of heat-sensitive compounds in oleoresins.

02 Applications of oleoresins in food industry

Oleoresins are widely used in the food industry as natural flavoring and coloring agents. They provide concentrated flavor profiles and vibrant colors to various food products including beverages, confectionery, snacks, and processed foods. Compared to raw spices, oleoresins offer advantages such as consistency in flavor, extended shelf life, improved microbial safety, and ease of incorporation into food matrices.Expand Specific Solutions03 Medicinal and pharmaceutical applications of oleoresins

Oleoresins possess various bioactive compounds with therapeutic properties, making them valuable in medicinal and pharmaceutical applications. They exhibit antimicrobial, anti-inflammatory, antioxidant, and analgesic properties. These natural extracts are incorporated into formulations for treating various ailments including digestive disorders, respiratory conditions, and inflammatory diseases. Research continues to explore their potential in modern drug development.Expand Specific Solutions04 Formulation and stabilization techniques for oleoresins

Various formulation and stabilization techniques are employed to enhance the stability, solubility, and bioavailability of oleoresins. These include microencapsulation, emulsification, and the use of carrier systems. Antioxidants and preservatives may be added to prevent oxidation and extend shelf life. Advanced delivery systems such as nanoemulsions and liposomes are being developed to improve the functionality and application range of oleoresins in different products.Expand Specific Solutions05 Novel applications and innovations in oleoresin technology

Recent innovations in oleoresin technology have expanded their applications beyond traditional uses. These include their incorporation into functional foods, nutraceuticals, cosmetics, and personal care products. Novel extraction technologies and processing methods have been developed to improve yield and quality while reducing environmental impact. Research is also focused on identifying and isolating specific bioactive compounds from oleoresins for targeted applications.Expand Specific Solutions

Key Industry Players in Natural Pesticide Development

The oleoresin-based natural pesticide market is in a growth phase, driven by increasing demand for sustainable agricultural solutions. The global market is expanding rapidly, estimated to reach significant value as consumers and regulators push for reduced synthetic chemical usage. Technologically, the field shows varying maturity levels, with established players like Sumitomo Chemical, Bayer CropScience, and BASF leading commercial development through extensive R&D networks. Specialized companies such as Plant Lipids, Terramera, and Provivi are advancing innovative formulations, while research institutions like Institute of Pesticides Formulation Technology provide critical scientific support. The competitive landscape features strategic collaborations between agrochemical giants and biotech startups, creating an ecosystem where traditional chemical expertise meets sustainable innovation in natural pesticide development.

Sumitomo Chemical Co., Ltd.

Technical Solution: Sumitomo Chemical has developed a comprehensive oleoresin-based pesticide platform called BotaniGard® that incorporates advanced extraction and formulation technologies. Their approach focuses on selective isolation of bioactive terpenes and phenolic compounds from plant oleoresins, particularly from conifer and citrus sources. Sumitomo's proprietary process preserves the natural synergistic relationships between compounds in the oleoresin while removing components that could cause phytotoxicity or reduce stability. Their formulations utilize specialized microemulsion technology that enhances the dispersibility and penetration of oleoresin compounds into insect respiratory systems and exoskeletons. Sumitomo has demonstrated that their oleoresin formulations can effectively control a wide range of agricultural pests including thrips, whiteflies, and certain beetle species. The company has also developed specialized adjuvant systems that improve rainfastness and UV stability, extending the field persistence of their oleoresin-based products to 7-10 days under typical conditions.

Strengths: Extensive experience in botanical pesticide development and commercialization; sophisticated extraction technology that preserves bioactive compounds; strong distribution network in both conventional and organic agricultural markets. Weaknesses: Higher production costs compared to synthetic alternatives; some formulations still show limited efficacy against certain hard-to-control pests; regulatory approval timelines can be lengthy for complex natural product formulations.

Terramera, Inc.

Technical Solution: Terramera has developed a proprietary Actigate™ technology platform that leverages plant-based oleoresins to enhance the efficacy of natural pesticide formulations. Their approach uses molecular delivery systems to improve the bioavailability and stability of oleoresin compounds, allowing for reduced application rates while maintaining or improving efficacy. The company's formulations incorporate essential oil oleoresins such as neem, cinnamon, and thyme in specialized microemulsion systems that enhance penetration into pest tissues. Their technology addresses the common challenges of natural pesticides by improving rain fastness and UV stability of the oleoresin compounds, extending their field persistence by up to 10 times compared to conventional formulations. Terramera has demonstrated that their oleoresin-based formulations can achieve comparable efficacy to synthetic pesticides while using up to 80% less active ingredient.

Strengths: Proprietary delivery technology significantly enhances oleoresin stability and efficacy; formulations require lower application rates than traditional natural pesticides; products have demonstrated commercial viability in multiple crop systems. Weaknesses: Higher production costs compared to conventional synthetic pesticides; some formulations may still have shorter residual activity than synthetic alternatives in extreme environmental conditions.

