Testing Conformal Coating Compatibility With Copper Substrates

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conformal Coating Technology Background and Objectives

Conformal coating technology has evolved significantly over the past five decades, transitioning from simple protective layers to sophisticated engineered materials designed to shield electronic components from environmental stressors. Initially developed for military and aerospace applications in the 1960s, these coatings have become essential in numerous industries including automotive, consumer electronics, medical devices, and industrial equipment manufacturing. The fundamental purpose remains consistent: to protect electronic assemblies from moisture, dust, chemicals, and temperature fluctuations that could compromise functionality and longevity.

The compatibility between conformal coatings and copper substrates represents a critical intersection in electronic manufacturing. Copper remains the predominant conductor material in printed circuit boards (PCBs) and electronic components due to its excellent electrical conductivity, thermal properties, and relative cost-effectiveness. However, copper's susceptibility to oxidation and corrosion presents significant challenges when applying protective coatings, particularly in environments with high humidity or corrosive elements.

Recent technological advancements have focused on developing coating formulations that not only adhere effectively to copper surfaces but also prevent copper migration and oxidation without compromising electrical performance. The industry has witnessed a shift from traditional solvent-based acrylics and silicones toward more environmentally friendly water-based formulations and UV-curable coatings with enhanced protection capabilities.

The primary technical objectives in testing conformal coating compatibility with copper substrates include: evaluating adhesion strength under various environmental conditions; assessing protection efficacy against moisture, salt spray, and chemical exposure; measuring the coating's impact on electrical properties; determining thermal cycling resistance; and analyzing long-term reliability through accelerated aging tests. These objectives align with the increasing miniaturization of electronic components and the growing demand for devices operating in harsh environments.

Global regulatory changes have significantly influenced coating technology development, with restrictions on volatile organic compounds (VOCs) and certain halogenated compounds driving innovation toward greener alternatives. Additionally, the rise of Internet of Things (IoT) devices and autonomous systems has elevated the importance of reliable protection for electronics exposed to diverse operating conditions.

The trajectory of conformal coating technology is moving toward multi-functional coatings that not only protect against environmental factors but also provide additional benefits such as improved thermal management, electromagnetic interference (EMI) shielding, and even self-healing capabilities. Understanding the fundamental interactions between these advanced coatings and copper substrates is essential for developing next-generation electronic protection solutions that meet increasingly demanding performance requirements.

The compatibility between conformal coatings and copper substrates represents a critical intersection in electronic manufacturing. Copper remains the predominant conductor material in printed circuit boards (PCBs) and electronic components due to its excellent electrical conductivity, thermal properties, and relative cost-effectiveness. However, copper's susceptibility to oxidation and corrosion presents significant challenges when applying protective coatings, particularly in environments with high humidity or corrosive elements.

Recent technological advancements have focused on developing coating formulations that not only adhere effectively to copper surfaces but also prevent copper migration and oxidation without compromising electrical performance. The industry has witnessed a shift from traditional solvent-based acrylics and silicones toward more environmentally friendly water-based formulations and UV-curable coatings with enhanced protection capabilities.

The primary technical objectives in testing conformal coating compatibility with copper substrates include: evaluating adhesion strength under various environmental conditions; assessing protection efficacy against moisture, salt spray, and chemical exposure; measuring the coating's impact on electrical properties; determining thermal cycling resistance; and analyzing long-term reliability through accelerated aging tests. These objectives align with the increasing miniaturization of electronic components and the growing demand for devices operating in harsh environments.

Global regulatory changes have significantly influenced coating technology development, with restrictions on volatile organic compounds (VOCs) and certain halogenated compounds driving innovation toward greener alternatives. Additionally, the rise of Internet of Things (IoT) devices and autonomous systems has elevated the importance of reliable protection for electronics exposed to diverse operating conditions.

The trajectory of conformal coating technology is moving toward multi-functional coatings that not only protect against environmental factors but also provide additional benefits such as improved thermal management, electromagnetic interference (EMI) shielding, and even self-healing capabilities. Understanding the fundamental interactions between these advanced coatings and copper substrates is essential for developing next-generation electronic protection solutions that meet increasingly demanding performance requirements.

