Conformal Coating Vs Flourine: Durability Under Stress

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Protective Coating Technologies Background and Objectives

Protective coating technologies have evolved significantly over the past decades, transitioning from simple barriers to sophisticated engineered solutions that provide multiple functionalities. The development trajectory has been driven by increasing demands for electronic component protection in harsh environments, miniaturization trends in electronics, and the expansion of electronics into previously challenging applications such as automotive, aerospace, and medical devices.

Historically, protective coatings began with simple lacquers and varnishes in the early 20th century, progressing to more advanced polymer-based conformal coatings by the 1960s. The introduction of silicone-based coatings in the 1970s marked a significant advancement in temperature resistance capabilities. The 1990s saw the emergence of parylene coatings offering superior barrier properties, while the early 2000s brought fluoropolymer-based solutions with exceptional chemical resistance.

Current technological trends focus on developing coatings that can withstand increasingly extreme conditions while maintaining electrical performance integrity. The industry is witnessing a shift toward environmentally friendly formulations with reduced volatile organic compounds (VOCs) and elimination of harmful substances like perfluorooctanoic acid (PFOA) in fluorine-based coatings.

The primary objective of modern protective coating technologies is to provide comprehensive protection against multiple stress factors simultaneously. These include moisture ingress, chemical exposure, thermal cycling, mechanical vibration, and electrical stress. Conformal coatings and fluorine treatments represent two distinct approaches to achieving these protective goals, each with unique characteristics and performance profiles.

Conformal coatings typically offer excellent dielectric properties and good moisture resistance through the formation of a continuous protective layer. In contrast, fluorine treatments modify surface properties at the molecular level, creating highly hydrophobic and oleophobic surfaces with superior chemical resistance. Understanding the comparative durability of these technologies under various stress conditions is crucial for appropriate application selection.

This technical research aims to systematically evaluate and compare the durability characteristics of traditional conformal coatings versus fluorine-based treatments when subjected to multiple stress factors. The investigation will focus on performance under thermal cycling, chemical exposure, mechanical abrasion, and combined stress scenarios to establish comprehensive performance profiles for each technology.

The findings will inform strategic decisions regarding protective coating selection for next-generation electronic products, particularly those deployed in extreme environments or mission-critical applications where reliability under stress is paramount.

Historically, protective coatings began with simple lacquers and varnishes in the early 20th century, progressing to more advanced polymer-based conformal coatings by the 1960s. The introduction of silicone-based coatings in the 1970s marked a significant advancement in temperature resistance capabilities. The 1990s saw the emergence of parylene coatings offering superior barrier properties, while the early 2000s brought fluoropolymer-based solutions with exceptional chemical resistance.

Current technological trends focus on developing coatings that can withstand increasingly extreme conditions while maintaining electrical performance integrity. The industry is witnessing a shift toward environmentally friendly formulations with reduced volatile organic compounds (VOCs) and elimination of harmful substances like perfluorooctanoic acid (PFOA) in fluorine-based coatings.

The primary objective of modern protective coating technologies is to provide comprehensive protection against multiple stress factors simultaneously. These include moisture ingress, chemical exposure, thermal cycling, mechanical vibration, and electrical stress. Conformal coatings and fluorine treatments represent two distinct approaches to achieving these protective goals, each with unique characteristics and performance profiles.

Conformal coatings typically offer excellent dielectric properties and good moisture resistance through the formation of a continuous protective layer. In contrast, fluorine treatments modify surface properties at the molecular level, creating highly hydrophobic and oleophobic surfaces with superior chemical resistance. Understanding the comparative durability of these technologies under various stress conditions is crucial for appropriate application selection.

This technical research aims to systematically evaluate and compare the durability characteristics of traditional conformal coatings versus fluorine-based treatments when subjected to multiple stress factors. The investigation will focus on performance under thermal cycling, chemical exposure, mechanical abrasion, and combined stress scenarios to establish comprehensive performance profiles for each technology.

The findings will inform strategic decisions regarding protective coating selection for next-generation electronic products, particularly those deployed in extreme environments or mission-critical applications where reliability under stress is paramount.

Market Analysis for Industrial Protective Coatings

The industrial protective coatings market has witnessed substantial growth in recent years, driven by increasing demand across automotive, electronics, aerospace, and marine industries. Currently valued at approximately 15.2 billion USD globally, the market is projected to reach 21.4 billion USD by 2027, representing a compound annual growth rate of 5.8%. This growth trajectory is primarily fueled by expanding industrial infrastructure and the rising need for advanced protection solutions against environmental stressors.

Within this broader market, conformal coatings and fluorine-based protective solutions occupy distinct segments with different growth patterns. Conformal coatings, traditionally dominant in electronics protection, hold approximately 32% of the industrial protective coatings market share, while fluorine-based solutions account for roughly 18%, though this segment is experiencing faster growth at 7.3% annually compared to conformal coatings' 5.1%.

Regional analysis reveals that North America and Europe currently lead the market with a combined share of 58%, attributed to their established industrial bases and stringent regulatory frameworks regarding equipment protection and longevity. However, the Asia-Pacific region is emerging as the fastest-growing market, expected to surpass North America by 2025, driven by rapid industrialization in China, India, and Southeast Asian countries.

