Conformal Coating Vs Nano-Coatings: Longevity and Durability

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Protective Coating Technologies Background and Objectives

Protective coating technologies have evolved significantly over the past several decades, transitioning from simple barrier methods to sophisticated engineered solutions that provide multiple layers of protection against environmental factors. The evolution began with traditional conformal coatings, which emerged in the mid-20th century primarily for military and aerospace applications, offering basic protection against moisture, dust, and chemical contaminants. These early solutions focused on creating physical barriers that encapsulated electronic components and circuit boards.

The technological landscape shifted dramatically in the late 1990s and early 2000s with the advent of nanotechnology, which introduced nano-coatings as a revolutionary alternative to conventional conformal coatings. This paradigm shift represented a fundamental change in approach—from macro-level protection to molecular-level engineering of protective surfaces. The development trajectory has been characterized by continuous improvements in material science, application techniques, and performance metrics.

Current protective coating technologies can be broadly categorized into two main approaches: traditional conformal coatings (acrylic, silicone, polyurethane, epoxy, and parylene) and advanced nano-coatings (hydrophobic, oleophobic, antimicrobial, and self-healing variants). Each category offers distinct advantages and limitations in terms of protection level, application process, and long-term performance.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of conformal coatings versus nano-coatings, with specific focus on their longevity and durability characteristics. This analysis aims to establish quantifiable metrics for evaluating coating performance under various environmental stressors, including temperature fluctuations, humidity exposure, chemical contact, mechanical abrasion, and UV radiation.

Additionally, this research seeks to identify the key factors that influence coating degradation over time and determine the effective service life of different coating technologies across diverse application environments. Understanding these degradation mechanisms is crucial for developing predictive models that can accurately forecast coating performance throughout a product's lifecycle.

The ultimate goal is to provide evidence-based recommendations for coating selection based on specific application requirements, environmental conditions, and expected service life. This includes developing a decision framework that considers factors such as substrate material, operating environment, maintenance capabilities, and cost constraints. Such a framework would enable more informed decision-making in industries where protective coatings play a critical role in product reliability and longevity.

Furthermore, this research aims to identify emerging trends and potential breakthrough technologies in the protective coating domain that could significantly enhance longevity and durability beyond current capabilities, thereby establishing a roadmap for future research and development efforts.

The technological landscape shifted dramatically in the late 1990s and early 2000s with the advent of nanotechnology, which introduced nano-coatings as a revolutionary alternative to conventional conformal coatings. This paradigm shift represented a fundamental change in approach—from macro-level protection to molecular-level engineering of protective surfaces. The development trajectory has been characterized by continuous improvements in material science, application techniques, and performance metrics.

Current protective coating technologies can be broadly categorized into two main approaches: traditional conformal coatings (acrylic, silicone, polyurethane, epoxy, and parylene) and advanced nano-coatings (hydrophobic, oleophobic, antimicrobial, and self-healing variants). Each category offers distinct advantages and limitations in terms of protection level, application process, and long-term performance.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of conformal coatings versus nano-coatings, with specific focus on their longevity and durability characteristics. This analysis aims to establish quantifiable metrics for evaluating coating performance under various environmental stressors, including temperature fluctuations, humidity exposure, chemical contact, mechanical abrasion, and UV radiation.

Additionally, this research seeks to identify the key factors that influence coating degradation over time and determine the effective service life of different coating technologies across diverse application environments. Understanding these degradation mechanisms is crucial for developing predictive models that can accurately forecast coating performance throughout a product's lifecycle.

The ultimate goal is to provide evidence-based recommendations for coating selection based on specific application requirements, environmental conditions, and expected service life. This includes developing a decision framework that considers factors such as substrate material, operating environment, maintenance capabilities, and cost constraints. Such a framework would enable more informed decision-making in industries where protective coatings play a critical role in product reliability and longevity.

Furthermore, this research aims to identify emerging trends and potential breakthrough technologies in the protective coating domain that could significantly enhance longevity and durability beyond current capabilities, thereby establishing a roadmap for future research and development efforts.

