How to Optimize Conformal Coating Properties for Wear Resistance

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conformal Coating Evolution and Objectives

Conformal coatings have undergone significant evolution since their initial development in the mid-20th century. Originally designed for military and aerospace applications to protect electronic components from harsh environmental conditions, these protective layers have transformed into sophisticated materials engineered for multiple performance attributes, with wear resistance becoming increasingly critical in modern applications.

The evolution of conformal coatings can be traced through several distinct phases. The first generation, developed in the 1950s-1960s, consisted primarily of basic acrylic and epoxy formulations offering rudimentary protection. The second generation (1970s-1980s) introduced silicone and polyurethane variants with improved flexibility and temperature resistance. The third generation (1990s-2000s) saw the development of specialized formulations with enhanced chemical resistance and electrical properties.

Current fourth-generation coatings (2010s-present) incorporate advanced nano-materials, hybrid polymers, and multi-functional additives that significantly improve wear resistance while maintaining other critical properties. This evolution has been driven by increasing demands from industries such as automotive electronics, medical devices, and consumer electronics, where components face mechanical stresses alongside environmental challenges.

The technological trajectory shows a clear trend toward multi-functional coatings that can simultaneously address multiple protection requirements. Recent innovations include self-healing capabilities, gradient-property structures, and environmentally friendly formulations that maintain high performance standards while reducing environmental impact.

The primary objectives for optimizing conformal coating wear resistance include: developing coatings with superior abrasion resistance without compromising flexibility; enhancing adhesion to diverse substrate materials; improving long-term durability under cyclic mechanical stresses; and maintaining performance across wide temperature and humidity ranges. Additionally, there are objectives to reduce curing times and energy requirements, minimize volatile organic compound (VOC) emissions, and ensure compatibility with automated application processes.

Future development goals focus on creating intelligent coating systems that can adapt to changing environmental conditions, incorporating real-time monitoring capabilities, and developing coatings with self-diagnostic and self-repair mechanisms. Research is also directed toward bio-inspired coating architectures that mimic naturally wear-resistant biological structures, potentially offering breakthrough improvements in durability and performance.

The evolution of conformal coatings can be traced through several distinct phases. The first generation, developed in the 1950s-1960s, consisted primarily of basic acrylic and epoxy formulations offering rudimentary protection. The second generation (1970s-1980s) introduced silicone and polyurethane variants with improved flexibility and temperature resistance. The third generation (1990s-2000s) saw the development of specialized formulations with enhanced chemical resistance and electrical properties.

Current fourth-generation coatings (2010s-present) incorporate advanced nano-materials, hybrid polymers, and multi-functional additives that significantly improve wear resistance while maintaining other critical properties. This evolution has been driven by increasing demands from industries such as automotive electronics, medical devices, and consumer electronics, where components face mechanical stresses alongside environmental challenges.

The technological trajectory shows a clear trend toward multi-functional coatings that can simultaneously address multiple protection requirements. Recent innovations include self-healing capabilities, gradient-property structures, and environmentally friendly formulations that maintain high performance standards while reducing environmental impact.

The primary objectives for optimizing conformal coating wear resistance include: developing coatings with superior abrasion resistance without compromising flexibility; enhancing adhesion to diverse substrate materials; improving long-term durability under cyclic mechanical stresses; and maintaining performance across wide temperature and humidity ranges. Additionally, there are objectives to reduce curing times and energy requirements, minimize volatile organic compound (VOC) emissions, and ensure compatibility with automated application processes.

Future development goals focus on creating intelligent coating systems that can adapt to changing environmental conditions, incorporating real-time monitoring capabilities, and developing coatings with self-diagnostic and self-repair mechanisms. Research is also directed toward bio-inspired coating architectures that mimic naturally wear-resistant biological structures, potentially offering breakthrough improvements in durability and performance.

Market Analysis for Wear-Resistant Coatings

The global market for wear-resistant coatings has experienced significant growth in recent years, driven by increasing demand across multiple industries including automotive, aerospace, electronics, and industrial manufacturing. The market value reached approximately $8.5 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.2% through 2028, potentially reaching $12.9 billion by the end of the forecast period.