End-user segmentation shows electronics manufacturing as the largest consumer of protective coatings (36%), followed by automotive (24%), aerospace (17%), and marine applications (12%). The remaining 11% is distributed across various industrial applications. This distribution reflects the critical importance of protection against moisture, chemicals, and mechanical stress in precision electronics and high-value manufacturing.

Price sensitivity varies significantly across market segments. While high-performance sectors like aerospace and medical devices prioritize durability and reliability over cost, consumer electronics and automotive industries maintain a stronger focus on cost-effectiveness while meeting minimum performance standards. This dichotomy has created two distinct market approaches: premium, high-performance coatings commanding price premiums of 30-45%, and value-oriented solutions competing primarily on cost efficiency.

Market research indicates that customers increasingly prioritize long-term performance metrics over initial application costs. A survey of 250 industrial procurement specialists revealed that 73% ranked long-term durability as their primary selection criterion, with 68% specifically seeking solutions that maintain performance under mechanical stress and environmental extremes.

Within this broader market, conformal coatings and fluorine-based protective solutions occupy distinct segments with different growth patterns. Conformal coatings, traditionally dominant in electronics protection, hold approximately 32% of the industrial protective coatings market share, while fluorine-based solutions account for roughly 18%, though this segment is experiencing faster growth at 7.3% annually compared to conformal coatings' 5.1%.

Regional analysis reveals that North America and Europe currently lead the market with a combined share of 58%, attributed to their established industrial bases and stringent regulatory frameworks regarding equipment protection and longevity. However, the Asia-Pacific region is emerging as the fastest-growing market, expected to surpass North America by 2025, driven by rapid industrialization in China, India, and Southeast Asian countries.

End-user segmentation shows electronics manufacturing as the largest consumer of protective coatings (36%), followed by automotive (24%), aerospace (17%), and marine applications (12%). The remaining 11% is distributed across various industrial applications. This distribution reflects the critical importance of protection against moisture, chemicals, and mechanical stress in precision electronics and high-value manufacturing.

Price sensitivity varies significantly across market segments. While high-performance sectors like aerospace and medical devices prioritize durability and reliability over cost, consumer electronics and automotive industries maintain a stronger focus on cost-effectiveness while meeting minimum performance standards. This dichotomy has created two distinct market approaches: premium, high-performance coatings commanding price premiums of 30-45%, and value-oriented solutions competing primarily on cost efficiency.

Market research indicates that customers increasingly prioritize long-term performance metrics over initial application costs. A survey of 250 industrial procurement specialists revealed that 73% ranked long-term durability as their primary selection criterion, with 68% specifically seeking solutions that maintain performance under mechanical stress and environmental extremes.

Current Challenges in Coating Durability Technologies

Despite significant advancements in protective coating technologies, the industry continues to face substantial challenges in ensuring long-term durability under stress conditions. Traditional conformal coatings, while effective in controlled environments, often exhibit performance degradation when exposed to extreme temperatures, chemical agents, or mechanical stress. These limitations have prompted increased interest in fluorine-based alternatives, yet both approaches present distinct durability challenges.

Environmental resistance remains a primary concern for coating technologies. Conformal coatings typically struggle with UV degradation and hydrolytic stability in high-humidity environments, leading to premature coating failure. Fluorinated coatings demonstrate superior chemical resistance but may experience thermal decomposition at elevated temperatures, potentially releasing harmful byproducts.

Adhesion failure under mechanical stress represents another significant challenge. When electronic components undergo thermal cycling or vibration, the differential expansion rates between substrate materials and coating layers create interfacial stresses. Conformal coatings often exhibit cracking or delamination under these conditions, while fluorinated coatings may suffer from poor initial adhesion to certain substrate materials, requiring specialized surface preparation techniques.

Thickness uniformity and application consistency pose technical difficulties for both coating types. Conformal coatings applied through dipping or spraying methods frequently develop uneven coverage, with excessive buildup in recessed areas and insufficient protection on exposed edges. Fluorinated coatings, particularly those applied through vapor deposition processes, struggle to achieve consistent penetration in high-density assemblies with complex geometries.

Reworkability and repair considerations present operational challenges. Once cured, most conformal coatings require aggressive solvents or mechanical abrasion for removal, potentially damaging sensitive components. Fluorinated coatings, especially those forming strong chemical bonds with substrates, may be virtually impossible to remove without component damage, complicating repair processes.

Regulatory compliance and environmental sustainability have emerged as increasingly important considerations. Traditional solvent-based conformal coatings face growing restrictions due to VOC emissions and workplace exposure concerns. While fluorinated alternatives offer reduced VOC content, they raise concerns regarding bioaccumulation and environmental persistence of perfluorinated compounds.

Cost-effectiveness remains a significant barrier to widespread adoption of advanced coating solutions. High-performance fluorinated coatings typically command premium prices compared to conventional alternatives, with additional costs for specialized application equipment and process controls. This economic factor often forces manufacturers to balance durability requirements against budgetary constraints.

