Testing Service Life Extension Potential of Conformal Coating

SEP 17, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conformal Coating Technology Background and Objectives

Conformal coating technology has evolved significantly since its inception in the 1940s, initially developed for military applications to protect electronic components from harsh environmental conditions. The progression from simple acrylic formulations to today's advanced multi-functional coatings represents a remarkable technological journey spanning over seven decades. This evolution has been driven by the increasing complexity of electronic systems and the growing demand for reliability in diverse operating environments.

The current technological landscape features five primary coating types: acrylic, epoxy, silicone, polyurethane, and parylene, each offering distinct performance characteristics suited to specific application requirements. Recent innovations have focused on developing nano-enhanced formulations, UV-curable systems, and environmentally friendly alternatives to traditional solvent-based coatings, reflecting the industry's response to regulatory pressures and sustainability concerns.

Service life extension represents a critical frontier in conformal coating technology. As electronic devices become more integral to critical infrastructure, healthcare systems, and transportation networks, the need to extend operational lifespans while maintaining performance integrity has become paramount. Current industry standards typically specify coating service lives of 5-10 years, but emerging applications in aerospace, medical implants, and industrial IoT demand protection spanning decades rather than years.

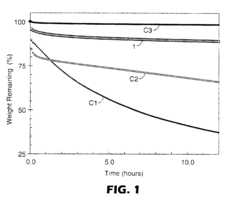

The primary objective of investigating service life extension potential is to develop testing methodologies that can accurately predict long-term performance without requiring actual decade-long testing periods. This involves establishing accelerated aging protocols that reliably correlate with real-world degradation mechanisms, identifying key performance indicators that signal impending coating failure, and creating mathematical models that can extrapolate short-term test results to predict long-term behavior.

Secondary objectives include quantifying the relationship between environmental stressors and coating degradation rates, evaluating the effectiveness of various pretreatment and application methods on longevity, and developing standardized protocols for service life assessment that can be adopted across the industry. These efforts align with broader trends toward predictive maintenance and life-cycle management in electronic systems.

The technological trajectory suggests movement toward adaptive coating systems that can respond to environmental changes, self-healing formulations that address microfractures before they compromise protection, and hybrid systems that combine the advantages of multiple coating types. These developments represent not merely incremental improvements but potentially transformative approaches to electronic protection that could fundamentally redefine service life expectations.

The current technological landscape features five primary coating types: acrylic, epoxy, silicone, polyurethane, and parylene, each offering distinct performance characteristics suited to specific application requirements. Recent innovations have focused on developing nano-enhanced formulations, UV-curable systems, and environmentally friendly alternatives to traditional solvent-based coatings, reflecting the industry's response to regulatory pressures and sustainability concerns.

Service life extension represents a critical frontier in conformal coating technology. As electronic devices become more integral to critical infrastructure, healthcare systems, and transportation networks, the need to extend operational lifespans while maintaining performance integrity has become paramount. Current industry standards typically specify coating service lives of 5-10 years, but emerging applications in aerospace, medical implants, and industrial IoT demand protection spanning decades rather than years.

The primary objective of investigating service life extension potential is to develop testing methodologies that can accurately predict long-term performance without requiring actual decade-long testing periods. This involves establishing accelerated aging protocols that reliably correlate with real-world degradation mechanisms, identifying key performance indicators that signal impending coating failure, and creating mathematical models that can extrapolate short-term test results to predict long-term behavior.

Secondary objectives include quantifying the relationship between environmental stressors and coating degradation rates, evaluating the effectiveness of various pretreatment and application methods on longevity, and developing standardized protocols for service life assessment that can be adopted across the industry. These efforts align with broader trends toward predictive maintenance and life-cycle management in electronic systems.

The technological trajectory suggests movement toward adaptive coating systems that can respond to environmental changes, self-healing formulations that address microfractures before they compromise protection, and hybrid systems that combine the advantages of multiple coating types. These developments represent not merely incremental improvements but potentially transformative approaches to electronic protection that could fundamentally redefine service life expectations.