Conformal coatings represent a specialized segment within this market, with particular applications in electronics, medical devices, and high-precision components. This segment alone accounts for roughly $2.1 billion of the total market and is growing at an accelerated rate of 7.8% annually, outpacing the broader wear-resistant coatings category.

Regional analysis reveals that Asia-Pacific dominates the market with a 42% share, followed by North America (28%) and Europe (21%). China and India are experiencing the fastest growth rates within the Asia-Pacific region, primarily due to rapid industrialization and increasing electronics manufacturing activities. The North American market is characterized by high demand for advanced coatings in aerospace and defense applications.

End-user segmentation shows electronics as the largest consumer of conformal wear-resistant coatings (38%), followed by automotive (24%), aerospace (17%), and industrial equipment (12%). The remaining 9% is distributed across various applications including medical devices and consumer goods. The electronics sector's dominance is expected to continue due to the miniaturization trend and increasing complexity of electronic components requiring enhanced protection.

Market drivers include stringent regulatory requirements for product longevity, increasing focus on reducing maintenance costs, and growing demand for high-performance materials in extreme operating environments. The push toward sustainability has also created demand for environmentally friendly coating solutions with reduced VOC emissions and improved recyclability.

Pricing trends indicate a premium market for high-performance conformal coatings, with specialized formulations commanding 30-40% higher prices than standard protective coatings. This price premium is justified by extended product lifecycles and reduced maintenance requirements, offering favorable total cost of ownership despite higher initial investment.

Customer demand patterns show increasing preference for multi-functional coatings that provide not only wear resistance but also additional properties such as chemical resistance, thermal stability, and electrical insulation. This trend toward integrated performance characteristics represents a significant market opportunity for innovative coating technologies.

Conformal coatings represent a specialized segment within this market, with particular applications in electronics, medical devices, and high-precision components. This segment alone accounts for roughly $2.1 billion of the total market and is growing at an accelerated rate of 7.8% annually, outpacing the broader wear-resistant coatings category.

Regional analysis reveals that Asia-Pacific dominates the market with a 42% share, followed by North America (28%) and Europe (21%). China and India are experiencing the fastest growth rates within the Asia-Pacific region, primarily due to rapid industrialization and increasing electronics manufacturing activities. The North American market is characterized by high demand for advanced coatings in aerospace and defense applications.

End-user segmentation shows electronics as the largest consumer of conformal wear-resistant coatings (38%), followed by automotive (24%), aerospace (17%), and industrial equipment (12%). The remaining 9% is distributed across various applications including medical devices and consumer goods. The electronics sector's dominance is expected to continue due to the miniaturization trend and increasing complexity of electronic components requiring enhanced protection.

Market drivers include stringent regulatory requirements for product longevity, increasing focus on reducing maintenance costs, and growing demand for high-performance materials in extreme operating environments. The push toward sustainability has also created demand for environmentally friendly coating solutions with reduced VOC emissions and improved recyclability.

Pricing trends indicate a premium market for high-performance conformal coatings, with specialized formulations commanding 30-40% higher prices than standard protective coatings. This price premium is justified by extended product lifecycles and reduced maintenance requirements, offering favorable total cost of ownership despite higher initial investment.

Customer demand patterns show increasing preference for multi-functional coatings that provide not only wear resistance but also additional properties such as chemical resistance, thermal stability, and electrical insulation. This trend toward integrated performance characteristics represents a significant market opportunity for innovative coating technologies.

Current Limitations and Technical Barriers

Despite significant advancements in conformal coating technology, several critical limitations and technical barriers continue to impede the optimization of wear resistance properties. Current conformal coating materials, including acrylics, silicones, polyurethanes, and epoxies, each present specific drawbacks when optimized for wear resistance applications. Acrylic coatings, while offering good humidity protection, demonstrate poor abrasion resistance and are susceptible to chemical damage. Silicone coatings, though flexible and temperature resistant, exhibit inadequate hardness profiles necessary for sustained wear protection.

Polyurethane coatings face challenges in achieving consistent thickness across complex geometries, resulting in uneven wear protection. This inconsistency creates vulnerability zones where premature coating failure frequently occurs. Additionally, the trade-off between flexibility and hardness remains a significant technical barrier, as increasing hardness for better wear resistance often results in decreased flexibility, leading to cracking under thermal or mechanical stress.