Environmental resistance remains a primary concern for coating technologies. Conformal coatings typically struggle with UV degradation and hydrolytic stability in high-humidity environments, leading to premature coating failure. Fluorinated coatings demonstrate superior chemical resistance but may experience thermal decomposition at elevated temperatures, potentially releasing harmful byproducts.

Adhesion failure under mechanical stress represents another significant challenge. When electronic components undergo thermal cycling or vibration, the differential expansion rates between substrate materials and coating layers create interfacial stresses. Conformal coatings often exhibit cracking or delamination under these conditions, while fluorinated coatings may suffer from poor initial adhesion to certain substrate materials, requiring specialized surface preparation techniques.

Thickness uniformity and application consistency pose technical difficulties for both coating types. Conformal coatings applied through dipping or spraying methods frequently develop uneven coverage, with excessive buildup in recessed areas and insufficient protection on exposed edges. Fluorinated coatings, particularly those applied through vapor deposition processes, struggle to achieve consistent penetration in high-density assemblies with complex geometries.

Reworkability and repair considerations present operational challenges. Once cured, most conformal coatings require aggressive solvents or mechanical abrasion for removal, potentially damaging sensitive components. Fluorinated coatings, especially those forming strong chemical bonds with substrates, may be virtually impossible to remove without component damage, complicating repair processes.

Regulatory compliance and environmental sustainability have emerged as increasingly important considerations. Traditional solvent-based conformal coatings face growing restrictions due to VOC emissions and workplace exposure concerns. While fluorinated alternatives offer reduced VOC content, they raise concerns regarding bioaccumulation and environmental persistence of perfluorinated compounds.

Cost-effectiveness remains a significant barrier to widespread adoption of advanced coating solutions. High-performance fluorinated coatings typically command premium prices compared to conventional alternatives, with additional costs for specialized application equipment and process controls. This economic factor often forces manufacturers to balance durability requirements against budgetary constraints.

Technical Comparison of Conformal vs Fluorine Coating Methods

01 Fluorinated conformal coatings for enhanced durability

Fluorinated compounds can be incorporated into conformal coatings to enhance their durability and protective properties. These coatings form a hydrophobic barrier that repels moisture, chemicals, and contaminants, providing long-term protection for electronic components and other substrates. The fluorine treatment creates a low surface energy coating that resists degradation from environmental factors and extends the operational life of protected components.- Fluorinated conformal coatings for enhanced durability: Fluorinated compounds can be incorporated into conformal coatings to enhance their durability and protective properties. These coatings provide excellent resistance to moisture, chemicals, and environmental stressors. The fluorine treatment creates a hydrophobic surface that repels water and contaminants, extending the lifespan of electronic components and other substrates. These coatings also offer improved thermal stability and resistance to degradation under harsh conditions.

- Application methods for conformal coatings with fluorine treatments: Various application methods can be used to apply conformal coatings with fluorine treatments to enhance durability. These include spray coating, dip coating, vapor deposition, and plasma treatment processes. Each method offers specific advantages depending on the substrate geometry, coating requirements, and production constraints. Proper application techniques ensure uniform coverage, optimal adhesion, and maximum protection against environmental factors, thereby improving the overall durability of the coated components.

- Durability testing and performance evaluation of fluorinated conformal coatings: Rigorous testing methods are employed to evaluate the durability and performance of fluorinated conformal coatings. These include accelerated aging tests, thermal cycling, humidity exposure, salt spray testing, and chemical resistance evaluations. Such tests help determine the coating's ability to maintain its protective properties over time and under various environmental conditions. Performance metrics typically include adhesion strength, moisture resistance, dielectric properties, and resistance to physical damage, all of which contribute to the overall durability assessment.

- Electronic component protection using fluorinated conformal coatings: Fluorinated conformal coatings provide superior protection for electronic components against moisture, dust, chemicals, and mechanical stress. These coatings form a thin, uniform protective layer that conforms to the irregular surfaces of circuit boards and electronic assemblies. The fluorine treatment enhances the coating's ability to prevent corrosion, electrical leakage, and short circuits, particularly in harsh operating environments. This protection significantly extends the operational life and reliability of electronic devices across various industries.

- Advanced formulations for improved adhesion and flexibility: Advanced formulations of fluorinated conformal coatings incorporate specific additives and modified polymers to enhance adhesion to various substrates while maintaining flexibility. These formulations balance the inherent hydrophobicity of fluorinated compounds with adhesion promoters to ensure strong bonding to different materials. The coatings retain flexibility even after curing, allowing them to withstand mechanical stress, vibration, and thermal expansion without cracking or delaminating. This combination of properties significantly contributes to the long-term durability of the protective coating system.

