How to Tailor Conformal Coating Formulation for Specific PCB Types

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conformal Coating Evolution and Objectives

Conformal coating technology has evolved significantly since its inception in the 1940s, initially developed for military applications to protect electronic components from harsh environmental conditions. The progression from simple acrylic formulations to today's advanced nano-coatings represents a technological journey driven by the increasing complexity of printed circuit boards (PCBs) and their expanding applications across industries.

The 1970s marked a pivotal shift with the introduction of silicone and polyurethane coatings, offering superior protection against moisture and chemical exposure. By the 1990s, as electronics miniaturization accelerated, parylene coatings emerged, providing ultra-thin, pinhole-free protection suitable for densely populated PCBs. The 2000s witnessed the development of UV-curable formulations, significantly reducing curing times from hours to seconds, thereby enhancing manufacturing efficiency.

Recent advancements have focused on environmentally friendly solutions, moving away from solvent-based formulations with high volatile organic compound (VOC) content toward water-based and solvent-free alternatives. This shift reflects both regulatory pressures and industry sustainability initiatives. Simultaneously, the integration of nanomaterials has revolutionized coating performance, offering unprecedented combinations of flexibility, thermal conductivity, and chemical resistance.

The primary objective of modern conformal coating formulation is to develop tailored solutions that address the specific requirements of different PCB types while maintaining optimal protection. This includes considerations for component density, operating environment, expected lifespan, and manufacturing constraints. For high-frequency PCBs, coatings must minimize signal interference while maintaining protection. For automotive applications, coatings must withstand extreme temperature fluctuations and vibration stress.

Another critical objective is improving the application precision and efficiency. As PCB designs become more complex with finer pitch components, selective coating technologies must evolve to ensure protection without compromising functionality. This includes developing formulations compatible with automated dispensing systems and optimizing viscosity profiles for different application methods.

Looking forward, the industry aims to develop adaptive coating systems that can self-heal when damaged and provide real-time monitoring of protection status. Research is also focused on creating multi-functional coatings that not only protect but actively enhance PCB performance through improved thermal management or electromagnetic interference (EMI) shielding properties.

The evolution trajectory suggests a future where conformal coatings will be customized at the molecular level for specific PCB applications, offering unprecedented protection while addressing emerging challenges in electronics miniaturization, reliability, and sustainability.

The 1970s marked a pivotal shift with the introduction of silicone and polyurethane coatings, offering superior protection against moisture and chemical exposure. By the 1990s, as electronics miniaturization accelerated, parylene coatings emerged, providing ultra-thin, pinhole-free protection suitable for densely populated PCBs. The 2000s witnessed the development of UV-curable formulations, significantly reducing curing times from hours to seconds, thereby enhancing manufacturing efficiency.

Recent advancements have focused on environmentally friendly solutions, moving away from solvent-based formulations with high volatile organic compound (VOC) content toward water-based and solvent-free alternatives. This shift reflects both regulatory pressures and industry sustainability initiatives. Simultaneously, the integration of nanomaterials has revolutionized coating performance, offering unprecedented combinations of flexibility, thermal conductivity, and chemical resistance.

The primary objective of modern conformal coating formulation is to develop tailored solutions that address the specific requirements of different PCB types while maintaining optimal protection. This includes considerations for component density, operating environment, expected lifespan, and manufacturing constraints. For high-frequency PCBs, coatings must minimize signal interference while maintaining protection. For automotive applications, coatings must withstand extreme temperature fluctuations and vibration stress.

Another critical objective is improving the application precision and efficiency. As PCB designs become more complex with finer pitch components, selective coating technologies must evolve to ensure protection without compromising functionality. This includes developing formulations compatible with automated dispensing systems and optimizing viscosity profiles for different application methods.

Looking forward, the industry aims to develop adaptive coating systems that can self-heal when damaged and provide real-time monitoring of protection status. Research is also focused on creating multi-functional coatings that not only protect but actively enhance PCB performance through improved thermal management or electromagnetic interference (EMI) shielding properties.

The evolution trajectory suggests a future where conformal coatings will be customized at the molecular level for specific PCB applications, offering unprecedented protection while addressing emerging challenges in electronics miniaturization, reliability, and sustainability.

PCB Protection Market Analysis

The global conformal coating market for PCB protection has experienced significant growth in recent years, driven by the increasing complexity of electronic devices and the growing demand for reliable protection solutions. The market was valued at approximately $926 million in 2021 and is projected to reach $1.5 billion by 2028, representing a compound annual growth rate (CAGR) of 7.2% during the forecast period.

