Enhance Conformal Coating Surface Smoothness for Aesthetics

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conformal Coating Evolution and Aesthetic Goals

Conformal coating technology has evolved significantly since its inception in the mid-20th century, initially developed for military and aerospace applications where electronic components required protection from harsh environmental conditions. The early formulations were primarily focused on functionality rather than appearance, with silicone and acrylic-based coatings dominating the market. These early coatings provided adequate protection but often resulted in uneven surfaces, visible brush marks, and inconsistent thickness that detracted from the aesthetic appeal of the finished product.

As consumer electronics proliferated in the 1980s and 1990s, the demand for conformal coatings expanded beyond purely functional applications to include considerations of product aesthetics. This shift coincided with the miniaturization of electronic components and the increasing visibility of circuit boards in consumer products, creating a need for coatings that not only protected but also enhanced visual appeal.

The technological evolution of conformal coatings has been characterized by several key developments. The introduction of UV-curable formulations in the late 1990s represented a significant advancement, allowing for faster processing times and reduced environmental impact. Subsequently, the development of nano-enhanced coatings in the early 2000s provided improved surface tension properties, contributing to smoother application and finish.

Current aesthetic goals in conformal coating technology center around achieving glass-like transparency, uniform thickness, and elimination of surface imperfections such as orange peel effect, bubbles, and flow lines. The industry is increasingly focused on coatings that can self-level during application and curing, creating a perfectly smooth surface that enhances rather than detracts from product appearance.

The trend toward transparent electronic devices and components has further elevated the importance of coating aesthetics. Modern consumers expect electronic products to have a premium look and feel, with visible internal components appearing as intentional design elements rather than merely functional necessities. This has driven research toward coatings that not only protect but also optically enhance the appearance of the underlying components.

Looking forward, the trajectory of conformal coating development is moving toward multi-functional formulations that combine superior aesthetic properties with enhanced protection capabilities. The integration of smart materials that can change appearance based on environmental conditions or user interaction represents the next frontier in coating technology, potentially enabling new forms of product differentiation and user experience.

As consumer electronics proliferated in the 1980s and 1990s, the demand for conformal coatings expanded beyond purely functional applications to include considerations of product aesthetics. This shift coincided with the miniaturization of electronic components and the increasing visibility of circuit boards in consumer products, creating a need for coatings that not only protected but also enhanced visual appeal.

The technological evolution of conformal coatings has been characterized by several key developments. The introduction of UV-curable formulations in the late 1990s represented a significant advancement, allowing for faster processing times and reduced environmental impact. Subsequently, the development of nano-enhanced coatings in the early 2000s provided improved surface tension properties, contributing to smoother application and finish.

Current aesthetic goals in conformal coating technology center around achieving glass-like transparency, uniform thickness, and elimination of surface imperfections such as orange peel effect, bubbles, and flow lines. The industry is increasingly focused on coatings that can self-level during application and curing, creating a perfectly smooth surface that enhances rather than detracts from product appearance.

The trend toward transparent electronic devices and components has further elevated the importance of coating aesthetics. Modern consumers expect electronic products to have a premium look and feel, with visible internal components appearing as intentional design elements rather than merely functional necessities. This has driven research toward coatings that not only protect but also optically enhance the appearance of the underlying components.

Looking forward, the trajectory of conformal coating development is moving toward multi-functional formulations that combine superior aesthetic properties with enhanced protection capabilities. The integration of smart materials that can change appearance based on environmental conditions or user interaction represents the next frontier in coating technology, potentially enabling new forms of product differentiation and user experience.

Market Demand for High-Aesthetic Surface Finishes

The global market for high-aesthetic surface finishes in conformal coatings has experienced significant growth in recent years, driven primarily by consumer electronics, automotive interior components, and luxury goods sectors. This growth reflects a fundamental shift in consumer preferences towards products that not only function well but also exhibit premium visual and tactile qualities.

Consumer electronics manufacturers have been at the forefront of demanding enhanced surface aesthetics, as devices like smartphones, tablets, and wearables have evolved from purely functional tools to fashion accessories and status symbols. Market research indicates that consumers are willing to pay a premium of 15-20% for devices with superior finish quality, particularly those with smooth, uniform coatings that create a perception of luxury and precision engineering.