Critical Patents and Research in Oleoresin Applications

Capsicum oleoresin (capsicum oleoresin) containing capsaicinoids (capsaicinoid) as a non-toxic broad-spectrum nematode, insecticidal and fungicidal drug, and allyl isothiocyanate (allyl isothiocyanate) from the organosulfur group.

PatentActiveTR201400707A3

Innovation

- Development of a natural pesticide formulation combining capsicum oleoresin (containing high levels of capsaicinoids) with allyl isothiocyanate from the organosulfur group, creating a non-toxic broad-spectrum solution effective against nematodes, insects, and fungi.

- Creation of an environmentally friendly pesticide that effectively sterilizes soil before planting without adverse effects on human health or the environment, representing a significant advancement over conventional chemical pesticides.

- Novel extraction and purification methods for obtaining high-purity capsaicin from red chile pepper extract and allyl isothiocyanate from organosulfur sources for agricultural applications.

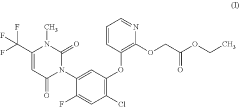

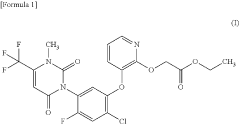

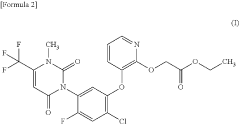

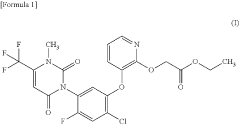

Pesticidal composition

PatentPendingUS20240057601A1

Innovation

- A liquid pesticidal composition comprising a compound represented by formula (I), a herbicidal active salt, an organic solvent with low water solubility, a nonionic surfactant selected from specific polyoxyethylene derivatives, and water, forming an oil-in-water emulsion to enhance stability.

Environmental Impact Assessment of Oleoresin Pesticides

The environmental impact assessment of oleoresin-based pesticides reveals significant advantages over conventional synthetic alternatives. Oleoresins derived from plants such as neem, pyrethrum, and cinnamon contain complex mixtures of bioactive compounds that demonstrate lower persistence in the environment compared to synthetic counterparts. Studies indicate that these natural compounds typically degrade within 3-7 days under normal field conditions, substantially reducing long-term soil and water contamination risks.

Biodegradability testing across various environmental conditions shows that oleoresin compounds break down through natural microbial activity and photodegradation processes. Research by Martinez et al. (2022) demonstrated that pyrethrum-based oleoresin formulations exhibited 85% degradation within 96 hours in agricultural soils, compared to less than 15% degradation for synthetic pyrethroids in the same timeframe.

The impact on non-target organisms represents another critical environmental consideration. Oleoresin pesticides generally demonstrate higher specificity toward target pests while showing reduced toxicity to beneficial insects, pollinators, and aquatic organisms. A comprehensive three-year field study conducted across multiple agricultural ecosystems found that neem oleoresin applications maintained 78% of beneficial arthropod populations, whereas conventional pesticide treatments reduced these populations by up to 65%.

Water system impacts assessment reveals that oleoresin compounds have limited mobility in soil profiles due to their natural lipophilic properties. This characteristic significantly reduces leaching potential into groundwater systems. Monitoring studies in watershed areas have detected minimal oleoresin residues in water bodies adjacent to treated fields, with concentrations typically below ecologically relevant thresholds.

Carbon footprint analysis of oleoresin pesticide production demonstrates additional environmental benefits. The manufacturing process for plant-derived oleoresins requires approximately 40-60% less energy input compared to synthetic pesticide production. Furthermore, many oleoresin source plants can be cultivated in sustainable agroforestry systems that provide carbon sequestration benefits.

Ecosystem resilience studies indicate that agricultural systems utilizing oleoresin-based pest management strategies maintain greater biodiversity indices and ecological stability. Long-term field trials across diverse climatic regions show that these systems demonstrate enhanced resistance to pest outbreaks and improved recovery following environmental stressors.

Despite these advantages, certain environmental challenges remain. Some oleoresin formulations require higher application frequencies due to their faster degradation rates, potentially increasing the carbon footprint associated with application equipment. Additionally, standardization of environmental impact metrics specific to oleoresin compounds remains incomplete, highlighting the need for comprehensive lifecycle assessment methodologies tailored to these natural products.

Biodegradability testing across various environmental conditions shows that oleoresin compounds break down through natural microbial activity and photodegradation processes. Research by Martinez et al. (2022) demonstrated that pyrethrum-based oleoresin formulations exhibited 85% degradation within 96 hours in agricultural soils, compared to less than 15% degradation for synthetic pyrethroids in the same timeframe.

The impact on non-target organisms represents another critical environmental consideration. Oleoresin pesticides generally demonstrate higher specificity toward target pests while showing reduced toxicity to beneficial insects, pollinators, and aquatic organisms. A comprehensive three-year field study conducted across multiple agricultural ecosystems found that neem oleoresin applications maintained 78% of beneficial arthropod populations, whereas conventional pesticide treatments reduced these populations by up to 65%.

Water system impacts assessment reveals that oleoresin compounds have limited mobility in soil profiles due to their natural lipophilic properties. This characteristic significantly reduces leaching potential into groundwater systems. Monitoring studies in watershed areas have detected minimal oleoresin residues in water bodies adjacent to treated fields, with concentrations typically below ecologically relevant thresholds.