Market Analysis for Advanced Electronic Protection Solutions

The electronic protection solutions market has witnessed significant growth in recent years, driven by increasing demand for reliable protection mechanisms for sensitive electronic components across various industries. The global market for advanced electronic protection coatings was valued at approximately 12.3 billion USD in 2022 and is projected to reach 18.7 billion USD by 2028, representing a compound annual growth rate (CAGR) of 7.2% during the forecast period.

The automotive sector currently holds the largest market share at 32%, followed by consumer electronics (27%), aerospace and defense (18%), industrial electronics (14%), and medical devices (9%). This distribution reflects the critical need for protection against environmental factors in these industries where electronic failure can lead to significant operational disruptions or safety concerns.

Regional analysis indicates North America and Europe as mature markets with established adoption patterns, collectively accounting for 58% of the global market. However, the Asia-Pacific region is experiencing the fastest growth rate at 9.5% annually, driven by rapid industrialization, expanding electronics manufacturing bases in China, South Korea, and Taiwan, and increasing automotive production.

The market is segmented by coating type, with traditional conformal coatings currently dominating at 65% market share. However, nano-coatings are experiencing accelerated adoption with a growth rate of 12.8% annually, significantly outpacing the overall market growth. This shift is primarily attributed to the superior performance characteristics of nano-coatings in harsh environments and their longer service life.

Key market drivers include miniaturization of electronic components, increasing deployment of electronics in harsh environments, growing awareness about the cost implications of electronic failures, and stringent reliability requirements in critical applications. The automotive industry's transition toward electric vehicles has emerged as a particularly strong growth catalyst, as these vehicles contain significantly more electronic components requiring protection.

Market challenges include price sensitivity in consumer electronics, technical barriers to adoption in legacy manufacturing processes, and environmental regulations affecting certain coating chemistries. The average price premium for nano-coatings over traditional conformal coatings remains at 30-40%, presenting a barrier to widespread adoption in cost-sensitive applications.

Customer surveys indicate that longevity and durability rank as the top purchasing criteria (42%), followed by ease of application (23%), environmental compliance (18%), and cost (17%). This prioritization demonstrates the market's increasing focus on total cost of ownership rather than initial implementation costs.

The automotive sector currently holds the largest market share at 32%, followed by consumer electronics (27%), aerospace and defense (18%), industrial electronics (14%), and medical devices (9%). This distribution reflects the critical need for protection against environmental factors in these industries where electronic failure can lead to significant operational disruptions or safety concerns.

Regional analysis indicates North America and Europe as mature markets with established adoption patterns, collectively accounting for 58% of the global market. However, the Asia-Pacific region is experiencing the fastest growth rate at 9.5% annually, driven by rapid industrialization, expanding electronics manufacturing bases in China, South Korea, and Taiwan, and increasing automotive production.

The market is segmented by coating type, with traditional conformal coatings currently dominating at 65% market share. However, nano-coatings are experiencing accelerated adoption with a growth rate of 12.8% annually, significantly outpacing the overall market growth. This shift is primarily attributed to the superior performance characteristics of nano-coatings in harsh environments and their longer service life.

Key market drivers include miniaturization of electronic components, increasing deployment of electronics in harsh environments, growing awareness about the cost implications of electronic failures, and stringent reliability requirements in critical applications. The automotive industry's transition toward electric vehicles has emerged as a particularly strong growth catalyst, as these vehicles contain significantly more electronic components requiring protection.

Market challenges include price sensitivity in consumer electronics, technical barriers to adoption in legacy manufacturing processes, and environmental regulations affecting certain coating chemistries. The average price premium for nano-coatings over traditional conformal coatings remains at 30-40%, presenting a barrier to widespread adoption in cost-sensitive applications.

Customer surveys indicate that longevity and durability rank as the top purchasing criteria (42%), followed by ease of application (23%), environmental compliance (18%), and cost (17%). This prioritization demonstrates the market's increasing focus on total cost of ownership rather than initial implementation costs.