The demand for conformal coatings is particularly strong in industries where electronic components are exposed to harsh environments, including automotive, aerospace, defense, medical devices, and industrial electronics. The automotive sector represents the largest market segment, accounting for nearly 30% of the total market share, as modern vehicles incorporate increasingly sophisticated electronic systems that require protection from moisture, dust, and chemical contaminants.

Regional analysis indicates that Asia-Pacific dominates the market, holding approximately 45% of the global share, primarily due to the high concentration of electronics manufacturing in countries like China, Japan, South Korea, and Taiwan. North America and Europe follow with market shares of approximately 25% and 20% respectively, with growth driven by advanced applications in aerospace, defense, and medical devices.

The market is segmented by coating type, with acrylic, silicone, polyurethane, epoxy, and parylene being the primary formulations. Acrylic coatings currently lead the market with approximately 35% share due to their balance of performance and cost-effectiveness. However, silicone coatings are experiencing the fastest growth rate at 8.5% annually, driven by their superior performance in extreme temperature environments.

Application-specific formulations represent a rapidly growing segment within the market, as manufacturers increasingly recognize that different PCB types and operating environments require tailored protection solutions. This trend is creating new opportunities for coating manufacturers who can develop specialized formulations for specific industries and applications.

Key market drivers include the miniaturization of electronic components, which increases vulnerability to environmental factors; the growth of IoT devices deployed in diverse environments; and increasingly stringent reliability requirements in critical applications. Additionally, environmental regulations are pushing the industry toward water-based and solvent-free formulations, creating both challenges and opportunities for manufacturers.

The competitive landscape features a mix of large chemical companies and specialized coating manufacturers, with key players including Henkel, Dow Corning, Chase Corporation, Dymax Corporation, and MG Chemicals. These companies are increasingly focusing on R&D to develop customized solutions for specific PCB types and applications, recognizing that tailored formulations represent a significant competitive advantage in this evolving market.

The demand for conformal coatings is particularly strong in industries where electronic components are exposed to harsh environments, including automotive, aerospace, defense, medical devices, and industrial electronics. The automotive sector represents the largest market segment, accounting for nearly 30% of the total market share, as modern vehicles incorporate increasingly sophisticated electronic systems that require protection from moisture, dust, and chemical contaminants.

Regional analysis indicates that Asia-Pacific dominates the market, holding approximately 45% of the global share, primarily due to the high concentration of electronics manufacturing in countries like China, Japan, South Korea, and Taiwan. North America and Europe follow with market shares of approximately 25% and 20% respectively, with growth driven by advanced applications in aerospace, defense, and medical devices.

The market is segmented by coating type, with acrylic, silicone, polyurethane, epoxy, and parylene being the primary formulations. Acrylic coatings currently lead the market with approximately 35% share due to their balance of performance and cost-effectiveness. However, silicone coatings are experiencing the fastest growth rate at 8.5% annually, driven by their superior performance in extreme temperature environments.

Application-specific formulations represent a rapidly growing segment within the market, as manufacturers increasingly recognize that different PCB types and operating environments require tailored protection solutions. This trend is creating new opportunities for coating manufacturers who can develop specialized formulations for specific industries and applications.

Key market drivers include the miniaturization of electronic components, which increases vulnerability to environmental factors; the growth of IoT devices deployed in diverse environments; and increasingly stringent reliability requirements in critical applications. Additionally, environmental regulations are pushing the industry toward water-based and solvent-free formulations, creating both challenges and opportunities for manufacturers.

The competitive landscape features a mix of large chemical companies and specialized coating manufacturers, with key players including Henkel, Dow Corning, Chase Corporation, Dymax Corporation, and MG Chemicals. These companies are increasingly focusing on R&D to develop customized solutions for specific PCB types and applications, recognizing that tailored formulations represent a significant competitive advantage in this evolving market.

Current Conformal Coating Technologies and Limitations

Conformal coating technologies have evolved significantly over the past decades, with several distinct formulations now dominating the market. Acrylic coatings remain popular due to their ease of application and rework capabilities, offering good moisture and dust protection while maintaining cost-effectiveness. Silicone coatings excel in extreme temperature environments (-65°C to 200°C) and provide superior flexibility, making them ideal for applications experiencing thermal cycling or mechanical stress.

Polyurethane coatings deliver excellent chemical and moisture resistance with good dielectric properties, though they present challenges in rework processes due to their strong adhesion. Epoxy coatings offer exceptional protection against humidity and chemicals, featuring the highest abrasion resistance among common formulations, but their rigid nature can lead to stress-induced failures during thermal cycling.

