Measure UV Resistance of Conformal Coating Materials

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UV Resistance Testing Background and Objectives

Conformal coating materials have been widely used in electronic manufacturing since the 1970s to protect printed circuit boards (PCBs) and electronic components from environmental factors such as moisture, dust, chemicals, and temperature fluctuations. Among these environmental challenges, ultraviolet (UV) radiation presents a significant threat to the longevity and reliability of these protective coatings. The measurement of UV resistance in conformal coating materials has evolved from rudimentary exposure tests to sophisticated analytical methodologies over the past decades.

The primary objective of UV resistance testing for conformal coatings is to evaluate and quantify how these materials withstand prolonged exposure to ultraviolet radiation without significant degradation in their protective properties. This assessment is crucial as UV-induced degradation can lead to yellowing, cracking, delamination, and ultimately failure of the protective barrier, compromising the functionality of the underlying electronic components.

Historical development in this field shows a progression from simple outdoor exposure tests to accelerated aging chambers that simulate years of UV exposure in compressed timeframes. The introduction of spectrophotometric analysis in the 1990s allowed for more precise quantification of UV-induced changes in optical properties, while advances in materials science enabled the development of more sophisticated analytical techniques for evaluating molecular-level degradation.

Current industry standards for UV resistance testing include ASTM G154, IEC 60068-2-5, and ISO 4892, which provide standardized methodologies for evaluating the effects of UV exposure on materials. These standards have evolved to address the increasing complexity of conformal coating formulations and the diverse environmental conditions in which electronic devices operate.

The technological evolution in this field aims to establish correlations between accelerated laboratory testing and real-world performance, enabling more accurate predictions of coating lifespan under various environmental conditions. This predictive capability is becoming increasingly important as electronic devices are deployed in more extreme environments, from desert solar installations to maritime applications where UV exposure is particularly intense.

Recent research focuses on developing multi-parameter assessment methodologies that evaluate not only visual changes but also electrical insulation properties, adhesion strength, and chemical composition alterations following UV exposure. These comprehensive approaches provide a more holistic understanding of how UV radiation affects the protective functionality of conformal coatings.

The ultimate goal of advancing UV resistance measurement techniques is to enable the development of more durable conformal coating materials that can maintain their protective properties throughout the intended service life of electronic devices, thereby enhancing reliability and reducing maintenance requirements in critical applications such as aerospace, automotive, and medical electronics.

The primary objective of UV resistance testing for conformal coatings is to evaluate and quantify how these materials withstand prolonged exposure to ultraviolet radiation without significant degradation in their protective properties. This assessment is crucial as UV-induced degradation can lead to yellowing, cracking, delamination, and ultimately failure of the protective barrier, compromising the functionality of the underlying electronic components.

Historical development in this field shows a progression from simple outdoor exposure tests to accelerated aging chambers that simulate years of UV exposure in compressed timeframes. The introduction of spectrophotometric analysis in the 1990s allowed for more precise quantification of UV-induced changes in optical properties, while advances in materials science enabled the development of more sophisticated analytical techniques for evaluating molecular-level degradation.

Current industry standards for UV resistance testing include ASTM G154, IEC 60068-2-5, and ISO 4892, which provide standardized methodologies for evaluating the effects of UV exposure on materials. These standards have evolved to address the increasing complexity of conformal coating formulations and the diverse environmental conditions in which electronic devices operate.

The technological evolution in this field aims to establish correlations between accelerated laboratory testing and real-world performance, enabling more accurate predictions of coating lifespan under various environmental conditions. This predictive capability is becoming increasingly important as electronic devices are deployed in more extreme environments, from desert solar installations to maritime applications where UV exposure is particularly intense.

Recent research focuses on developing multi-parameter assessment methodologies that evaluate not only visual changes but also electrical insulation properties, adhesion strength, and chemical composition alterations following UV exposure. These comprehensive approaches provide a more holistic understanding of how UV radiation affects the protective functionality of conformal coatings.

The ultimate goal of advancing UV resistance measurement techniques is to enable the development of more durable conformal coating materials that can maintain their protective properties throughout the intended service life of electronic devices, thereby enhancing reliability and reducing maintenance requirements in critical applications such as aerospace, automotive, and medical electronics.