Market Analysis for Copper-Compatible Conformal Coatings

The global market for conformal coatings compatible with copper substrates has been experiencing significant growth, driven primarily by the expanding electronics industry and increasing demand for reliable protection solutions in harsh environments. The current market size for conformal coatings is estimated at $2.1 billion, with copper-compatible formulations representing approximately 35% of this segment. This specialized market is projected to grow at a compound annual growth rate (CAGR) of 5.8% through 2028.

The electronics sector remains the dominant consumer of copper-compatible conformal coatings, accounting for nearly 60% of total market demand. Within this sector, consumer electronics manufacturers utilize these coatings extensively to protect copper circuitry in smartphones, tablets, and wearable devices from environmental factors and mechanical stress.

Automotive applications represent the second-largest market segment at 18%, with particular emphasis on protecting copper components in advanced driver assistance systems (ADAS), infotainment systems, and electric vehicle power electronics. The automotive segment is also showing the fastest growth rate at 7.2% annually, driven by the rapid electrification of vehicle fleets worldwide.

Aerospace and defense applications constitute approximately 12% of the market, where high-reliability coatings for copper substrates are essential for mission-critical systems operating in extreme conditions. This segment demands premium products with superior performance characteristics and extensive testing documentation.

Regionally, Asia-Pacific dominates the market with a 45% share, led by manufacturing powerhouses China, Taiwan, and South Korea. North America follows at 28%, with Europe accounting for 22% of global demand. Emerging markets in South America and Africa are showing promising growth potential but currently represent only 5% of the global market.

Customer preferences are increasingly shifting toward environmentally friendly formulations, with low-VOC and solvent-free options gaining market share. This trend is particularly pronounced in European markets where regulatory pressures are most stringent. Additionally, there is growing demand for coatings that offer multiple protection features beyond basic moisture resistance, including thermal management properties and enhanced adhesion to copper surfaces.

Price sensitivity varies significantly by application, with consumer electronics manufacturers highly focused on cost-effective solutions, while aerospace and medical device manufacturers prioritize performance and reliability over price considerations. The average price point for premium copper-compatible conformal coatings ranges from $85 to $120 per liter, while standard formulations typically sell for $40 to $75 per liter.

The electronics sector remains the dominant consumer of copper-compatible conformal coatings, accounting for nearly 60% of total market demand. Within this sector, consumer electronics manufacturers utilize these coatings extensively to protect copper circuitry in smartphones, tablets, and wearable devices from environmental factors and mechanical stress.

Automotive applications represent the second-largest market segment at 18%, with particular emphasis on protecting copper components in advanced driver assistance systems (ADAS), infotainment systems, and electric vehicle power electronics. The automotive segment is also showing the fastest growth rate at 7.2% annually, driven by the rapid electrification of vehicle fleets worldwide.

Aerospace and defense applications constitute approximately 12% of the market, where high-reliability coatings for copper substrates are essential for mission-critical systems operating in extreme conditions. This segment demands premium products with superior performance characteristics and extensive testing documentation.

Regionally, Asia-Pacific dominates the market with a 45% share, led by manufacturing powerhouses China, Taiwan, and South Korea. North America follows at 28%, with Europe accounting for 22% of global demand. Emerging markets in South America and Africa are showing promising growth potential but currently represent only 5% of the global market.

Customer preferences are increasingly shifting toward environmentally friendly formulations, with low-VOC and solvent-free options gaining market share. This trend is particularly pronounced in European markets where regulatory pressures are most stringent. Additionally, there is growing demand for coatings that offer multiple protection features beyond basic moisture resistance, including thermal management properties and enhanced adhesion to copper surfaces.

Price sensitivity varies significantly by application, with consumer electronics manufacturers highly focused on cost-effective solutions, while aerospace and medical device manufacturers prioritize performance and reliability over price considerations. The average price point for premium copper-compatible conformal coatings ranges from $85 to $120 per liter, while standard formulations typically sell for $40 to $75 per liter.