Current Challenges in Coating Technologies

Despite significant advancements in protective coating technologies, several persistent challenges continue to impede optimal performance in both conformal coatings and nano-coatings. The primary challenge facing traditional conformal coatings is achieving consistent thickness across complex geometries. When applied to intricate electronic components or irregular surfaces, conventional spray or dip methods often result in uneven coverage, creating vulnerable areas prone to environmental damage. This inconsistency directly impacts longevity, as thinner areas deteriorate faster than properly coated sections.

Adhesion remains another critical challenge, particularly in environments with thermal cycling or mechanical stress. Both coating types struggle with maintaining long-term adhesion to various substrate materials, especially when exposed to temperature fluctuations that cause differential expansion and contraction. This thermal mismatch frequently leads to coating delamination, cracking, and eventual failure of protection.

Environmental resistance presents evolving challenges as devices face increasingly harsh operating conditions. Traditional conformal coatings often demonstrate inadequate resistance to extreme temperatures, chemicals, and moisture over extended periods. While nano-coatings offer superior initial protection, their long-term stability under combined stressors remains questionable, with potential degradation pathways not fully characterized.

Application processes for both technologies present significant hurdles. Conformal coatings typically require careful masking of sensitive areas and often involve environmentally problematic solvents. Nano-coatings, while potentially more environmentally friendly, demand precise application parameters and specialized equipment, limiting widespread adoption. The scalability of nano-coating processes from laboratory to mass production environments continues to challenge manufacturers seeking consistent quality.

Quality control and verification represent persistent difficulties, particularly for nano-coatings where conventional thickness measurements may not apply. The industry lacks standardized testing protocols specifically designed for nano-scale protective layers, making performance comparisons and quality assurance problematic. This gap in standardization hampers adoption despite promising laboratory results.

Cost-effectiveness remains a significant barrier, especially for nano-coatings. While offering superior protection characteristics, their higher material costs, specialized application equipment, and more complex processing requirements create economic obstacles to widespread implementation. The industry continues to seek the optimal balance between enhanced protection and economic viability.

Regulatory compliance adds another layer of complexity, with increasing restrictions on volatile organic compounds (VOCs) and other potentially harmful substances traditionally used in conformal coatings. Developing alternatives that meet environmental regulations while maintaining performance specifications presents ongoing challenges for coating manufacturers and end-users alike.

Adhesion remains another critical challenge, particularly in environments with thermal cycling or mechanical stress. Both coating types struggle with maintaining long-term adhesion to various substrate materials, especially when exposed to temperature fluctuations that cause differential expansion and contraction. This thermal mismatch frequently leads to coating delamination, cracking, and eventual failure of protection.

Environmental resistance presents evolving challenges as devices face increasingly harsh operating conditions. Traditional conformal coatings often demonstrate inadequate resistance to extreme temperatures, chemicals, and moisture over extended periods. While nano-coatings offer superior initial protection, their long-term stability under combined stressors remains questionable, with potential degradation pathways not fully characterized.

Application processes for both technologies present significant hurdles. Conformal coatings typically require careful masking of sensitive areas and often involve environmentally problematic solvents. Nano-coatings, while potentially more environmentally friendly, demand precise application parameters and specialized equipment, limiting widespread adoption. The scalability of nano-coating processes from laboratory to mass production environments continues to challenge manufacturers seeking consistent quality.

Quality control and verification represent persistent difficulties, particularly for nano-coatings where conventional thickness measurements may not apply. The industry lacks standardized testing protocols specifically designed for nano-scale protective layers, making performance comparisons and quality assurance problematic. This gap in standardization hampers adoption despite promising laboratory results.

Cost-effectiveness remains a significant barrier, especially for nano-coatings. While offering superior protection characteristics, their higher material costs, specialized application equipment, and more complex processing requirements create economic obstacles to widespread implementation. The industry continues to seek the optimal balance between enhanced protection and economic viability.

Regulatory compliance adds another layer of complexity, with increasing restrictions on volatile organic compounds (VOCs) and other potentially harmful substances traditionally used in conformal coatings. Developing alternatives that meet environmental regulations while maintaining performance specifications presents ongoing challenges for coating manufacturers and end-users alike.