Current application methods present another set of limitations. Spray coating techniques struggle with achieving uniform coverage on intricate components, while dipping methods often result in excessive material accumulation in recessed areas. Automated selective coating systems, while precise, remain cost-prohibitive for many manufacturing operations and require complex programming for optimal results.

The curing process introduces additional challenges, particularly in balancing cure time with coating performance. UV-curable coatings offer rapid processing but may leave shadowed areas uncured, while thermal curing methods require extended processing times that impact production efficiency. Incomplete curing significantly compromises wear resistance properties, creating weak points susceptible to early degradation.

Environmental and regulatory constraints further complicate optimization efforts. Many high-performance coating formulations contain volatile organic compounds (VOCs) and hazardous air pollutants that face increasing regulatory restrictions. Water-based alternatives, while environmentally preferable, typically demonstrate inferior wear resistance characteristics compared to solvent-based systems.

Testing methodologies represent another barrier to advancement. Current standardized wear testing protocols often fail to accurately simulate real-world conditions, leading to performance discrepancies between laboratory results and field applications. The lack of accelerated testing methods that reliably predict long-term wear behavior hampers material development cycles and validation processes.

Finally, the industry faces significant challenges in developing multi-functional coatings that simultaneously provide wear resistance alongside other critical properties such as electrical insulation, thermal management, and chemical resistance. This integration challenge often results in compromised wear performance when attempting to satisfy multiple protection requirements within a single coating system.

Polyurethane coatings face challenges in achieving consistent thickness across complex geometries, resulting in uneven wear protection. This inconsistency creates vulnerability zones where premature coating failure frequently occurs. Additionally, the trade-off between flexibility and hardness remains a significant technical barrier, as increasing hardness for better wear resistance often results in decreased flexibility, leading to cracking under thermal or mechanical stress.

Current application methods present another set of limitations. Spray coating techniques struggle with achieving uniform coverage on intricate components, while dipping methods often result in excessive material accumulation in recessed areas. Automated selective coating systems, while precise, remain cost-prohibitive for many manufacturing operations and require complex programming for optimal results.

The curing process introduces additional challenges, particularly in balancing cure time with coating performance. UV-curable coatings offer rapid processing but may leave shadowed areas uncured, while thermal curing methods require extended processing times that impact production efficiency. Incomplete curing significantly compromises wear resistance properties, creating weak points susceptible to early degradation.

Environmental and regulatory constraints further complicate optimization efforts. Many high-performance coating formulations contain volatile organic compounds (VOCs) and hazardous air pollutants that face increasing regulatory restrictions. Water-based alternatives, while environmentally preferable, typically demonstrate inferior wear resistance characteristics compared to solvent-based systems.

Testing methodologies represent another barrier to advancement. Current standardized wear testing protocols often fail to accurately simulate real-world conditions, leading to performance discrepancies between laboratory results and field applications. The lack of accelerated testing methods that reliably predict long-term wear behavior hampers material development cycles and validation processes.

Finally, the industry faces significant challenges in developing multi-functional coatings that simultaneously provide wear resistance alongside other critical properties such as electrical insulation, thermal management, and chemical resistance. This integration challenge often results in compromised wear performance when attempting to satisfy multiple protection requirements within a single coating system.

State-of-the-Art Wear Resistance Solutions

01 Polymer-based conformal coatings with enhanced wear resistance

Polymer-based conformal coatings can be formulated to provide superior wear resistance properties. These coatings typically incorporate specialized polymers such as polyurethanes, acrylics, or epoxies that form a protective layer over electronic components or other substrates. The addition of cross-linking agents and hardeners can significantly improve the coating's durability against mechanical abrasion and wear. These formulations often balance flexibility and hardness to maintain protection while accommodating substrate movement and thermal expansion.- Polymer-based conformal coatings with enhanced wear resistance: Polymer-based conformal coatings can be formulated to provide superior wear resistance for electronic components and other surfaces. These coatings typically incorporate specialized polymers such as polyurethanes, acrylics, or epoxies that form a protective layer against mechanical abrasion and environmental stressors. The addition of cross-linking agents and hardeners can significantly improve the durability and wear resistance of these coatings while maintaining flexibility and adhesion to the substrate.

