How to Approve Conformal Coating Performance in Mil-Spec Standards

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Military Conformal Coating Standards Evolution

Military conformal coating standards have evolved significantly since their inception in the mid-20th century. The first formal military specification for conformal coatings, MIL-I-46058C, was established in the 1960s to address the growing need for protecting electronic assemblies in harsh military environments. This standard set the foundation for subsequent developments in conformal coating requirements and testing methodologies.

During the 1970s and 1980s, as electronic components became more sophisticated and miniaturized, military standards evolved to address new challenges in protection against moisture, salt spray, fungus, and thermal cycling. The introduction of MIL-STD-810 incorporated environmental testing protocols that directly impacted conformal coating performance requirements.

A significant shift occurred in 1998 when the Department of Defense implemented acquisition reform initiatives, leading to the cancellation of MIL-I-46058C and its replacement with IPC-CC-830. This transition marked a move from military-specific standards toward industry consensus standards, though with military endorsement and oversight.

The early 2000s saw further refinement with the introduction of J-STD-001 Requirements for Soldered Electrical and Electronic Assemblies, which included specific provisions for conformal coating in military applications. This standard incorporated more precise testing methodologies and performance criteria, reflecting advancements in both coating materials and application technologies.

In 2014, a significant update came with the release of IPC-HDBK-830, Guidelines for Design, Selection and Application of Conformal Coatings. This comprehensive handbook addressed the growing complexity of conformal coating materials and processes, providing detailed guidance for military and aerospace applications.

Recent developments have focused on addressing emerging challenges such as lead-free solder compatibility, miniaturization of components, and increasingly harsh operating environments. The 2018 revision of IPC-CC-830C incorporated more stringent requirements for coating thickness uniformity, adhesion performance, and chemical resistance.

The most recent evolution has been toward performance-based specifications rather than prescriptive requirements. Modern military standards now emphasize qualification testing that simulates actual field conditions, moving away from generic pass/fail criteria toward application-specific performance metrics. This approach allows for innovation in coating materials while ensuring reliability in mission-critical military applications.

Current military conformal coating standards also reflect growing environmental concerns, with specifications increasingly addressing VOC content, elimination of hazardous materials, and sustainability considerations while maintaining the rigorous performance requirements essential for military applications.

During the 1970s and 1980s, as electronic components became more sophisticated and miniaturized, military standards evolved to address new challenges in protection against moisture, salt spray, fungus, and thermal cycling. The introduction of MIL-STD-810 incorporated environmental testing protocols that directly impacted conformal coating performance requirements.

A significant shift occurred in 1998 when the Department of Defense implemented acquisition reform initiatives, leading to the cancellation of MIL-I-46058C and its replacement with IPC-CC-830. This transition marked a move from military-specific standards toward industry consensus standards, though with military endorsement and oversight.

The early 2000s saw further refinement with the introduction of J-STD-001 Requirements for Soldered Electrical and Electronic Assemblies, which included specific provisions for conformal coating in military applications. This standard incorporated more precise testing methodologies and performance criteria, reflecting advancements in both coating materials and application technologies.

In 2014, a significant update came with the release of IPC-HDBK-830, Guidelines for Design, Selection and Application of Conformal Coatings. This comprehensive handbook addressed the growing complexity of conformal coating materials and processes, providing detailed guidance for military and aerospace applications.

Recent developments have focused on addressing emerging challenges such as lead-free solder compatibility, miniaturization of components, and increasingly harsh operating environments. The 2018 revision of IPC-CC-830C incorporated more stringent requirements for coating thickness uniformity, adhesion performance, and chemical resistance.

The most recent evolution has been toward performance-based specifications rather than prescriptive requirements. Modern military standards now emphasize qualification testing that simulates actual field conditions, moving away from generic pass/fail criteria toward application-specific performance metrics. This approach allows for innovation in coating materials while ensuring reliability in mission-critical military applications.

Current military conformal coating standards also reflect growing environmental concerns, with specifications increasingly addressing VOC content, elimination of hazardous materials, and sustainability considerations while maintaining the rigorous performance requirements essential for military applications.

Market Requirements for Mil-Spec Conformal Coatings

The military and aerospace sectors represent the most demanding environments for electronic components, requiring conformal coatings that meet stringent performance standards. Market analysis indicates that the global military conformal coating market is projected to grow at a compound annual growth rate of 5.7% through 2028, driven primarily by increasing defense budgets and modernization programs across major military powers.

Defense contractors and military equipment manufacturers require conformal coatings that comply with MIL-I-46058C, MIL-PRF-55677, and the newer IPC-CC-830C standards. These specifications have become the baseline requirements for any coating solution entering this market segment. Survey data from procurement officers indicates that 87% consider compliance with these standards non-negotiable when selecting coating products.

Environmental resistance represents the foremost market requirement, with particular emphasis on coatings that can withstand extreme temperature fluctuations (-65°C to +125°C), high humidity (up to 98% RH), salt fog exposure, and chemical resistance. Military applications in maritime environments demand enhanced protection against salt spray corrosion, while airborne systems require resistance to atmospheric pressure changes and ozone exposure.