Comparative Analysis of Conformal vs Nano-Coating Solutions

01 Nano-coating materials for enhanced durability

Various nano-coating materials can significantly enhance the durability and longevity of conformal coatings. These materials include nanoparticles, nanocomposites, and specialized polymers that provide superior resistance to environmental factors such as moisture, chemicals, and temperature fluctuations. The nano-scale structure of these coatings creates a more uniform and defect-free protective layer, resulting in extended service life and improved reliability for electronic components and other substrates.- Nano-coating materials for enhanced durability: Advanced nano-coating materials can significantly improve the longevity and durability of conformal coatings. These materials often incorporate nanoparticles or nanostructures that provide superior resistance to environmental factors such as moisture, chemicals, and temperature fluctuations. The nano-scale properties allow for better adhesion to substrates while maintaining flexibility and creating more effective protective barriers against corrosion and oxidation.

- Environmental resistance technologies: Specialized formulations for conformal coatings that enhance resistance to harsh environmental conditions including extreme temperatures, humidity, salt spray, and UV exposure. These coatings incorporate specific additives and polymer structures that maintain their protective properties over extended periods even when exposed to challenging environments. The technologies focus on preventing degradation mechanisms that typically limit coating lifespans in industrial, marine, or outdoor applications.

- Self-healing and regenerative coating systems: Innovative coating technologies that incorporate self-healing mechanisms to repair minor damage automatically, extending the functional lifespan of the protective layer. These systems may utilize encapsulated healing agents that release when the coating is damaged, or reversible chemical bonds that can reform after being broken. This self-repair capability significantly improves the long-term durability of conformal coatings by addressing the micro-cracks and abrasions that would otherwise lead to premature failure.

- Application methods for improved coating adhesion and uniformity: Specialized application techniques and pre-treatment processes that enhance the adhesion, coverage, and uniformity of conformal and nano-coatings. These methods include plasma treatment, vapor deposition, spin coating, and automated spraying systems that ensure optimal coating thickness and consistency. Proper application significantly impacts the longevity of coatings by eliminating weak points, ensuring complete coverage, and maximizing the bond between the coating and substrate.

- Testing and qualification methods for coating durability: Standardized testing protocols and qualification methods specifically designed to evaluate and predict the long-term performance of conformal and nano-coatings. These include accelerated aging tests, thermal cycling, humidity exposure, salt spray testing, and mechanical stress evaluations. The methods provide quantifiable metrics for comparing different coating solutions and ensuring they meet specific durability requirements for various applications and environments.

02 Environmental resistance technologies

Advanced conformal coatings incorporate specific technologies to resist harsh environmental conditions, thereby extending their longevity. These technologies include UV-resistant additives, moisture barriers, thermal stabilizers, and chemical resistance enhancers. By protecting against multiple environmental stressors simultaneously, these coatings maintain their protective properties over extended periods, even in challenging conditions such as high humidity, extreme temperatures, or exposure to corrosive substances.Expand Specific Solutions03 Application methods for improved coating performance

The method of applying conformal and nano-coatings significantly impacts their durability and longevity. Techniques such as plasma deposition, vapor deposition, spin coating, and automated spray systems can create more uniform and defect-free coatings compared to manual methods. Proper surface preparation, controlled curing processes, and multi-layer application strategies also contribute to enhanced adhesion and long-term performance of the protective coatings.Expand Specific Solutions04 Self-healing and adaptive coating technologies

Innovative self-healing and adaptive coating technologies represent a significant advancement in conformal coating durability. These coatings contain microcapsules with healing agents or feature dynamic chemical structures that can repair minor damage automatically. Some advanced formulations can adapt to changing environmental conditions, providing optimal protection across various scenarios. These self-repairing capabilities significantly extend the effective lifespan of the protective coating and reduce maintenance requirements.Expand Specific Solutions05 Testing and quality assurance methods