Market Demand Analysis for Extended Service Life Coatings

The conformal coating market is experiencing significant growth driven by the increasing demand for extended service life solutions across multiple industries. The global conformal coating market was valued at approximately 926 million USD in 2020 and is projected to reach 1,519 million USD by 2026, growing at a CAGR of 5.8% during the forecast period. This growth trajectory underscores the expanding market need for protective coatings that can extend the operational lifespan of electronic components and systems.

The aerospace and defense sectors represent primary demand drivers, where electronic components must withstand extreme environmental conditions including temperature fluctuations, humidity, and vibration. These industries require coatings that can guarantee performance reliability over extended operational periods, often exceeding 15-20 years. The financial implications of component failure in these sectors are substantial, making investment in high-performance conformal coatings economically justified.

Consumer electronics manufacturers are increasingly adopting conformal coatings to enhance product durability and reduce warranty claims. Market research indicates that smartphones with enhanced moisture protection through conformal coating have demonstrated a 35% reduction in moisture-related failures. This translates to significant cost savings and improved brand reputation for manufacturers.

The automotive industry presents another substantial market opportunity, particularly with the rapid growth of electric vehicles (EVs) and advanced driver-assistance systems (ADAS). These systems incorporate sophisticated electronics that require protection from harsh under-hood environments and road contaminants. The automotive electronics market is expected to grow at 8.5% CAGR through 2027, directly influencing demand for high-performance conformal coatings.

Industrial IoT applications represent an emerging market segment with substantial growth potential. As connected sensors and control systems are deployed in challenging industrial environments, the need for extended service life coatings becomes critical. Market analysis suggests that industrial IoT implementations can reduce maintenance costs by 25% when components are properly protected against environmental factors.

Regional market analysis reveals that Asia-Pacific dominates the conformal coating market, accounting for approximately 40% of global demand, followed by North America and Europe. This regional distribution aligns with electronics manufacturing hubs and industrial centers.

Customer requirements are evolving toward coatings that not only provide longer service life but also offer additional functionalities such as thermal management, EMI shielding, and enhanced adhesion properties. This trend is driving innovation in multi-functional coating formulations that can address multiple protection requirements simultaneously.

The aerospace and defense sectors represent primary demand drivers, where electronic components must withstand extreme environmental conditions including temperature fluctuations, humidity, and vibration. These industries require coatings that can guarantee performance reliability over extended operational periods, often exceeding 15-20 years. The financial implications of component failure in these sectors are substantial, making investment in high-performance conformal coatings economically justified.

Consumer electronics manufacturers are increasingly adopting conformal coatings to enhance product durability and reduce warranty claims. Market research indicates that smartphones with enhanced moisture protection through conformal coating have demonstrated a 35% reduction in moisture-related failures. This translates to significant cost savings and improved brand reputation for manufacturers.

The automotive industry presents another substantial market opportunity, particularly with the rapid growth of electric vehicles (EVs) and advanced driver-assistance systems (ADAS). These systems incorporate sophisticated electronics that require protection from harsh under-hood environments and road contaminants. The automotive electronics market is expected to grow at 8.5% CAGR through 2027, directly influencing demand for high-performance conformal coatings.

Industrial IoT applications represent an emerging market segment with substantial growth potential. As connected sensors and control systems are deployed in challenging industrial environments, the need for extended service life coatings becomes critical. Market analysis suggests that industrial IoT implementations can reduce maintenance costs by 25% when components are properly protected against environmental factors.

Regional market analysis reveals that Asia-Pacific dominates the conformal coating market, accounting for approximately 40% of global demand, followed by North America and Europe. This regional distribution aligns with electronics manufacturing hubs and industrial centers.

Customer requirements are evolving toward coatings that not only provide longer service life but also offer additional functionalities such as thermal management, EMI shielding, and enhanced adhesion properties. This trend is driving innovation in multi-functional coating formulations that can address multiple protection requirements simultaneously.

Current Status and Challenges in Conformal Coating Durability

Conformal coating technology has evolved significantly over the past decades, with current global market valued at approximately $1.2 billion and projected to grow at a CAGR of 5-7% through 2028. Despite widespread adoption across electronics manufacturing, aerospace, automotive, and medical device industries, significant challenges persist in accurately predicting and extending service life of these protective coatings.

