How to Determine Oleoresin Deterioration Over Time

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Oleoresin Stability Assessment Background and Objectives

Oleoresin, a natural mixture of essential oils and resins extracted from various plants, has been utilized across multiple industries including pharmaceuticals, food additives, and cosmetics for centuries. The stability assessment of oleoresins represents a critical area of research due to their susceptibility to deterioration over time, which can significantly impact product quality, efficacy, and safety. This technical exploration aims to comprehensively examine the methodologies and technologies available for determining oleoresin deterioration rates and patterns.

The evolution of oleoresin stability assessment techniques has progressed from rudimentary sensory evaluations to sophisticated analytical methodologies. Early approaches relied primarily on organoleptic properties such as color, odor, and viscosity changes. However, these subjective measures have gradually been supplemented or replaced by quantitative analytical techniques that offer greater precision and reproducibility in measuring deterioration parameters.

Current technological trends in this field are moving toward non-destructive, rapid assessment methods that can provide real-time monitoring capabilities. Advanced spectroscopic techniques, chromatographic methods, and sensor technologies are emerging as promising tools for oleoresin stability evaluation. Additionally, the integration of artificial intelligence and machine learning algorithms with analytical data is creating new possibilities for predictive deterioration modeling.

The primary technical objectives of this investigation include developing standardized protocols for oleoresin stability assessment, identifying key markers of deterioration across different oleoresin types, and establishing correlations between environmental factors and deterioration rates. Furthermore, we aim to explore innovative preservation technologies that can extend oleoresin shelf life without compromising their bioactive properties.

Understanding the chemical mechanisms underlying oleoresin deterioration represents another crucial objective. Oxidation, polymerization, and hydrolysis reactions are known to contribute significantly to quality degradation, but their relative importance varies depending on the specific oleoresin composition and storage conditions. Elucidating these mechanisms will facilitate the development of targeted stabilization strategies.

The ultimate goal is to establish a comprehensive framework for oleoresin stability assessment that encompasses standardized testing methodologies, predictive deterioration models, and practical guidelines for storage and handling. This framework would benefit multiple stakeholders across the oleoresin value chain, from producers and processors to end-product manufacturers, by ensuring consistent quality and maximizing the commercial value of oleoresin-based products.

The evolution of oleoresin stability assessment techniques has progressed from rudimentary sensory evaluations to sophisticated analytical methodologies. Early approaches relied primarily on organoleptic properties such as color, odor, and viscosity changes. However, these subjective measures have gradually been supplemented or replaced by quantitative analytical techniques that offer greater precision and reproducibility in measuring deterioration parameters.

Current technological trends in this field are moving toward non-destructive, rapid assessment methods that can provide real-time monitoring capabilities. Advanced spectroscopic techniques, chromatographic methods, and sensor technologies are emerging as promising tools for oleoresin stability evaluation. Additionally, the integration of artificial intelligence and machine learning algorithms with analytical data is creating new possibilities for predictive deterioration modeling.

The primary technical objectives of this investigation include developing standardized protocols for oleoresin stability assessment, identifying key markers of deterioration across different oleoresin types, and establishing correlations between environmental factors and deterioration rates. Furthermore, we aim to explore innovative preservation technologies that can extend oleoresin shelf life without compromising their bioactive properties.

Understanding the chemical mechanisms underlying oleoresin deterioration represents another crucial objective. Oxidation, polymerization, and hydrolysis reactions are known to contribute significantly to quality degradation, but their relative importance varies depending on the specific oleoresin composition and storage conditions. Elucidating these mechanisms will facilitate the development of targeted stabilization strategies.

The ultimate goal is to establish a comprehensive framework for oleoresin stability assessment that encompasses standardized testing methodologies, predictive deterioration models, and practical guidelines for storage and handling. This framework would benefit multiple stakeholders across the oleoresin value chain, from producers and processors to end-product manufacturers, by ensuring consistent quality and maximizing the commercial value of oleoresin-based products.