The automotive industry represents another substantial market segment, with high-end vehicle manufacturers investing heavily in interior components that feature flawless surface finishes. The tactile experience of interacting with smooth, consistently coated surfaces has become a key differentiator in the luxury automotive market, where perceived quality directly influences purchasing decisions.

Medical device manufacturers have also recognized the importance of aesthetic surface finishes, particularly for patient-facing devices. Studies show that patients report higher confidence in medical equipment that exhibits professional, smooth finishes, creating an association between visual quality and perceived effectiveness of the device.

Market analysis reveals regional variations in demand patterns. Asia-Pacific leads in volume demand, particularly in consumer electronics manufacturing hubs, while North American and European markets demonstrate higher willingness to pay premiums for superior aesthetic qualities. This regional differentiation creates opportunities for tiered product offerings in the conformal coating market.

Industry forecasts project the market for high-aesthetic conformal coatings to grow at a compound annual rate of 7.8% through 2028, outpacing the broader conformal coating market's growth rate of 5.3%. This accelerated growth is attributed to increasing consumer expectations regarding product aesthetics across all price points, not just in premium segments.

Manufacturers across industries report that surface imperfections, particularly orange peel effects, uneven thickness, and visible particulate contamination, represent significant quality control challenges that directly impact rejection rates and customer satisfaction. The economic impact of these aesthetic defects extends beyond immediate production costs to include brand perception and customer loyalty metrics.

Consumer electronics manufacturers have been at the forefront of demanding enhanced surface aesthetics, as devices like smartphones, tablets, and wearables have evolved from purely functional tools to fashion accessories and status symbols. Market research indicates that consumers are willing to pay a premium of 15-20% for devices with superior finish quality, particularly those with smooth, uniform coatings that create a perception of luxury and precision engineering.

The automotive industry represents another substantial market segment, with high-end vehicle manufacturers investing heavily in interior components that feature flawless surface finishes. The tactile experience of interacting with smooth, consistently coated surfaces has become a key differentiator in the luxury automotive market, where perceived quality directly influences purchasing decisions.

Medical device manufacturers have also recognized the importance of aesthetic surface finishes, particularly for patient-facing devices. Studies show that patients report higher confidence in medical equipment that exhibits professional, smooth finishes, creating an association between visual quality and perceived effectiveness of the device.

Market analysis reveals regional variations in demand patterns. Asia-Pacific leads in volume demand, particularly in consumer electronics manufacturing hubs, while North American and European markets demonstrate higher willingness to pay premiums for superior aesthetic qualities. This regional differentiation creates opportunities for tiered product offerings in the conformal coating market.

Industry forecasts project the market for high-aesthetic conformal coatings to grow at a compound annual rate of 7.8% through 2028, outpacing the broader conformal coating market's growth rate of 5.3%. This accelerated growth is attributed to increasing consumer expectations regarding product aesthetics across all price points, not just in premium segments.

Manufacturers across industries report that surface imperfections, particularly orange peel effects, uneven thickness, and visible particulate contamination, represent significant quality control challenges that directly impact rejection rates and customer satisfaction. The economic impact of these aesthetic defects extends beyond immediate production costs to include brand perception and customer loyalty metrics.

Current Challenges in Conformal Coating Smoothness

Despite significant advancements in conformal coating technologies, achieving optimal surface smoothness remains a persistent challenge for manufacturers seeking superior aesthetic qualities. Current conformal coating processes frequently result in surface imperfections that compromise the visual appeal of electronic components and consumer devices. These imperfections include orange peel effects, bubbles, pinholes, and uneven thickness distribution, all of which detract from the premium appearance desired in high-end products.

Material limitations constitute a primary obstacle in achieving smooth conformal coatings. Traditional coating materials such as acrylics, silicones, and polyurethanes each present unique challenges regarding flow characteristics, curing behavior, and surface tension properties. Silicone coatings, while offering excellent flexibility and temperature resistance, are particularly prone to surface irregularities due to their high viscosity and distinctive curing mechanism.

