Design Criteria for Conformal Coating in IoT Device Protection

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

IoT Conformal Coating Background and Objectives

Conformal coating technology for IoT device protection has evolved significantly over the past three decades, transitioning from simple moisture barriers to sophisticated multi-functional protective layers. Originally developed for military and aerospace applications in the 1960s, these coatings have become increasingly critical for consumer electronics and IoT devices as miniaturization trends expose sensitive components to harsh environmental conditions. The evolution has been driven by the growing deployment of IoT devices in challenging environments including industrial settings, outdoor installations, and even medical implants.

The primary objective of modern conformal coating design for IoT applications is to create an optimal balance between protection efficacy and device functionality. This includes developing coatings that provide comprehensive environmental protection while maintaining thermal management properties, allowing for signal transmission, and preserving the operational integrity of sensors and communication modules. Additionally, these coatings must accommodate the increasingly complex geometries of IoT devices, including flexible substrates and three-dimensional interconnects.

Current technological trends in conformal coating development focus on nano-enhanced materials that offer superior protection at significantly reduced thicknesses. These advanced formulations aim to address the unique challenges posed by IoT devices, such as the need for coatings that can protect against multiple environmental threats simultaneously while remaining thin enough to avoid interference with device performance. Research indicates that next-generation coatings will likely incorporate self-healing properties and active protection mechanisms that can respond dynamically to environmental changes.

The market trajectory for conformal coatings in IoT protection shows a compound annual growth rate of approximately 5.8% between 2020 and 2025, reflecting the expanding IoT ecosystem and increasing awareness of device reliability requirements. This growth is particularly pronounced in sectors deploying IoT solutions in harsh environments, such as industrial automation, smart agriculture, and outdoor smart city infrastructure.

Technical standards for conformal coatings have also evolved, with organizations like IPC and IEEE developing specialized guidelines for IoT applications. These standards increasingly address not only traditional protection parameters but also considerations specific to IoT functionality, such as RF transparency and compatibility with energy harvesting components. The convergence of these technical developments points toward a future where conformal coatings become an integral part of IoT device design rather than a post-production consideration.

The primary objective of modern conformal coating design for IoT applications is to create an optimal balance between protection efficacy and device functionality. This includes developing coatings that provide comprehensive environmental protection while maintaining thermal management properties, allowing for signal transmission, and preserving the operational integrity of sensors and communication modules. Additionally, these coatings must accommodate the increasingly complex geometries of IoT devices, including flexible substrates and three-dimensional interconnects.

Current technological trends in conformal coating development focus on nano-enhanced materials that offer superior protection at significantly reduced thicknesses. These advanced formulations aim to address the unique challenges posed by IoT devices, such as the need for coatings that can protect against multiple environmental threats simultaneously while remaining thin enough to avoid interference with device performance. Research indicates that next-generation coatings will likely incorporate self-healing properties and active protection mechanisms that can respond dynamically to environmental changes.

The market trajectory for conformal coatings in IoT protection shows a compound annual growth rate of approximately 5.8% between 2020 and 2025, reflecting the expanding IoT ecosystem and increasing awareness of device reliability requirements. This growth is particularly pronounced in sectors deploying IoT solutions in harsh environments, such as industrial automation, smart agriculture, and outdoor smart city infrastructure.

Technical standards for conformal coatings have also evolved, with organizations like IPC and IEEE developing specialized guidelines for IoT applications. These standards increasingly address not only traditional protection parameters but also considerations specific to IoT functionality, such as RF transparency and compatibility with energy harvesting components. The convergence of these technical developments points toward a future where conformal coatings become an integral part of IoT device design rather than a post-production consideration.

Market Demand Analysis for Protected IoT Devices

The IoT device market is experiencing unprecedented growth, with projections indicating the number of connected devices worldwide will exceed 25 billion by 2025. This explosive expansion creates a substantial demand for protective solutions, particularly conformal coatings, which shield sensitive electronics from environmental threats. Market research reveals that industries including healthcare, automotive, industrial automation, and consumer electronics are driving this demand, with each sector requiring specialized protection parameters based on their operating environments.