Market Demand for UV-Resistant Conformal Coatings

The global market for UV-resistant conformal coatings has experienced significant growth in recent years, driven primarily by the expanding electronics industry and increasing demand for reliable protection solutions in harsh environments. The market value for specialized conformal coatings reached approximately $12.8 billion in 2022, with UV-resistant variants constituting about 28% of this segment. Industry analysts project a compound annual growth rate of 5.7% through 2028.

Electronics manufacturers represent the largest consumer segment, particularly those producing outdoor equipment, automotive electronics, aerospace components, and medical devices. These industries require materials that can withstand prolonged UV exposure without degradation of protective properties. The automotive sector alone accounts for 23% of the total market demand, as vehicle electronics increasingly face harsh environmental conditions including direct sunlight exposure.

Consumer electronics manufacturers have also emerged as significant market players, seeking UV-resistant coatings for portable devices that may experience frequent outdoor use. This segment has grown at 7.2% annually since 2019, outpacing the overall market growth rate.

Geographically, Asia-Pacific dominates the market with 42% share, driven by the concentration of electronics manufacturing in countries like China, Japan, South Korea, and Taiwan. North America follows with 27% market share, with particular strength in aerospace, defense, and medical device applications where performance requirements are exceptionally stringent.

The demand for enhanced UV resistance correlates directly with warranty costs across industries. Electronics manufacturers report that environmental damage, including UV degradation, contributes to approximately 31% of warranty claims for outdoor electronic products. This has intensified research into more effective UV-resistant formulations.

Market research indicates growing customer preference for multifunctional coatings that combine UV resistance with other protective properties such as moisture resistance, chemical resistance, and thermal stability. This trend has pushed coating manufacturers to develop advanced formulations that address multiple environmental threats simultaneously.

Regulatory factors are also shaping market demand, with environmental regulations in Europe and North America driving interest in water-based and low-VOC UV-resistant coating solutions. The transition toward more environmentally friendly formulations represents both a challenge and opportunity for manufacturers in this space.

Electronics manufacturers represent the largest consumer segment, particularly those producing outdoor equipment, automotive electronics, aerospace components, and medical devices. These industries require materials that can withstand prolonged UV exposure without degradation of protective properties. The automotive sector alone accounts for 23% of the total market demand, as vehicle electronics increasingly face harsh environmental conditions including direct sunlight exposure.

Consumer electronics manufacturers have also emerged as significant market players, seeking UV-resistant coatings for portable devices that may experience frequent outdoor use. This segment has grown at 7.2% annually since 2019, outpacing the overall market growth rate.

Geographically, Asia-Pacific dominates the market with 42% share, driven by the concentration of electronics manufacturing in countries like China, Japan, South Korea, and Taiwan. North America follows with 27% market share, with particular strength in aerospace, defense, and medical device applications where performance requirements are exceptionally stringent.

The demand for enhanced UV resistance correlates directly with warranty costs across industries. Electronics manufacturers report that environmental damage, including UV degradation, contributes to approximately 31% of warranty claims for outdoor electronic products. This has intensified research into more effective UV-resistant formulations.

Market research indicates growing customer preference for multifunctional coatings that combine UV resistance with other protective properties such as moisture resistance, chemical resistance, and thermal stability. This trend has pushed coating manufacturers to develop advanced formulations that address multiple environmental threats simultaneously.

Regulatory factors are also shaping market demand, with environmental regulations in Europe and North America driving interest in water-based and low-VOC UV-resistant coating solutions. The transition toward more environmentally friendly formulations represents both a challenge and opportunity for manufacturers in this space.

Current Challenges in UV Resistance Measurement

Despite significant advancements in UV resistance measurement methodologies, the field continues to face several critical challenges that impede accurate assessment of conformal coating materials. One primary obstacle is the lack of standardized testing protocols specifically designed for conformal coatings. While standards like ASTM G154 and ISO 4892 exist for general UV testing, they fail to address the unique characteristics of thin-film conformal coatings applied to electronic substrates.

The correlation between accelerated aging tests and real-world performance remains problematic. Current accelerated UV testing chambers often produce radiation profiles that inadequately simulate natural sunlight spectra, particularly in the critical UV-B (280-315nm) range where most photodegradation occurs. This spectral mismatch leads to unreliable predictions of actual field performance, with acceleration factors varying widely depending on coating chemistry.

Measurement reproducibility presents another significant challenge. Inter-laboratory studies have revealed variations exceeding 15% in UV resistance results for identical coating samples, highlighting issues with equipment calibration, sample preparation consistency, and environmental control during testing. These variations make comparative analysis between different coating formulations exceptionally difficult.