Durability under mechanical stress constitutes another critical market demand. Military electronics frequently experience shock loads up to 100G and vibration across broad frequency ranges. Coating solutions must maintain adhesion and protective properties without cracking or delamination under these conditions. Field failure analysis reports indicate that 23% of electronic failures in military equipment stem from inadequate coating performance under mechanical stress.

Reparability and field serviceability have emerged as growing requirements, particularly for deployed systems where maintenance must occur in non-ideal conditions. The market increasingly favors coatings that allow for component replacement without extensive removal procedures, while still maintaining their protective integrity around the repair site.

Long-term reliability data has become a significant market differentiator. Military procurement cycles often extend 10-15 years, and equipment is expected to remain in service for decades. Consequently, coating manufacturers must provide accelerated aging test data demonstrating performance over extended periods. Defense contractors typically require a minimum 10-year performance guarantee under specified environmental conditions.

Specialized requirements are growing for coatings used in stealth applications, where radar absorption properties and minimal electromagnetic interference are paramount. Similarly, space applications demand coatings with low outgassing characteristics that comply with ASTM E595 standards, a requirement that has seen 40% growth in specification mentions over the past five years.

Defense contractors and military equipment manufacturers require conformal coatings that comply with MIL-I-46058C, MIL-PRF-55677, and the newer IPC-CC-830C standards. These specifications have become the baseline requirements for any coating solution entering this market segment. Survey data from procurement officers indicates that 87% consider compliance with these standards non-negotiable when selecting coating products.

Environmental resistance represents the foremost market requirement, with particular emphasis on coatings that can withstand extreme temperature fluctuations (-65°C to +125°C), high humidity (up to 98% RH), salt fog exposure, and chemical resistance. Military applications in maritime environments demand enhanced protection against salt spray corrosion, while airborne systems require resistance to atmospheric pressure changes and ozone exposure.

Durability under mechanical stress constitutes another critical market demand. Military electronics frequently experience shock loads up to 100G and vibration across broad frequency ranges. Coating solutions must maintain adhesion and protective properties without cracking or delamination under these conditions. Field failure analysis reports indicate that 23% of electronic failures in military equipment stem from inadequate coating performance under mechanical stress.

Reparability and field serviceability have emerged as growing requirements, particularly for deployed systems where maintenance must occur in non-ideal conditions. The market increasingly favors coatings that allow for component replacement without extensive removal procedures, while still maintaining their protective integrity around the repair site.

Long-term reliability data has become a significant market differentiator. Military procurement cycles often extend 10-15 years, and equipment is expected to remain in service for decades. Consequently, coating manufacturers must provide accelerated aging test data demonstrating performance over extended periods. Defense contractors typically require a minimum 10-year performance guarantee under specified environmental conditions.

Specialized requirements are growing for coatings used in stealth applications, where radar absorption properties and minimal electromagnetic interference are paramount. Similarly, space applications demand coatings with low outgassing characteristics that comply with ASTM E595 standards, a requirement that has seen 40% growth in specification mentions over the past five years.

Current Challenges in Conformal Coating Validation

Despite significant advancements in conformal coating technologies, the validation process according to military specifications presents several persistent challenges. The current MIL-STD-810 and MIL-I-46058 standards require extensive testing regimens that often struggle to keep pace with evolving coating formulations and application methods. One primary challenge is the inconsistency in test interpretation across different testing facilities, leading to variable results for identical coating systems.

Environmental testing protocols, particularly for harsh conditions like salt fog exposure (MIL-STD-810G Method 509.6) and temperature cycling (MIL-STD-810G Method 503.6), frequently yield conflicting data when performed at different laboratories. This inconsistency undermines confidence in coating performance validation and complicates qualification processes for manufacturers.

The accelerated aging tests prescribed in military standards often fail to accurately predict real-world performance. Current methodologies compress decades of environmental exposure into weeks of testing, but the correlation between accelerated test results and actual field performance remains questionable. This disconnect creates significant uncertainty in long-term reliability assessments.

Thickness measurement and verification present another significant challenge. While standards specify acceptable thickness ranges, the non-uniform application inherent to certain geometrically complex electronic assemblies makes consistent measurement difficult. Current inspection technologies struggle to verify coating thickness in hidden areas and under components, creating potential blind spots in quality assurance.

Modern electronic designs featuring high-density component placement further complicate validation processes. Traditional test methods were developed when circuit boards had simpler layouts and larger feature sizes. Today's miniaturized components create capillary spaces and shadowed areas that resist proper coating application and subsequent inspection, yet the validation standards have not been adequately updated to address these challenges.

Emerging coating materials, particularly those with enhanced environmental properties or specialized characteristics like thermal conductivity, often lack specific validation protocols within existing military standards. Testing facilities must adapt general requirements to these new materials, creating inconsistency in qualification approaches.