The durability assessment of conformal coatings currently faces several technical limitations. Standard testing protocols such as IPC-CC-830C and MIL-I-46058C provide baseline performance metrics but fail to accurately simulate real-world aging conditions that combine multiple environmental stressors simultaneously. This disconnect between laboratory testing and field performance creates significant uncertainty in lifetime predictions.

Material degradation mechanisms represent another major challenge, as UV exposure, thermal cycling, humidity, and chemical exposure interact in complex ways that accelerate coating breakdown. Current accelerated aging tests often fail to capture these synergistic effects, leading to overestimation of coating longevity in actual deployment environments.

Geographically, conformal coating technology development shows distinct regional characteristics. North American and European research focuses heavily on environmentally friendly formulations that comply with RoHS and REACH regulations, while maintaining performance standards. Asian manufacturers, particularly in China and South Korea, have made significant advances in high-volume, cost-effective production techniques, though sometimes with less emphasis on environmental compliance.

The industry also faces challenges in measurement standardization. Different manufacturers employ varying methodologies to assess coating thickness, adhesion strength, and dielectric properties, making direct comparisons between products difficult. This lack of standardization complicates qualification processes for critical applications.

Recent technological innovations have introduced nano-enhanced coatings with improved barrier properties and self-healing capabilities, though these advanced formulations present new challenges in durability testing and qualification. The integration of these novel materials requires updated testing methodologies that can accurately predict their long-term performance.

A significant knowledge gap exists in understanding the long-term effects of coating rework and repair on overall protection efficacy. As electronic assemblies become more complex and miniaturized, the ability to effectively rework coated assemblies without compromising protection becomes increasingly important, yet standardized assessment methods for repaired coatings remain underdeveloped.

The durability assessment of conformal coatings currently faces several technical limitations. Standard testing protocols such as IPC-CC-830C and MIL-I-46058C provide baseline performance metrics but fail to accurately simulate real-world aging conditions that combine multiple environmental stressors simultaneously. This disconnect between laboratory testing and field performance creates significant uncertainty in lifetime predictions.

Material degradation mechanisms represent another major challenge, as UV exposure, thermal cycling, humidity, and chemical exposure interact in complex ways that accelerate coating breakdown. Current accelerated aging tests often fail to capture these synergistic effects, leading to overestimation of coating longevity in actual deployment environments.

Geographically, conformal coating technology development shows distinct regional characteristics. North American and European research focuses heavily on environmentally friendly formulations that comply with RoHS and REACH regulations, while maintaining performance standards. Asian manufacturers, particularly in China and South Korea, have made significant advances in high-volume, cost-effective production techniques, though sometimes with less emphasis on environmental compliance.

The industry also faces challenges in measurement standardization. Different manufacturers employ varying methodologies to assess coating thickness, adhesion strength, and dielectric properties, making direct comparisons between products difficult. This lack of standardization complicates qualification processes for critical applications.

Recent technological innovations have introduced nano-enhanced coatings with improved barrier properties and self-healing capabilities, though these advanced formulations present new challenges in durability testing and qualification. The integration of these novel materials requires updated testing methodologies that can accurately predict their long-term performance.

A significant knowledge gap exists in understanding the long-term effects of coating rework and repair on overall protection efficacy. As electronic assemblies become more complex and miniaturized, the ability to effectively rework coated assemblies without compromising protection becomes increasingly important, yet standardized assessment methods for repaired coatings remain underdeveloped.