The complex interaction between UV exposure and other environmental stressors compounds measurement difficulties. Conformal coatings in real applications rarely experience UV radiation in isolation; they simultaneously encounter humidity, temperature cycling, and chemical exposure. Current measurement approaches struggle to replicate these synergistic degradation mechanisms, leading to incomplete performance profiles.

Quantification methods for UV degradation also present challenges. While visual inspection, gloss measurement, and color change analysis are common, they provide limited insight into functional property changes. More sophisticated techniques like FTIR spectroscopy can detect chemical changes but require specialized expertise for proper interpretation and may not directly correlate with coating performance metrics relevant to electronic protection.

Miniaturization trends in electronics have introduced additional complications, as coatings must now be evaluated at increasingly thinner application thicknesses (often <50μm). At these dimensions, traditional UV resistance measurement techniques lose sensitivity, and edge effects become disproportionately influential, necessitating new micro-scale evaluation methodologies.

Finally, the industry faces challenges in developing predictive models that can accurately forecast long-term UV stability based on short-term test data. Current mathematical models struggle to account for non-linear degradation patterns and the complex photochemistry of modern multi-component coating systems, limiting their practical utility for product development and qualification.

The correlation between accelerated aging tests and real-world performance remains problematic. Current accelerated UV testing chambers often produce radiation profiles that inadequately simulate natural sunlight spectra, particularly in the critical UV-B (280-315nm) range where most photodegradation occurs. This spectral mismatch leads to unreliable predictions of actual field performance, with acceleration factors varying widely depending on coating chemistry.

Measurement reproducibility presents another significant challenge. Inter-laboratory studies have revealed variations exceeding 15% in UV resistance results for identical coating samples, highlighting issues with equipment calibration, sample preparation consistency, and environmental control during testing. These variations make comparative analysis between different coating formulations exceptionally difficult.

The complex interaction between UV exposure and other environmental stressors compounds measurement difficulties. Conformal coatings in real applications rarely experience UV radiation in isolation; they simultaneously encounter humidity, temperature cycling, and chemical exposure. Current measurement approaches struggle to replicate these synergistic degradation mechanisms, leading to incomplete performance profiles.

Quantification methods for UV degradation also present challenges. While visual inspection, gloss measurement, and color change analysis are common, they provide limited insight into functional property changes. More sophisticated techniques like FTIR spectroscopy can detect chemical changes but require specialized expertise for proper interpretation and may not directly correlate with coating performance metrics relevant to electronic protection.

Miniaturization trends in electronics have introduced additional complications, as coatings must now be evaluated at increasingly thinner application thicknesses (often <50μm). At these dimensions, traditional UV resistance measurement techniques lose sensitivity, and edge effects become disproportionately influential, necessitating new micro-scale evaluation methodologies.

Finally, the industry faces challenges in developing predictive models that can accurately forecast long-term UV stability based on short-term test data. Current mathematical models struggle to account for non-linear degradation patterns and the complex photochemistry of modern multi-component coating systems, limiting their practical utility for product development and qualification.

Standard UV Resistance Measurement Protocols

01 UV-resistant polymer compositions for conformal coatings

Various polymer compositions can be formulated to provide UV resistance in conformal coatings. These include polyurethane, silicone, acrylic, and epoxy-based formulations that contain UV stabilizers or inherently UV-resistant polymers. These materials form protective layers that shield electronic components from UV radiation while maintaining flexibility and adhesion properties necessary for conformal coating applications.- UV-resistant polymer compositions for conformal coatings: Various polymer compositions can be formulated to provide UV resistance in conformal coatings. These include polyurethane, silicone, acrylic, and epoxy-based formulations that incorporate specific additives to enhance UV stability. These polymer systems create protective barriers that maintain their integrity when exposed to ultraviolet radiation, preventing yellowing and degradation of the underlying components.

- UV absorbers and stabilizers in conformal coatings: Specific UV absorbers and stabilizers can be incorporated into conformal coating formulations to enhance their resistance to ultraviolet radiation. These additives, such as benzotriazoles, benzophenones, and hindered amine light stabilizers (HALS), work by absorbing harmful UV radiation or neutralizing free radicals formed during photodegradation, thereby extending the coating's service life and maintaining its protective properties.

