Optimizing Conformal Coating Thickness for Moisture Resistance

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conformal Coating Technology Background and Objectives

Conformal coating technology has evolved significantly over the past five decades, originating from military and aerospace applications in the 1970s where electronic components required protection from harsh environmental conditions. The progression from simple acrylic and silicone formulations to today's advanced nano-coatings represents a continuous pursuit of enhanced protection capabilities while maintaining electrical performance integrity.

The global electronic manufacturing industry has witnessed exponential growth in miniaturization and functionality density, creating unprecedented challenges for moisture protection. Conformal coatings serve as the primary defense mechanism against moisture ingress, corrosion, and electrical failures in printed circuit boards (PCBs) and electronic assemblies. The coating thickness optimization represents a critical balance between adequate protection and maintaining component functionality.

Current industry standards, including IPC-CC-830B and MIL-I-46058C, provide general guidelines for conformal coating applications but lack specific optimization parameters for varying environmental conditions and component geometries. This technological gap has led to either over-coating, which increases production costs and can cause thermal management issues, or under-coating, resulting in insufficient protection and premature product failures.

The moisture resistance capability of conformal coatings exhibits a non-linear relationship with coating thickness. Research indicates that while increasing thickness generally improves moisture barrier properties, the relationship plateaus at certain thresholds depending on the coating chemistry and application method. Understanding this relationship is fundamental to optimization efforts.

Recent technological advancements in coating materials, including hydrophobic additives, nano-fillers, and multi-layer approaches, have created new possibilities for thickness optimization. These innovations allow for thinner coatings while maintaining or even enhancing moisture resistance properties, thereby addressing the miniaturization challenges faced by modern electronics.

The primary objective of conformal coating thickness optimization is to establish a scientific methodology for determining the minimum effective coating thickness that provides adequate moisture protection for specific application environments. This includes developing predictive models that account for coating material properties, application methods, component geometry, and expected environmental exposure conditions.

Secondary objectives include reducing material consumption and processing time, minimizing environmental impact through reduced volatile organic compound (VOC) emissions, and establishing industry-specific best practices for thickness measurement and quality control procedures that ensure consistent moisture protection performance across production batches.

The global electronic manufacturing industry has witnessed exponential growth in miniaturization and functionality density, creating unprecedented challenges for moisture protection. Conformal coatings serve as the primary defense mechanism against moisture ingress, corrosion, and electrical failures in printed circuit boards (PCBs) and electronic assemblies. The coating thickness optimization represents a critical balance between adequate protection and maintaining component functionality.

Current industry standards, including IPC-CC-830B and MIL-I-46058C, provide general guidelines for conformal coating applications but lack specific optimization parameters for varying environmental conditions and component geometries. This technological gap has led to either over-coating, which increases production costs and can cause thermal management issues, or under-coating, resulting in insufficient protection and premature product failures.

The moisture resistance capability of conformal coatings exhibits a non-linear relationship with coating thickness. Research indicates that while increasing thickness generally improves moisture barrier properties, the relationship plateaus at certain thresholds depending on the coating chemistry and application method. Understanding this relationship is fundamental to optimization efforts.

Recent technological advancements in coating materials, including hydrophobic additives, nano-fillers, and multi-layer approaches, have created new possibilities for thickness optimization. These innovations allow for thinner coatings while maintaining or even enhancing moisture resistance properties, thereby addressing the miniaturization challenges faced by modern electronics.

The primary objective of conformal coating thickness optimization is to establish a scientific methodology for determining the minimum effective coating thickness that provides adequate moisture protection for specific application environments. This includes developing predictive models that account for coating material properties, application methods, component geometry, and expected environmental exposure conditions.

Secondary objectives include reducing material consumption and processing time, minimizing environmental impact through reduced volatile organic compound (VOC) emissions, and establishing industry-specific best practices for thickness measurement and quality control procedures that ensure consistent moisture protection performance across production batches.