Current Testing Methodologies for Coating Longevity Assessment

01 Advanced coating materials for extended service life

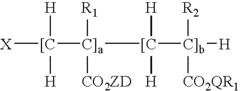

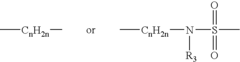

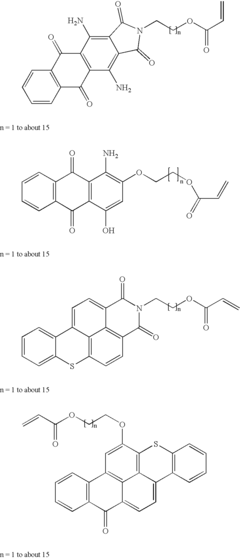

Various advanced materials can be used in conformal coatings to extend service life of electronic components. These include specialized polymers, composite materials, and multi-layer coating systems that provide enhanced protection against environmental factors such as moisture, chemicals, and temperature fluctuations. These advanced materials offer superior adhesion, flexibility, and durability compared to conventional coatings, resulting in longer-lasting protection for electronic assemblies.- Advanced coating materials for enhanced durability: Specialized conformal coating materials such as fluoropolymers, silicones, and parylene can significantly extend service life of electronic components by providing superior protection against moisture, chemicals, and environmental contaminants. These advanced materials offer improved adhesion properties, flexibility, and resistance to thermal cycling, which helps maintain protective integrity over extended periods. The formulations can be customized with additives to enhance specific protective properties based on the intended operating environment.

- Multi-layer coating systems for comprehensive protection: Implementing multi-layer coating systems provides enhanced protection and extended service life by combining the beneficial properties of different coating materials. The primary layer typically offers strong adhesion to the substrate, while subsequent layers provide specialized protection against specific environmental factors. This approach creates redundant barriers against moisture ingress and contaminants, ensuring continued functionality even if one layer becomes compromised. The strategic combination of different materials can address multiple failure modes simultaneously.

- Application techniques for optimal coating performance: Advanced application methods such as vapor deposition, selective coating, and automated spraying systems can significantly improve coating uniformity, thickness control, and coverage of complex geometries. These techniques ensure proper coating of high-density components and difficult-to-reach areas, eliminating weak points that could lead to premature failure. Precise control over the application process results in more consistent protection and extended service life by minimizing coating defects such as pinholes, bubbles, and thin spots.

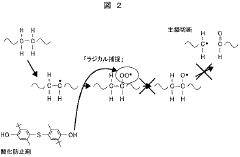

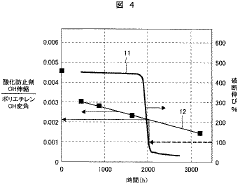

- Environmental resistance enhancements: Incorporating specific additives and modifiers into conformal coatings can enhance resistance to harsh environmental conditions such as extreme temperatures, UV exposure, chemical exposure, and high humidity. These formulations may include UV stabilizers, antioxidants, fungicides, and flame retardants to address specific environmental challenges. Enhanced environmental resistance directly correlates with extended service life by preventing degradation mechanisms that would otherwise lead to coating failure and subsequent component damage.

- Repair and maintenance strategies for coating longevity: Implementing effective repair and maintenance protocols for conformal coatings can significantly extend their service life. These strategies include periodic inspection techniques, selective reapplication of damaged areas, and cleaning procedures that remove contaminants without damaging the coating. Proper maintenance prevents minor coating defects from developing into critical failures and allows for targeted interventions before component protection is compromised. Some advanced coatings are specifically designed to facilitate repair processes through improved reworkability.

02 Environmental resistance enhancement techniques

Techniques to enhance the environmental resistance of conformal coatings include incorporating additives that improve moisture resistance, UV stability, and chemical resistance. These formulations may contain specialized fillers, stabilizers, and cross-linking agents that work together to create a more robust protective barrier. By improving resistance to environmental stressors, these techniques significantly extend the service life of coated electronic components, particularly in harsh operating conditions.Expand Specific Solutions03 Application methods for optimal coating performance

The method of applying conformal coatings significantly impacts their performance and longevity. Advanced application techniques such as selective coating, vapor deposition, and automated spraying systems ensure uniform coverage, optimal thickness, and proper curing. These methods minimize defects like bubbles, pinholes, and uneven coverage that could compromise protection. Proper pre-cleaning and surface preparation protocols further enhance coating adhesion and overall effectiveness, extending the service life of the protective layer.Expand Specific Solutions04 Thermal management and stress reduction designs

Specialized conformal coating formulations and designs that address thermal management and mechanical stress can significantly extend service life. These coatings incorporate features that help dissipate heat, accommodate thermal expansion and contraction, and absorb mechanical vibrations. By reducing thermal and mechanical stress on electronic components, these coatings prevent cracking, delamination, and other failure modes, thereby extending the operational lifespan of protected electronics.Expand Specific Solutions05 Self-healing and reparable coating technologies