- Nanoparticle-enhanced UV protection in conformal coatings: Nanoparticles such as zinc oxide, titanium dioxide, and cerium oxide can be dispersed in conformal coating formulations to provide enhanced UV protection. These nanoparticles effectively absorb and scatter ultraviolet radiation while maintaining coating transparency. The small particle size allows for uniform distribution throughout the coating matrix, providing consistent protection without compromising the coating's electrical insulation properties.

- Multi-layer conformal coating systems for UV protection: Multi-layer conformal coating systems can be designed to provide enhanced UV resistance. These systems typically consist of a base layer for adhesion and electrical insulation, a middle layer containing UV absorbers and stabilizers, and a top layer with additional UV protection and environmental resistance. This layered approach provides comprehensive protection against ultraviolet radiation while maintaining other required properties such as moisture resistance and dielectric strength.

- UV-curable conformal coatings with inherent UV resistance: UV-curable conformal coating formulations can be designed with inherent UV resistance. These coatings utilize specific oligomers and monomers that, once cured, form networks resistant to further UV degradation. The formulations may include cycloaliphatic components, fluorinated compounds, or silicon-based materials that provide stability against ultraviolet radiation while offering rapid curing, low VOC emissions, and excellent electrical insulation properties.

02 UV-blocking additives and stabilizers

Specific additives can be incorporated into conformal coating formulations to enhance UV resistance. These include UV absorbers like benzotriazoles and benzophenones, hindered amine light stabilizers (HALS), and inorganic particles such as zinc oxide and titanium dioxide. These additives work by absorbing harmful UV radiation or neutralizing free radicals formed during UV exposure, thereby extending the coating's service life and protecting underlying substrates.Expand Specific Solutions03 Nanoparticle-enhanced UV-resistant coatings

Nanomaterials are increasingly being incorporated into conformal coatings to improve UV resistance. Nanoparticles such as nano-silica, nano-titanium dioxide, and nano-zinc oxide can be dispersed within coating matrices to provide superior UV protection without compromising optical clarity or other coating properties. These nanocomposite coatings offer enhanced durability and protection for electronic components in outdoor or high-UV environments.Expand Specific Solutions04 Multi-layer conformal coating systems for UV protection

Multi-layer coating approaches can provide enhanced UV protection for sensitive electronics. These systems typically combine different materials with complementary properties - such as a primary protective layer with good adhesion and flexibility, topped with a UV-resistant outer layer. This approach allows for optimization of both the protective and UV-resistant properties without compromising other performance characteristics.Expand Specific Solutions05 UV-curable conformal coatings with built-in UV resistance

UV-curable conformal coating formulations can be designed with inherent UV resistance after curing. These coatings typically contain specialized monomers, oligomers, and photoinitiators that not only enable rapid UV curing but also form chemical structures resistant to UV degradation. The resulting coatings provide excellent protection against UV radiation while offering advantages like fast processing, low VOC emissions, and good mechanical properties.Expand Specific Solutions

Key Industry Players in Conformal Coating Materials

The UV resistance testing of conformal coating materials is currently in a growth phase, with the market expanding due to increasing demand in electronics, automotive, and aerospace industries. The global conformal coating market is estimated to reach $15-20 billion by 2025, driven by miniaturization trends and harsh environment applications. Technologically, the field is moderately mature but evolving, with companies like 3M, PPG Industries, and Momentive Performance Materials leading innovation through advanced polymer formulations. Siemens and FUJIFILM are advancing testing methodologies, while specialty chemical manufacturers such as Wacker Chemie, Kansai Paint, and Evonik Operations are developing UV-resistant formulations with enhanced durability properties. Academic-industry collaborations with institutions like Georgia Tech Research Corp. are accelerating material science breakthroughs in this domain.

3M Innovative Properties Co.

Technical Solution: 3M has developed advanced UV resistance testing protocols for conformal coatings that combine accelerated weathering chambers with spectrophotometric analysis. Their proprietary QUV accelerated weathering testers simulate sunlight using fluorescent UV lamps, controlled temperature, and moisture conditions to replicate years of outdoor exposure in just weeks. 3M's methodology incorporates ASTM G154 standards while adding proprietary metrics that measure both physical degradation and electrical performance retention. Their dual-measurement approach quantifies both visual changes (yellowing, cracking) and functional properties (dielectric strength, adhesion) before and after exposure. 3M has also pioneered correlation studies between accelerated testing and real-world performance data collected from field installations across diverse climate zones.