Application methodologies significantly impact coating smoothness. Conventional techniques including dipping, spraying, and brushing often introduce inconsistencies in coating thickness and texture. Spray application, though widely employed, frequently produces micro-textured surfaces resembling orange peel when parameters such as spray pressure, distance, and material viscosity are not precisely controlled. Automated systems have improved consistency but have not eliminated these issues entirely.

Environmental factors during application and curing processes substantially influence coating smoothness. Humidity, temperature fluctuations, and airborne contaminants can trigger premature curing, create moisture entrapment, or facilitate dust inclusion, all resulting in visible surface defects. Controlling these variables in production environments presents considerable difficulties, particularly in facilities without cleanroom capabilities.

The inherent conflict between functional requirements and aesthetic considerations compounds these challenges. Conformal coatings must primarily provide protection against moisture, chemicals, and mechanical stress, which often necessitates formulations that prioritize these protective properties over surface appearance. Balancing these competing demands requires sophisticated material engineering that many current solutions have not fully achieved.

Quality control and measurement standards for surface smoothness represent another significant challenge. The industry lacks standardized, quantitative methods for evaluating aesthetic qualities of conformal coatings. Most assessments rely on subjective visual inspection or basic gloss measurements, which fail to capture the multidimensional aspects of perceived smoothness and premium appearance. This absence of objective metrics hampers both development efforts and quality assurance processes.

Material limitations constitute a primary obstacle in achieving smooth conformal coatings. Traditional coating materials such as acrylics, silicones, and polyurethanes each present unique challenges regarding flow characteristics, curing behavior, and surface tension properties. Silicone coatings, while offering excellent flexibility and temperature resistance, are particularly prone to surface irregularities due to their high viscosity and distinctive curing mechanism.

Application methodologies significantly impact coating smoothness. Conventional techniques including dipping, spraying, and brushing often introduce inconsistencies in coating thickness and texture. Spray application, though widely employed, frequently produces micro-textured surfaces resembling orange peel when parameters such as spray pressure, distance, and material viscosity are not precisely controlled. Automated systems have improved consistency but have not eliminated these issues entirely.

Environmental factors during application and curing processes substantially influence coating smoothness. Humidity, temperature fluctuations, and airborne contaminants can trigger premature curing, create moisture entrapment, or facilitate dust inclusion, all resulting in visible surface defects. Controlling these variables in production environments presents considerable difficulties, particularly in facilities without cleanroom capabilities.

The inherent conflict between functional requirements and aesthetic considerations compounds these challenges. Conformal coatings must primarily provide protection against moisture, chemicals, and mechanical stress, which often necessitates formulations that prioritize these protective properties over surface appearance. Balancing these competing demands requires sophisticated material engineering that many current solutions have not fully achieved.

Quality control and measurement standards for surface smoothness represent another significant challenge. The industry lacks standardized, quantitative methods for evaluating aesthetic qualities of conformal coatings. Most assessments rely on subjective visual inspection or basic gloss measurements, which fail to capture the multidimensional aspects of perceived smoothness and premium appearance. This absence of objective metrics hampers both development efforts and quality assurance processes.

Current Surface Smoothness Enhancement Techniques

01 Surface preparation techniques for conformal coating smoothness

Various surface preparation techniques can be employed to enhance the smoothness of conformal coatings. These include cleaning processes to remove contaminants, polishing methods to reduce surface roughness, and pre-treatment procedures that improve coating adhesion. Proper surface preparation ensures that the conformal coating can be applied evenly, resulting in a smoother finish that provides better protection for electronic components.- Surface preparation techniques for conformal coating smoothness: Various surface preparation techniques can significantly improve the smoothness of conformal coatings. These include cleaning, polishing, and treating the substrate surface before applying the coating. Proper preparation removes contaminants, reduces surface irregularities, and ensures better adhesion, resulting in a smoother final coating with fewer defects and improved protection properties.