Healthcare IoT devices, for instance, require coatings that can withstand frequent disinfection procedures while maintaining biocompatibility. The medical IoT segment is growing at approximately 28% annually, creating significant opportunities for advanced protective solutions that meet stringent regulatory requirements.

In the automotive sector, where harsh conditions prevail, demand for ruggedized IoT devices protected by high-performance conformal coatings is increasing as vehicles incorporate more connected technologies. This segment values coatings that offer resistance to vibration, temperature extremes, and chemical exposure.

Consumer electronics represents the largest volume market for protected IoT devices, with consumers increasingly expecting durability in wearables, smart home devices, and portable electronics. Market surveys indicate that 67% of consumers consider device durability a critical purchasing factor, directly influencing their willingness to pay premium prices.

Geographic market analysis shows Asia-Pacific leading manufacturing demand for conformal coating materials, while North America and Europe drive innovation in specialized coating technologies. Emerging markets are showing accelerated adoption rates as IoT infrastructure expands globally.

The economic value proposition for protected IoT devices is compelling. Field failure data indicates that unprotected devices in challenging environments experience failure rates 3-5 times higher than protected counterparts. When calculating total cost of ownership, the implementation of appropriate conformal coating can reduce warranty claims by up to 60% and extend device lifespan by 40-70% depending on the application environment.

Market segmentation reveals growing demand for environmentally friendly coating solutions, with 72% of OEMs expressing interest in sustainable alternatives to traditional solvent-based coatings. This trend aligns with global regulatory pressures and corporate sustainability initiatives.

Supply chain analysis indicates potential constraints in specialized coating materials, particularly those meeting stringent performance requirements while maintaining environmental compliance. This creates strategic opportunities for material innovation and process development to address market gaps in the protective coatings ecosystem for IoT devices.

Healthcare IoT devices, for instance, require coatings that can withstand frequent disinfection procedures while maintaining biocompatibility. The medical IoT segment is growing at approximately 28% annually, creating significant opportunities for advanced protective solutions that meet stringent regulatory requirements.

In the automotive sector, where harsh conditions prevail, demand for ruggedized IoT devices protected by high-performance conformal coatings is increasing as vehicles incorporate more connected technologies. This segment values coatings that offer resistance to vibration, temperature extremes, and chemical exposure.

Consumer electronics represents the largest volume market for protected IoT devices, with consumers increasingly expecting durability in wearables, smart home devices, and portable electronics. Market surveys indicate that 67% of consumers consider device durability a critical purchasing factor, directly influencing their willingness to pay premium prices.

Geographic market analysis shows Asia-Pacific leading manufacturing demand for conformal coating materials, while North America and Europe drive innovation in specialized coating technologies. Emerging markets are showing accelerated adoption rates as IoT infrastructure expands globally.

The economic value proposition for protected IoT devices is compelling. Field failure data indicates that unprotected devices in challenging environments experience failure rates 3-5 times higher than protected counterparts. When calculating total cost of ownership, the implementation of appropriate conformal coating can reduce warranty claims by up to 60% and extend device lifespan by 40-70% depending on the application environment.

Market segmentation reveals growing demand for environmentally friendly coating solutions, with 72% of OEMs expressing interest in sustainable alternatives to traditional solvent-based coatings. This trend aligns with global regulatory pressures and corporate sustainability initiatives.

Supply chain analysis indicates potential constraints in specialized coating materials, particularly those meeting stringent performance requirements while maintaining environmental compliance. This creates strategic opportunities for material innovation and process development to address market gaps in the protective coatings ecosystem for IoT devices.

Current Conformal Coating Technologies and Challenges

Conformal coating technologies for IoT device protection have evolved significantly over the past decade, with several distinct formulations now dominating the market. Acrylic coatings remain the most widely used due to their balance of protection, cost-effectiveness, and ease of application and repair. These coatings offer good moisture and dust resistance while maintaining excellent dielectric properties. Silicone coatings have gained prominence for applications requiring extreme temperature tolerance (-65°C to 200°C) and flexibility, making them ideal for IoT devices deployed in harsh environments.