Specialized testing and quality assurance methods are essential for verifying the longevity and durability of conformal and nano-coatings. These include accelerated aging tests, thermal cycling, salt spray exposure, humidity resistance testing, and adhesion evaluations. Advanced analytical techniques such as scanning electron microscopy and spectroscopic analysis help identify potential failure mechanisms and optimize coating formulations. Comprehensive testing protocols ensure that coatings will maintain their protective properties throughout the intended service life of the protected components.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The conformal coating vs nano-coating market is currently in a growth phase, with an expanding market size driven by increasing demand for electronic device protection across multiple industries. The technology maturity landscape shows traditional conformal coating as well-established, while nano-coating represents the innovative frontier with superior water-repellent and durability properties. Key players demonstrate varying technological approaches: 3M and Nordson dominate the traditional conformal coating sector with established manufacturing processes, while emerging companies like Jiangsu Favored Nanotechnology and Integrated Surface Technologies lead nano-coating innovation. Hon Hai Precision (Foxconn) and Seiko Epson represent major electronics manufacturers integrating these technologies, while research institutions like Naval Research Laboratory and Zhejiang University contribute to fundamental advancements in coating durability and performance characteristics.

3M Innovative Properties Co.

Technical Solution: 3M has developed a comprehensive portfolio of both conformal coatings and nano-coating technologies. Their conformal coating solutions include acrylic, urethane, silicone, and hybrid formulations designed for circuit board protection. Their proprietary Novec Electronic Grade Coatings utilize fluorinated compounds that provide thin-film protection (1-2 microns) while maintaining high dielectric strength. For nano-coatings, 3M employs plasma-enhanced chemical vapor deposition (PECVD) to create hydrophobic and oleophobic surfaces at nanoscale thicknesses. Their nano-coating technology incorporates fluoropolymer chemistry that creates covalent bonds with substrates, resulting in exceptional durability against abrasion and chemical exposure. Testing shows their nano-coatings maintain performance after 500+ abrasion cycles and exposure to pH ranges from 2-12[1][3].

Strengths: Extensive R&D capabilities allow for customized solutions across industries; global manufacturing ensures consistent quality and supply chain reliability; comprehensive testing protocols validate long-term performance claims. Weaknesses: Premium pricing compared to standard coating options; some nano-coating solutions require specialized application equipment; certain formulations contain fluorinated compounds facing increasing regulatory scrutiny.

Nordson Corp.

Technical Solution: Nordson has pioneered automated precision dispensing systems specifically optimized for both conformal coating and nano-coating applications. Their conformal coating technology focuses on selective application methods using their PreciseCoat and Film-Coater systems, which enable precise material deposition with minimal waste. For traditional conformal coatings, they've developed specialized spray valves and programmable motion systems that ensure uniform coverage even on complex PCB topographies. In the nano-coating space, Nordson has developed ultra-low viscosity dispensing technology capable of applying coatings at thicknesses below 100nm with exceptional uniformity. Their proprietary "MicroDot" technology enables selective nano-coating application at specific component levels rather than entire board treatment. Nordson's systems incorporate advanced vision systems for real-time quality control and coating verification, ensuring consistent application across high-volume manufacturing environments[2][5].

Strengths: Industry-leading precision in automated dispensing systems; comprehensive process control capabilities ensure coating consistency; modular design allows for production line integration and scalability. Weaknesses: Primary focus on application equipment rather than coating formulations requires partnerships with material suppliers; high capital investment for complete systems; requires technical expertise for optimal configuration and maintenance.

Key Patents and Technical Innovations in Coating Technologies

3D hybrid composite coating

PatentWO2019147959A1

Innovation

- A flexible self-cleaning coating is developed using a hierarchical architecture composed of functionalized epoxy resin and industrially available activated carbon or silica, featuring strong bonding and high chemical resistance, achieved through a ternary polymer composition with a fluoropolymer, fluoroalkyl-modified particles, and a radical initiator, enhancing mechanical and chemical stability.

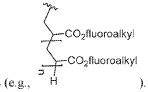

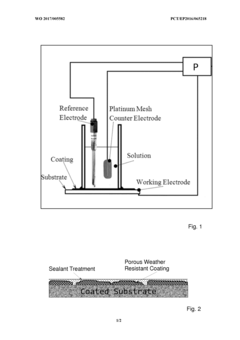

A surface treatment for enhanced resistance to corrosion and synergistic wear and corrosion (tribocorrosion) degradation

PatentWO2017005582A1

Innovation

- A Rare Earth Metal (REM)-based hybrid organic/inorganic coating is applied using a near-neutral pH electrodeposition process, which seals the porosity of underlying coatings, providing a conformal barrier that enhances both wear and corrosion resistance by penetrating and sealing the pores of wear-resistant coatings.