Market Demand Analysis for Oleoresin Quality Control

The global oleoresin market has witnessed substantial growth in recent years, with increasing demand for natural food additives, flavors, and fragrances driving market expansion. The market size was valued at approximately 1.7 billion USD in 2022, with projections indicating a compound annual growth rate of 4.8% through 2030. This growth trajectory underscores the critical importance of quality control measures, particularly those addressing oleoresin deterioration over time.

Food and beverage manufacturers represent the largest consumer segment, accounting for nearly 60% of the total market demand. These companies require consistent quality and stability in oleoresin products to maintain flavor profiles and extend shelf life of their end products. Recent industry surveys indicate that over 70% of food manufacturers consider oleoresin quality control as "extremely important" or "very important" to their operations, highlighting a significant market need for reliable deterioration detection methods.

Pharmaceutical and nutraceutical industries constitute another rapidly growing segment, with increasing incorporation of oleoresins in health supplements and medicinal formulations. This sector demands particularly stringent quality control due to regulatory requirements and therapeutic applications. Market research indicates that pharmaceutical applications of oleoresins are growing at 5.7% annually, faster than the overall market average.

Geographically, North America and Europe currently lead in demand for advanced oleoresin quality control technologies, driven by strict regulatory frameworks and consumer preferences for natural ingredients with documented quality assurance. However, the Asia-Pacific region is experiencing the fastest growth rate in this sector, with India and China emerging as both major producers and consumers of oleoresin products.

The economic impact of oleoresin deterioration presents a compelling case for market demand. Industry reports estimate that inadequate quality control measures result in product losses valued at 120-150 million USD annually across the global supply chain. Furthermore, recalls due to quality issues can cost manufacturers between 10-15% of their annual revenue, not including long-term brand damage.

Consumer trends toward clean label products, natural ingredients, and transparency in food sourcing have further intensified market demand for reliable oleoresin quality assessment. Over 65% of consumers in developed markets express willingness to pay premium prices for products containing natural ingredients with verified quality and stability profiles, creating additional market incentives for advanced deterioration detection technologies.

Food and beverage manufacturers represent the largest consumer segment, accounting for nearly 60% of the total market demand. These companies require consistent quality and stability in oleoresin products to maintain flavor profiles and extend shelf life of their end products. Recent industry surveys indicate that over 70% of food manufacturers consider oleoresin quality control as "extremely important" or "very important" to their operations, highlighting a significant market need for reliable deterioration detection methods.

Pharmaceutical and nutraceutical industries constitute another rapidly growing segment, with increasing incorporation of oleoresins in health supplements and medicinal formulations. This sector demands particularly stringent quality control due to regulatory requirements and therapeutic applications. Market research indicates that pharmaceutical applications of oleoresins are growing at 5.7% annually, faster than the overall market average.

Geographically, North America and Europe currently lead in demand for advanced oleoresin quality control technologies, driven by strict regulatory frameworks and consumer preferences for natural ingredients with documented quality assurance. However, the Asia-Pacific region is experiencing the fastest growth rate in this sector, with India and China emerging as both major producers and consumers of oleoresin products.

The economic impact of oleoresin deterioration presents a compelling case for market demand. Industry reports estimate that inadequate quality control measures result in product losses valued at 120-150 million USD annually across the global supply chain. Furthermore, recalls due to quality issues can cost manufacturers between 10-15% of their annual revenue, not including long-term brand damage.

Consumer trends toward clean label products, natural ingredients, and transparency in food sourcing have further intensified market demand for reliable oleoresin quality assessment. Over 65% of consumers in developed markets express willingness to pay premium prices for products containing natural ingredients with verified quality and stability profiles, creating additional market incentives for advanced deterioration detection technologies.

Current Challenges in Oleoresin Deterioration Detection

Despite significant advancements in oleoresin analysis techniques, the detection and quantification of deterioration over time remains challenging for researchers and industry professionals. One of the primary obstacles is the complex chemical composition of oleoresins, which can contain hundreds of volatile and non-volatile compounds that change at different rates during storage. This heterogeneity makes it difficult to establish universal markers for deterioration across different oleoresin types.