Polyurethane coatings provide superior chemical and abrasion resistance, though they present challenges in rework processes. Epoxy formulations offer exceptional protection against moisture and chemicals but suffer from rigidity that can stress components during thermal cycling. Parylene coatings, applied through vapor deposition polymerization, provide the thinnest and most uniform coverage but require specialized vacuum chamber equipment, significantly increasing application costs.

Despite these advancements, the IoT industry faces several critical challenges in conformal coating implementation. Miniaturization trends in IoT devices create difficulties in achieving uniform coating application on increasingly dense PCBs with fine-pitch components. The coating must navigate tight spaces between components without creating air pockets or uneven coverage that could compromise protection.

Environmental compliance presents another significant challenge, as regulations increasingly restrict volatile organic compounds (VOCs) and certain halogenated compounds traditionally used in coatings. Manufacturers must reformulate products while maintaining performance characteristics, often resulting in trade-offs between environmental safety and protective capabilities.

Application precision remains problematic, particularly for selective coating processes where masking is required to keep connectors and test points free from coating. Automated selective coating systems improve precision but add equipment costs and complexity to production lines. The industry also struggles with quality control and verification methods, as traditional inspection techniques may not detect microscopic defects in coating coverage that could lead to device failure.

Thermal management considerations create additional complications, as coatings can potentially act as thermal insulators, trapping heat generated by IoT components. This is particularly problematic for edge computing devices with higher processing requirements. Coating formulations must balance protective properties with thermal conductivity to prevent overheating issues in compact IoT form factors.

The accelerated development cycles typical in IoT product development further complicate matters, as manufacturers have limited time for coating qualification and reliability testing, potentially leading to field failures when devices are deployed in unexpected environmental conditions.

Polyurethane coatings provide superior chemical and abrasion resistance, though they present challenges in rework processes. Epoxy formulations offer exceptional protection against moisture and chemicals but suffer from rigidity that can stress components during thermal cycling. Parylene coatings, applied through vapor deposition polymerization, provide the thinnest and most uniform coverage but require specialized vacuum chamber equipment, significantly increasing application costs.

Despite these advancements, the IoT industry faces several critical challenges in conformal coating implementation. Miniaturization trends in IoT devices create difficulties in achieving uniform coating application on increasingly dense PCBs with fine-pitch components. The coating must navigate tight spaces between components without creating air pockets or uneven coverage that could compromise protection.

Environmental compliance presents another significant challenge, as regulations increasingly restrict volatile organic compounds (VOCs) and certain halogenated compounds traditionally used in coatings. Manufacturers must reformulate products while maintaining performance characteristics, often resulting in trade-offs between environmental safety and protective capabilities.

Application precision remains problematic, particularly for selective coating processes where masking is required to keep connectors and test points free from coating. Automated selective coating systems improve precision but add equipment costs and complexity to production lines. The industry also struggles with quality control and verification methods, as traditional inspection techniques may not detect microscopic defects in coating coverage that could lead to device failure.

Thermal management considerations create additional complications, as coatings can potentially act as thermal insulators, trapping heat generated by IoT components. This is particularly problematic for edge computing devices with higher processing requirements. Coating formulations must balance protective properties with thermal conductivity to prevent overheating issues in compact IoT form factors.

The accelerated development cycles typical in IoT product development further complicate matters, as manufacturers have limited time for coating qualification and reliability testing, potentially leading to field failures when devices are deployed in unexpected environmental conditions.

Existing Conformal Coating Design Methodologies

01 Types of conformal coating materials for electronic protection

Various materials can be used as conformal coatings to protect electronic components from environmental factors. These include acrylic, silicone, polyurethane, epoxy, and parylene coatings. Each material offers different properties in terms of moisture resistance, chemical resistance, temperature stability, and ease of application. The selection of coating material depends on the specific protection requirements and operating conditions of the electronic components.- Types of conformal coating materials for electronic protection: Various materials can be used as conformal coatings to protect electronic components from environmental factors. These include acrylics, polyurethanes, silicones, epoxies, and parylene. Each material offers different properties in terms of moisture resistance, chemical resistance, temperature stability, and dielectric strength. The selection of coating material depends on the specific application requirements and environmental conditions the electronic components will face.