Parylene coatings, applied through chemical vapor deposition, provide uniform, pinhole-free protection even on complex geometries, though they require specialized equipment and are difficult to rework. Newer nano-coatings are emerging with ultra-thin profiles and self-healing properties, though they remain in early adoption phases.

Despite these advancements, significant limitations persist across current conformal coating technologies. Formulation-specific challenges include poor adhesion to certain substrate materials, particularly with newer lead-free solder compositions and high-density interconnect boards. Many coatings struggle to maintain consistent performance across wide temperature ranges, often becoming brittle at low temperatures or losing structural integrity at high temperatures.

Application uniformity remains problematic, especially for complex PCB geometries with high component density or fine-pitch components. Edge coverage and shadowing effects create vulnerable areas where protection is compromised. Curing processes for many formulations require precise environmental controls, extending production time and increasing energy consumption.

Environmental and regulatory constraints increasingly limit the use of certain solvents and chemicals traditionally found in high-performance coatings, forcing manufacturers to reformulate with potentially less effective alternatives. Additionally, most current formulations lack adaptability to specific environmental threats, requiring manufacturers to choose between overengineering protection or risking premature failure.

The industry also faces challenges with coating removal and rework processes, as many high-performance coatings that provide excellent protection also create significant obstacles for component replacement or board modification. This limitation becomes particularly problematic in prototyping, testing, and repair scenarios where multiple iterations may be required.

Polyurethane coatings deliver excellent chemical and moisture resistance with good dielectric properties, though they present challenges in rework processes due to their strong adhesion. Epoxy coatings offer exceptional protection against humidity and chemicals, featuring the highest abrasion resistance among common formulations, but their rigid nature can lead to stress-induced failures during thermal cycling.

Parylene coatings, applied through chemical vapor deposition, provide uniform, pinhole-free protection even on complex geometries, though they require specialized equipment and are difficult to rework. Newer nano-coatings are emerging with ultra-thin profiles and self-healing properties, though they remain in early adoption phases.

Despite these advancements, significant limitations persist across current conformal coating technologies. Formulation-specific challenges include poor adhesion to certain substrate materials, particularly with newer lead-free solder compositions and high-density interconnect boards. Many coatings struggle to maintain consistent performance across wide temperature ranges, often becoming brittle at low temperatures or losing structural integrity at high temperatures.

Application uniformity remains problematic, especially for complex PCB geometries with high component density or fine-pitch components. Edge coverage and shadowing effects create vulnerable areas where protection is compromised. Curing processes for many formulations require precise environmental controls, extending production time and increasing energy consumption.

Environmental and regulatory constraints increasingly limit the use of certain solvents and chemicals traditionally found in high-performance coatings, forcing manufacturers to reformulate with potentially less effective alternatives. Additionally, most current formulations lack adaptability to specific environmental threats, requiring manufacturers to choose between overengineering protection or risking premature failure.

The industry also faces challenges with coating removal and rework processes, as many high-performance coatings that provide excellent protection also create significant obstacles for component replacement or board modification. This limitation becomes particularly problematic in prototyping, testing, and repair scenarios where multiple iterations may be required.

Existing Formulation Approaches for Different PCB Types

01 Customization of conformal coating materials

Conformal coating formulations can be tailored by selecting specific base materials to meet particular application requirements. Different polymers such as acrylics, silicones, polyurethanes, and epoxies can be used as the foundation for conformal coatings, each offering unique properties like flexibility, chemical resistance, or thermal stability. The selection of these base materials allows for customization of the coating's performance characteristics to suit specific electronic protection needs.- Customizable conformal coating compositions: Conformal coating formulations can be tailored by adjusting the composition of polymers, resins, and additives to meet specific application requirements. These customizable compositions allow for optimization of properties such as flexibility, adhesion, chemical resistance, and thermal stability. By modifying the ratio of components or incorporating specialized additives, manufacturers can create coatings that provide optimal protection for various electronic components and environmental conditions.

- Application-specific conformal coating techniques: Various application techniques can be employed to customize the deposition of conformal coatings based on specific requirements. These techniques include spray coating, dip coating, brush application, and automated selective coating. Each method offers different advantages in terms of coverage, thickness control, and precision. The selection of the appropriate application technique allows for tailoring the coating process to accommodate complex geometries, sensitive components, or high-volume production needs.