- Nanoparticle-reinforced conformal coatings: Incorporating nanoparticles such as silica, alumina, or carbon-based materials into conformal coating formulations can dramatically enhance wear resistance properties. These nanoparticles create a reinforced matrix within the coating that distributes mechanical stress and prevents crack propagation. The nanoscale size of these particles allows them to fill microscopic voids in the coating, resulting in a more uniform and denser protective layer with improved hardness and abrasion resistance while maintaining the conformal nature of the coating.

- Multi-layer conformal coating systems: Multi-layer conformal coating systems combine different materials to achieve enhanced wear resistance. These systems typically consist of a primer layer for adhesion, a main protective layer with specific wear-resistant properties, and sometimes a top coat for additional protection. Each layer serves a specific function, with the combination providing superior protection against mechanical wear, chemical exposure, and environmental factors. This approach allows for customization of wear resistance properties while maintaining the conformality needed for complex geometries.

- Surface treatment methods for improved coating adhesion and wear resistance: Various surface treatment methods can be employed prior to applying conformal coatings to enhance wear resistance. These include plasma treatment, chemical etching, and mechanical roughening to improve adhesion between the substrate and coating. Better adhesion results in coatings that are less likely to delaminate under mechanical stress, thereby improving overall wear resistance. Additionally, certain surface treatments can create a gradient interface between the substrate and coating, distributing mechanical forces more effectively.

- Self-healing conformal coatings for prolonged wear resistance: Self-healing conformal coatings represent an advanced approach to maintaining wear resistance over extended periods. These coatings incorporate microcapsules containing healing agents or utilize reversible chemical bonds that can repair minor damage automatically when triggered by mechanical stress, heat, or other stimuli. This self-repair mechanism prevents the propagation of small scratches or abrasions into larger failures, significantly extending the effective lifetime of the protective coating even under continuous wear conditions.

02 Nanoparticle-reinforced conformal coatings

Incorporating nanoparticles into conformal coating formulations can dramatically enhance wear resistance properties. Materials such as nano-silica, nano-alumina, carbon nanotubes, or graphene can be dispersed within the coating matrix to create a reinforced structure. These nanoparticles increase the mechanical strength and abrasion resistance of the coating while maintaining other desirable properties like flexibility and adhesion. The small size of nanoparticles allows them to fill microscopic gaps in the coating, creating a more uniform and durable protective layer that resists mechanical wear and environmental degradation.Expand Specific Solutions03 Multi-layer conformal coating systems

Multi-layer conformal coating systems combine different materials to achieve enhanced wear resistance. These systems typically consist of a primer layer for adhesion, a main protective layer, and sometimes a top coat for specific surface properties. Each layer serves a distinct purpose in the overall protection scheme, with specialized formulations that work together to provide superior wear resistance. The combination of different materials allows for optimization of properties like hardness, flexibility, and chemical resistance, resulting in a coating system that can withstand mechanical abrasion and wear while maintaining protection of the underlying substrate.Expand Specific Solutions04 Ceramic and inorganic conformal coatings

Ceramic and inorganic-based conformal coatings offer exceptional wear resistance properties for applications requiring extreme durability. These coatings utilize materials such as silicon dioxide, aluminum oxide, or other ceramic compounds to create a hard, wear-resistant surface. Deposition methods like plasma-enhanced chemical vapor deposition (PECVD) or atomic layer deposition (ALD) can be used to apply these coatings with precise thickness control. The resulting protective layers exhibit superior hardness, thermal stability, and resistance to mechanical abrasion, making them suitable for harsh environment applications where traditional polymer coatings might fail.Expand Specific Solutions05 Self-healing conformal coatings

Self-healing conformal coatings represent an advanced approach to maintaining wear resistance over time. These innovative formulations incorporate microcapsules containing healing agents or utilize reversible chemical bonds that can repair damage automatically when it occurs. When the coating experiences wear or abrasion that creates microcracks, the healing mechanism is triggered, releasing repair compounds or reforming bonds to restore the protective barrier. This self-repair capability extends the effective lifetime of the coating and maintains wear resistance properties even after mechanical damage, reducing the need for maintenance or reapplication in challenging environments.Expand Specific Solutions