Innovative self-healing and reparable coating technologies represent a significant advancement in extending conformal coating service life. These coatings contain microcapsules with healing agents or feature reversible chemical bonds that can repair minor damage automatically when triggered by environmental conditions or mechanical stress. Some formulations also allow for easy field repair or reapplication without complete removal of the original coating, providing cost-effective maintenance options and prolonging the protective function of the coating system.Expand Specific Solutions

Key Industry Players in Conformal Coating Development

The conformal coating service life extension market is currently in a growth phase, characterized by increasing demand for electronic component protection in harsh environments. The market size is expanding due to rising applications in automotive, aerospace, and consumer electronics sectors. Technologically, the field is moderately mature with established players like Nordson Corp., DuPont, and HzO leading innovation in nano-coating technologies. Boeing and IBM represent major industrial consumers driving requirements for enhanced durability. Companies like Semblant and 3M are advancing material science solutions, while research institutions such as Georgia Tech and IMEC contribute fundamental knowledge. Asian manufacturers including Tata Consultancy Services and Chengdu Taly are expanding market presence, creating a globally competitive landscape with differentiation through proprietary formulations and application methods.

Nordson Corp.

Technical Solution: Nordson has developed advanced conformal coating testing methodologies that focus on service life extension through precision application systems. Their technology utilizes automated selective coating equipment with path optimization algorithms to ensure uniform coating thickness across complex PCB geometries. The company's approach incorporates accelerated aging chambers that simulate extreme environmental conditions (temperature cycling from -65°C to +150°C, humidity exposure at 85% RH, and salt fog testing) to predict long-term performance. Nordson's proprietary vision inspection systems can detect coating anomalies as small as 10 microns, allowing for real-time quality control during the application process. Their research has demonstrated that precisely controlled coating thickness variations (between 25-250 microns depending on application requirements) can extend service life by up to 300% in harsh environments compared to uncoated electronics.

Strengths: Superior precision in application control leading to consistent coating thickness and coverage; integrated inspection systems for quality assurance; extensive environmental testing capabilities. Weaknesses: Higher initial equipment investment compared to manual application methods; requires specialized operator training; system complexity may increase maintenance requirements.

3M Innovative Properties Co.

Technical Solution: 3M has pioneered a comprehensive testing protocol for conformal coating life extension that combines material science innovation with environmental stress testing. Their approach utilizes fluoropolymer-based nanocoatings with hydrophobic properties that achieve water contact angles exceeding 110°, providing superior moisture protection. The company's testing methodology incorporates mixed flowing gas (MFG) exposure chambers that simulate multiple corrosive environments simultaneously, allowing for accelerated life testing that correlates to real-world performance. 3M's proprietary coating formulations undergo rigorous thermal shock testing (-55°C to +125°C with 15-minute dwell times) for up to 1,000 cycles to verify coating adhesion and flexibility over time. Their research has established that optimized silicone-acrylic hybrid coatings can extend PCB service life by 5-7 years in industrial environments while maintaining electrical performance within 2% of original specifications.

Strengths: Industry-leading material science expertise; extensive environmental testing capabilities; proven correlation between accelerated testing and field performance; wide range of coating formulations for different applications. Weaknesses: Premium pricing compared to standard coating solutions; some formulations require specialized application equipment; longer curing times for certain high-performance coatings.

Critical Technical Innovations in Service Life Extension

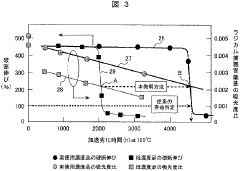

Service life inspection method of cable coating material

PatentInactiveJP2012173183A

Innovation

- A method involving infrared spectroscopic measurement to quantify the concentration of functional groups in the antioxidant's molecular structure, determining the deterioration degree and rate by the absorbance ratio, allowing for early prediction of the coating material's life by plotting thermal deterioration tests at multiple temperatures and using Arrhenius plots.