Current Challenges in Coating-Copper Interface Technology

The interface between conformal coatings and copper substrates presents several significant technical challenges that continue to impede optimal performance in electronic applications. Adhesion issues remain paramount, as copper's tendency to form oxides rapidly upon exposure to atmospheric conditions creates an unstable surface for coating attachment. This oxidation layer, while only nanometers thick, substantially reduces the mechanical bonding strength between coating materials and the underlying copper substrate, leading to delamination under thermal cycling or mechanical stress.

Corrosion protection represents another critical challenge, particularly in environments with high humidity or corrosive contaminants. Despite conformal coatings being designed specifically to prevent corrosion, microscopic defects in the coating layer can create pathways for moisture and corrosive agents to reach the copper surface, initiating localized corrosion cells that propagate beneath the coating. This phenomenon, known as underfilm corrosion, is particularly problematic as it remains undetectable until significant damage has occurred.

Thermal expansion mismatch between copper substrates and polymeric coating materials introduces substantial interface stress during temperature fluctuations. Copper typically exhibits a coefficient of thermal expansion (CTE) of approximately 17 ppm/°C, while common conformal coating materials such as acrylics, silicones, and polyurethanes have CTEs ranging from 50-300 ppm/°C. This disparity creates cyclical stress at the interface during operational temperature changes, eventually leading to coating failure.

Chemical compatibility issues further complicate the coating-copper relationship. Certain coating formulations contain solvents or curing agents that can react with copper surfaces, forming complexes that inhibit proper adhesion or accelerate corrosion processes. Additionally, some coating chemistries may catalyze copper oxidation during the curing process, creating a fundamentally compromised interface from the outset.

Testing methodologies for coating-copper compatibility face their own challenges. Accelerated aging tests often fail to accurately predict real-world performance, as they cannot fully replicate the complex interplay of environmental factors, mechanical stresses, and electrochemical processes that occur in actual applications. Current standardized testing protocols frequently yield inconsistent results across different laboratories, making comparative analysis difficult and limiting the development of universal compatibility metrics.

The miniaturization trend in electronics compounds these challenges, as thinner copper traces and higher component densities create more complex surface geometries with sharper edges and tighter spaces. These features make uniform coating application increasingly difficult, leading to thickness variations that compromise protection and reliability in critical areas.

Corrosion protection represents another critical challenge, particularly in environments with high humidity or corrosive contaminants. Despite conformal coatings being designed specifically to prevent corrosion, microscopic defects in the coating layer can create pathways for moisture and corrosive agents to reach the copper surface, initiating localized corrosion cells that propagate beneath the coating. This phenomenon, known as underfilm corrosion, is particularly problematic as it remains undetectable until significant damage has occurred.

Thermal expansion mismatch between copper substrates and polymeric coating materials introduces substantial interface stress during temperature fluctuations. Copper typically exhibits a coefficient of thermal expansion (CTE) of approximately 17 ppm/°C, while common conformal coating materials such as acrylics, silicones, and polyurethanes have CTEs ranging from 50-300 ppm/°C. This disparity creates cyclical stress at the interface during operational temperature changes, eventually leading to coating failure.

Chemical compatibility issues further complicate the coating-copper relationship. Certain coating formulations contain solvents or curing agents that can react with copper surfaces, forming complexes that inhibit proper adhesion or accelerate corrosion processes. Additionally, some coating chemistries may catalyze copper oxidation during the curing process, creating a fundamentally compromised interface from the outset.

Testing methodologies for coating-copper compatibility face their own challenges. Accelerated aging tests often fail to accurately predict real-world performance, as they cannot fully replicate the complex interplay of environmental factors, mechanical stresses, and electrochemical processes that occur in actual applications. Current standardized testing protocols frequently yield inconsistent results across different laboratories, making comparative analysis difficult and limiting the development of universal compatibility metrics.