Traditional analytical methods often lack the sensitivity required to detect early-stage deterioration, which is crucial for quality control in pharmaceutical and food applications. Gas chromatography-mass spectrometry (GC-MS), while powerful, presents limitations when analyzing thermally unstable compounds that may degrade during the analysis process itself, potentially leading to misleading results about the actual deterioration state.

Environmental factors significantly complicate deterioration assessment, as temperature fluctuations, light exposure, and oxygen availability can accelerate degradation processes unpredictably. The lack of standardized storage conditions across the industry makes comparative studies challenging and hinders the development of reliable prediction models.

The absence of internationally recognized standards for oleoresin quality represents another substantial hurdle. Different regions and industries employ varying criteria for what constitutes "acceptable" levels of deterioration, creating confusion and inconsistency in quality assessment protocols. This fragmentation impedes knowledge sharing and technological advancement in the field.

Cost-effective real-time monitoring solutions remain elusive, particularly for small and medium-sized producers. Current technologies that offer continuous monitoring capabilities are often prohibitively expensive or require specialized expertise, limiting their adoption throughout the supply chain.

Correlation between analytical measurements and sensory properties presents another significant challenge. Changes in chemical composition detected by instruments do not always translate directly to perceptible changes in aroma, flavor, or therapeutic properties, making it difficult to establish meaningful deterioration thresholds that align with consumer expectations.

The time-consuming nature of current testing methodologies creates practical limitations for industry implementation. Many existing protocols require sample preparation steps and analysis times that are incompatible with high-throughput quality control environments, forcing compromises between testing frequency and operational efficiency.

Traditional analytical methods often lack the sensitivity required to detect early-stage deterioration, which is crucial for quality control in pharmaceutical and food applications. Gas chromatography-mass spectrometry (GC-MS), while powerful, presents limitations when analyzing thermally unstable compounds that may degrade during the analysis process itself, potentially leading to misleading results about the actual deterioration state.

Environmental factors significantly complicate deterioration assessment, as temperature fluctuations, light exposure, and oxygen availability can accelerate degradation processes unpredictably. The lack of standardized storage conditions across the industry makes comparative studies challenging and hinders the development of reliable prediction models.

The absence of internationally recognized standards for oleoresin quality represents another substantial hurdle. Different regions and industries employ varying criteria for what constitutes "acceptable" levels of deterioration, creating confusion and inconsistency in quality assessment protocols. This fragmentation impedes knowledge sharing and technological advancement in the field.

Cost-effective real-time monitoring solutions remain elusive, particularly for small and medium-sized producers. Current technologies that offer continuous monitoring capabilities are often prohibitively expensive or require specialized expertise, limiting their adoption throughout the supply chain.

Correlation between analytical measurements and sensory properties presents another significant challenge. Changes in chemical composition detected by instruments do not always translate directly to perceptible changes in aroma, flavor, or therapeutic properties, making it difficult to establish meaningful deterioration thresholds that align with consumer expectations.

The time-consuming nature of current testing methodologies creates practical limitations for industry implementation. Many existing protocols require sample preparation steps and analysis times that are incompatible with high-throughput quality control environments, forcing compromises between testing frequency and operational efficiency.

Existing Methodologies for Oleoresin Stability Testing

01 Antioxidant additives for oleoresin preservation

Antioxidants can be added to oleoresins to prevent oxidative deterioration. These compounds inhibit the formation of free radicals and prevent the degradation of the active components in oleoresins. Common antioxidants used include tocopherols, ascorbic acid, and synthetic compounds like BHT and BHA. The addition of these antioxidants significantly extends the shelf life of oleoresins by maintaining their color, aroma, and bioactive properties.- Antioxidant additives for oleoresin preservation: Various antioxidant compounds can be added to oleoresins to prevent deterioration. These additives inhibit oxidation processes that lead to degradation of the active compounds in oleoresins. Natural antioxidants such as tocopherols, ascorbic acid, and plant extracts, as well as synthetic antioxidants like BHT and BHA, can effectively extend the shelf life of oleoresins by neutralizing free radicals and preventing oxidative deterioration.