Dyed fluoropolymers

PatentInactiveUS6894105B2

Innovation

- Development of dyed fluoropolymers where the dye is covalently bonded to the polymer, using fluorochemical (meth)acrylate monomers and (meth)acrylate functional dyes, providing improved thermal stability, adhesion, and resistance to leaching, without the need for a cure mechanism.

Environmental Impact and Sustainability Considerations

The environmental impact of conformal coating processes and materials has become increasingly significant as electronics manufacturers face stricter regulations and growing sustainability demands. Traditional conformal coating materials often contain volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) that contribute to air pollution and pose health risks to workers. Extending the service life of conformal coatings through advanced testing methodologies directly addresses these environmental concerns by reducing the frequency of reapplication and associated waste generation.

Life cycle assessment (LCA) studies indicate that the environmental footprint of electronic products is significantly affected by the durability of protective elements such as conformal coatings. By enhancing coating longevity through improved testing protocols, manufacturers can reduce the overall environmental impact across the product lifecycle. This approach aligns with circular economy principles, where resource efficiency and product lifespan extension are prioritized over the traditional linear model of production and disposal.

Recent advancements in bio-based and water-soluble conformal coating formulations offer promising alternatives to conventional petroleum-based products. These environmentally friendly options demonstrate comparable performance characteristics while significantly reducing ecological impact. Testing methodologies that accurately predict the service life of these sustainable alternatives are essential for their broader market adoption and environmental benefit realization.

Energy consumption during coating application and curing processes represents another critical environmental consideration. Extended service life testing must account for the energy efficiency of different coating technologies, as energy-intensive processes with longer-lasting results may ultimately prove more sustainable than frequently repeated low-energy applications. Comprehensive testing frameworks should incorporate these energy metrics to provide a holistic view of environmental performance.

Waste management challenges associated with conformal coating removal and reapplication can be substantially mitigated through service life extension. Current industry practices often involve chemical strippers and mechanical removal techniques that generate hazardous waste. By developing testing methodologies that accurately predict coating durability under various environmental stressors, manufacturers can optimize maintenance schedules and minimize unnecessary reapplication, thereby reducing chemical waste and associated environmental contamination.

Regulatory compliance represents an increasingly important driver for sustainable conformal coating practices. Global initiatives such as the European Union's Restriction of Hazardous Substances (RoHS) directive and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation have established stringent requirements for electronic components. Testing protocols that verify extended service life while ensuring compliance with these evolving regulations provide manufacturers with a competitive advantage in environmentally conscious markets.

Life cycle assessment (LCA) studies indicate that the environmental footprint of electronic products is significantly affected by the durability of protective elements such as conformal coatings. By enhancing coating longevity through improved testing protocols, manufacturers can reduce the overall environmental impact across the product lifecycle. This approach aligns with circular economy principles, where resource efficiency and product lifespan extension are prioritized over the traditional linear model of production and disposal.

Recent advancements in bio-based and water-soluble conformal coating formulations offer promising alternatives to conventional petroleum-based products. These environmentally friendly options demonstrate comparable performance characteristics while significantly reducing ecological impact. Testing methodologies that accurately predict the service life of these sustainable alternatives are essential for their broader market adoption and environmental benefit realization.

Energy consumption during coating application and curing processes represents another critical environmental consideration. Extended service life testing must account for the energy efficiency of different coating technologies, as energy-intensive processes with longer-lasting results may ultimately prove more sustainable than frequently repeated low-energy applications. Comprehensive testing frameworks should incorporate these energy metrics to provide a holistic view of environmental performance.

Waste management challenges associated with conformal coating removal and reapplication can be substantially mitigated through service life extension. Current industry practices often involve chemical strippers and mechanical removal techniques that generate hazardous waste. By developing testing methodologies that accurately predict coating durability under various environmental stressors, manufacturers can optimize maintenance schedules and minimize unnecessary reapplication, thereby reducing chemical waste and associated environmental contamination.

Regulatory compliance represents an increasingly important driver for sustainable conformal coating practices. Global initiatives such as the European Union's Restriction of Hazardous Substances (RoHS) directive and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation have established stringent requirements for electronic components. Testing protocols that verify extended service life while ensuring compliance with these evolving regulations provide manufacturers with a competitive advantage in environmentally conscious markets.