The miniaturization trend in electronics compounds these challenges, as thinner copper traces and higher component densities create more complex surface geometries with sharper edges and tighter spaces. These features make uniform coating application increasingly difficult, leading to thickness variations that compromise protection and reliability in critical areas.

Existing Compatibility Testing Methods and Standards

01 Material compatibility for conformal coatings

Various materials can be used as conformal coatings, each with specific compatibility characteristics. These materials include acrylics, silicones, polyurethanes, and epoxies. The selection of coating material depends on its compatibility with the substrate, components, and environmental conditions. Proper material selection ensures adhesion, protection, and longevity of the coated electronic assemblies without causing damage to sensitive components.- Material compatibility for conformal coatings: Different conformal coating materials exhibit varying levels of compatibility with electronic components and substrates. The selection of appropriate coating materials such as acrylics, silicones, polyurethanes, or epoxies must consider their chemical compatibility with the underlying components to prevent adverse reactions. Compatibility testing is essential to ensure that the coating does not damage sensitive components or cause delamination, particularly with components containing plastics, elastomers, or pre-existing surface treatments.

- Application methods affecting compatibility: The method of applying conformal coatings significantly impacts compatibility with electronic assemblies. Various application techniques including spray coating, dip coating, brush application, and automated selective coating each present different compatibility challenges. The application method must be selected based on component sensitivity, geometry complexity, and required coating thickness. Proper masking techniques are essential to protect sensitive areas where coating adhesion would cause functionality issues or where coating is not desired.

- Thermal and environmental resistance compatibility: Conformal coatings must maintain compatibility with substrates and components under various thermal and environmental conditions. Coatings need to accommodate thermal expansion differences between the coating and underlying materials to prevent cracking or delamination during temperature cycling. Environmental resistance properties must be matched to the intended operating conditions, including humidity resistance, chemical exposure protection, and UV stability, while maintaining adhesion to the substrate throughout the product lifecycle.

- Rework and repair compatibility considerations: Conformal coatings must be selected with consideration for potential future rework or repair operations. Some coating formulations allow for easier removal when component replacement is necessary, while others provide more permanent protection but complicate repair processes. Compatibility with rework processes involves selecting coatings that can be precisely removed using appropriate solvents or mechanical methods without damaging surrounding components. This balance between protection and serviceability is critical for maintaining electronic assembly lifecycle management.

- Electrical performance compatibility: Conformal coatings must maintain electrical compatibility with the coated assembly, particularly regarding dielectric properties and signal integrity. The coating's dielectric constant, dissipation factor, and volume resistivity must be appropriate for the circuit's operating frequency and voltage requirements. Coatings should not introduce parasitic capacitance or impedance changes that could affect high-frequency performance. Additionally, the coating must maintain consistent electrical properties throughout environmental exposure and aging to ensure long-term reliability of the protected electronics.

02 Application methods for conformal coatings

Different application methods can be used for conformal coatings, including spraying, dipping, brushing, and automated selective coating. Each method has specific compatibility requirements with the coating material and the components being coated. The application method affects coating thickness, uniformity, and coverage, which in turn impacts the protection level and compatibility with the underlying components.Expand Specific Solutions03 Thermal compatibility considerations

Conformal coatings must be thermally compatible with both the substrate and components they protect. This includes considerations for coefficient of thermal expansion, operating temperature ranges, and heat dissipation properties. Thermal compatibility ensures that the coating maintains its protective properties during temperature cycling without cracking, delaminating, or causing thermal stress to the components.Expand Specific Solutions04 Chemical resistance and environmental protection

Conformal coatings must provide chemical resistance and environmental protection while remaining compatible with the underlying materials. Coatings need to protect against moisture, dust, chemicals, and other contaminants without reacting with the components or substrate. The coating's chemical composition must be selected to ensure it doesn't cause corrosion or degradation of the protected electronics over time.Expand Specific Solutions05 Reworkability and repair compatibility

Conformal coatings should be compatible with rework and repair processes. This includes considerations for how easily the coating can be removed for component replacement or repair without damaging the underlying circuitry. Some coatings offer better reworkability through selective application techniques, the use of masking during application, or formulations designed to be removed with specific solvents that won't damage components.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Coating Industry