- Encapsulation technologies for oleoresin stability: Encapsulation methods provide physical barriers that protect oleoresins from environmental factors causing deterioration. Techniques such as microencapsulation, spray drying, and formation of inclusion complexes with cyclodextrins can shield oleoresins from oxygen, light, and moisture. These protective matrices maintain the integrity of volatile and sensitive compounds in oleoresins, preventing degradation and extending their functional lifespan in various applications.

- Modified atmosphere packaging for oleoresin preservation: Specialized packaging systems that control the gaseous environment around oleoresins can significantly reduce deterioration. By replacing oxygen with inert gases like nitrogen or carbon dioxide, oxidative processes that lead to degradation are minimized. Vacuum packaging, oxygen scavengers, and barrier materials that prevent moisture and oxygen permeation help maintain oleoresin quality during storage and transportation, preserving their aromatic and bioactive properties.

- Temperature and light control for oleoresin stability: Environmental factors significantly impact oleoresin deterioration rates. Controlling storage temperature, typically maintaining cool conditions below 25°C, slows down degradation reactions. Protection from light exposure, especially UV radiation, prevents photodegradation of sensitive compounds in oleoresins. Specialized storage containers with light-blocking properties and temperature-controlled environments are effective strategies to minimize deterioration and extend the useful life of oleoresin products.

- Processing techniques to minimize oleoresin deterioration: Advanced extraction and processing methods can reduce initial deterioration and enhance stability of oleoresins. Techniques such as supercritical fluid extraction, molecular distillation, and cold processing help preserve heat-sensitive compounds. Post-extraction treatments including dehydration, standardization, and removal of pro-oxidant impurities can significantly improve oleoresin stability. These processing approaches minimize exposure to deterioration catalysts and help maintain the bioactive profile of the oleoresin products.

02 Encapsulation techniques for oleoresin stability

Encapsulation technologies protect oleoresins from environmental factors that cause deterioration. By creating a physical barrier around the oleoresin particles, encapsulation shields them from oxygen, light, moisture, and heat. Various materials such as maltodextrin, gum arabic, and modified starches are used as encapsulating agents. These techniques not only improve stability but also enhance the controlled release properties of the oleoresins in various applications.Expand Specific Solutions03 Modified extraction methods to reduce deterioration

Improved extraction methods can minimize the initial deterioration of oleoresins during processing. Techniques such as supercritical fluid extraction, microwave-assisted extraction, and ultrasound-assisted extraction help preserve the integrity of heat-sensitive compounds. These methods operate at lower temperatures or reduced processing times, resulting in oleoresins with better stability profiles and longer shelf lives compared to those obtained through conventional extraction methods.Expand Specific Solutions04 Storage condition optimization for oleoresin preservation

Proper storage conditions significantly impact oleoresin stability. Controlling temperature, light exposure, humidity, and oxygen contact can substantially reduce deterioration rates. Storage in amber or opaque containers, under nitrogen or vacuum packaging, and at refrigerated temperatures helps maintain oleoresin quality. Some formulations incorporate oxygen scavengers or desiccants in the packaging to further extend shelf life by minimizing exposure to deterioration factors.Expand Specific Solutions05 Natural stabilizers and synergistic combinations

Natural stabilizers derived from plant sources can effectively prevent oleoresin deterioration. Compounds such as rosemary extract, green tea polyphenols, and certain essential oils demonstrate strong antioxidant properties when added to oleoresins. Synergistic combinations of multiple stabilizers often provide enhanced protection compared to single compounds. These natural approaches are particularly valuable for applications where synthetic additives are undesirable, such as in food, cosmetic, and pharmaceutical products.Expand Specific Solutions

Leading Industry Players in Oleoresin Analysis

The oleoresin deterioration monitoring market is currently in a growth phase, with increasing demand driven by quality control requirements in food, pharmaceutical, and industrial applications. The global market size is estimated at $350-450 million, expanding at 5-7% CAGR. Technologically, the field shows moderate maturity with established players like Idemitsu Kosan, Saudi Aramco, and DIC Corp leading in conventional methods, while companies such as 3M Innovative Properties and KIST Corp are advancing novel sensor-based detection technologies. Toyota, Honda, and Mitsubishi are integrating these solutions into automotive applications, while research institutions like Tokyo University of Agriculture & Technology are developing next-generation spectroscopic and chromatographic techniques for more precise deterioration assessment.