Reliability Standards and Certification Requirements

Conformal coating reliability is governed by a comprehensive framework of international and industry-specific standards that ensure consistent performance across diverse operating environments. IPC-CC-830 serves as the foundational standard, establishing classification systems for conformal coatings based on their material properties and performance characteristics. This standard defines rigorous testing methodologies for evaluating coating resistance to moisture, chemicals, and thermal stress, providing manufacturers with clear benchmarks for quality assurance.

The military specification MIL-I-46058C, though officially superseded, continues to influence reliability requirements, particularly for defense and aerospace applications where operational conditions are exceptionally demanding. Its testing protocols for environmental resistance remain relevant references in contemporary certification processes. For automotive applications, the AEC-Q200 standard incorporates specific requirements for conformal coatings used in electronic components, emphasizing thermal cycling and humidity resistance testing to simulate real-world automotive environments.

UL 746E specifically addresses the flammability and electrical insulation properties of conformal coatings, establishing critical safety parameters that products must meet before market introduction. This certification is particularly important for consumer electronics and applications where fire safety is paramount. The IEC 60068 series provides standardized environmental testing procedures that evaluate coating performance under temperature extremes, humidity, and mechanical stress, offering globally recognized methodologies for reliability assessment.

For service life extension applications, the emerging IPC-CC-830C introduces enhanced accelerated aging protocols designed to predict long-term performance more accurately. These protocols typically involve exposure to elevated temperatures, humidity cycling, and UV radiation at intensities that accelerate degradation mechanisms without introducing failure modes not present in normal operation.

Certification requirements typically mandate independent laboratory verification through standardized test sequences. These sequences generally include thermal shock testing (typically -65°C to +125°C), humidity resistance (85% RH at 85°C for 1000 hours), salt fog exposure, and chemical resistance evaluations. For life extension applications, additional requirements often include extended thermal aging tests and combined environment exposures that simulate decades of operational stress in compressed timeframes.

Compliance documentation must demonstrate traceability between test results and specific material batches, with statistical analysis of performance variability across multiple samples. Increasingly, certification bodies are requiring manufacturers to implement ongoing reliability monitoring programs that track coating performance throughout the extended service period, with periodic verification testing to confirm continued compliance with reliability standards.

The military specification MIL-I-46058C, though officially superseded, continues to influence reliability requirements, particularly for defense and aerospace applications where operational conditions are exceptionally demanding. Its testing protocols for environmental resistance remain relevant references in contemporary certification processes. For automotive applications, the AEC-Q200 standard incorporates specific requirements for conformal coatings used in electronic components, emphasizing thermal cycling and humidity resistance testing to simulate real-world automotive environments.

UL 746E specifically addresses the flammability and electrical insulation properties of conformal coatings, establishing critical safety parameters that products must meet before market introduction. This certification is particularly important for consumer electronics and applications where fire safety is paramount. The IEC 60068 series provides standardized environmental testing procedures that evaluate coating performance under temperature extremes, humidity, and mechanical stress, offering globally recognized methodologies for reliability assessment.

For service life extension applications, the emerging IPC-CC-830C introduces enhanced accelerated aging protocols designed to predict long-term performance more accurately. These protocols typically involve exposure to elevated temperatures, humidity cycling, and UV radiation at intensities that accelerate degradation mechanisms without introducing failure modes not present in normal operation.

Certification requirements typically mandate independent laboratory verification through standardized test sequences. These sequences generally include thermal shock testing (typically -65°C to +125°C), humidity resistance (85% RH at 85°C for 1000 hours), salt fog exposure, and chemical resistance evaluations. For life extension applications, additional requirements often include extended thermal aging tests and combined environment exposures that simulate decades of operational stress in compressed timeframes.

Compliance documentation must demonstrate traceability between test results and specific material batches, with statistical analysis of performance variability across multiple samples. Increasingly, certification bodies are requiring manufacturers to implement ongoing reliability monitoring programs that track coating performance throughout the extended service period, with periodic verification testing to confirm continued compliance with reliability standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!