Market Demand Analysis for Moisture-Resistant Electronics

The global market for moisture-resistant electronics has been experiencing substantial growth, driven by increasing applications in harsh environments and the rising demand for reliable electronic devices. The conformal coating market, a critical component in moisture protection, was valued at approximately 2.1 billion USD in 2022 and is projected to reach 3.4 billion USD by 2028, representing a compound annual growth rate of 8.3% during the forecast period.

Consumer electronics represents the largest segment demanding moisture-resistant solutions, accounting for nearly 35% of the market share. This is primarily due to the growing consumer preference for waterproof and moisture-resistant smartphones, wearables, and portable devices. According to industry reports, over 60% of smartphone failures are attributed to moisture damage, highlighting the critical need for effective protection solutions.

The automotive industry follows as the second-largest market segment, with an estimated 28% share. The increasing integration of electronic components in vehicles, particularly in electric and autonomous vehicles, has amplified the demand for reliable moisture protection. Modern vehicles contain up to 150 electronic control units, all requiring protection against environmental factors including moisture.

Industrial electronics and aerospace applications collectively represent approximately 25% of the market. These sectors demand high-performance conformal coatings that can withstand extreme conditions while maintaining optimal thickness for weight considerations and thermal management.

Regional analysis indicates that Asia-Pacific dominates the market with a 45% share, attributed to the region's strong electronics manufacturing base. North America and Europe follow with 25% and 20% market shares respectively, with significant demand coming from automotive and aerospace industries.

Market research indicates that end-users are increasingly prioritizing long-term reliability over initial cost, with 78% of procurement specialists citing moisture resistance as a "very important" or "critical" factor in component selection. This represents a significant shift from previous years when cost was the primary consideration.

The demand for optimized conformal coating thickness is particularly evident in miniaturized electronics, where space constraints require precise application while maintaining effective moisture protection. Industry surveys reveal that 67% of electronics manufacturers are actively seeking improved coating technologies that can provide enhanced moisture resistance with minimal thickness.

Emerging applications in medical devices, renewable energy systems, and IoT devices are expected to create new market opportunities, with these segments projected to grow at rates exceeding 12% annually through 2028. These applications often require specialized moisture protection solutions tailored to their unique operating environments and reliability requirements.

Consumer electronics represents the largest segment demanding moisture-resistant solutions, accounting for nearly 35% of the market share. This is primarily due to the growing consumer preference for waterproof and moisture-resistant smartphones, wearables, and portable devices. According to industry reports, over 60% of smartphone failures are attributed to moisture damage, highlighting the critical need for effective protection solutions.

The automotive industry follows as the second-largest market segment, with an estimated 28% share. The increasing integration of electronic components in vehicles, particularly in electric and autonomous vehicles, has amplified the demand for reliable moisture protection. Modern vehicles contain up to 150 electronic control units, all requiring protection against environmental factors including moisture.

Industrial electronics and aerospace applications collectively represent approximately 25% of the market. These sectors demand high-performance conformal coatings that can withstand extreme conditions while maintaining optimal thickness for weight considerations and thermal management.

Regional analysis indicates that Asia-Pacific dominates the market with a 45% share, attributed to the region's strong electronics manufacturing base. North America and Europe follow with 25% and 20% market shares respectively, with significant demand coming from automotive and aerospace industries.

Market research indicates that end-users are increasingly prioritizing long-term reliability over initial cost, with 78% of procurement specialists citing moisture resistance as a "very important" or "critical" factor in component selection. This represents a significant shift from previous years when cost was the primary consideration.

The demand for optimized conformal coating thickness is particularly evident in miniaturized electronics, where space constraints require precise application while maintaining effective moisture protection. Industry surveys reveal that 67% of electronics manufacturers are actively seeking improved coating technologies that can provide enhanced moisture resistance with minimal thickness.

Emerging applications in medical devices, renewable energy systems, and IoT devices are expected to create new market opportunities, with these segments projected to grow at rates exceeding 12% annually through 2028. These applications often require specialized moisture protection solutions tailored to their unique operating environments and reliability requirements.

Current Conformal Coating Thickness Standards and Challenges

The conformal coating industry currently follows several established standards that guide thickness specifications, with IPC-CC-830, MIL-I-46058C, and IEC 60664 being the most widely referenced. These standards typically recommend coating thicknesses ranging from 25 to 250 microns (1-10 mils), depending on the specific application environment and required protection level. However, these broad ranges often create implementation challenges for manufacturers seeking optimal moisture resistance without compromising other performance factors.