Industry Leaders and Competitive Landscape

The conformal coating wear resistance market is currently in a growth phase, with increasing demand across electronics, automotive, and aerospace sectors. The market size is expanding due to the rising need for durable protective coatings in harsh environments, estimated to reach several billion dollars by 2025. Technologically, the field is moderately mature but evolving rapidly, with companies like Nordson Corp. and HzO leading innovation in nano-coating technologies. BASF Coatings, Wacker Chemie, and Henkel are advancing polymer-based solutions, while Jiangsu Favored Nanotechnology specializes in liquid ingress protection. 3M and Huawei are investing in R&D for next-generation coatings with enhanced wear properties, creating a competitive landscape where material science breakthroughs are driving differentiation and market positioning.

Nordson Corp.

Technical Solution: Nordson has developed advanced precision dispensing systems for conformal coating application that optimize wear resistance through controlled thickness uniformity. Their technology utilizes automated selective coating equipment with multi-axis motion control that ensures precise material deposition with tolerances as tight as ±0.1mm. The company's integrated vision systems perform real-time inspection during application, allowing for immediate adjustments to coating parameters. Nordson's approach focuses on optimizing the application process through precise control of viscosity, flow rate, and spray pattern, which significantly impacts the final coating's wear resistance properties. Their systems incorporate thermal management technology that maintains optimal material temperature throughout the application process, ensuring consistent cross-linking and polymerization of coating materials. This results in enhanced molecular bonding and improved wear resistance characteristics of the final coating.

Strengths: Superior precision in coating application leads to consistent wear resistance properties; integrated quality control systems ensure coating integrity. Weaknesses: Higher initial investment costs compared to manual application methods; requires specialized technical expertise for optimal system configuration and maintenance.

3M Innovative Properties Co.

Technical Solution: 3M has pioneered fluoropolymer-enhanced conformal coating formulations specifically engineered for superior wear resistance in harsh environments. Their proprietary technology incorporates nano-scale ceramic particles (typically 20-50nm in diameter) uniformly dispersed within a modified acrylic or silicone matrix. This creates a composite coating with significantly improved abrasion resistance while maintaining flexibility. 3M's approach includes a multi-layer application methodology where an initial adhesion-promoting layer is followed by a main protective layer with optimized cross-linking density. Their coatings achieve Taber Abrasion test results showing up to 40% improvement in wear resistance compared to conventional conformal coatings. The company has also developed UV-traceable additives that don't compromise the mechanical properties while enabling quality inspection. 3M's formulations feature controlled surface energy properties that enhance both wear resistance and repellency against contaminants.

Strengths: Exceptional balance between flexibility and hardness; superior chemical resistance alongside wear resistance; established global supply chain ensuring product availability. Weaknesses: Premium pricing compared to standard conformal coatings; some formulations require specialized application equipment for optimal performance.

Key Patents and Technical Innovations

Wear Resistant Coatings

PatentPendingUS20230407100A1

Innovation

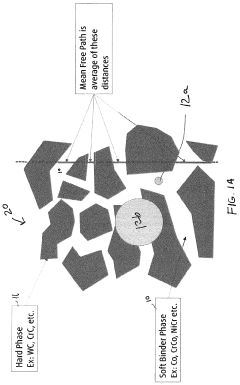

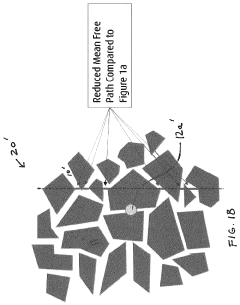

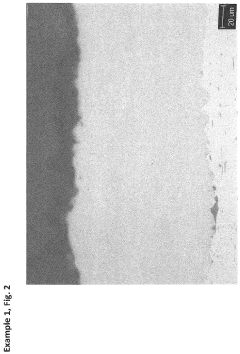

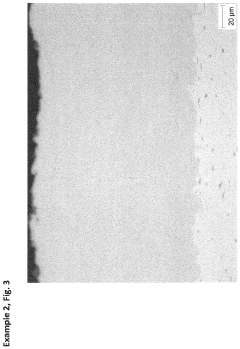

- A wear-resistant coating with a high fraction of carbide-based materials (83-94 wt.%) and a metallic binder, applied using a modified high-velocity thermal spray process, minimizing porosity and oxide content, and optimizing the mean free path of the metallic binder to reduce contact with fine abrasive particles, thereby enhancing abrasion resistance.