The conformal coating compatibility with copper substrates market is currently in a growth phase, driven by increasing demand for electronic component protection across automotive, aerospace, and consumer electronics sectors. The global market size is estimated at approximately $1.2 billion, with projected annual growth of 5-7% through 2025. Technologically, the field is moderately mature but evolving rapidly with innovations in environmentally friendly formulations. Leading players include PPG Industries and DuPont de Nemours offering advanced polymer-based solutions, 3M Innovative Properties with specialized adhesion technologies, and Wacker Chemie and Covestro Deutschland focusing on silicone-based coatings. Emerging competitors like Sundew Technologies are introducing novel atomic layer deposition methods, while established companies such as Nordson Corp and MacDermid are enhancing application equipment and processes for improved copper substrate compatibility.

PPG Industries Ohio, Inc.

Technical Solution: PPG has developed advanced conformal coating systems specifically engineered for copper substrate compatibility, utilizing their proprietary CORAFLON® and ENVIROCRON® technologies. Their testing methodology incorporates accelerated environmental testing chambers that simulate extreme conditions including thermal cycling (-65°C to 125°C), high humidity (85% RH), and salt fog exposure to evaluate coating adhesion and protection efficacy. PPG employs electrochemical impedance spectroscopy (EIS) to quantitatively measure coating barrier properties and implements cross-cut adhesion testing (ASTM D3359) to assess coating-substrate bond integrity. Their solutions feature modified acrylic and polyurethane formulations with specialized copper-compatible adhesion promoters that form chemical bonds with copper oxide layers while maintaining electrical insulation properties required for electronic applications.

Strengths: Superior adhesion to copper substrates even after environmental aging; excellent chemical resistance against flux residues and industrial contaminants; transparent formulations allowing visual inspection of underlying circuitry. Weaknesses: Higher cost compared to standard conformal coatings; some formulations require longer cure times; may require specialized application equipment for optimal performance.

3M Innovative Properties Co.

Technical Solution: 3M has pioneered a comprehensive testing protocol for their Novec™ Electronic Grade Coatings on copper substrates, focusing on long-term reliability in harsh environments. Their methodology includes copper corrosion testing using mixed flowing gas (MFG) chambers that simulate industrial pollutants (H2S, NO2, Cl2) at accelerated rates. 3M's fluorinated polymer coatings create an ultra-thin (1-2μm) hydrophobic barrier that repels moisture while maintaining excellent dielectric properties. Their testing regimen incorporates thermal shock resistance (-65°C to 200°C), humidity aging (85°C/85% RH for 1000+ hours), and salt spray exposure (ASTM B117) with continuous electrical performance monitoring. 3M has developed specialized surface preparation techniques using plasma treatment and proprietary primers that enhance adhesion to copper without compromising the substrate's electrical conductivity or introducing galvanic corrosion risks.

Strengths: Exceptional moisture and chemical resistance; ultra-thin application preserves thermal properties; low surface energy prevents contaminant adhesion; excellent dielectric properties. Weaknesses: Higher initial cost than traditional coatings; requires specialized application equipment; some formulations have limited reworkability after curing.

Key Patents and Research on Copper-Coating Interactions

Process for increasing the adhesion of a metal surface to a polymer

PatentWO2008005094A2

Innovation

- A process involving a composition of water and a source of cupric ions at a pH between 2.8 and 4.2 is used to form a stable oxide conversion coating on copper surfaces, which is resistant to scratching and discoloration, and can be applied using conventional spray equipment at temperatures below 140°F, enhancing adhesion to polymeric substrates.

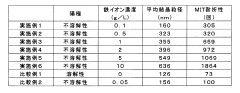

Copper-coated polyimide substrate and manufacturing method thereof

PatentActiveJP2008130585A

Innovation

- A method involving the formation of a nickel-chromium alloy layer and copper layer by sputtering, followed by electroplating using an insoluble anode and a copper plating solution with controlled iron ion concentration (0.1 to 10 g/L) to achieve a copper film with an average grain size of 160 to 700 nm, enhancing bending resistance.