The increasing focus on environmental compliance has introduced additional complications. As traditional coating formulations containing volatile organic compounds (VOCs) are phased out in favor of water-based or UV-curable alternatives, validation methods optimized for solvent-based systems may not accurately assess the performance characteristics of these newer, greener formulations.

Environmental testing protocols, particularly for harsh conditions like salt fog exposure (MIL-STD-810G Method 509.6) and temperature cycling (MIL-STD-810G Method 503.6), frequently yield conflicting data when performed at different laboratories. This inconsistency undermines confidence in coating performance validation and complicates qualification processes for manufacturers.

The accelerated aging tests prescribed in military standards often fail to accurately predict real-world performance. Current methodologies compress decades of environmental exposure into weeks of testing, but the correlation between accelerated test results and actual field performance remains questionable. This disconnect creates significant uncertainty in long-term reliability assessments.

Thickness measurement and verification present another significant challenge. While standards specify acceptable thickness ranges, the non-uniform application inherent to certain geometrically complex electronic assemblies makes consistent measurement difficult. Current inspection technologies struggle to verify coating thickness in hidden areas and under components, creating potential blind spots in quality assurance.

Modern electronic designs featuring high-density component placement further complicate validation processes. Traditional test methods were developed when circuit boards had simpler layouts and larger feature sizes. Today's miniaturized components create capillary spaces and shadowed areas that resist proper coating application and subsequent inspection, yet the validation standards have not been adequately updated to address these challenges.

Emerging coating materials, particularly those with enhanced environmental properties or specialized characteristics like thermal conductivity, often lack specific validation protocols within existing military standards. Testing facilities must adapt general requirements to these new materials, creating inconsistency in qualification approaches.

The increasing focus on environmental compliance has introduced additional complications. As traditional coating formulations containing volatile organic compounds (VOCs) are phased out in favor of water-based or UV-curable alternatives, validation methods optimized for solvent-based systems may not accurately assess the performance characteristics of these newer, greener formulations.

Established Testing Methodologies for Mil-Spec Compliance

01 Thermal performance and heat management in conformal coatings

Conformal coatings can be engineered to provide thermal management properties for electronic components. These coatings help in dissipating heat generated by electronic devices, preventing overheating and ensuring optimal performance. Advanced formulations incorporate thermally conductive materials that maintain electrical insulation while facilitating heat transfer. This thermal management capability is particularly important for high-power electronics and devices operating in extreme temperature environments.- Moisture and environmental protection properties: Conformal coatings provide protection against moisture, humidity, and harsh environmental conditions, preventing corrosion and extending the lifespan of electronic components. These coatings form a protective barrier that shields electronic assemblies from water, chemicals, dust, and other contaminants that could cause electrical failures or short circuits. The performance of these coatings is measured by their ability to maintain protection under various environmental stresses including temperature cycling and humidity exposure.

- Thermal management and heat dissipation: Conformal coatings can be formulated to enhance thermal management of electronic components by improving heat dissipation. These specialized coatings help maintain optimal operating temperatures for electronic devices, preventing overheating and thermal damage. Some formulations incorporate thermally conductive materials that facilitate heat transfer away from sensitive components while still providing the necessary electrical insulation. This dual functionality is particularly important in high-power density applications where thermal management is critical for performance and reliability.

- Application methods and coating uniformity: The performance of conformal coatings is significantly influenced by the application method and resulting coating uniformity. Various techniques including spraying, dipping, brushing, and automated selective coating are used to apply these materials. Each method affects the coating thickness, coverage, and overall protection level. Achieving uniform coverage without voids, bubbles, or excessive buildup is essential for optimal performance. Advanced application technologies help ensure consistent coating thickness across complex geometries and component configurations, which directly impacts the coating's protective capabilities.

- Material composition and chemical resistance: The performance of conformal coatings depends heavily on their material composition, which determines properties such as chemical resistance, flexibility, and adhesion. Common coating materials include acrylics, silicones, polyurethanes, epoxies, and parylene, each offering different performance characteristics. Some formulations provide enhanced resistance to specific chemicals, solvents, or fuels, while others offer superior flexibility to withstand mechanical stress and vibration. The selection of coating material must be matched to the specific environmental challenges and operational requirements of the electronic assembly.

- Electrical insulation and dielectric properties: Conformal coatings provide critical electrical insulation that prevents short circuits and current leakage between components. The dielectric properties of these coatings are essential performance characteristics that determine their ability to maintain electrical isolation under various operating conditions. High-performance coatings maintain their dielectric strength even when exposed to moisture, contaminants, or temperature fluctuations. Some specialized formulations offer enhanced dielectric properties for high-voltage applications or environments with significant electromagnetic interference, providing both protection and improved signal integrity.