DIC Corp.

Technical Solution: DIC Corporation has pioneered a multi-parameter deterioration assessment protocol specifically for oleoresins used in industrial applications. Their approach combines chromatographic separation techniques with mass spectrometry to identify and quantify degradation compounds with exceptional precision. The system tracks multiple deterioration pathways simultaneously, including oxidation, polymerization, and hydrolysis reactions. DIC's technology employs accelerated aging tests under controlled conditions to establish deterioration kinetics models that can predict shelf-life under various storage scenarios. Their method incorporates rheological measurements to correlate chemical changes with functional properties, providing both chemical and physical deterioration indicators. The system includes specialized sample preparation protocols that minimize artifact formation during analysis, ensuring measurements reflect actual deterioration rather than analytical artifacts.

Strengths: Exceptional analytical precision allows detection of subtle deterioration changes; comprehensive approach addresses multiple deterioration mechanisms; strong correlation between measured parameters and functional properties. Weaknesses: Requires sophisticated laboratory equipment; time-consuming analysis process; higher cost per sample compared to simpler methods.

Tokyo University of Agriculture & Technology

Technical Solution: Tokyo University of Agriculture & Technology has developed a comprehensive oleoresin deterioration assessment methodology combining traditional analytical techniques with advanced spectroscopic methods. Their approach utilizes Fourier Transform Infrared (FTIR) spectroscopy coupled with chemometric analysis to identify molecular changes associated with deterioration. The methodology includes standardized sampling protocols that minimize variability between measurements, enabling reliable trend analysis over time. Their research has established specific spectral markers that correlate strongly with different stages of oleoresin deterioration, creating a deterioration index that quantifies quality changes. The university's approach incorporates accelerated aging studies under various environmental conditions to develop predictive models for shelf-life estimation. Their methodology has been validated across multiple oleoresin types, demonstrating broad applicability across different botanical sources and extraction methods. The technique can detect deterioration changes before they become apparent through conventional quality tests.

Strengths: Strong scientific foundation with extensive peer-reviewed validation; adaptable to various oleoresin types; non-destructive testing capability preserves samples. Weaknesses: Requires specialized spectroscopic equipment; significant expertise needed for data interpretation; academic approach may require adaptation for industrial implementation.

Key Analytical Techniques for Deterioration Markers

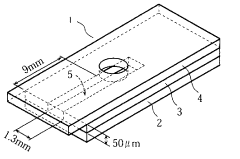

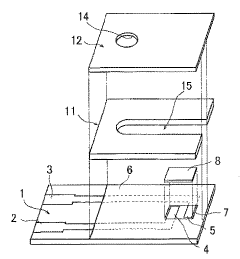

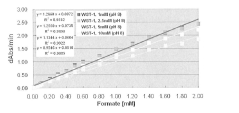

Determination method of oil deterioration and device using the same

PatentActiveJPWO2012147822A1

Innovation

- A biosensing system using enzymes such as formate dehydrogenase, acetate kinase, and propionyl-CoA transferase, combined with chromogenic or electrochemical detection, to measure the concentrations of formic acid, acetic acid, and propionic acid in oils, allowing for rapid and sensitive analysis.

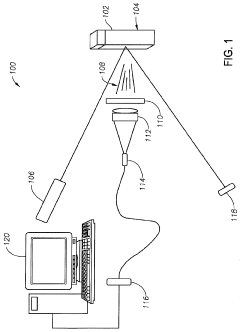

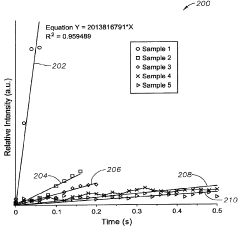

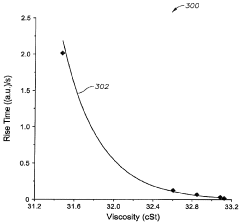

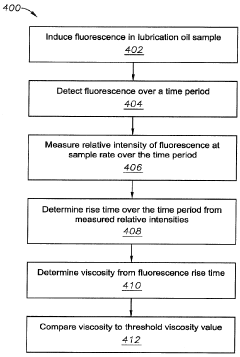

Determining the deterioration of oils using fluorescence rise-time

PatentPendingSG10201913234XA

Innovation

- A method that determines the viscosity of lubrication oils by measuring the fluorescence rise-time of an oil sample using a light source, such as a laser, and comparing it to a threshold to assess deterioration, allowing for real-time monitoring and notification of oil degradation.