A significant challenge in the industry is the lack of application-specific thickness guidelines that account for varying environmental conditions. While general standards exist, they rarely address the nuanced requirements of different operational environments, from high-humidity industrial settings to marine applications with salt spray exposure. This gap forces manufacturers to rely on empirical testing or overly conservative approaches, potentially leading to material waste or inadequate protection.

Measurement and quality control present another substantial hurdle. Current inspection methods, including optical measurement, cross-sectioning, and ultrasonic techniques, often struggle to provide consistent, accurate thickness readings across complex PCB topographies. The irregular surfaces of modern electronic assemblies, with densely packed components of varying heights, create measurement blind spots that compromise quality assurance processes.

Material limitations further complicate thickness optimization efforts. Traditional coating materials like acrylics, silicones, and polyurethanes exhibit different viscosity characteristics, surface tension behaviors, and curing profiles, making standardized application processes challenging. The industry lacks comprehensive data correlating specific material properties with optimal application parameters for moisture resistance.

The trade-off between thickness and functional performance represents perhaps the most critical challenge. While increased thickness generally improves moisture resistance, it can negatively impact thermal management, add weight, increase material costs, and extend curing times. Finding the optimal balance point remains largely a trial-and-error process without sufficient scientific modeling to guide decision-making.

Emerging technologies like IoT devices and wearable electronics are pushing the boundaries of traditional coating approaches, demanding thinner yet more effective moisture barriers. These applications often operate in unpredictable environments while requiring minimal added weight and volume, creating new challenges that existing standards struggle to address.

Regulatory compliance adds another layer of complexity, with different regions implementing varying requirements for environmental protection, flammability, and chemical composition. These regulations sometimes conflict with optimal thickness parameters for moisture resistance, forcing manufacturers to compromise performance to meet compliance standards.

A significant challenge in the industry is the lack of application-specific thickness guidelines that account for varying environmental conditions. While general standards exist, they rarely address the nuanced requirements of different operational environments, from high-humidity industrial settings to marine applications with salt spray exposure. This gap forces manufacturers to rely on empirical testing or overly conservative approaches, potentially leading to material waste or inadequate protection.

Measurement and quality control present another substantial hurdle. Current inspection methods, including optical measurement, cross-sectioning, and ultrasonic techniques, often struggle to provide consistent, accurate thickness readings across complex PCB topographies. The irregular surfaces of modern electronic assemblies, with densely packed components of varying heights, create measurement blind spots that compromise quality assurance processes.

Material limitations further complicate thickness optimization efforts. Traditional coating materials like acrylics, silicones, and polyurethanes exhibit different viscosity characteristics, surface tension behaviors, and curing profiles, making standardized application processes challenging. The industry lacks comprehensive data correlating specific material properties with optimal application parameters for moisture resistance.

The trade-off between thickness and functional performance represents perhaps the most critical challenge. While increased thickness generally improves moisture resistance, it can negatively impact thermal management, add weight, increase material costs, and extend curing times. Finding the optimal balance point remains largely a trial-and-error process without sufficient scientific modeling to guide decision-making.

Emerging technologies like IoT devices and wearable electronics are pushing the boundaries of traditional coating approaches, demanding thinner yet more effective moisture barriers. These applications often operate in unpredictable environments while requiring minimal added weight and volume, creating new challenges that existing standards struggle to address.

Regulatory compliance adds another layer of complexity, with different regions implementing varying requirements for environmental protection, flammability, and chemical composition. These regulations sometimes conflict with optimal thickness parameters for moisture resistance, forcing manufacturers to compromise performance to meet compliance standards.