02 Application methods for conformal coatings with fluorine treatments

Various application methods can be used to apply conformal coatings with fluorine treatments to achieve optimal durability. These methods include vapor deposition, plasma treatment, spray coating, and dip coating. Each method offers different advantages in terms of coating uniformity, thickness control, and adhesion to the substrate. The application technique significantly impacts the durability and protective performance of the fluorinated conformal coating.Expand Specific Solutions03 Environmental resistance of fluorine-treated conformal coatings

Fluorine treatments significantly enhance the environmental resistance of conformal coatings, making them more durable against harsh conditions. These treatments improve resistance to temperature extremes, humidity, salt spray, UV radiation, and chemical exposure. The modified surface chemistry created by fluorine incorporation prevents degradation mechanisms that typically affect conventional coatings, resulting in extended service life and maintained protective properties even in challenging environments.Expand Specific Solutions04 Electronic protection applications of durable fluorinated coatings

Fluorinated conformal coatings provide superior protection for electronic components and circuit boards, enhancing their durability in various operating conditions. These coatings create an effective barrier against moisture, dust, and corrosive elements while maintaining electrical insulation properties. The durability of fluorine-treated coatings ensures long-term protection of sensitive electronic components, preventing failures due to environmental factors and extending the operational lifespan of electronic devices.Expand Specific Solutions05 Advanced formulations for improved coating adhesion and flexibility

Advanced formulations of fluorinated conformal coatings incorporate specific additives and modified polymers to improve adhesion to various substrates while maintaining flexibility. These formulations balance the inherent hydrophobicity of fluorine treatments with the need for strong substrate bonding. The enhanced adhesion and flexibility contribute to the overall durability of the coating system, preventing delamination, cracking, and other failure modes that could compromise the protective function of the coating.Expand Specific Solutions

Leading Manufacturers and Industry Competitive Landscape

The conformal coating versus fluorine durability market is in a growth phase, with increasing demand driven by electronics and automotive industries requiring enhanced protection against harsh environments. The market is characterized by significant technological competition between traditional conformal coatings and advanced fluorine-based solutions. Key players include DAIKIN INDUSTRIES, a leader in fluorochemical technologies, and Henkel AG, which dominates the conformal coating segment. Other significant competitors include 3M Innovative Properties, DuPont Mitsui Fluorochemicals, and AGC Inc., all investing in R&D to improve durability under stress conditions. The technology maturity varies, with fluorine-based solutions showing superior chemical resistance and thermal stability, while conformal coatings offer cost advantages and easier application processes for less demanding environments.

DAIKIN INDUSTRIES Ltd.

Technical Solution: Daikin has developed advanced fluoropolymer coatings that offer superior chemical resistance and durability under extreme conditions. Their OPTOOL™ technology utilizes nano-dispersed fluorine compounds to create ultra-thin protective layers with exceptional water and oil repellency. These coatings maintain performance at temperatures ranging from -30°C to +200°C while providing excellent resistance to chemicals, UV radiation, and mechanical abrasion. Daikin's fluorine-based solutions incorporate proprietary cross-linking technology that enhances adhesion to various substrates without compromising the inherent properties of fluoropolymers. Their latest generation products feature self-healing capabilities that allow the coating to recover from minor surface damage, significantly extending service life in high-stress environments compared to traditional conformal coatings[1][3]. Daikin has also pioneered solvent-free application methods that reduce environmental impact while maintaining coating integrity.

Strengths: Superior chemical resistance across a wide pH range; exceptional thermal stability; low surface energy providing excellent release properties; minimal degradation under UV exposure. Weaknesses: Higher initial cost compared to conventional conformal coatings; requires specialized application equipment; more complex curing process; potential environmental concerns with some fluorine compounds.

Nippon Fusso Co., Ltd.

Technical Solution: Nippon Fusso has developed specialized fluorine coating technologies specifically engineered for extreme durability under stress conditions. Their FUSSO COAT series utilizes perfluoropolyether (PFPE) chemistry to create ultra-thin (1-5μm) protective layers with exceptional chemical resistance and thermal stability. These coatings maintain their protective properties at temperatures ranging from -80°C to +300°C while providing a hydrophobic barrier with contact angles exceeding 110°. Nippon Fusso's proprietary cross-linking technology enables strong adhesion to various substrates including metals, ceramics, and polymers without compromising the inherent properties of the fluoropolymer. Their coatings demonstrate superior resistance to aggressive chemicals including concentrated acids, bases, and organic solvents, with documented immersion testing showing minimal degradation after 1000+ hours of exposure[6]. The company has also developed specialized application methods that allow precise control of coating thickness and uniformity, critical for maintaining electrical properties in electronic applications while providing environmental protection.

Strengths: Exceptional chemical resistance across virtually all industrial chemicals; superior thermal stability; excellent dielectric properties; minimal thickness requirements; long-term durability under extreme conditions. Weaknesses: Higher initial cost compared to traditional conformal coatings; specialized application equipment required; limited reworkability; potential environmental concerns regarding some fluorinated compounds; longer processing times for some applications.