Environmental Impact and Sustainability Considerations

The environmental impact of protective coatings has become increasingly important as industries face stricter regulations and growing consumer demand for sustainable products. When comparing conformal coatings and nano-coatings, several key environmental considerations emerge that significantly influence their adoption across various sectors.

Traditional conformal coatings often contain volatile organic compounds (VOCs) that contribute to air pollution and pose health risks during application and curing processes. Many conventional acrylic and polyurethane conformal coatings release harmful emissions that require specialized ventilation systems and disposal protocols. These environmental concerns have prompted regulatory bodies worldwide to implement increasingly stringent restrictions on VOC content in industrial coatings.

In contrast, nano-coatings generally offer a more environmentally friendly profile. Many nano-coating formulations are water-based or contain significantly lower VOC levels than their traditional counterparts. The ultra-thin application layer of nano-coatings also means less material usage per protected surface, reducing overall resource consumption and waste generation throughout the product lifecycle.

The manufacturing processes for both coating types present different environmental challenges. Conformal coating production often involves energy-intensive processes and chemical precursors with substantial carbon footprints. Nano-coating manufacturing, while potentially using exotic materials, typically requires less energy and generates fewer waste byproducts due to the precision of nanoscale material synthesis.

End-of-life considerations reveal further distinctions. Conventional conformal coatings can be difficult to remove during electronic component recycling processes, potentially contaminating recycling streams or necessitating energy-intensive removal techniques. Nano-coatings, being significantly thinner, generally present fewer recycling obstacles and may allow for more efficient material recovery.

Sustainability certifications are increasingly influencing market adoption. Products utilizing environmentally friendly coating solutions can qualify for green building certifications, sustainable electronics designations, and other eco-labels that provide competitive advantages in environmentally conscious markets. Several nano-coating manufacturers have successfully positioned their products as sustainable alternatives, highlighting reduced chemical usage and lower environmental impact.

Recent life cycle assessment (LCA) studies comparing these technologies suggest that nano-coatings generally demonstrate superior environmental performance across multiple impact categories, including global warming potential, resource depletion, and ecotoxicity. However, concerns remain regarding the potential environmental implications of nanoparticle release during weathering or disposal of nano-coated products, an area requiring further research and regulatory attention.

Traditional conformal coatings often contain volatile organic compounds (VOCs) that contribute to air pollution and pose health risks during application and curing processes. Many conventional acrylic and polyurethane conformal coatings release harmful emissions that require specialized ventilation systems and disposal protocols. These environmental concerns have prompted regulatory bodies worldwide to implement increasingly stringent restrictions on VOC content in industrial coatings.

In contrast, nano-coatings generally offer a more environmentally friendly profile. Many nano-coating formulations are water-based or contain significantly lower VOC levels than their traditional counterparts. The ultra-thin application layer of nano-coatings also means less material usage per protected surface, reducing overall resource consumption and waste generation throughout the product lifecycle.

The manufacturing processes for both coating types present different environmental challenges. Conformal coating production often involves energy-intensive processes and chemical precursors with substantial carbon footprints. Nano-coating manufacturing, while potentially using exotic materials, typically requires less energy and generates fewer waste byproducts due to the precision of nanoscale material synthesis.

End-of-life considerations reveal further distinctions. Conventional conformal coatings can be difficult to remove during electronic component recycling processes, potentially contaminating recycling streams or necessitating energy-intensive removal techniques. Nano-coatings, being significantly thinner, generally present fewer recycling obstacles and may allow for more efficient material recovery.

Sustainability certifications are increasingly influencing market adoption. Products utilizing environmentally friendly coating solutions can qualify for green building certifications, sustainable electronics designations, and other eco-labels that provide competitive advantages in environmentally conscious markets. Several nano-coating manufacturers have successfully positioned their products as sustainable alternatives, highlighting reduced chemical usage and lower environmental impact.