02 Environmental protection and moisture resistance properties

Conformal coatings provide protection against environmental factors such as moisture, dust, chemicals, and salt spray. These coatings create a barrier that prevents corrosion and electrical shorts caused by environmental contaminants. The moisture resistance properties are particularly valuable for electronics used in humid or outdoor environments. Advanced formulations can maintain their protective properties even under extreme conditions, extending the lifespan and reliability of coated electronic components.Expand Specific Solutions03 Application methods and coating uniformity

Various application methods for conformal coatings affect the performance and quality of the protective layer. Techniques include spray coating, dip coating, brush application, and automated selective coating. Each method offers different advantages in terms of coverage, thickness control, and suitability for specific component geometries. The uniformity of the coating is critical for ensuring consistent protection across the entire substrate, with advanced application technologies enabling precise control over coating thickness and distribution.Expand Specific Solutions04 Electrical insulation and dielectric properties

Conformal coatings provide electrical insulation that prevents short circuits and current leakage between components. The dielectric properties of these coatings are crucial for maintaining electrical integrity in high-voltage applications. Different coating materials offer varying levels of dielectric strength, with some formulations specifically designed for high-frequency or high-voltage environments. The electrical insulation performance can be enhanced through additives that improve the dielectric constant and breakdown voltage resistance.Expand Specific Solutions05 Chemical resistance and durability

The chemical resistance of conformal coatings determines their ability to withstand exposure to solvents, acids, bases, and other aggressive substances. Durable coatings maintain their protective properties over extended periods, even when subjected to harsh operating conditions. Advanced formulations incorporate cross-linking polymers and specialized additives that enhance resistance to chemical degradation. The durability of these coatings directly impacts the longevity and reliability of the protected electronic components, particularly in industrial, automotive, and aerospace applications.Expand Specific Solutions

Leading Manufacturers and Testing Laboratories

The conformal coating performance approval landscape in Mil-Spec standards is currently in a mature growth phase, with an estimated market size of $1.2-1.5 billion annually and steady 5-7% growth. Industry leaders like Nordson Corp. and DuPont de Nemours have established comprehensive testing protocols that align with military specifications, while specialized players such as Luna Labs USA and Bulk Chemicals focus on niche applications requiring extreme environmental durability. The technical maturity varies across coating types, with silicone and acrylic solutions being well-established, while newer nano-coatings from companies like Axalta and Nippon Paint represent emerging technologies still undergoing military qualification processes. Defense contractors including ArianeGroup and Chengdu Aircraft Industrial Group drive innovation through demanding application requirements.

Nordson Corp.

Technical Solution: Nordson has developed advanced selective conformal coating systems specifically designed to meet Mil-Spec standards, including their Asymtek series that utilizes precision dispensing technology. Their approach focuses on automated application systems that ensure uniform coating thickness (25-250 microns) and complete coverage of PCB assemblies. Nordson's technology incorporates closed-loop process controls with real-time monitoring capabilities to verify coating parameters against Mil-Spec requirements. Their systems include integrated UV inspection capabilities to detect coating anomalies and ensure compliance with MIL-I-46058C and IPC-CC-830B standards. Nordson's validation methodology includes environmental stress testing, thermal shock resistance (-65°C to +125°C), and humidity aging tests (95% RH at 65°C for 1000 hours) to verify long-term protection in harsh military environments.

Strengths: Superior precision in automated application systems, comprehensive process control capabilities, and integrated inspection technologies. Their systems offer excellent repeatability and traceability for military applications. Weaknesses: Higher initial investment costs compared to manual application methods, and requires specialized operator training for optimal performance.

DuPont de Nemours, Inc.

Technical Solution: DuPont has engineered high-performance conformal coating materials specifically formulated to meet rigorous military specifications. Their portfolio includes Kapton® polyimide-based coatings that provide exceptional thermal stability (operating range -269°C to +400°C) and chemical resistance. DuPont's approach to Mil-Spec approval involves comprehensive material characterization including accelerated aging tests that simulate decades of service life. Their coatings undergo extensive qualification testing including salt fog resistance (MIL-STD-810G, Method 509.6), fungus resistance (MIL-STD-810G, Method 508.7), and fluid compatibility testing with military hydraulic fluids and fuels. DuPont's validation protocol incorporates electrical property testing after environmental exposure, ensuring maintained dielectric strength (>7000 V/mil) and insulation resistance (>1×10^14 ohms) even after extreme environmental conditioning.

Strengths: Exceptional material performance in extreme environments, comprehensive testing protocols that exceed minimum Mil-Spec requirements, and established track record with defense contractors. Weaknesses: Premium pricing compared to standard industrial coatings, and some formulations require specialized application equipment and curing conditions.