- Advanced coating application methods for enhanced smoothness: Different application methods can be employed to achieve smoother conformal coatings. Techniques such as spray coating, dip coating, and vapor deposition offer varying degrees of surface smoothness. Controlled application parameters including temperature, humidity, and application speed significantly impact the final surface quality. Advanced automated systems can provide more consistent coating thickness and superior surface finish compared to manual application methods.

- Formulation additives for improved coating flow and leveling: Specific additives in conformal coating formulations can enhance surface smoothness by improving flow characteristics and leveling properties. Flow modifiers, leveling agents, and surfactants reduce surface tension and allow the coating to spread more evenly. Silicone-based additives and specialized polymers can eliminate surface defects such as orange peel, fish eyes, and craters, resulting in a more uniform and smoother protective layer.

- Curing processes and their impact on surface smoothness: The curing process significantly affects the final surface smoothness of conformal coatings. Controlled curing parameters including temperature profiles, humidity levels, and curing time optimize polymer cross-linking and prevent surface defects. UV curing, thermal curing, and moisture curing methods each offer different advantages for surface quality. Gradual or staged curing approaches can minimize stress in the coating and prevent surface irregularities from forming during the solidification process.

- Quality control and measurement techniques for surface smoothness: Various measurement and quality control techniques are essential for evaluating and ensuring conformal coating surface smoothness. Optical profilometry, atomic force microscopy, and laser scanning provide quantitative data on surface roughness parameters. Visual inspection methods using specialized lighting can identify surface defects. Standardized testing protocols help maintain consistent surface quality across production batches, ensuring the protective and aesthetic properties of the conformal coating meet specifications.

02 Advanced coating application methods for improved surface finish

Different application methods can significantly impact the surface smoothness of conformal coatings. Techniques such as spray coating, dip coating, and automated dispensing systems can be optimized to achieve uniform coating thickness and minimize surface irregularities. Parameters like application speed, distance, and environmental conditions during application play crucial roles in determining the final surface smoothness of the conformal coating.Expand Specific Solutions03 Formulation additives for enhanced coating leveling

Specific additives can be incorporated into conformal coating formulations to improve surface leveling and smoothness. These include flow modifiers, leveling agents, and surface tension adjusters that help the coating to spread evenly and self-level during application and curing. The proper selection and concentration of these additives can significantly enhance the surface smoothness of the final coating while maintaining other desired properties.Expand Specific Solutions04 Curing process optimization for surface smoothness

The curing process significantly affects the final surface smoothness of conformal coatings. Parameters such as temperature profiles, humidity levels, and curing time can be optimized to prevent surface defects like orange peel, bubbles, or uneven shrinkage. Advanced curing technologies, including UV curing, thermal curing, and moisture curing, can be tailored to specific coating formulations to achieve optimal surface smoothness.Expand Specific Solutions05 Surface quality measurement and control methods

Various techniques and instruments can be used to measure and control the surface smoothness of conformal coatings. These include optical profilometry, atomic force microscopy, and laser scanning methods that provide quantitative data on surface roughness parameters. Implementing quality control processes with these measurement techniques enables manufacturers to maintain consistent surface smoothness standards and identify process improvements for conformal coating applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The conformal coating surface smoothness enhancement market is currently in a growth phase, driven by increasing demand for aesthetic improvements in electronics, automotive, and consumer products. The global market size is estimated to be expanding at a CAGR of 5-7%, with particular acceleration in high-end applications. Technologically, the field is moderately mature but evolving rapidly, with key players demonstrating varying levels of innovation. Companies like 3M, DuPont, and Merck Patent GmbH lead with advanced formulation technologies, while specialized players such as Kansai Paint and Wacker Chemie focus on application-specific solutions. Boeing and TDK represent end-users driving requirements for aerospace and electronics applications respectively. Research institutions like North Carolina State University and Leibniz-Institut für Oberflächenmodifizierung are advancing fundamental coating science, creating a competitive ecosystem balancing established chemical giants with specialized coating innovators.

3M Innovative Properties Co.