- Environmental and performance adaptations: Conformal coatings can be formulated to withstand specific environmental challenges such as extreme temperatures, humidity, chemical exposure, or mechanical stress. By incorporating specialized additives or modifying the base polymer system, coatings can be tailored to provide enhanced protection against particular environmental factors. This customization ensures optimal performance and longevity of electronic components in their intended operating environments.

- Industry-specific conformal coating solutions: Different industries have unique requirements for conformal coatings based on their operating conditions and regulatory standards. Specialized formulations have been developed for automotive, aerospace, medical, and consumer electronics applications. These tailored solutions address industry-specific challenges such as vibration resistance for automotive applications, biocompatibility for medical devices, or miniaturization requirements for consumer electronics, while complying with relevant industry standards and regulations.

- Smart and functional conformal coatings: Advanced conformal coating formulations incorporate functional additives to provide enhanced capabilities beyond basic protection. These smart coatings may include features such as thermal management properties, electromagnetic interference (EMI) shielding, self-healing capabilities, or flame retardancy. By integrating these functional elements into the coating formulation, manufacturers can address multiple protection requirements with a single coating solution, optimizing both performance and manufacturing efficiency.

02 Additive incorporation for enhanced properties

Conformal coating formulations can be enhanced through the incorporation of various additives to achieve specific performance characteristics. These additives include UV stabilizers for outdoor applications, flame retardants for safety requirements, anti-static agents for sensitive electronics, and hydrophobic compounds for moisture resistance. By carefully selecting and balancing these additives, manufacturers can tailor conformal coatings to meet specialized environmental protection requirements while maintaining other critical properties.Expand Specific Solutions03 Application-specific viscosity adjustment

The viscosity of conformal coating formulations can be customized to suit different application methods and substrate geometries. Solvents and diluents can be incorporated to adjust flow characteristics for spray, dip, or selective coating processes. For complex circuit boards with high component density, lower viscosity formulations enable better penetration under components, while higher viscosity formulations provide better edge coverage and vertical surface adhesion. These adjustments ensure optimal coating thickness and uniformity across various electronic assembly designs.Expand Specific Solutions04 Environmental and regulatory compliance formulations

Conformal coating formulations can be tailored to meet specific environmental regulations and sustainability requirements. This includes developing low-VOC or VOC-free formulations, eliminating restricted substances like certain halogenated compounds, and creating water-based alternatives to traditional solvent-based coatings. These environmentally compliant formulations maintain protective properties while reducing environmental impact and helping manufacturers meet regional regulatory standards such as RoHS, REACH, and industry-specific requirements.Expand Specific Solutions05 Cure mechanism customization

The curing mechanism of conformal coatings can be tailored to accommodate different manufacturing processes and performance requirements. Options include UV-curable formulations for rapid processing, moisture-cure systems for ambient temperature applications, heat-accelerated curing for production efficiency, and dual-cure systems combining multiple mechanisms. By customizing the cure chemistry, manufacturers can optimize production throughput, energy consumption, and ensure complete polymerization in shadow areas or under components where certain cure methods might be less effective.Expand Specific Solutions

Leading Manufacturers and Industry Landscape

The conformal coating formulation market for PCBs is in a growth phase, driven by increasing demand for electronics protection across industries. The market size is expanding due to the rising complexity of PCB applications requiring specialized protection solutions. Technologically, the field shows varying maturity levels with established players like Nordson Corp., 3M, and HzO offering advanced nano-coating technologies, while companies such as Wacker Chemie and BASF focus on specialized chemical formulations. Newer entrants like Jiangsu Favored Nanotechnology are innovating with nano-scale solutions for liquid ingress protection. The competitive landscape features diversification between traditional coating manufacturers and technology-focused companies developing tailored solutions for specific PCB environments and applications.

Nordson Corp.

Technical Solution: Nordson has developed advanced selective conformal coating systems that precisely tailor formulations to specific PCB requirements. Their technology utilizes automated dispensing equipment with multi-axis motion control to apply precisely controlled coating patterns with minimal waste. Their approach includes material-specific formulation adjustments based on PCB substrate composition, component density, and operating environment. Nordson's systems incorporate real-time viscosity monitoring and temperature control to maintain optimal application parameters for different coating chemistries (acrylic, silicone, polyurethane, etc.). The company has pioneered programmable pattern recognition technology that automatically identifies different PCB types and applies the appropriate coating thickness and coverage based on pre-defined specifications.

Strengths: Exceptional precision in selective coating application, reducing material waste and ensuring critical components receive appropriate protection. Advanced automation capabilities enable high-volume production with consistent quality. Weaknesses: Higher initial investment compared to manual coating systems, and requires technical expertise for programming and maintenance.