Current Thickness Optimization Methods and Solutions

01 Optimal thickness ranges for conformal coatings

Conformal coatings are typically applied within specific thickness ranges to ensure proper protection while maintaining component functionality. The optimal thickness often ranges from 25 to 250 microns depending on the application requirements. Thinner coatings may provide adequate protection for less demanding environments, while thicker coatings offer enhanced protection against moisture, chemicals, and mechanical stress. The thickness must be carefully controlled to avoid issues such as component stress, heat dissipation problems, or inadequate coverage.- Optimal thickness ranges for conformal coatings: Conformal coatings are typically applied within specific thickness ranges to ensure proper protection while maintaining component functionality. The optimal thickness often ranges from 25 to 250 microns depending on the application requirements. Thinner coatings may provide adequate protection for less demanding environments, while thicker coatings offer enhanced protection against moisture, chemicals, and mechanical stress. The thickness must be carefully controlled to avoid issues such as component stress, thermal insulation problems, or inadequate coverage.

- Thickness measurement and control methods: Various methods are employed to measure and control conformal coating thickness during application. These include optical measurement systems, ultrasonic thickness gauges, and real-time monitoring technologies. Advanced application equipment may incorporate feedback systems that adjust coating parameters based on thickness measurements. Some processes use weight-based calculations to estimate coating thickness across a substrate. Proper thickness control ensures consistent protection while minimizing material waste and preventing application defects.

- Material-specific thickness considerations: Different conformal coating materials require specific thickness considerations based on their chemical and physical properties. Acrylic coatings typically perform well at lower thicknesses, while silicone coatings may require greater thickness for optimal protection. Polyurethane and epoxy coatings have their own optimal thickness ranges depending on the protection level needed. The viscosity, solid content, and curing mechanism of the coating material directly influence the achievable thickness and application methods. Material selection must account for the required thickness to ensure proper protection.

- Application techniques affecting coating thickness: The application technique significantly impacts the achievable thickness and uniformity of conformal coatings. Spray coating typically produces thinner, more uniform layers, while dip coating can achieve thicker coatings but may result in uneven thickness at edges and corners. Brush application often results in variable thickness and is typically used for touch-up work. Automated selective coating systems can precisely control thickness in specific areas. Multiple coating layers may be applied to build up thickness while avoiding issues like solvent entrapment or improper curing that can occur with single thick applications.

- Environmental and performance factors related to coating thickness: The operating environment and performance requirements directly influence the optimal conformal coating thickness. Harsh environments with high humidity, chemical exposure, or extreme temperatures typically require thicker coatings. Electronic components with fine pitch or high-frequency operation may require precisely controlled, thinner coatings to avoid electrical performance issues. Thermal management considerations may limit maximum coating thickness to prevent heat buildup. The coating thickness must balance protection needs with factors such as flexibility, weight constraints, and thermal cycling resistance to ensure long-term reliability.

02 Thickness measurement and control methods

Various methods are employed to measure and control conformal coating thickness during application. These include optical measurement systems, ultrasonic thickness gauges, and real-time monitoring technologies. Advanced application equipment may incorporate feedback systems that adjust coating parameters based on thickness measurements. Some processes use weight-based calculations to estimate coating thickness across a substrate. Quality control procedures often include sampling and cross-sectional analysis to verify coating thickness meets specifications.Expand Specific Solutions03 Material-specific thickness considerations

Different conformal coating materials require specific thickness considerations based on their chemical and physical properties. Acrylic coatings typically perform well at lower thicknesses, while silicone coatings may require greater thickness to achieve optimal protection. Polyurethane and epoxy coatings have their own optimal thickness ranges depending on the protection level needed. The viscosity of the coating material significantly impacts the achievable thickness in a single application, with some materials requiring multiple layers to reach desired thickness without defects.Expand Specific Solutions04 Application techniques affecting thickness uniformity

The method of application significantly impacts the uniformity and consistency of conformal coating thickness. Spray coating techniques can achieve relatively uniform thickness but may struggle with complex geometries. Dipping provides good coverage but can result in thickness variations due to gravity effects. Selective coating technologies allow precise thickness control in specific areas. Automated application systems help maintain consistent thickness across production batches. Surface preparation and environmental conditions during application also affect coating thickness uniformity.Expand Specific Solutions05 Thickness requirements for specialized applications