Critical Patents and Technical Documentation

Coatings for suppressing metallic whiskers

PatentInactiveUS20110206909A1

Innovation

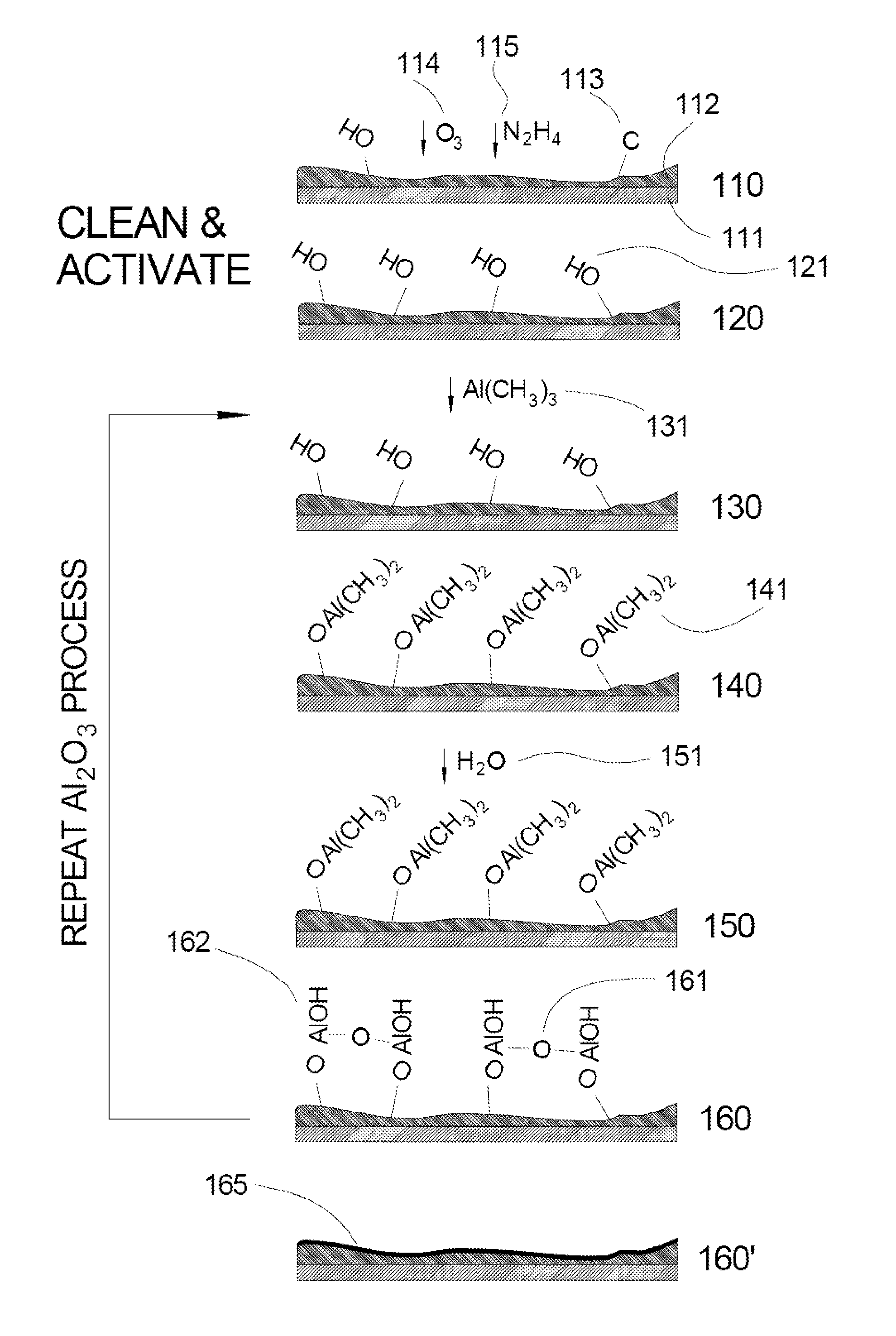

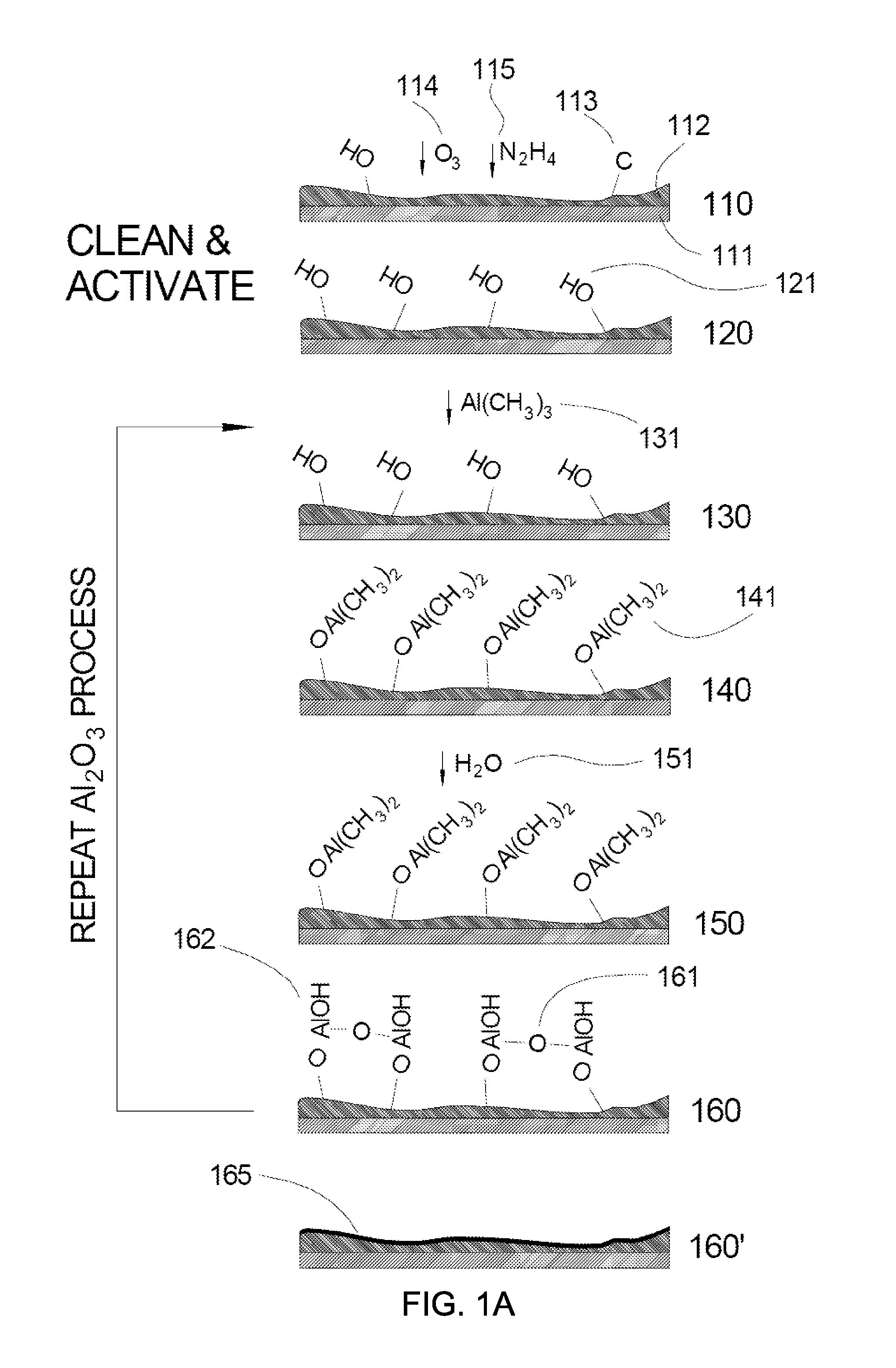

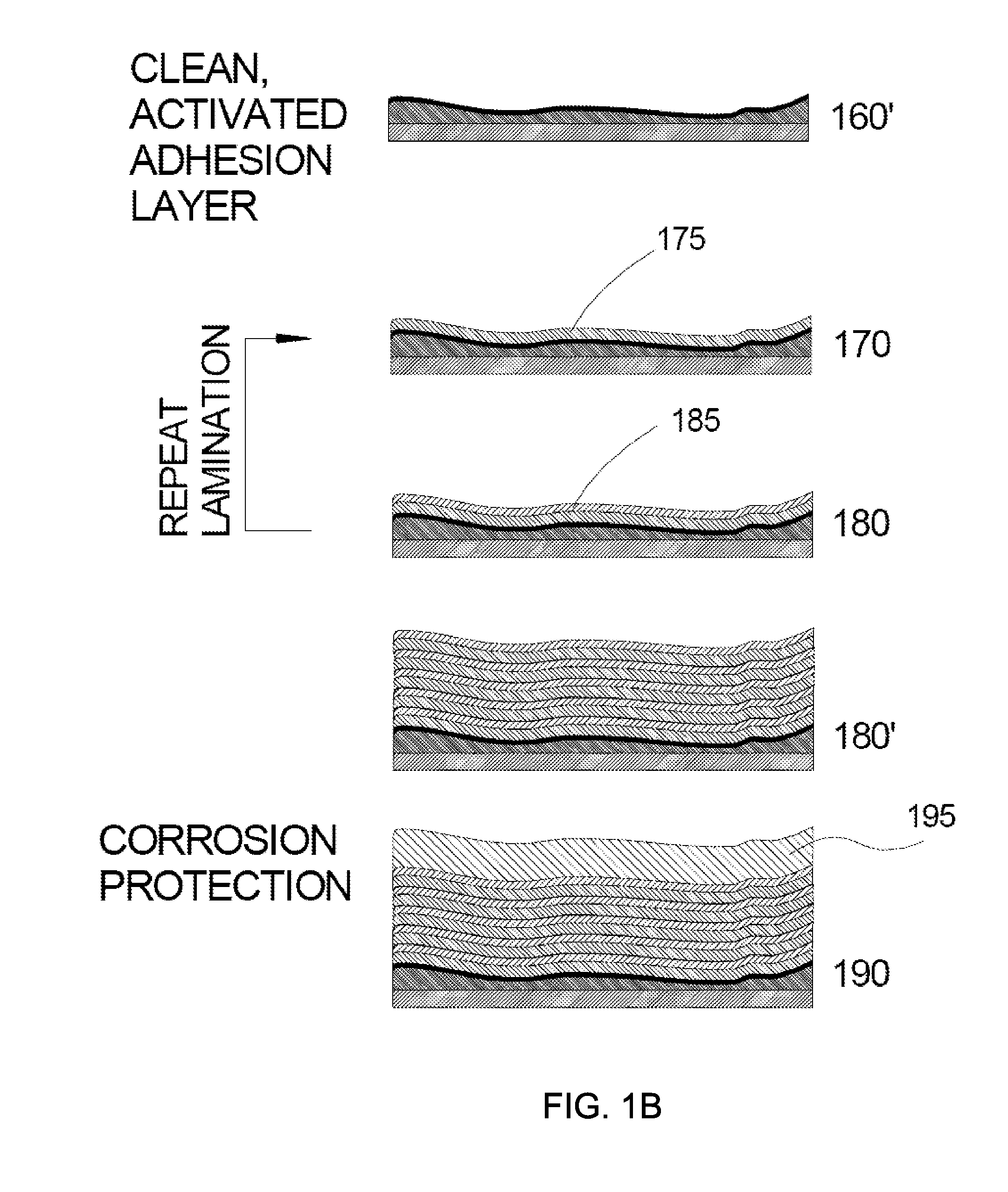

- The development of Whisker-Cap coatings (WCCs) that induce tensile stress on metallic features, comprising a laminate structure with an adhesion layer, alternating middle layers, and an outermost cap layer, deposited using atomic layer deposition (ALD), which creates sufficient tensile stress to suppress whisker growth and prevent tin pest phase transition.

Combined self-sealing, and chemical and visual camouflage coating

PatentInactiveUS20100285247A1

Innovation

- A combined-function protective coating comprising a self-sealing underlayer and a chemical-agent and biological-agent resistant overcoating material, applied in a two- or three-layer structure, ensuring compatibility and bonding between layers, with a solvent-based primer enhancing the surface grip and providing anti-penetration and self-healing properties.

Environmental Impact and Sustainability Considerations

The environmental impact of conformal coating processes in military applications has become increasingly significant as sustainability considerations gain prominence in defense manufacturing. Traditional conformal coating materials often contain volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) that pose environmental risks during application, curing, and disposal phases. Military specifications are evolving to address these concerns while maintaining the rigorous performance requirements essential for mission-critical electronics protection.