- Application methods for conformal coatings: Conformal coatings can be applied using various techniques including spraying, dipping, brushing, selective coating, and vapor deposition. Each method offers different advantages in terms of coverage, thickness control, and suitability for different production volumes. Automated application systems can improve consistency and efficiency in high-volume manufacturing environments, while selective coating techniques allow for precise application to specific areas of circuit boards.

- Environmental and thermal protection features: Conformal coatings provide protection against various environmental factors including moisture, dust, chemicals, and temperature fluctuations. Enhanced formulations can offer specific protection against harsh environments such as salt spray, humidity, and extreme temperatures. Some coatings incorporate additives that improve thermal conductivity to help dissipate heat from electronic components, which is crucial for maintaining optimal operating temperatures and extending device lifespan.

- Specialized coatings for specific industries: Specialized conformal coating formulations have been developed for specific industries such as automotive, aerospace, medical devices, and consumer electronics. These tailored coatings address industry-specific challenges such as vibration resistance for automotive applications, radiation resistance for aerospace, biocompatibility for medical devices, and miniaturization requirements for consumer electronics. The coatings may incorporate specific additives or modified chemical structures to meet these specialized requirements.

- Curing and removal processes: Various curing methods are employed for conformal coatings, including UV curing, thermal curing, moisture curing, and room temperature curing. The selection of curing method affects production speed, energy consumption, and coating properties. Some coatings are designed to be reworkable, allowing for selective removal when repairs or component replacements are needed. Specialized solvents and mechanical methods can be used for coating removal without damaging the underlying components.

02 Application methods for conformal coatings

Conformal coatings can be applied using various techniques to ensure optimal coverage and protection. Common application methods include spray coating, dip coating, brush coating, and automated selective coating. Advanced techniques such as vapor deposition for parylene coatings are also used for specialized applications. The choice of application method affects coating thickness, uniformity, and production efficiency.Expand Specific Solutions03 Environmental and mechanical protection features

Conformal coatings provide protection against various environmental and mechanical stressors. They shield electronic components from moisture, dust, chemicals, salt spray, and fungal growth. Additionally, they offer mechanical protection against vibration, thermal shock, and physical impact. Enhanced formulations may include UV stabilizers, flame retardants, and anti-static properties to address specific protection requirements in harsh operating environments.Expand Specific Solutions04 Specialized coatings for specific industries

Industry-specific conformal coating formulations have been developed to meet unique protection requirements. For automotive electronics, coatings resistant to fuel and oil are essential. Aerospace applications require coatings that can withstand extreme temperature fluctuations and low pressure environments. Medical device coatings focus on biocompatibility and sterilization resistance. Marine electronics need coatings with superior salt fog resistance and waterproofing properties.Expand Specific Solutions05 Reworkability and repair considerations

Some conformal coatings are designed with reworkability features that allow for repair and modification of electronic assemblies after coating application. These coatings can be selectively removed using specific solvents or mechanical methods without damaging the underlying components. Considerations for reworkable coatings include cure temperature, adhesion properties, and compatibility with cleaning agents. This feature is particularly important for prototyping, testing, and maintenance of electronic devices.Expand Specific Solutions

Leading Manufacturers and Suppliers in Conformal Coating Industry

The IoT device protection conformal coating market is in a growth phase, characterized by increasing adoption across diverse industries. The market is expanding rapidly due to the proliferation of IoT devices requiring environmental protection, with projections indicating substantial growth over the next five years. Technologically, conformal coating solutions are evolving from traditional methods to advanced nano-coating technologies. Leading players like Nordson Corp. and HzO, Inc. are developing specialized solutions for IoT applications, while companies such as Actnano and Semblant Ltd. are pioneering nanotechnology-based protective coatings. Established industrial giants including 3M, Honeywell, and Texas Instruments are leveraging their manufacturing expertise to develop integrated protection solutions, creating a competitive landscape balanced between specialized coating innovators and diversified technology corporations.