Shelf-life Prediction Models for Oleoresin Products

Shelf-life prediction models for oleoresin products represent a critical advancement in quality control and inventory management within the food, pharmaceutical, and cosmetic industries. These models utilize mathematical algorithms and statistical methods to forecast the deterioration rate of oleoresins over time under various storage conditions.

The Arrhenius equation serves as the foundation for many oleoresin shelf-life models, establishing the relationship between temperature and deterioration rate. This equation allows manufacturers to predict how temperature fluctuations accelerate oxidation processes, which are primary contributors to oleoresin degradation. Advanced models incorporate additional parameters beyond temperature, including exposure to light, oxygen levels, and humidity, creating multi-factorial prediction frameworks.

Machine learning approaches have recently enhanced prediction accuracy by analyzing historical stability data across diverse oleoresin types. These algorithms can identify subtle patterns in deterioration that traditional models might miss, particularly for complex oleoresin mixtures with multiple active compounds. Neural networks and support vector machines have demonstrated particular promise in capturing non-linear degradation behaviors characteristic of natural oleoresins.

Accelerated stability testing protocols complement these models by subjecting oleoresin samples to intensified stress conditions. The resulting data enables the extrapolation of shelf-life under normal storage conditions, significantly reducing the time required for stability assessments. When combined with real-time monitoring technologies, these models can dynamically adjust predictions based on actual storage condition variations.

Industry-specific models have emerged to address the unique deterioration mechanisms of different oleoresin applications. Food-grade oleoresin models prioritize sensory quality retention and microbial stability, while pharmaceutical models focus on therapeutic compound preservation and regulatory compliance. These specialized approaches improve prediction accuracy by incorporating sector-specific degradation pathways and quality thresholds.

Probabilistic shelf-life models represent the cutting edge in this field, providing not just point estimates but confidence intervals for product viability. These models acknowledge the inherent variability in natural oleoresin composition and processing conditions, offering risk-based approaches to quality assurance and inventory management that better reflect real-world uncertainties in oleoresin stability.

The Arrhenius equation serves as the foundation for many oleoresin shelf-life models, establishing the relationship between temperature and deterioration rate. This equation allows manufacturers to predict how temperature fluctuations accelerate oxidation processes, which are primary contributors to oleoresin degradation. Advanced models incorporate additional parameters beyond temperature, including exposure to light, oxygen levels, and humidity, creating multi-factorial prediction frameworks.

Machine learning approaches have recently enhanced prediction accuracy by analyzing historical stability data across diverse oleoresin types. These algorithms can identify subtle patterns in deterioration that traditional models might miss, particularly for complex oleoresin mixtures with multiple active compounds. Neural networks and support vector machines have demonstrated particular promise in capturing non-linear degradation behaviors characteristic of natural oleoresins.

Accelerated stability testing protocols complement these models by subjecting oleoresin samples to intensified stress conditions. The resulting data enables the extrapolation of shelf-life under normal storage conditions, significantly reducing the time required for stability assessments. When combined with real-time monitoring technologies, these models can dynamically adjust predictions based on actual storage condition variations.

Industry-specific models have emerged to address the unique deterioration mechanisms of different oleoresin applications. Food-grade oleoresin models prioritize sensory quality retention and microbial stability, while pharmaceutical models focus on therapeutic compound preservation and regulatory compliance. These specialized approaches improve prediction accuracy by incorporating sector-specific degradation pathways and quality thresholds.