Strengths: Comprehensive testing methodology that evaluates both aesthetic and functional properties; extensive historical database for performance correlation; global testing facilities enabling region-specific UV resistance profiles. Weakness: Proprietary testing equipment may limit accessibility; testing protocols may be optimized for 3M's own materials rather than providing industry-neutral evaluations.

PPG Industries Ohio, Inc.

Technical Solution: PPG has developed a sophisticated UV resistance measurement system for conformal coatings called UVSCANTM that combines spectral analysis with physical property testing. Their approach utilizes specialized xenon-arc chambers that precisely replicate the solar spectrum while monitoring coating performance in real-time. PPG's methodology incorporates both ASTM G155 and ISO 16474-2 standards, enhanced with proprietary algorithms that predict long-term performance from accelerated test data. Their system measures critical parameters including gloss retention, color stability, surface degradation, and mechanical property changes at programmed intervals. PPG has also developed specialized testing for automotive and aerospace applications where UV exposure is combined with other environmental stressors like temperature cycling, chemical exposure, and humidity fluctuations to simulate real-world conditions more accurately.

Strengths: Industry-leading correlation between accelerated testing and real-world performance; specialized testing protocols for different industry applications; comprehensive data analytics for performance prediction. Weaknesses: Testing equipment requires significant capital investment; methodology may be optimized for higher-end coating systems rather than economical solutions.

Advanced Spectroscopic Analysis Techniques

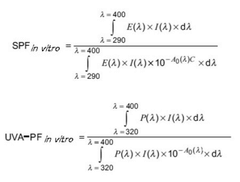

Method for measuring ultraviolet protection effect or infrared protection effect of aqueous composition containing ultraviolet absorbing agent or infrared blocking agent, and apparatus for preparing measurement sample

PatentWO2018047707A1

Innovation

- Applying a light-absorbing aqueous composition to a substrate with a contact angle of 0 to 70 degrees, achieved through plasma or corona discharge treatment, to ensure a uniform and thin coating film, allowing for accurate measurement of absorbance and protection effects.

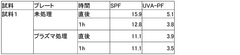

Apparatus for monitoring a coating

PatentInactiveGB2575543A

Innovation

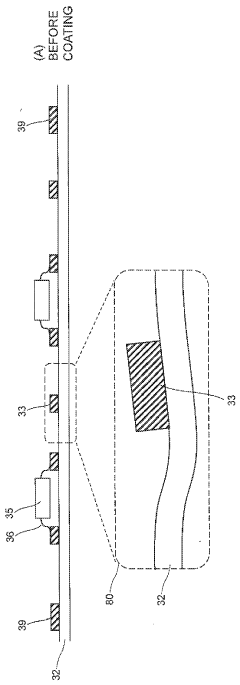

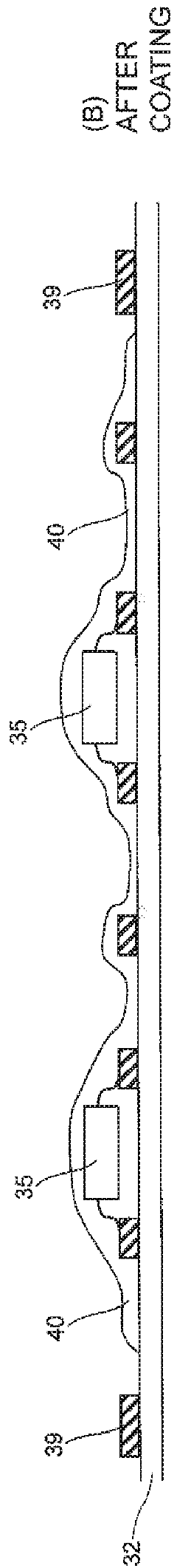

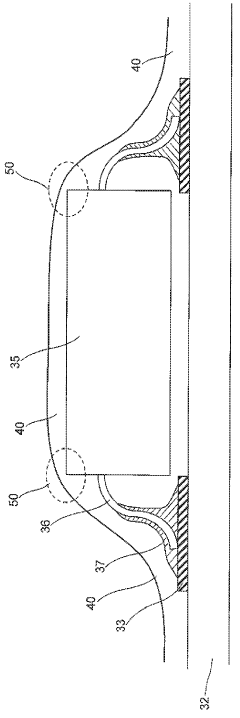

- A non-destructive apparatus and method that determines the thickness of conformal coatings by measuring the height profiles of electronic assemblies before and after coating application, compensating for optical properties using an adjustment factor, and utilizing a triangulation scanner or optical radiation source to assess coating thickness across the entire assembly, including components and solder joints.