Recent advancements in conformal coating technology have introduced water-based and UV-curable alternatives that significantly reduce VOC emissions compared to conventional solvent-based formulations. These environmentally friendly options can reduce harmful emissions by up to 80% while still meeting Mil-Spec performance standards for moisture resistance, chemical protection, and thermal cycling endurance. The transition to these sustainable alternatives represents a critical balance between environmental responsibility and maintaining the high reliability demanded by military applications.

Lifecycle assessment (LCA) methodologies are increasingly being incorporated into conformal coating approval processes to evaluate environmental impacts from raw material extraction through manufacturing, use, and end-of-life disposal. Military standards now encourage manufacturers to document carbon footprint metrics, resource consumption patterns, and waste generation statistics as part of their qualification submissions. This holistic approach ensures that environmental considerations are factored into performance evaluations rather than treated as separate concerns.

Waste management protocols for conformal coating processes have also evolved significantly. Modern Mil-Spec standards now address proper handling and disposal of coating materials, solvents, and application equipment. Closed-loop recycling systems for solvents and application equipment cleaning have demonstrated potential to reduce hazardous waste generation by up to 60% in military electronics manufacturing facilities, while simultaneously reducing operational costs.

Energy efficiency during the curing process represents another important sustainability consideration. Traditional thermal curing methods consume substantial energy, whereas newer UV and LED curing technologies can reduce energy consumption by 40-70%. Military specifications now include provisions for evaluating energy efficiency as part of the overall performance approval process, encouraging manufacturers to develop and implement more sustainable curing technologies that maintain coating integrity while reducing environmental impact.

Regulatory compliance across global jurisdictions presents additional challenges for conformal coating approval. Materials that meet performance requirements in one region may face restrictions in others due to varying environmental regulations. Military specifications increasingly require documentation of compliance with international environmental standards such as RoHS, REACH, and regional VOC limitations to ensure global deployability of coated electronic systems while maintaining environmental responsibility.

Recent advancements in conformal coating technology have introduced water-based and UV-curable alternatives that significantly reduce VOC emissions compared to conventional solvent-based formulations. These environmentally friendly options can reduce harmful emissions by up to 80% while still meeting Mil-Spec performance standards for moisture resistance, chemical protection, and thermal cycling endurance. The transition to these sustainable alternatives represents a critical balance between environmental responsibility and maintaining the high reliability demanded by military applications.

Lifecycle assessment (LCA) methodologies are increasingly being incorporated into conformal coating approval processes to evaluate environmental impacts from raw material extraction through manufacturing, use, and end-of-life disposal. Military standards now encourage manufacturers to document carbon footprint metrics, resource consumption patterns, and waste generation statistics as part of their qualification submissions. This holistic approach ensures that environmental considerations are factored into performance evaluations rather than treated as separate concerns.