Specialized electronic applications have unique conformal coating thickness requirements. High-voltage electronics typically require thicker coatings for enhanced insulation properties. Aerospace and automotive applications may specify precise thickness ranges to meet industry standards and reliability requirements. Medical devices often need thin, uniform coatings that maintain biocompatibility. Military and harsh environment applications generally require thicker coatings with specific performance characteristics. The coating thickness must be optimized to balance protection with other factors such as weight, flexibility, and thermal management.Expand Specific Solutions

Leading Manufacturers and Industry Competition Analysis

The conformal coating thickness optimization market for moisture resistance is in a growth phase, with increasing demand driven by electronics miniaturization and reliability requirements. The market size is expanding as industries adopt advanced protection solutions for sensitive components. Technology maturity varies across players, with established leaders like Nordson Corp., 3M Innovative Properties, and Henkel AG offering comprehensive solutions based on decades of research. Emerging innovators such as HzO, Inc., Favored Tech, and Integrated Surface Technologies are advancing nano-coating technologies that provide superior moisture protection with minimal thickness. Apple's involvement signals the technology's importance in consumer electronics, while research institutions like Georgia Tech and Loughborough University contribute fundamental advancements in coating science, creating a competitive landscape balancing established processes with breakthrough innovations.

Nordson Corp.

Technical Solution: Nordson has developed advanced selective conformal coating systems that utilize precision dispensing technology to optimize coating thickness for moisture resistance. Their automated systems employ closed-loop feedback control mechanisms that continuously monitor and adjust coating parameters in real-time. The technology incorporates laser-based thickness measurement systems that can detect variations as small as 1-2 microns, allowing for exceptional consistency across complex PCB topographies. Nordson's selective coating approach enables targeted application to moisture-sensitive components while avoiding areas where coating is undesirable, reducing material waste by up to 30% compared to traditional methods[1]. Their systems also feature multi-axis motion control with accuracy of ±25 microns, ensuring precise coating placement even on high-density boards with fine-pitch components[2]. The company has further enhanced moisture resistance through development of specialized tilt and rotate mechanisms that ensure uniform coverage on component sidewalls and under-package areas that are traditionally difficult to protect.

Strengths: Exceptional precision in coating application with advanced closed-loop feedback systems; significant material savings through selective application; superior edge coverage on complex geometries. Weaknesses: Higher initial capital investment compared to manual spray systems; requires more complex programming for optimal performance; some specialized coatings may require custom dispensing head configurations.

3M Innovative Properties Co.

Technical Solution: 3M has pioneered a multi-layer conformal coating system specifically engineered to optimize moisture resistance across varying environmental conditions. Their technology employs a base layer of hydrophobic fluoropolymer that chemically bonds to substrate surfaces, creating a moisture barrier with contact angles exceeding 110 degrees[3]. This is complemented by a secondary nanocomposite layer containing specialized silica particles that create a labyrinthine path for moisture molecules, effectively extending diffusion pathways by up to 300% compared to conventional coatings[4]. The company's proprietary application process utilizes electrostatic assistance to achieve uniform thickness even on complex geometries, with standard deviation in thickness typically below 5% across the coated surface. 3M's system also incorporates self-healing capabilities through inclusion of encapsulated hydrophobic agents that are released upon coating damage, maintaining moisture protection integrity even after mechanical stress. Their coatings achieve moisture vapor transmission rates below 2.0 g/m²/day at 38°C/90% RH while maintaining flexibility to withstand thermal cycling without cracking.

Strengths: Exceptional long-term moisture protection through multi-layer approach; self-healing capabilities that extend effective protection lifetime; excellent adhesion to diverse substrate materials. Weaknesses: Higher material costs compared to standard acrylic or silicone coatings; requires specialized application equipment for optimal performance; longer curing times for complete moisture resistance development.

Key Technical Innovations in Moisture Barrier Coatings

Method of conformal coating using noncontact dispensing

PatentInactiveEP1678989A1

Innovation

- A noncontact dispensing method using a jetting system that propels viscous conformal coating material through a nozzle with forward momentum to form droplets, allowing for precise control over the application of small areas and geometries without overspray, eliminating the need for masking.