Environmental Factors Affecting Coating Degradation

The degradation of conformal coatings under ultraviolet (UV) exposure is influenced by multiple environmental factors that can work synergistically to accelerate material breakdown. Temperature plays a critical role in this process, as higher temperatures typically increase the rate of photochemical reactions initiated by UV radiation. Research indicates that for every 10°C increase in temperature, the degradation rate of many coating materials can double, creating a significant challenge for applications in environments with both high UV and thermal stress.

Humidity represents another crucial factor affecting coating performance under UV exposure. Water molecules can penetrate coating matrices, causing hydrolysis reactions that weaken polymer bonds already compromised by UV radiation. Studies have shown that relative humidity levels above 75% can dramatically accelerate UV-induced degradation in many acrylic and polyurethane-based conformal coatings, reducing their effective service life by up to 40%.

Atmospheric pollutants, particularly ozone, sulfur dioxide, and nitrogen oxides, can interact with UV-damaged coating surfaces to create aggressive chemical environments. These pollutants can initiate secondary degradation mechanisms that would not occur with UV exposure alone. Industrial environments with high concentrations of these contaminants have demonstrated coating failure rates up to three times faster than controlled laboratory UV testing would predict.

Mechanical stress factors, including vibration, thermal cycling, and physical abrasion, can exacerbate UV degradation by creating microcracks that expose additional surface area to radiation. These physical stresses are particularly relevant in automotive and aerospace applications, where coated electronic components experience both UV exposure and continuous mechanical loading.

The presence of oxygen is fundamental to many UV degradation mechanisms, as it enables photo-oxidation processes that break down polymer chains. Research has demonstrated that UV degradation rates in oxygen-rich environments can be up to five times faster than in inert atmospheres, highlighting the importance of considering atmospheric composition when evaluating coating performance.

Cyclic exposure patterns, where materials experience alternating periods of UV radiation and darkness, often produce more severe degradation than continuous exposure at equivalent cumulative doses. This phenomenon, known as the "recovery effect," occurs because certain chemical reactions initiated during UV exposure continue during dark periods, creating unique degradation pathways not observed in constant exposure testing.

AI-powered predictive models are now being developed to simulate the combined effects of these environmental factors, allowing for more accurate estimation of coating service life under specific deployment conditions. These models incorporate multi-factor analysis to account for the complex interactions between UV radiation and other environmental stressors.

Humidity represents another crucial factor affecting coating performance under UV exposure. Water molecules can penetrate coating matrices, causing hydrolysis reactions that weaken polymer bonds already compromised by UV radiation. Studies have shown that relative humidity levels above 75% can dramatically accelerate UV-induced degradation in many acrylic and polyurethane-based conformal coatings, reducing their effective service life by up to 40%.

Atmospheric pollutants, particularly ozone, sulfur dioxide, and nitrogen oxides, can interact with UV-damaged coating surfaces to create aggressive chemical environments. These pollutants can initiate secondary degradation mechanisms that would not occur with UV exposure alone. Industrial environments with high concentrations of these contaminants have demonstrated coating failure rates up to three times faster than controlled laboratory UV testing would predict.

Mechanical stress factors, including vibration, thermal cycling, and physical abrasion, can exacerbate UV degradation by creating microcracks that expose additional surface area to radiation. These physical stresses are particularly relevant in automotive and aerospace applications, where coated electronic components experience both UV exposure and continuous mechanical loading.

The presence of oxygen is fundamental to many UV degradation mechanisms, as it enables photo-oxidation processes that break down polymer chains. Research has demonstrated that UV degradation rates in oxygen-rich environments can be up to five times faster than in inert atmospheres, highlighting the importance of considering atmospheric composition when evaluating coating performance.

Cyclic exposure patterns, where materials experience alternating periods of UV radiation and darkness, often produce more severe degradation than continuous exposure at equivalent cumulative doses. This phenomenon, known as the "recovery effect," occurs because certain chemical reactions initiated during UV exposure continue during dark periods, creating unique degradation pathways not observed in constant exposure testing.

AI-powered predictive models are now being developed to simulate the combined effects of these environmental factors, allowing for more accurate estimation of coating service life under specific deployment conditions. These models incorporate multi-factor analysis to account for the complex interactions between UV radiation and other environmental stressors.