Environmental Impact and Sustainability Considerations

The environmental impact of conformal coating processes on copper substrates represents a critical consideration in modern electronics manufacturing. Traditional conformal coating materials often contain volatile organic compounds (VOCs) and hazardous air pollutants that pose significant environmental and health risks. When testing compatibility with copper substrates, manufacturers must evaluate not only performance metrics but also the ecological footprint of the entire coating system throughout its lifecycle.

Recent regulatory frameworks, including RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), have accelerated the transition toward more environmentally friendly conformal coating solutions. Water-based and UV-curable coatings have emerged as sustainable alternatives, demonstrating reduced environmental impact while maintaining adequate protection for copper substrates. These formulations typically release fewer harmful emissions during application and curing processes compared to conventional solvent-based systems.

The sustainability profile of conformal coatings extends beyond their chemical composition to encompass energy consumption during application and curing. Thermal curing methods traditionally require significant energy inputs, whereas UV-curing technologies offer substantial energy savings—up to 80% in some applications—when testing compatibility with copper substrates. This energy efficiency translates directly to reduced carbon emissions in manufacturing operations.

End-of-life considerations present another dimension of environmental impact when evaluating coating-substrate compatibility. Ideally, conformal coatings should not impede the recyclability of copper components, which possess high intrinsic recycling value. Testing protocols should therefore include assessments of coating removability and substrate recoverability to ensure that protective measures do not compromise circular economy principles.

Water consumption and wastewater generation during application and cleaning processes represent additional environmental factors in compatibility testing. Advanced application technologies such as selective coating systems minimize material waste and reduce cleaning requirements, thereby conserving resources and limiting pollution potential. When evaluating coating compatibility with copper substrates, manufacturers should quantify these resource efficiencies as part of comprehensive sustainability metrics.

Carbon footprint analysis of different coating-substrate combinations provides valuable comparative data for environmentally conscious design decisions. Life Cycle Assessment (LCA) methodologies can reveal unexpected environmental impacts across the supply chain, from raw material extraction through manufacturing to disposal. Such analyses increasingly influence material selection criteria alongside traditional performance parameters when testing conformal coating compatibility with copper substrates.

Recent regulatory frameworks, including RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), have accelerated the transition toward more environmentally friendly conformal coating solutions. Water-based and UV-curable coatings have emerged as sustainable alternatives, demonstrating reduced environmental impact while maintaining adequate protection for copper substrates. These formulations typically release fewer harmful emissions during application and curing processes compared to conventional solvent-based systems.

The sustainability profile of conformal coatings extends beyond their chemical composition to encompass energy consumption during application and curing. Thermal curing methods traditionally require significant energy inputs, whereas UV-curing technologies offer substantial energy savings—up to 80% in some applications—when testing compatibility with copper substrates. This energy efficiency translates directly to reduced carbon emissions in manufacturing operations.

End-of-life considerations present another dimension of environmental impact when evaluating coating-substrate compatibility. Ideally, conformal coatings should not impede the recyclability of copper components, which possess high intrinsic recycling value. Testing protocols should therefore include assessments of coating removability and substrate recoverability to ensure that protective measures do not compromise circular economy principles.

Water consumption and wastewater generation during application and cleaning processes represent additional environmental factors in compatibility testing. Advanced application technologies such as selective coating systems minimize material waste and reduce cleaning requirements, thereby conserving resources and limiting pollution potential. When evaluating coating compatibility with copper substrates, manufacturers should quantify these resource efficiencies as part of comprehensive sustainability metrics.

Carbon footprint analysis of different coating-substrate combinations provides valuable comparative data for environmentally conscious design decisions. Life Cycle Assessment (LCA) methodologies can reveal unexpected environmental impacts across the supply chain, from raw material extraction through manufacturing to disposal. Such analyses increasingly influence material selection criteria alongside traditional performance parameters when testing conformal coating compatibility with copper substrates.