Waste management protocols for conformal coating processes have also evolved significantly. Modern Mil-Spec standards now address proper handling and disposal of coating materials, solvents, and application equipment. Closed-loop recycling systems for solvents and application equipment cleaning have demonstrated potential to reduce hazardous waste generation by up to 60% in military electronics manufacturing facilities, while simultaneously reducing operational costs.

Energy efficiency during the curing process represents another important sustainability consideration. Traditional thermal curing methods consume substantial energy, whereas newer UV and LED curing technologies can reduce energy consumption by 40-70%. Military specifications now include provisions for evaluating energy efficiency as part of the overall performance approval process, encouraging manufacturers to develop and implement more sustainable curing technologies that maintain coating integrity while reducing environmental impact.

Regulatory compliance across global jurisdictions presents additional challenges for conformal coating approval. Materials that meet performance requirements in one region may face restrictions in others due to varying environmental regulations. Military specifications increasingly require documentation of compliance with international environmental standards such as RoHS, REACH, and regional VOC limitations to ensure global deployability of coated electronic systems while maintaining environmental responsibility.

Qualification Process and Documentation Requirements

The qualification process for conformal coating in military applications follows a structured approach defined by MIL-STD-810, MIL-I-46058C, and IPC-CC-830B standards. Organizations must first establish a comprehensive test plan that addresses environmental stressors specific to the intended deployment environment. This plan should detail test parameters, acceptance criteria, and sampling methodologies aligned with military specifications.

Documentation requirements begin with material certification, where manufacturers must provide detailed chemical composition data and compliance statements for each coating material. These documents must verify that the coating meets military-grade requirements for flame resistance, fungus resistance, and outgassing characteristics. Material Safety Data Sheets (MSDS) and technical data sheets must be maintained throughout the qualification process.

Process validation documentation forms the cornerstone of qualification efforts. This includes detailed process control parameters such as application methods, cure profiles, thickness measurements, and environmental conditions during application. Statistical Process Control (SPC) data must demonstrate process capability indices (Cpk) exceeding 1.33 for critical parameters, ensuring consistent performance across production runs.

Test reports constitute another critical documentation component. These must include detailed results from thermal shock testing (typically -65°C to +125°C), humidity resistance (85% RH for 1000 hours), salt fog exposure (5% NaCl solution for 48 hours), and electrical property verification. Each test report must reference the applicable military standard section, detail the test methodology, and provide clear pass/fail determinations with supporting data.

Traceability documentation establishes links between raw materials, process parameters, and finished products. This includes batch records, operator certifications, equipment calibration logs, and inspection results. Military standards require maintenance of these records for a minimum of five years, with some programs requiring retention throughout the product lifecycle plus an additional two years.

Non-conformance handling procedures must be documented to address any deviations from specification requirements. These procedures should detail containment actions, root cause analysis methodologies, corrective action implementation, and verification protocols. All non-conformances must be documented with formal Material Review Board (MRB) dispositions when applicable.

Final qualification documentation packages typically require formal approval from both quality assurance personnel and customer representatives. These packages consolidate all test reports, process validation data, material certifications, and conformance statements into a comprehensive qualification report that serves as the baseline for ongoing production.

Documentation requirements begin with material certification, where manufacturers must provide detailed chemical composition data and compliance statements for each coating material. These documents must verify that the coating meets military-grade requirements for flame resistance, fungus resistance, and outgassing characteristics. Material Safety Data Sheets (MSDS) and technical data sheets must be maintained throughout the qualification process.

Process validation documentation forms the cornerstone of qualification efforts. This includes detailed process control parameters such as application methods, cure profiles, thickness measurements, and environmental conditions during application. Statistical Process Control (SPC) data must demonstrate process capability indices (Cpk) exceeding 1.33 for critical parameters, ensuring consistent performance across production runs.

Test reports constitute another critical documentation component. These must include detailed results from thermal shock testing (typically -65°C to +125°C), humidity resistance (85% RH for 1000 hours), salt fog exposure (5% NaCl solution for 48 hours), and electrical property verification. Each test report must reference the applicable military standard section, detail the test methodology, and provide clear pass/fail determinations with supporting data.

Traceability documentation establishes links between raw materials, process parameters, and finished products. This includes batch records, operator certifications, equipment calibration logs, and inspection results. Military standards require maintenance of these records for a minimum of five years, with some programs requiring retention throughout the product lifecycle plus an additional two years.

Non-conformance handling procedures must be documented to address any deviations from specification requirements. These procedures should detail containment actions, root cause analysis methodologies, corrective action implementation, and verification protocols. All non-conformances must be documented with formal Material Review Board (MRB) dispositions when applicable.

Final qualification documentation packages typically require formal approval from both quality assurance personnel and customer representatives. These packages consolidate all test reports, process validation data, material certifications, and conformance statements into a comprehensive qualification report that serves as the baseline for ongoing production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!