Recent life cycle assessment (LCA) studies comparing these technologies suggest that nano-coatings generally demonstrate superior environmental performance across multiple impact categories, including global warming potential, resource depletion, and ecotoxicity. However, concerns remain regarding the potential environmental implications of nanoparticle release during weathering or disposal of nano-coated products, an area requiring further research and regulatory attention.

Cost-Benefit Analysis of Implementation Strategies

When evaluating implementation strategies for conformal coating versus nano-coating technologies, cost-benefit analysis reveals significant economic considerations that extend beyond initial application expenses. The implementation of conformal coatings typically requires substantial capital investment in equipment such as automated spray systems, dipping tanks, or selective coating machines, ranging from $50,000 to $250,000 depending on production volume and precision requirements. Operational costs include material expenses ($5-15 per liter), maintenance of application equipment, and quality control processes.

Nano-coating implementation presents a different cost structure, with higher initial material costs ($20-40 per liter) but potentially lower equipment investment requirements. Many nano-coating solutions can be applied using modified conventional equipment, reducing capital expenditure by 15-30% compared to traditional conformal coating systems. However, specialized curing equipment and environmental controls may offset these savings in certain applications.

Labor costs vary significantly between technologies. Conformal coating processes often require skilled technicians for masking, application, and inspection, with labor representing 25-40% of total implementation costs. Nano-coating processes generally require less manual intervention but may demand more specialized training, with labor typically accounting for 15-30% of implementation expenses.

Long-term economic benefits favor nano-coatings in harsh environment applications. Data from accelerated aging tests indicates that nano-coated electronics in marine environments demonstrate 30-45% longer functional lifespans compared to traditional conformal coatings, translating to reduced replacement costs and maintenance intervals. For automotive applications, this extended protection can represent lifetime cost savings of $75-120 per unit.

Return on investment (ROI) calculations reveal that while nano-coatings require 20-35% higher initial implementation costs, the break-even point typically occurs within 18-24 months for high-reliability applications. For consumer electronics with shorter product lifecycles, traditional conformal coatings may present better ROI unless premium pricing can be justified by enhanced product durability claims.

Scalability considerations also impact cost-benefit outcomes. Conformal coating processes demonstrate more predictable scaling economics, with per-unit costs decreasing approximately 12-18% when production volumes double. Nano-coating technologies currently show less favorable scaling economics, with cost reductions of only 8-12% at similar volume increases, though this gap is narrowing as the technology matures and supply chains develop.

Nano-coating implementation presents a different cost structure, with higher initial material costs ($20-40 per liter) but potentially lower equipment investment requirements. Many nano-coating solutions can be applied using modified conventional equipment, reducing capital expenditure by 15-30% compared to traditional conformal coating systems. However, specialized curing equipment and environmental controls may offset these savings in certain applications.

Labor costs vary significantly between technologies. Conformal coating processes often require skilled technicians for masking, application, and inspection, with labor representing 25-40% of total implementation costs. Nano-coating processes generally require less manual intervention but may demand more specialized training, with labor typically accounting for 15-30% of implementation expenses.

Long-term economic benefits favor nano-coatings in harsh environment applications. Data from accelerated aging tests indicates that nano-coated electronics in marine environments demonstrate 30-45% longer functional lifespans compared to traditional conformal coatings, translating to reduced replacement costs and maintenance intervals. For automotive applications, this extended protection can represent lifetime cost savings of $75-120 per unit.

Return on investment (ROI) calculations reveal that while nano-coatings require 20-35% higher initial implementation costs, the break-even point typically occurs within 18-24 months for high-reliability applications. For consumer electronics with shorter product lifecycles, traditional conformal coatings may present better ROI unless premium pricing can be justified by enhanced product durability claims.

Scalability considerations also impact cost-benefit outcomes. Conformal coating processes demonstrate more predictable scaling economics, with per-unit costs decreasing approximately 12-18% when production volumes double. Nano-coating technologies currently show less favorable scaling economics, with cost reductions of only 8-12% at similar volume increases, though this gap is narrowing as the technology matures and supply chains develop.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!