Reliability Testing Protocols for Coated Copper Assemblies

Reliability testing protocols for coated copper assemblies must be comprehensive and systematic to ensure long-term performance in various operating environments. These protocols typically begin with baseline testing of uncoated copper substrates to establish reference points for subsequent comparative analysis. This includes surface resistivity measurements, adhesion testing, and microscopic examination of the copper surface morphology before coating application.

The testing regimen should incorporate environmental stress testing that simulates real-world conditions. Temperature cycling tests (-65°C to +125°C) are essential to evaluate the coating's ability to maintain adhesion during thermal expansion and contraction of the copper substrate. Humidity testing at 85% relative humidity and 85°C for 1000 hours helps assess moisture resistance and potential for delamination under humid conditions.

Salt fog exposure testing according to ASTM B117 standards provides critical data on corrosion protection capabilities, particularly important for copper which is susceptible to oxidation. The protocol should include both continuous and cyclic salt fog exposure to simulate coastal or industrial environments where copper assemblies may be deployed.

Electrical testing forms another crucial component, including dielectric strength measurements, insulation resistance testing, and surface resistivity evaluations before and after environmental exposure. These tests verify that the conformal coating maintains its electrical insulation properties when applied to copper substrates under stress conditions.

Chemical compatibility testing should expose coated copper samples to various solvents, cleaning agents, and chemicals commonly encountered in manufacturing and service environments. This helps identify potential chemical interactions that might compromise coating integrity or accelerate copper corrosion beneath the coating.

Mechanical testing protocols should include cross-hatch adhesion testing (ASTM D3359), abrasion resistance evaluation, and flexibility assessment to ensure the coating can withstand physical stresses without cracking or peeling from the copper surface. Impact resistance testing provides data on coating durability under sudden mechanical stress.

Advanced analytical techniques such as Scanning Electron Microscopy (SEM) with Energy Dispersive X-ray Spectroscopy (EDX) should be employed to examine the coating-copper interface at a microscopic level, identifying any diffusion, migration, or chemical interaction between the coating materials and copper substrate over time.

Accelerated aging tests using UV exposure, combined with temperature and humidity cycling, help predict long-term performance and establish expected service life of the coated copper assemblies in various application environments.

The testing regimen should incorporate environmental stress testing that simulates real-world conditions. Temperature cycling tests (-65°C to +125°C) are essential to evaluate the coating's ability to maintain adhesion during thermal expansion and contraction of the copper substrate. Humidity testing at 85% relative humidity and 85°C for 1000 hours helps assess moisture resistance and potential for delamination under humid conditions.

Salt fog exposure testing according to ASTM B117 standards provides critical data on corrosion protection capabilities, particularly important for copper which is susceptible to oxidation. The protocol should include both continuous and cyclic salt fog exposure to simulate coastal or industrial environments where copper assemblies may be deployed.

Electrical testing forms another crucial component, including dielectric strength measurements, insulation resistance testing, and surface resistivity evaluations before and after environmental exposure. These tests verify that the conformal coating maintains its electrical insulation properties when applied to copper substrates under stress conditions.

Chemical compatibility testing should expose coated copper samples to various solvents, cleaning agents, and chemicals commonly encountered in manufacturing and service environments. This helps identify potential chemical interactions that might compromise coating integrity or accelerate copper corrosion beneath the coating.

Mechanical testing protocols should include cross-hatch adhesion testing (ASTM D3359), abrasion resistance evaluation, and flexibility assessment to ensure the coating can withstand physical stresses without cracking or peeling from the copper surface. Impact resistance testing provides data on coating durability under sudden mechanical stress.

Advanced analytical techniques such as Scanning Electron Microscopy (SEM) with Energy Dispersive X-ray Spectroscopy (EDX) should be employed to examine the coating-copper interface at a microscopic level, identifying any diffusion, migration, or chemical interaction between the coating materials and copper substrate over time.

Accelerated aging tests using UV exposure, combined with temperature and humidity cycling, help predict long-term performance and establish expected service life of the coated copper assemblies in various application environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!