Nordson Corp.

Technical Solution: Nordson has developed advanced precision dispensing systems specifically for conformal coating applications in IoT devices. Their technology includes automated selective coating equipment that utilizes both atomized spray and non-atomized film coating techniques to achieve precise material application. Their systems feature path programming capabilities that ensure coating is applied only where needed, avoiding sensitive components like connectors and test points. Nordson's solutions incorporate UV cure verification systems that validate coating coverage in real-time, ensuring quality control throughout the manufacturing process. Their equipment is designed to handle the increasing miniaturization of IoT devices, with precision down to 0.1mm coating width capabilities and the ability to navigate complex 3D topographies common in modern IoT circuit boards.

Strengths: Exceptional precision in application control, automated systems reduce human error, integrated quality verification systems. Weaknesses: Higher initial capital investment compared to manual methods, requires technical expertise for programming and maintenance, may have limitations with extremely complex board geometries.

3M Innovative Properties Co.

Technical Solution: 3M has pioneered fluoropolymer-based conformal coatings specifically engineered for IoT device protection. Their technology utilizes a combination of acrylic, urethane, and silicone-based formulations that provide exceptional moisture resistance while maintaining electrical insulation properties. 3M's coatings feature low viscosity formulations (typically 30-250 cPs) that enable penetration into tight spaces between components, critical for densely packed IoT devices. Their solutions incorporate fast-curing mechanisms that reduce manufacturing cycle times, with some formulations curing in under 30 minutes at room temperature. 3M has also developed specialized coatings with enhanced chemical resistance to withstand exposure to industrial environments where IoT sensors are increasingly deployed. Their coatings maintain flexibility across wide temperature ranges (-65°C to +200°C), accommodating the thermal cycling common in IoT applications.

Strengths: Extensive material science expertise, formulations tailored to specific environmental challenges, established global supply chain and technical support. Weaknesses: Some formulations may require specialized application equipment, premium pricing compared to generic alternatives, removal for rework can be challenging with certain formulations.

Key Innovations in IoT Device Protection Materials

Conformal coatings comprising carbon nanotubes

PatentInactiveUS20070120100A1

Innovation

- A conformal coating comprising an insulating layer and a conductive layer, where the conductive layer is made of carbon nanotubes, providing EMI shielding with a range of 5-70 dB attenuation, and can be combined with conventional polymers like acrylics, epoxies, and silicones.

Process for manufacturing an electronic device

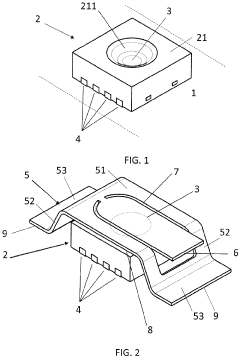

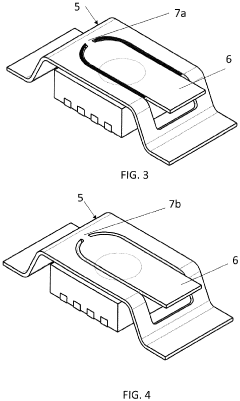

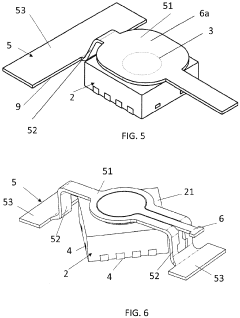

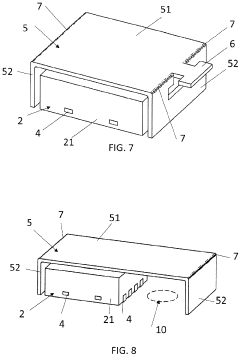

PatentPendingEP3879561A1

Innovation

- A process involving surface mounting a protection cap on a substrate to cover sensitive areas, allowing conformal coating to be applied while ensuring the sensitive areas remain uncoated, using a protection cap that can be automatically mounted and removed or deformed post-coating, ensuring reliable protection of the substrate and components.