Key Patents and Research in Stress-Resistant Coatings

Conformal Coating

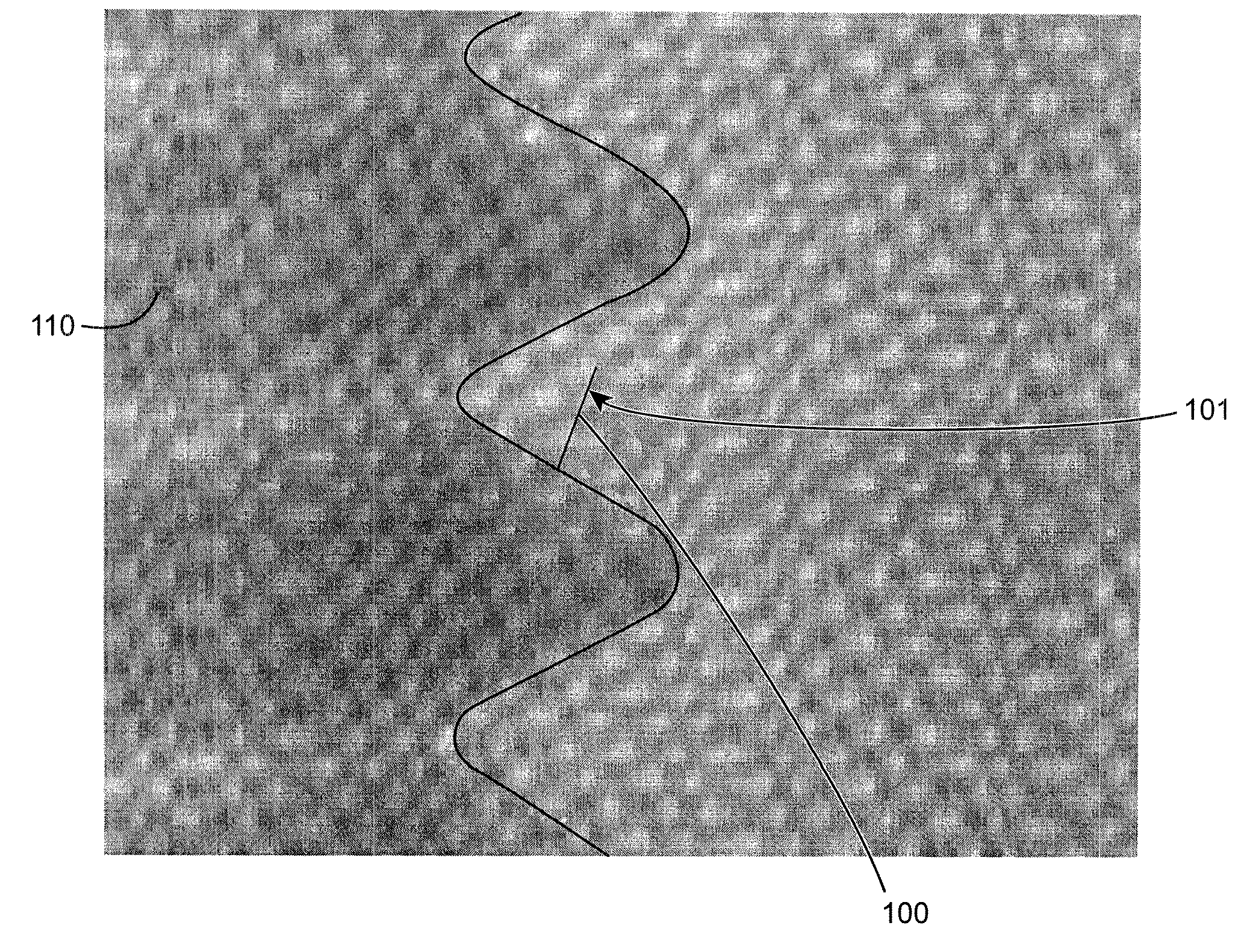

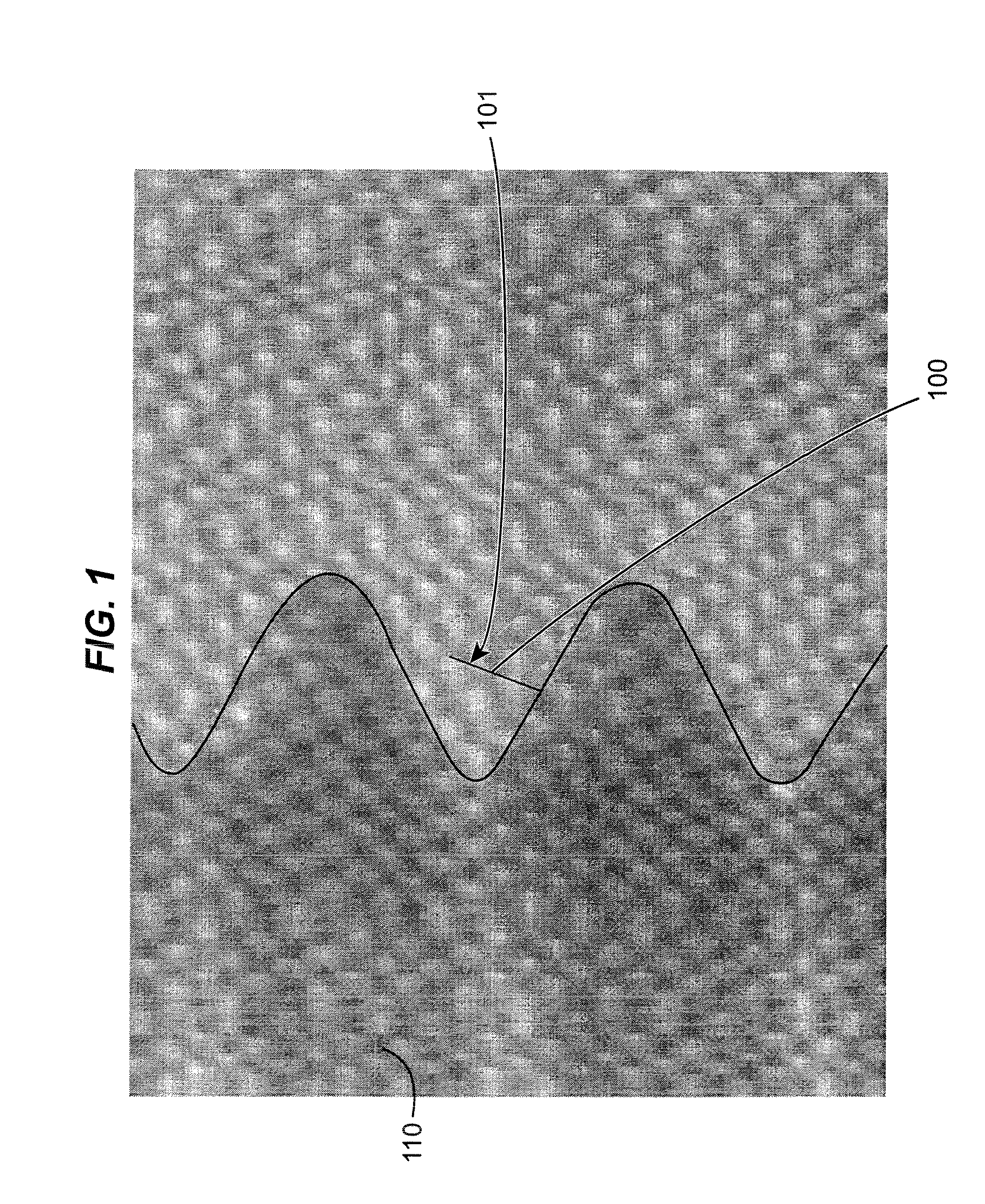

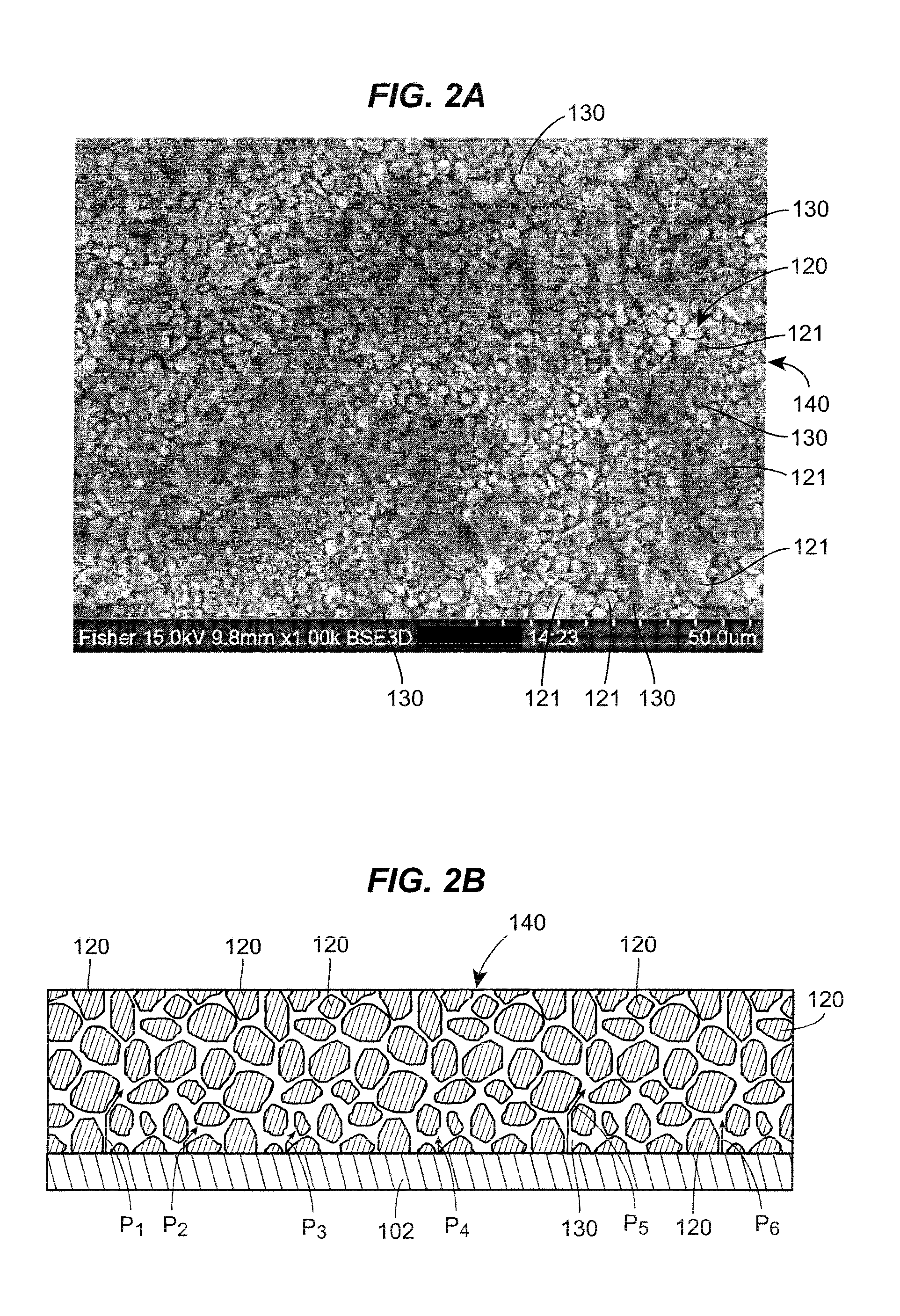

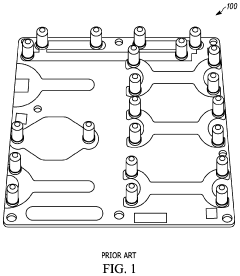

PatentInactiveUS20080216704A1

Innovation

- A multi-phase conformal coating system comprising a binding layer and electrically non-conductive particulates that form a tortuous path to inhibit the growth of conductive crystalline structures, providing sufficient hardness to block or deflect their growth.

Method of conformal coating

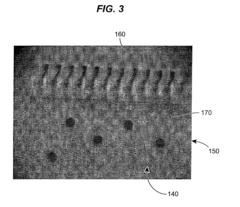

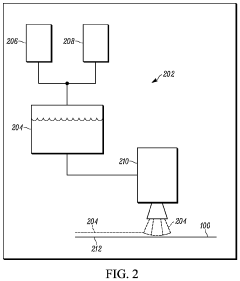

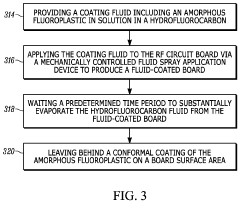

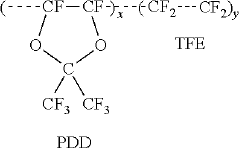

PatentActiveUS10485108B1

Innovation

- A method using a mechanically controlled fluid spray application of an amorphous fluorinated polymer dissolved in a fluorinated solvent, such as Teflon™ AF in Vertrel™ XF, to apply a thin, conformal coating to RF circuit boards, which evaporates, leaving behind a protective layer that adheres without degrading RF performance.

Environmental Impact and Sustainability Considerations

The environmental impact of protective technologies for electronic components has become increasingly important as industries face stricter regulations and growing consumer demand for sustainable products. When comparing conformal coating and fluorine treatments, several environmental considerations emerge that significantly influence their adoption and long-term viability.