Accelerated Aging Test Methodologies

Accelerated aging test methodologies represent a critical approach for evaluating the UV resistance of conformal coating materials in a time-efficient manner. These methodologies simulate prolonged exposure to ultraviolet radiation and other environmental stressors through intensified conditions, allowing researchers to predict long-term performance characteristics within a compressed timeframe.

The most widely adopted accelerated UV aging test is ASTM G154, which utilizes fluorescent UV lamps to simulate sunlight exposure. This test alternates between UV exposure and condensation cycles, typically running for 1,000 to 2,000 hours to represent several years of actual environmental exposure. The QUV accelerated weathering tester has become the industry standard equipment for implementing this methodology.

Another significant methodology is ASTM D4587, specifically designed for coatings and related products. This test employs UVA-340 lamps that closely match the solar spectrum in the critical short wavelength UV region, providing more accurate simulation of natural weathering conditions for conformal coatings used in outdoor electronic applications.

For more severe testing requirements, xenon arc chambers (ASTM G155) offer full-spectrum simulation including UV, visible light, and infrared radiation. This methodology is particularly valuable for conformal coatings designed for aerospace and automotive applications where materials face extreme environmental conditions.

Temperature cycling tests are frequently combined with UV exposure to evaluate the synergistic effects of thermal stress and photodegradation. ASTM D1183 outlines procedures for resistance to artificial weathering with exposure to artificial light and water, incorporating temperature variations to simulate day-night cycles.

The IEC 61215 methodology, though primarily developed for photovoltaic modules, has been adapted for testing conformal coatings used in solar applications. This comprehensive test includes 1,000 hours of UV preconditioning followed by thermal cycling, humidity freeze, and damp heat exposure.

Quantitative assessment metrics within these methodologies typically include yellowness index (ASTM E313), gloss retention (ASTM D523), color change (ASTM D2244), and surface degradation analysis through scanning electron microscopy. Mechanical property evaluations such as adhesion strength (ASTM D3359), pencil hardness (ASTM D3363), and flexibility (ASTM D522) provide additional performance indicators after accelerated aging.

Correlation factors between accelerated testing and real-world performance remain a significant challenge, with most methodologies employing multiplication factors ranging from 3:1 to 12:1 depending on the specific environmental conditions being simulated. Recent advancements in methodology development have focused on improving these correlation models through machine learning algorithms that analyze historical performance data.

The most widely adopted accelerated UV aging test is ASTM G154, which utilizes fluorescent UV lamps to simulate sunlight exposure. This test alternates between UV exposure and condensation cycles, typically running for 1,000 to 2,000 hours to represent several years of actual environmental exposure. The QUV accelerated weathering tester has become the industry standard equipment for implementing this methodology.

Another significant methodology is ASTM D4587, specifically designed for coatings and related products. This test employs UVA-340 lamps that closely match the solar spectrum in the critical short wavelength UV region, providing more accurate simulation of natural weathering conditions for conformal coatings used in outdoor electronic applications.

For more severe testing requirements, xenon arc chambers (ASTM G155) offer full-spectrum simulation including UV, visible light, and infrared radiation. This methodology is particularly valuable for conformal coatings designed for aerospace and automotive applications where materials face extreme environmental conditions.

Temperature cycling tests are frequently combined with UV exposure to evaluate the synergistic effects of thermal stress and photodegradation. ASTM D1183 outlines procedures for resistance to artificial weathering with exposure to artificial light and water, incorporating temperature variations to simulate day-night cycles.

The IEC 61215 methodology, though primarily developed for photovoltaic modules, has been adapted for testing conformal coatings used in solar applications. This comprehensive test includes 1,000 hours of UV preconditioning followed by thermal cycling, humidity freeze, and damp heat exposure.

Quantitative assessment metrics within these methodologies typically include yellowness index (ASTM E313), gloss retention (ASTM D523), color change (ASTM D2244), and surface degradation analysis through scanning electron microscopy. Mechanical property evaluations such as adhesion strength (ASTM D3359), pencil hardness (ASTM D3363), and flexibility (ASTM D522) provide additional performance indicators after accelerated aging.

Correlation factors between accelerated testing and real-world performance remain a significant challenge, with most methodologies employing multiplication factors ranging from 3:1 to 12:1 depending on the specific environmental conditions being simulated. Recent advancements in methodology development have focused on improving these correlation models through machine learning algorithms that analyze historical performance data.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!