Environmental Impact and Sustainability Considerations

The environmental impact of conformal coating processes in IoT device protection has become increasingly significant as global sustainability initiatives gain momentum. Traditional coating materials often contain volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) that contribute to air pollution and pose health risks to workers. Recent regulatory frameworks, including the European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH), have accelerated the transition toward environmentally friendly alternatives in the electronics manufacturing sector.

Water-based and UV-curable conformal coatings represent promising sustainable alternatives, offering reduced VOC emissions while maintaining adequate protection levels for IoT devices. These formulations typically reduce harmful emissions by 80-95% compared to conventional solvent-based systems. Additionally, their application processes generally consume less energy, with UV-curing methods requiring approximately 30-40% less energy than thermal curing approaches used for traditional coatings.

End-of-life considerations present another critical environmental dimension. The increasing volume of electronic waste (e-waste), projected to reach 74 million metric tons annually by 2030, underscores the importance of designing conformal coatings that do not impede recycling processes. Bio-based and biodegradable coating materials derived from renewable resources such as plant oils and starches are emerging as viable options, though their long-term protection capabilities require further validation for IoT applications in harsh environments.

Life Cycle Assessment (LCA) studies indicate that the environmental footprint of conformal coatings extends beyond manufacturing to include raw material extraction, transportation, application, use phase, and disposal. Comprehensive LCA data reveals that thin-film coatings with optimized application techniques can reduce the overall carbon footprint by 15-25% compared to conventional thick-layer protection methods, while maintaining equivalent protection standards for IoT devices.

Manufacturing process optimization presents significant opportunities for environmental improvement. Precision application technologies such as selective coating and automated spray systems can reduce material waste by up to 30-40%, decreasing both environmental impact and production costs. Furthermore, closed-loop solvent recovery systems can recapture and reuse up to 90% of solvents that would otherwise be released into the atmosphere or require disposal as hazardous waste.

The development of conformal coatings with extended service life directly contributes to IoT device longevity, reducing replacement frequency and associated resource consumption. Research indicates that high-performance sustainable coatings can extend device operational life in outdoor environments by 3-5 years, representing a significant sustainability advantage through reduced material consumption and e-waste generation over time.

Water-based and UV-curable conformal coatings represent promising sustainable alternatives, offering reduced VOC emissions while maintaining adequate protection levels for IoT devices. These formulations typically reduce harmful emissions by 80-95% compared to conventional solvent-based systems. Additionally, their application processes generally consume less energy, with UV-curing methods requiring approximately 30-40% less energy than thermal curing approaches used for traditional coatings.

End-of-life considerations present another critical environmental dimension. The increasing volume of electronic waste (e-waste), projected to reach 74 million metric tons annually by 2030, underscores the importance of designing conformal coatings that do not impede recycling processes. Bio-based and biodegradable coating materials derived from renewable resources such as plant oils and starches are emerging as viable options, though their long-term protection capabilities require further validation for IoT applications in harsh environments.

Life Cycle Assessment (LCA) studies indicate that the environmental footprint of conformal coatings extends beyond manufacturing to include raw material extraction, transportation, application, use phase, and disposal. Comprehensive LCA data reveals that thin-film coatings with optimized application techniques can reduce the overall carbon footprint by 15-25% compared to conventional thick-layer protection methods, while maintaining equivalent protection standards for IoT devices.

Manufacturing process optimization presents significant opportunities for environmental improvement. Precision application technologies such as selective coating and automated spray systems can reduce material waste by up to 30-40%, decreasing both environmental impact and production costs. Furthermore, closed-loop solvent recovery systems can recapture and reuse up to 90% of solvents that would otherwise be released into the atmosphere or require disposal as hazardous waste.

The development of conformal coatings with extended service life directly contributes to IoT device longevity, reducing replacement frequency and associated resource consumption. Research indicates that high-performance sustainable coatings can extend device operational life in outdoor environments by 3-5 years, representing a significant sustainability advantage through reduced material consumption and e-waste generation over time.

Regulatory Compliance and Industry Standards

Regulatory compliance and industry standards play a crucial role in the design and implementation of conformal coatings for IoT device protection. These standards ensure that coated devices meet safety requirements, perform reliably in intended environments, and comply with regional and international regulations. The landscape of applicable standards is complex and continuously evolving as IoT applications expand into new sectors.