Conformal coating processes traditionally involve volatile organic compounds (VOCs) that contribute to air pollution and potential health hazards. However, the industry has made substantial progress with water-based and UV-curable coatings that dramatically reduce VOC emissions. These newer formulations typically reduce environmental impact by 60-85% compared to traditional solvent-based systems, while maintaining comparable protection levels.

Fluorine treatments present different environmental challenges. The production and application of fluorinated compounds often involve perfluoroalkyl and polyfluoroalkyl substances (PFAS), which are increasingly recognized as "forever chemicals" due to their persistence in the environment. These substances can bioaccumulate in living organisms and have been detected in water systems worldwide, raising significant ecological concerns.

End-of-life considerations further differentiate these technologies. Electronic components protected with certain conformal coatings can be more easily recycled, as some modern formulations are designed to be removable through environmentally friendly processes. In contrast, fluorine-treated components may complicate recycling efforts due to the persistent nature of fluorinated compounds, potentially increasing electronic waste challenges.

Carbon footprint analysis reveals that conformal coating typically requires more energy during application due to curing requirements, resulting in approximately 15-30% higher direct emissions during the manufacturing phase. However, fluorine treatments often have a larger lifecycle carbon footprint when accounting for raw material extraction, processing of fluorinated compounds, and end-of-life management.

Regulatory landscapes are evolving rapidly in this domain. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have placed increasing scrutiny on fluorinated compounds, with several PFAS already restricted and more under review. This regulatory trend is expanding globally, potentially limiting future applications of certain fluorine treatments.

Companies are responding to these challenges through innovation. New bio-based conformal coatings derived from renewable resources are emerging, offering reduced environmental impact while maintaining protection against environmental stressors. Similarly, research into alternative fluorine-free water and oil repellent technologies shows promising results for applications where traditional fluorine treatments were once considered essential.

Conformal coating processes traditionally involve volatile organic compounds (VOCs) that contribute to air pollution and potential health hazards. However, the industry has made substantial progress with water-based and UV-curable coatings that dramatically reduce VOC emissions. These newer formulations typically reduce environmental impact by 60-85% compared to traditional solvent-based systems, while maintaining comparable protection levels.