Technical Solution: 3M has developed advanced conformal coating technologies that enhance surface smoothness through their proprietary fluoropolymer-based solutions. Their approach involves multi-layer coating systems with self-leveling properties that minimize surface tension variations during application and curing. The company utilizes nano-silica additives (20-50nm) dispersed within acrylic and urethane matrices to create exceptionally smooth surfaces with Ra values below 0.1μm. 3M's process incorporates controlled viscosity management during application, with precise temperature ramping (5-10°C/min) during curing to prevent surface defects. Their UV-curable formulations contain modified flow agents that promote molecular reorganization during the liquid phase, resulting in optically smooth surfaces with enhanced aesthetic appeal. The technology also employs surface-active additives that reduce orange peel effects by up to 85% compared to conventional coatings.

Strengths: Superior surface leveling capabilities across various substrate materials; excellent optical clarity with gloss levels >95%; exceptional weathering resistance maintaining aesthetics over extended periods. Weaknesses: Higher material costs compared to standard conformal coatings; requires specialized application equipment for optimal results; more complex process control parameters needed for consistent quality.

Merck Patent GmbH

Technical Solution: Merck has pioneered liquid crystal polymer (LCP) technology for conformal coatings with exceptional surface smoothness. Their approach utilizes self-organizing molecular structures that naturally form ultra-smooth surfaces during curing. The technology incorporates specially designed reactive mesogenic compounds that align parallel to the substrate surface, creating molecularly flat protective layers. Merck's formulations include proprietary surface tension modifiers that reduce coating defects by promoting uniform wetting and leveling during application. Their process involves precise thermal management during curing, with controlled temperature gradients (typically 2-3°C/minute) to optimize molecular alignment. The resulting coatings exhibit remarkably low surface roughness (Ra values of 0.05-0.08μm) while maintaining excellent protective properties. Merck has also developed hybrid organic-inorganic coating systems incorporating functionalized siloxanes that enhance both smoothness and durability, with cross-linking densities carefully controlled to balance flexibility and surface hardness.

Strengths: Exceptional molecular-level smoothness; outstanding optical properties with minimal light scattering; excellent chemical resistance while maintaining aesthetic qualities. Weaknesses: Higher production costs than conventional coatings; requires precise application conditions; more sensitive to substrate preparation quality; limited compatibility with some electronic components.

Key Innovations in Coating Material Science

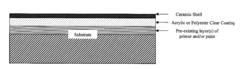

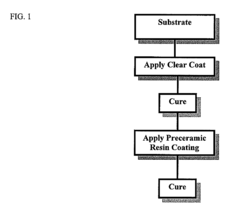

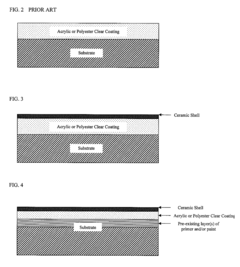

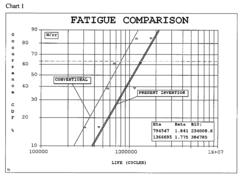

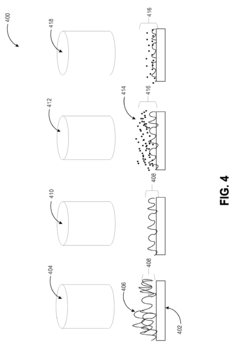

Method of surface coating to enhance durability of aesthetics and substrate component fatigue

PatentInactiveUS20090162544A1

Innovation

- A method involving a uniform clear coating layer followed by a preceramic resin film application, resulting in a cured ceramic shell of 3 to 12 microns thickness, which enhances impact resistance, abrasion resistance, corrosion resistance, and ease of cleaning.

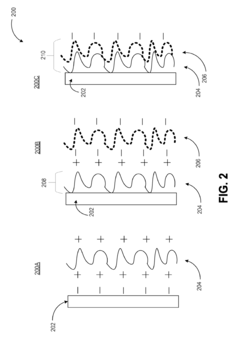

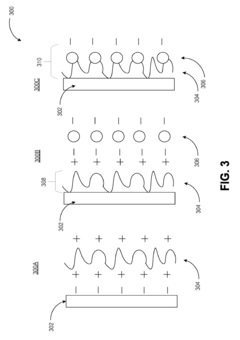

Methods and systems for increasing surface smoothness of three-dimensional printed article

PatentInactiveUS10220409B2

Innovation

- A water-based treatment using layer-by-layer (LBL) deposition, where an initial 3D printed article with an anionic surface is treated with a polycation solution followed by an anionic microparticle solution, forming a conformal coating that enhances surface smoothness without using volatile organics.