IPC-CC-830C represents the foundational standard for conformal coating materials used in electronic assemblies. This standard classifies coatings into different types (AR, ER, SR, UR, XY) based on their chemical composition and establishes performance requirements for each type. For IoT devices deployed in harsh environments, compliance with IPC-CC-830C ensures baseline protection against moisture, dust, and chemical contaminants.

UL 746E specifically addresses polymeric materials used for coating electronic circuits, focusing on flammability, electrical properties, and long-term reliability. IoT devices intended for consumer applications must often meet these requirements to obtain safety certifications necessary for market access. Similarly, IEC 60068 series standards define environmental testing procedures that coated IoT devices must withstand, including temperature cycling, humidity exposure, and salt spray resistance.

Military and aerospace applications have more stringent requirements outlined in MIL-I-46058C and NASA-STD-8739.1, which specify additional testing protocols for conformal coatings in mission-critical systems. While consumer IoT devices may not require this level of compliance, industrial and medical IoT applications increasingly adopt these higher standards to ensure reliability.

Regional regulations add another layer of complexity. The European Union's RoHS and REACH directives restrict the use of certain hazardous substances in electronic equipment, directly impacting coating formulations. Similarly, China's RoHS and various national environmental regulations worldwide necessitate region-specific coating solutions for globally distributed IoT products.

Emerging standards specifically addressing IoT device protection are being developed by organizations such as ASTM International and IEEE. These standards focus on the unique challenges of IoT deployments, including miniaturization, power constraints, and extended field life requirements. The IEC 63203 series, currently under development, aims to establish standards specifically for wearable electronic devices, including appropriate protection methodologies.

Industry-specific standards further complicate the regulatory landscape. Medical IoT devices must comply with ISO 13485 and FDA requirements, automotive IoT applications must meet ISO 26262 and various automotive standards, while industrial IoT systems often need to satisfy IEC 61508 for functional safety. Each sector imposes unique requirements on conformal coating performance, documentation, and validation processes.

IPC-CC-830C represents the foundational standard for conformal coating materials used in electronic assemblies. This standard classifies coatings into different types (AR, ER, SR, UR, XY) based on their chemical composition and establishes performance requirements for each type. For IoT devices deployed in harsh environments, compliance with IPC-CC-830C ensures baseline protection against moisture, dust, and chemical contaminants.

UL 746E specifically addresses polymeric materials used for coating electronic circuits, focusing on flammability, electrical properties, and long-term reliability. IoT devices intended for consumer applications must often meet these requirements to obtain safety certifications necessary for market access. Similarly, IEC 60068 series standards define environmental testing procedures that coated IoT devices must withstand, including temperature cycling, humidity exposure, and salt spray resistance.

Military and aerospace applications have more stringent requirements outlined in MIL-I-46058C and NASA-STD-8739.1, which specify additional testing protocols for conformal coatings in mission-critical systems. While consumer IoT devices may not require this level of compliance, industrial and medical IoT applications increasingly adopt these higher standards to ensure reliability.

Regional regulations add another layer of complexity. The European Union's RoHS and REACH directives restrict the use of certain hazardous substances in electronic equipment, directly impacting coating formulations. Similarly, China's RoHS and various national environmental regulations worldwide necessitate region-specific coating solutions for globally distributed IoT products.

Emerging standards specifically addressing IoT device protection are being developed by organizations such as ASTM International and IEEE. These standards focus on the unique challenges of IoT deployments, including miniaturization, power constraints, and extended field life requirements. The IEC 63203 series, currently under development, aims to establish standards specifically for wearable electronic devices, including appropriate protection methodologies.

Industry-specific standards further complicate the regulatory landscape. Medical IoT devices must comply with ISO 13485 and FDA requirements, automotive IoT applications must meet ISO 26262 and various automotive standards, while industrial IoT systems often need to satisfy IEC 61508 for functional safety. Each sector imposes unique requirements on conformal coating performance, documentation, and validation processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!