Wear resistant coating

PatentInactiveEP1413647A2

Innovation

- A wear protection layer composed of alternating individual layers with a nanocrystalline hard material phase and amorphous carbon phase, where the phase ratio is tailored to create a composite structure with improved mechanical and tribological properties, allowing for cohesive connections and adjustable friction and wear resistance.

Environmental Impact and Sustainability Considerations

The environmental impact of conformal coating processes has become increasingly significant as industries strive for more sustainable manufacturing practices. Traditional conformal coating materials often contain volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) that contribute to air pollution and pose health risks to workers. Recent regulatory frameworks, including the European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH), have accelerated the transition toward environmentally friendly alternatives.

Water-based and UV-curable conformal coatings represent promising sustainable options, offering reduced VOC emissions while maintaining wear resistance properties. These formulations typically reduce environmental impact by 40-60% compared to conventional solvent-based systems. Life cycle assessment (LCA) studies indicate that UV-curable coatings, in particular, demonstrate superior environmental performance due to their rapid curing process that requires less energy consumption and produces minimal waste.

Material recyclability presents another critical sustainability consideration. Thermoplastic-based conformal coatings offer advantages in end-of-life management as they can be more easily removed and potentially recycled, unlike thermoset alternatives that typically require energy-intensive disposal methods. Biobased coating materials derived from renewable resources such as plant oils and starches are emerging as viable alternatives, with research showing they can achieve comparable wear resistance while reducing carbon footprint by up to 30%.

Application efficiency also significantly impacts environmental sustainability. Advanced spray technologies and automated application systems can reduce material waste by 15-25% compared to manual processes. Additionally, precision application techniques minimize overspray and reduce the need for masking materials, further decreasing waste generation and resource consumption.

The durability aspect of wear-resistant conformal coatings contributes substantially to sustainability through extended product lifecycles. Coatings that provide superior protection against mechanical wear, chemical exposure, and environmental stressors can extend electronic component lifespans by 3-5 years, reducing electronic waste generation and resource consumption associated with replacement manufacturing.

Energy consumption during coating application and curing represents another environmental consideration. Low-temperature curing formulations and energy-efficient curing technologies, such as LED-UV systems, can reduce energy requirements by up to 70% compared to conventional thermal curing methods, significantly lowering the carbon footprint of the coating process while maintaining optimal wear resistance properties.

Water-based and UV-curable conformal coatings represent promising sustainable options, offering reduced VOC emissions while maintaining wear resistance properties. These formulations typically reduce environmental impact by 40-60% compared to conventional solvent-based systems. Life cycle assessment (LCA) studies indicate that UV-curable coatings, in particular, demonstrate superior environmental performance due to their rapid curing process that requires less energy consumption and produces minimal waste.

Material recyclability presents another critical sustainability consideration. Thermoplastic-based conformal coatings offer advantages in end-of-life management as they can be more easily removed and potentially recycled, unlike thermoset alternatives that typically require energy-intensive disposal methods. Biobased coating materials derived from renewable resources such as plant oils and starches are emerging as viable alternatives, with research showing they can achieve comparable wear resistance while reducing carbon footprint by up to 30%.

Application efficiency also significantly impacts environmental sustainability. Advanced spray technologies and automated application systems can reduce material waste by 15-25% compared to manual processes. Additionally, precision application techniques minimize overspray and reduce the need for masking materials, further decreasing waste generation and resource consumption.

The durability aspect of wear-resistant conformal coatings contributes substantially to sustainability through extended product lifecycles. Coatings that provide superior protection against mechanical wear, chemical exposure, and environmental stressors can extend electronic component lifespans by 3-5 years, reducing electronic waste generation and resource consumption associated with replacement manufacturing.