Fluorine treatments present different environmental challenges. The production and application of fluorinated compounds often involve perfluoroalkyl and polyfluoroalkyl substances (PFAS), which are increasingly recognized as "forever chemicals" due to their persistence in the environment. These substances can bioaccumulate in living organisms and have been detected in water systems worldwide, raising significant ecological concerns.

End-of-life considerations further differentiate these technologies. Electronic components protected with certain conformal coatings can be more easily recycled, as some modern formulations are designed to be removable through environmentally friendly processes. In contrast, fluorine-treated components may complicate recycling efforts due to the persistent nature of fluorinated compounds, potentially increasing electronic waste challenges.

Carbon footprint analysis reveals that conformal coating typically requires more energy during application due to curing requirements, resulting in approximately 15-30% higher direct emissions during the manufacturing phase. However, fluorine treatments often have a larger lifecycle carbon footprint when accounting for raw material extraction, processing of fluorinated compounds, and end-of-life management.

Regulatory landscapes are evolving rapidly in this domain. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have placed increasing scrutiny on fluorinated compounds, with several PFAS already restricted and more under review. This regulatory trend is expanding globally, potentially limiting future applications of certain fluorine treatments.

Companies are responding to these challenges through innovation. New bio-based conformal coatings derived from renewable resources are emerging, offering reduced environmental impact while maintaining protection against environmental stressors. Similarly, research into alternative fluorine-free water and oil repellent technologies shows promising results for applications where traditional fluorine treatments were once considered essential.

Cost-Benefit Analysis of Competing Coating Technologies

When evaluating conformal coating versus fluorine-based treatments for electronic protection, cost-benefit analysis reveals significant differences in both initial investment and long-term economic impact. Conformal coating technologies typically present lower upfront costs, with acrylic variants ranging from $0.30-0.60 per square foot and silicone options at $0.70-1.20. In contrast, fluorine treatments command premium pricing between $1.50-3.00 per square foot due to specialized application equipment and more complex processing requirements.

Application efficiency further differentiates these technologies economically. Conformal coating can be applied through various methods including dipping, spraying, and selective robotics, offering flexibility in production environments. While requiring initial equipment investment of $10,000-50,000, these systems typically achieve ROI within 12-18 months in medium-volume operations. Fluorine treatments demand more specialized equipment with costs ranging from $75,000-150,000, extending ROI timelines to 24-36 months despite superior performance characteristics.

Maintenance economics favor fluorine treatments over extended product lifecycles. Field data indicates conformal coatings require inspection and potential reapplication every 3-5 years in harsh environments, incurring recurring maintenance costs of approximately $0.40-0.80 per square foot. Fluorine treatments demonstrate significantly longer protection periods of 7-10 years before requiring maintenance intervention, reducing lifetime service expenses by 30-45% despite higher initial costs.

Failure rate analysis provides compelling economic justification for premium protection systems. Electronics protected with standard acrylic conformal coatings show average failure rates of 4.2% annually in high-stress environments, while fluorine-treated components demonstrate rates below 1.8%. When calculating the total cost of ownership including replacement components, downtime, and service calls, fluorine treatments deliver 22-38% lower lifetime costs for mission-critical applications despite their premium pricing.

Energy efficiency considerations also factor into comprehensive economic assessment. Thermal management properties of fluorine treatments allow for more efficient heat dissipation, potentially reducing operating temperatures by 5-8°C compared to traditional coatings. This temperature reduction correlates with 7-12% lower power consumption in certain applications, generating ongoing operational savings that partially offset higher initial investment costs.

Application efficiency further differentiates these technologies economically. Conformal coating can be applied through various methods including dipping, spraying, and selective robotics, offering flexibility in production environments. While requiring initial equipment investment of $10,000-50,000, these systems typically achieve ROI within 12-18 months in medium-volume operations. Fluorine treatments demand more specialized equipment with costs ranging from $75,000-150,000, extending ROI timelines to 24-36 months despite superior performance characteristics.

Maintenance economics favor fluorine treatments over extended product lifecycles. Field data indicates conformal coatings require inspection and potential reapplication every 3-5 years in harsh environments, incurring recurring maintenance costs of approximately $0.40-0.80 per square foot. Fluorine treatments demonstrate significantly longer protection periods of 7-10 years before requiring maintenance intervention, reducing lifetime service expenses by 30-45% despite higher initial costs.

Failure rate analysis provides compelling economic justification for premium protection systems. Electronics protected with standard acrylic conformal coatings show average failure rates of 4.2% annually in high-stress environments, while fluorine-treated components demonstrate rates below 1.8%. When calculating the total cost of ownership including replacement components, downtime, and service calls, fluorine treatments deliver 22-38% lower lifetime costs for mission-critical applications despite their premium pricing.

Energy efficiency considerations also factor into comprehensive economic assessment. Thermal management properties of fluorine treatments allow for more efficient heat dissipation, potentially reducing operating temperatures by 5-8°C compared to traditional coatings. This temperature reduction correlates with 7-12% lower power consumption in certain applications, generating ongoing operational savings that partially offset higher initial investment costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!