Probabilistic shelf-life models represent the cutting edge in this field, providing not just point estimates but confidence intervals for product viability. These models acknowledge the inherent variability in natural oleoresin composition and processing conditions, offering risk-based approaches to quality assurance and inventory management that better reflect real-world uncertainties in oleoresin stability.

Regulatory Standards for Oleoresin Quality and Safety

The regulatory landscape for oleoresin quality and safety is complex and multifaceted, spanning international, regional, and national frameworks. The Food and Drug Administration (FDA) in the United States classifies most oleoresins as Generally Recognized as Safe (GRAS) substances, but requires specific quality parameters to be maintained throughout their shelf life. These parameters include peroxide value, acid value, and volatile compound profiles that indicate deterioration.

The European Food Safety Authority (EFSA) has established more stringent guidelines, particularly through Commission Regulation (EU) No 231/2012, which specifies purity criteria for food additives including oleoresins. These regulations mandate regular testing for contaminants such as heavy metals, pesticide residues, and microbial contamination, all of which can accelerate deterioration processes.

ISO standards, particularly ISO 22000 and ISO 9001, provide frameworks for quality management systems that oleoresin producers must implement to ensure consistent product quality over time. These standards emphasize the importance of shelf-life studies and stability testing under various environmental conditions to predict deterioration patterns accurately.

The Codex Alimentarius Commission has developed international standards for spice oleoresins that include specifications for moisture content, volatile oil content, and refractive index—all parameters that change as deterioration occurs. Their guidelines recommend accelerated stability testing protocols to determine shelf life under different storage conditions.

In emerging markets like India and China, which are major oleoresin producers, national standards such as India's Food Safety and Standards Authority (FSSAI) regulations and China's GB standards provide detailed specifications for oleoresin quality. These standards often include traditional parameters alongside modern analytical requirements for detecting oxidation and polymerization.

Industry associations like the American Spice Trade Association (ASTA) and the European Spice Association (ESA) have developed voluntary standards that often exceed regulatory requirements. These include detailed protocols for monitoring oleoresin deterioration through sensory evaluation, color measurement, and advanced chromatographic techniques.

Compliance with these regulatory standards necessitates implementing comprehensive quality control programs that include regular testing schedules, validated analytical methods, and proper documentation of deterioration indicators. Many regulations now require manufacturers to establish and validate shelf-life determination methodologies specific to their oleoresin products, considering factors such as packaging materials, storage conditions, and intended use.

The European Food Safety Authority (EFSA) has established more stringent guidelines, particularly through Commission Regulation (EU) No 231/2012, which specifies purity criteria for food additives including oleoresins. These regulations mandate regular testing for contaminants such as heavy metals, pesticide residues, and microbial contamination, all of which can accelerate deterioration processes.

ISO standards, particularly ISO 22000 and ISO 9001, provide frameworks for quality management systems that oleoresin producers must implement to ensure consistent product quality over time. These standards emphasize the importance of shelf-life studies and stability testing under various environmental conditions to predict deterioration patterns accurately.

The Codex Alimentarius Commission has developed international standards for spice oleoresins that include specifications for moisture content, volatile oil content, and refractive index—all parameters that change as deterioration occurs. Their guidelines recommend accelerated stability testing protocols to determine shelf life under different storage conditions.

In emerging markets like India and China, which are major oleoresin producers, national standards such as India's Food Safety and Standards Authority (FSSAI) regulations and China's GB standards provide detailed specifications for oleoresin quality. These standards often include traditional parameters alongside modern analytical requirements for detecting oxidation and polymerization.

Industry associations like the American Spice Trade Association (ASTA) and the European Spice Association (ESA) have developed voluntary standards that often exceed regulatory requirements. These include detailed protocols for monitoring oleoresin deterioration through sensory evaluation, color measurement, and advanced chromatographic techniques.

Compliance with these regulatory standards necessitates implementing comprehensive quality control programs that include regular testing schedules, validated analytical methods, and proper documentation of deterioration indicators. Many regulations now require manufacturers to establish and validate shelf-life determination methodologies specific to their oleoresin products, considering factors such as packaging materials, storage conditions, and intended use.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!