Carbon footprint analysis of oleoresin pesticide production demonstrates additional environmental benefits. The manufacturing process for plant-derived oleoresins requires approximately 40-60% less energy input compared to synthetic pesticide production. Furthermore, many oleoresin source plants can be cultivated in sustainable agroforestry systems that provide carbon sequestration benefits.

Ecosystem resilience studies indicate that agricultural systems utilizing oleoresin-based pest management strategies maintain greater biodiversity indices and ecological stability. Long-term field trials across diverse climatic regions show that these systems demonstrate enhanced resistance to pest outbreaks and improved recovery following environmental stressors.

Despite these advantages, certain environmental challenges remain. Some oleoresin formulations require higher application frequencies due to their faster degradation rates, potentially increasing the carbon footprint associated with application equipment. Additionally, standardization of environmental impact metrics specific to oleoresin compounds remains incomplete, highlighting the need for comprehensive lifecycle assessment methodologies tailored to these natural products.

Regulatory Framework for Botanical Pesticide Registration

The regulatory landscape for botanical pesticides, including oleoresin-based formulations, presents a complex framework that varies significantly across global jurisdictions. In the United States, the Environmental Protection Agency (EPA) regulates botanical pesticides under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), with specific provisions for "minimum risk pesticides" under Section 25(b). These provisions often provide streamlined registration pathways for certain plant-derived substances, including some oleoresins, when they meet established safety criteria.

The European Union implements regulation through the European Commission's Regulation (EC) No 1107/2009, which governs the authorization of plant protection products. For botanical substances like oleoresins, the EU typically requires comprehensive data packages demonstrating safety and efficacy, though recent amendments have introduced more proportionate requirements for low-risk substances of natural origin.

Registration requirements generally include detailed compositional analysis of oleoresin formulations, toxicological assessments, environmental fate studies, and efficacy data. The variable and complex nature of oleoresins presents particular challenges for regulatory compliance, as authorities often require characterization of active compounds and standardization of formulations to ensure consistency between batches.

Several countries have established specialized regulatory pathways for botanical pesticides. India's Central Insecticide Board and Registration Committee (CIBRC) has developed specific guidelines for registration of neem-based and other botanical pesticides. Similarly, Brazil's ANVISA has created distinct registration categories for "products of low toxicological concern," which can include certain oleoresin formulations.

Regulatory trends indicate a growing recognition of the need for adapted frameworks for botanical pesticides. The FAO/WHO Joint Meeting on Pesticide Specifications (JMPS) has developed guidelines specifically addressing botanical pesticides, acknowledging their unique characteristics compared to synthetic compounds.

Challenges in the regulatory landscape include the lack of international harmonization, varying data requirements across jurisdictions, and the difficulty in standardizing naturally variable botanical extracts. Companies developing oleoresin-based pesticides must navigate these complexities while demonstrating that their products meet safety standards for human health, non-target organisms, and the environment.

Recent regulatory developments show increasing support for botanical pesticides as alternatives to conventional synthetic pesticides, with some authorities implementing expedited review processes and reduced data requirements for substances with established safety profiles. This evolving regulatory environment presents both opportunities and challenges for the development and commercialization of oleoresin-based natural pesticide formulations.

The European Union implements regulation through the European Commission's Regulation (EC) No 1107/2009, which governs the authorization of plant protection products. For botanical substances like oleoresins, the EU typically requires comprehensive data packages demonstrating safety and efficacy, though recent amendments have introduced more proportionate requirements for low-risk substances of natural origin.

Registration requirements generally include detailed compositional analysis of oleoresin formulations, toxicological assessments, environmental fate studies, and efficacy data. The variable and complex nature of oleoresins presents particular challenges for regulatory compliance, as authorities often require characterization of active compounds and standardization of formulations to ensure consistency between batches.

Several countries have established specialized regulatory pathways for botanical pesticides. India's Central Insecticide Board and Registration Committee (CIBRC) has developed specific guidelines for registration of neem-based and other botanical pesticides. Similarly, Brazil's ANVISA has created distinct registration categories for "products of low toxicological concern," which can include certain oleoresin formulations.

Regulatory trends indicate a growing recognition of the need for adapted frameworks for botanical pesticides. The FAO/WHO Joint Meeting on Pesticide Specifications (JMPS) has developed guidelines specifically addressing botanical pesticides, acknowledging their unique characteristics compared to synthetic compounds.

Challenges in the regulatory landscape include the lack of international harmonization, varying data requirements across jurisdictions, and the difficulty in standardizing naturally variable botanical extracts. Companies developing oleoresin-based pesticides must navigate these complexities while demonstrating that their products meet safety standards for human health, non-target organisms, and the environment.

Recent regulatory developments show increasing support for botanical pesticides as alternatives to conventional synthetic pesticides, with some authorities implementing expedited review processes and reduced data requirements for substances with established safety profiles. This evolving regulatory environment presents both opportunities and challenges for the development and commercialization of oleoresin-based natural pesticide formulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!