Energy consumption during coating application and curing represents another environmental consideration. Low-temperature curing formulations and energy-efficient curing technologies, such as LED-UV systems, can reduce energy requirements by up to 70% compared to conventional thermal curing methods, significantly lowering the carbon footprint of the coating process while maintaining optimal wear resistance properties.

Testing Methodologies and Performance Standards

Standardized testing methodologies are essential for evaluating the wear resistance properties of conformal coatings in a consistent and reliable manner. The ASTM D4060 Taber Abrasion Test stands as the industry benchmark, measuring weight loss and wear index after subjecting coated specimens to abrasive wheels under controlled conditions. This test provides quantifiable data on coating durability under mechanical stress, allowing for objective comparisons between different formulations.

Scratch resistance testing, typically performed using the ASTM D7027 standard, employs stylus-based instruments to apply progressively increasing loads until coating failure occurs. The critical load at failure serves as a key performance indicator for wear resistance. Complementary to this, nanoindentation testing (ASTM E2546) measures hardness and elastic modulus at the microscale, providing insights into the fundamental mechanical properties that contribute to wear resistance.

Environmental cycling tests combine wear testing with exposure to environmental stressors such as temperature fluctuations, humidity, and UV radiation. These tests, including ASTM D1735 for water resistance and ASTM G154 for accelerated weathering, evaluate how environmental factors affect the long-term wear performance of conformal coatings in real-world applications.

Industry-specific standards further refine testing requirements based on application domains. IPC-CC-830 for electronics applications establishes minimum performance requirements for conformal coatings used in electronic assemblies. Similarly, MIL-I-46058 (military specification) and IEC 60068 (international standard) define rigorous testing protocols for coatings used in harsh operating environments.

Performance metrics must be clearly defined and consistently measured to enable meaningful comparisons. Key parameters include wear rate (volume loss per unit time), coefficient of friction, scratch resistance threshold, and adhesion strength after wear testing. Advanced surface analysis techniques such as scanning electron microscopy (SEM) and atomic force microscopy (AFM) provide detailed characterization of wear mechanisms and surface morphology changes.

Accelerated aging protocols simulate extended service conditions within compressed timeframes, allowing for prediction of long-term performance. These protocols typically involve cyclic exposure to multiple stressors at elevated intensities, with periodic wear resistance evaluations to track performance degradation over time. The correlation between accelerated test results and real-world performance must be established through careful validation studies.

Scratch resistance testing, typically performed using the ASTM D7027 standard, employs stylus-based instruments to apply progressively increasing loads until coating failure occurs. The critical load at failure serves as a key performance indicator for wear resistance. Complementary to this, nanoindentation testing (ASTM E2546) measures hardness and elastic modulus at the microscale, providing insights into the fundamental mechanical properties that contribute to wear resistance.

Environmental cycling tests combine wear testing with exposure to environmental stressors such as temperature fluctuations, humidity, and UV radiation. These tests, including ASTM D1735 for water resistance and ASTM G154 for accelerated weathering, evaluate how environmental factors affect the long-term wear performance of conformal coatings in real-world applications.

Industry-specific standards further refine testing requirements based on application domains. IPC-CC-830 for electronics applications establishes minimum performance requirements for conformal coatings used in electronic assemblies. Similarly, MIL-I-46058 (military specification) and IEC 60068 (international standard) define rigorous testing protocols for coatings used in harsh operating environments.

Performance metrics must be clearly defined and consistently measured to enable meaningful comparisons. Key parameters include wear rate (volume loss per unit time), coefficient of friction, scratch resistance threshold, and adhesion strength after wear testing. Advanced surface analysis techniques such as scanning electron microscopy (SEM) and atomic force microscopy (AFM) provide detailed characterization of wear mechanisms and surface morphology changes.

Accelerated aging protocols simulate extended service conditions within compressed timeframes, allowing for prediction of long-term performance. These protocols typically involve cyclic exposure to multiple stressors at elevated intensities, with periodic wear resistance evaluations to track performance degradation over time. The correlation between accelerated test results and real-world performance must be established through careful validation studies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!