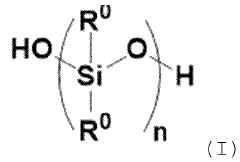

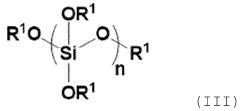

Moisture-curing conformal coating compositions

PatentWO2021259460A1

Innovation

- A solvent-free, one-component moisture-curing conformal coating composition comprising linear hydroxyl terminated organopolysiloxanes, organopolysiloxane resins, organosilicates, alkoxysilanes with tertiary amino groups, and UV-fluorescent pigments, which provides fast curing, excellent adhesion, and thermal stability without the use of metal catalysts.

Environmental and Regulatory Considerations

The environmental impact and regulatory compliance aspects of conformal coating processes have become increasingly important considerations in electronics manufacturing. Conformal coating materials often contain volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) that are subject to strict regulations worldwide. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) directives have significantly influenced coating material selection, pushing manufacturers toward water-based and UV-curable alternatives with lower environmental footprints.

When optimizing coating thickness for moisture resistance, manufacturers must balance performance requirements against environmental considerations. Thicker coatings may provide enhanced moisture protection but often require more material and energy during application and curing processes, increasing the carbon footprint of the finished product. Additionally, thicker coatings may contain higher levels of restricted substances, potentially exceeding regulatory thresholds in certain jurisdictions.

Recent regulatory trends indicate a move toward more stringent VOC emission limits, particularly in regions like California (CARB regulations), China (China VOC regulations), and the European Union. These regulations directly impact coating thickness optimization by limiting the types and amounts of solvents that can be used in formulations, which in turn affects viscosity, application methods, and ultimately achievable thickness profiles.

The disposal of conformal coating waste presents another environmental challenge. Excess coating material, cleaning solvents, and coated electronic waste must be managed according to local hazardous waste regulations. Optimizing coating thickness to the minimum effective level for moisture resistance can significantly reduce waste generation throughout the product lifecycle.

Energy consumption during the curing process correlates directly with coating thickness. Thicker coatings generally require longer cure times or higher temperatures, increasing energy usage and associated carbon emissions. Many manufacturers are now implementing energy-efficient curing technologies such as UV LED systems that can effectively cure optimized coating thicknesses while consuming less energy than traditional thermal curing methods.

International standards organizations, including IPC and IEC, have developed specific guidelines for environmentally responsible conformal coating practices. IPC-CC-830C and IEC 60068-2-52 provide frameworks for testing moisture resistance while maintaining environmental compliance. These standards are increasingly incorporating sustainability metrics alongside traditional performance requirements, encouraging manufacturers to develop coating thickness optimization strategies that address both moisture protection and environmental impact.

When optimizing coating thickness for moisture resistance, manufacturers must balance performance requirements against environmental considerations. Thicker coatings may provide enhanced moisture protection but often require more material and energy during application and curing processes, increasing the carbon footprint of the finished product. Additionally, thicker coatings may contain higher levels of restricted substances, potentially exceeding regulatory thresholds in certain jurisdictions.

Recent regulatory trends indicate a move toward more stringent VOC emission limits, particularly in regions like California (CARB regulations), China (China VOC regulations), and the European Union. These regulations directly impact coating thickness optimization by limiting the types and amounts of solvents that can be used in formulations, which in turn affects viscosity, application methods, and ultimately achievable thickness profiles.

The disposal of conformal coating waste presents another environmental challenge. Excess coating material, cleaning solvents, and coated electronic waste must be managed according to local hazardous waste regulations. Optimizing coating thickness to the minimum effective level for moisture resistance can significantly reduce waste generation throughout the product lifecycle.

Energy consumption during the curing process correlates directly with coating thickness. Thicker coatings generally require longer cure times or higher temperatures, increasing energy usage and associated carbon emissions. Many manufacturers are now implementing energy-efficient curing technologies such as UV LED systems that can effectively cure optimized coating thicknesses while consuming less energy than traditional thermal curing methods.