Environmental Impact and Sustainability Considerations

The environmental impact of conformal coating processes has become increasingly significant as industries strive for sustainable manufacturing practices. Traditional conformal coating methods often involve volatile organic compounds (VOCs) and hazardous air pollutants that contribute to air quality degradation and pose health risks to workers. Recent regulatory frameworks, including the European Union's Restriction of Hazardous Substances (RoHS) directive and various regional clean air acts, have accelerated the transition toward environmentally friendly coating alternatives.

Water-based conformal coatings represent a promising sustainable solution, offering reduced VOC emissions while maintaining aesthetic surface smoothness. These formulations typically contain 80-95% less harmful solvents compared to conventional solvent-based systems. However, challenges remain in achieving equivalent surface tension properties and flow characteristics that influence the final aesthetic appearance.

Energy consumption during curing processes presents another environmental consideration. UV-curable coatings have gained traction for their reduced energy requirements, consuming approximately 75% less energy than thermal curing methods while delivering superior surface smoothness. This reduction translates to a significantly lower carbon footprint across large-scale manufacturing operations.

Material efficiency improvements have emerged through precision application technologies such as selective coating and atomized spray systems. These approaches minimize overspray and reduce material waste by up to 30% compared to traditional dipping methods, while simultaneously enhancing surface uniformity and aesthetic quality. The environmental benefits extend to reduced chemical waste management requirements and associated disposal costs.

End-of-life considerations have prompted research into biodegradable conformal coating formulations. Bio-based polymers derived from renewable resources show promise in creating coatings that maintain aesthetic properties while offering improved environmental profiles. Early studies indicate these materials can achieve comparable surface smoothness while decomposing 40-60% faster than petroleum-based alternatives under controlled conditions.

Lifecycle assessment (LCA) methodologies are increasingly being applied to evaluate the comprehensive environmental impact of conformal coating processes. These assessments reveal that improvements in surface smoothness often correlate with reduced material usage and extended product lifespans, creating a positive environmental feedback loop. Products with superior aesthetic finishes typically experience longer market acceptance and delayed replacement cycles, further enhancing sustainability through reduced consumption patterns.

Water-based conformal coatings represent a promising sustainable solution, offering reduced VOC emissions while maintaining aesthetic surface smoothness. These formulations typically contain 80-95% less harmful solvents compared to conventional solvent-based systems. However, challenges remain in achieving equivalent surface tension properties and flow characteristics that influence the final aesthetic appearance.

Energy consumption during curing processes presents another environmental consideration. UV-curable coatings have gained traction for their reduced energy requirements, consuming approximately 75% less energy than thermal curing methods while delivering superior surface smoothness. This reduction translates to a significantly lower carbon footprint across large-scale manufacturing operations.

Material efficiency improvements have emerged through precision application technologies such as selective coating and atomized spray systems. These approaches minimize overspray and reduce material waste by up to 30% compared to traditional dipping methods, while simultaneously enhancing surface uniformity and aesthetic quality. The environmental benefits extend to reduced chemical waste management requirements and associated disposal costs.

End-of-life considerations have prompted research into biodegradable conformal coating formulations. Bio-based polymers derived from renewable resources show promise in creating coatings that maintain aesthetic properties while offering improved environmental profiles. Early studies indicate these materials can achieve comparable surface smoothness while decomposing 40-60% faster than petroleum-based alternatives under controlled conditions.

Lifecycle assessment (LCA) methodologies are increasingly being applied to evaluate the comprehensive environmental impact of conformal coating processes. These assessments reveal that improvements in surface smoothness often correlate with reduced material usage and extended product lifespans, creating a positive environmental feedback loop. Products with superior aesthetic finishes typically experience longer market acceptance and delayed replacement cycles, further enhancing sustainability through reduced consumption patterns.