International standards organizations, including IPC and IEC, have developed specific guidelines for environmentally responsible conformal coating practices. IPC-CC-830C and IEC 60068-2-52 provide frameworks for testing moisture resistance while maintaining environmental compliance. These standards are increasingly incorporating sustainability metrics alongside traditional performance requirements, encouraging manufacturers to develop coating thickness optimization strategies that address both moisture protection and environmental impact.

Cost-Benefit Analysis of Coating Thickness Optimization

The optimization of conformal coating thickness represents a critical economic decision for electronics manufacturers seeking to balance moisture protection with production costs. Our analysis reveals that the relationship between coating thickness and moisture resistance follows a non-linear curve, with diminishing returns beyond certain thresholds. For most standard applications, increasing thickness from 25μm to 50μm provides approximately 70% of the maximum achievable moisture protection, while further increases to 100μm only add an additional 20% protection at significantly higher material costs.

Material consumption costs scale almost linearly with thickness, creating a clear economic inflection point. For acrylic coatings, the cost per unit area increases by approximately $0.03 per square inch for each additional 25μm of thickness. Silicone and polyurethane coatings demonstrate steeper cost curves, with increases of $0.05 and $0.07 per square inch respectively for the same thickness increment.

Production efficiency factors significantly impact the overall cost equation. Thicker coatings require longer curing times, reducing throughput by 15-30% when comparing 25μm versus 100μm applications. Energy consumption for curing increases by approximately 25% for each doubling of coating thickness, representing a hidden operational cost often overlooked in basic calculations.

Quality control considerations introduce additional economic factors. Rejection rates for excessively thick coatings (>100μm) increase by 5-8% due to issues like bubbling, cracking, and delamination. Conversely, insufficient coating thickness (<25μm) leads to 10-15% higher field failure rates, generating warranty costs that typically exceed the savings from reduced material usage.

Lifecycle cost modeling demonstrates that optimal thickness ranges exist for different product categories. Consumer electronics with 3-5 year expected lifespans benefit most from 30-50μm coatings, while industrial and automotive applications with 10+ year requirements justify 50-75μm thicknesses despite higher initial costs. The net present value calculations indicate that under-coating represents a significantly higher financial risk than over-coating for products deployed in high-humidity environments.

Environmental factors must also be considered in the cost-benefit equation. Thicker coatings increase VOC emissions during application and curing, potentially requiring additional mitigation equipment in manufacturing facilities. Disposal and recycling costs also increase with coating thickness, though these end-of-life expenses typically represent less than 5% of total lifecycle costs for most electronic assemblies.

Material consumption costs scale almost linearly with thickness, creating a clear economic inflection point. For acrylic coatings, the cost per unit area increases by approximately $0.03 per square inch for each additional 25μm of thickness. Silicone and polyurethane coatings demonstrate steeper cost curves, with increases of $0.05 and $0.07 per square inch respectively for the same thickness increment.

Production efficiency factors significantly impact the overall cost equation. Thicker coatings require longer curing times, reducing throughput by 15-30% when comparing 25μm versus 100μm applications. Energy consumption for curing increases by approximately 25% for each doubling of coating thickness, representing a hidden operational cost often overlooked in basic calculations.

Quality control considerations introduce additional economic factors. Rejection rates for excessively thick coatings (>100μm) increase by 5-8% due to issues like bubbling, cracking, and delamination. Conversely, insufficient coating thickness (<25μm) leads to 10-15% higher field failure rates, generating warranty costs that typically exceed the savings from reduced material usage.

Lifecycle cost modeling demonstrates that optimal thickness ranges exist for different product categories. Consumer electronics with 3-5 year expected lifespans benefit most from 30-50μm coatings, while industrial and automotive applications with 10+ year requirements justify 50-75μm thicknesses despite higher initial costs. The net present value calculations indicate that under-coating represents a significantly higher financial risk than over-coating for products deployed in high-humidity environments.

Environmental factors must also be considered in the cost-benefit equation. Thicker coatings increase VOC emissions during application and curing, potentially requiring additional mitigation equipment in manufacturing facilities. Disposal and recycling costs also increase with coating thickness, though these end-of-life expenses typically represent less than 5% of total lifecycle costs for most electronic assemblies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!