Quality Control and Testing Methodologies

Quality control and testing methodologies are critical components in the pursuit of enhanced conformal coating surface smoothness for aesthetic applications. The evaluation of coating quality requires a comprehensive approach that combines visual inspection, quantitative measurement, and standardized testing protocols. Surface profilometry stands as a primary method for quantifying surface smoothness, utilizing optical or contact-based instruments to measure surface roughness parameters such as Ra (average roughness) and Rz (maximum height). These measurements provide objective data for comparing different coating formulations and application techniques.

Gloss measurement represents another essential testing methodology, directly correlating with perceived aesthetic quality. Using glossmeters at standardized angles (typically 20°, 60°, and 85°), manufacturers can quantify the specular reflection characteristics of coated surfaces. Higher gloss readings generally indicate smoother surfaces with enhanced aesthetic appeal, though market preferences may vary across different product categories.

Advanced imaging techniques have revolutionized quality control processes in conformal coating applications. Digital microscopy, scanning electron microscopy (SEM), and 3D optical profiling enable detailed visualization and analysis of surface topography at micro and nano scales. These technologies allow for the identification of coating defects such as orange peel, fisheyes, craters, and other imperfections that might compromise aesthetic quality while remaining invisible to the naked eye.

Automated vision systems equipped with machine learning algorithms represent the cutting edge in quality control for high-volume production environments. These systems can detect subtle variations in surface appearance, ensuring consistency across production batches. The integration of artificial intelligence has significantly improved detection accuracy while reducing false positives in defect identification.

Standardized testing protocols such as ASTM D523 (Standard Test Method for Specular Gloss) and ISO 2813 (Paints and varnishes — Determination of gloss value) provide industry-accepted frameworks for evaluating surface quality. Additionally, accelerated weathering tests (ASTM G154, ISO 16474) help predict the long-term aesthetic durability of conformal coatings under various environmental conditions, ensuring that surface smoothness and appearance remain stable throughout the product lifecycle.

Cross-hatch adhesion testing (ASTM D3359) and impact resistance testing complement aesthetic evaluations by ensuring that improvements in surface smoothness do not compromise functional performance. The ideal coating must balance aesthetic qualities with mechanical durability, making comprehensive testing methodologies essential for product development and quality assurance.

Gloss measurement represents another essential testing methodology, directly correlating with perceived aesthetic quality. Using glossmeters at standardized angles (typically 20°, 60°, and 85°), manufacturers can quantify the specular reflection characteristics of coated surfaces. Higher gloss readings generally indicate smoother surfaces with enhanced aesthetic appeal, though market preferences may vary across different product categories.

Advanced imaging techniques have revolutionized quality control processes in conformal coating applications. Digital microscopy, scanning electron microscopy (SEM), and 3D optical profiling enable detailed visualization and analysis of surface topography at micro and nano scales. These technologies allow for the identification of coating defects such as orange peel, fisheyes, craters, and other imperfections that might compromise aesthetic quality while remaining invisible to the naked eye.

Automated vision systems equipped with machine learning algorithms represent the cutting edge in quality control for high-volume production environments. These systems can detect subtle variations in surface appearance, ensuring consistency across production batches. The integration of artificial intelligence has significantly improved detection accuracy while reducing false positives in defect identification.

Standardized testing protocols such as ASTM D523 (Standard Test Method for Specular Gloss) and ISO 2813 (Paints and varnishes — Determination of gloss value) provide industry-accepted frameworks for evaluating surface quality. Additionally, accelerated weathering tests (ASTM G154, ISO 16474) help predict the long-term aesthetic durability of conformal coatings under various environmental conditions, ensuring that surface smoothness and appearance remain stable throughout the product lifecycle.

Cross-hatch adhesion testing (ASTM D3359) and impact resistance testing complement aesthetic evaluations by ensuring that improvements in surface smoothness do not compromise functional performance. The ideal coating must balance aesthetic qualities with mechanical durability, making comprehensive testing methodologies essential for product development and quality assurance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!