3M Innovative Properties Co.

Technical Solution: 3M has developed a comprehensive approach to tailoring conformal coatings for specific PCB applications through their multi-layer protection system. Their technology involves customizable fluoropolymer-based formulations that can be adjusted for different substrate materials and operating environments. The company utilizes nano-scale additives to enhance specific properties like moisture resistance, thermal conductivity, or flexibility depending on PCB requirements. 3M's coating systems incorporate proprietary cross-linking chemistry that allows for rapid curing while maintaining excellent adhesion across diverse substrate materials. Their formulations feature adjustable viscosity profiles that can be optimized for different application methods (spray, dip, brush) and component geometries. For high-reliability applications, 3M has developed self-healing coating variants that can repair minor damage through thermally-activated flow properties.

Strengths: Exceptional chemical resistance and long-term stability across extreme environmental conditions. Highly customizable formulations that can be precisely tailored to specific industry requirements (automotive, aerospace, consumer electronics). Weaknesses: Premium pricing compared to standard coating solutions, and some formulations require specialized application equipment.

Key Innovations in Coating-PCB Compatibility

Methods for preparing nano-protective coating

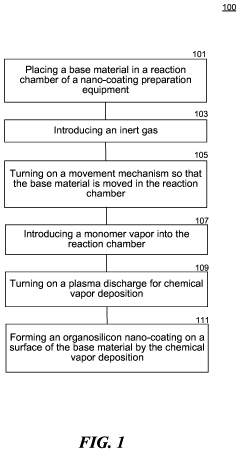

PatentActiveUS20200188953A1

Innovation

- A method involving the use of organosilicon monomers with silicon-oxygen bonds, where the substrate is moved during plasma discharge to control energy and monomer distribution, forming a dense cross-linked structure without solvents, enhancing the coating's thickness control and environmental friendliness.

Method of conformal coating using noncontact dispensing

PatentInactiveEP1678989A1

Innovation

- A noncontact dispensing method using a jetting system that propels viscous conformal coating material through a nozzle with forward momentum to form droplets, allowing for precise control over the application of small areas and geometries without overspray, eliminating the need for masking.

Environmental Compliance and Sustainability Factors

Environmental regulations and sustainability considerations have become increasingly critical factors in conformal coating formulation for PCBs. The global shift toward stricter environmental standards, exemplified by regulations like RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), and various VOC (Volatile Organic Compounds) emission limits, has fundamentally transformed the conformal coating landscape. Manufacturers must now carefully balance performance requirements with environmental compliance when tailoring formulations for specific PCB types.

Traditional solvent-based conformal coatings, while offering excellent protection and application properties, often contain high levels of VOCs and hazardous air pollutants (HAPs). This has accelerated the development of alternative formulations, including water-based coatings, high-solids formulations, and UV-curable systems that significantly reduce environmental impact while maintaining protective qualities for different PCB applications.

The sustainability profile of conformal coatings extends beyond their chemical composition to encompass their entire lifecycle. Energy consumption during application and curing processes varies significantly between coating types, with UV-curable coatings typically requiring less energy than thermal-cure alternatives. This consideration becomes particularly relevant when tailoring solutions for high-volume PCB production, where energy efficiency translates to both environmental benefits and cost savings.

Waste management represents another critical environmental factor in coating selection. Some formulations facilitate easier rework and repair processes, reducing waste generation throughout the PCB lifecycle. Additionally, coating removal methods must be evaluated for their environmental impact, as harsh solvents traditionally used for removal can introduce additional environmental concerns.

Regional regulatory variations further complicate formulation decisions. European markets typically enforce stricter environmental standards than other regions, necessitating different formulation approaches depending on the intended market for the finished PCB assembly. This regulatory fragmentation requires manufacturers to develop flexible formulation strategies that can adapt to diverse compliance requirements.

Emerging bio-based and renewable content conformal coatings represent the cutting edge of sustainability in this field. These formulations incorporate plant-derived components to reduce reliance on petrochemical feedstocks. While still evolving in terms of performance characteristics, they show particular promise for less demanding PCB applications where environmental credentials are prioritized over extreme protection requirements.

The environmental impact of packaging and transportation must also be considered in the overall sustainability assessment of conformal coating solutions. Concentrated formulations that require less packaging material and generate lower transportation emissions are gaining favor, particularly for global supply chains where logistics footprints are significant.

Traditional solvent-based conformal coatings, while offering excellent protection and application properties, often contain high levels of VOCs and hazardous air pollutants (HAPs). This has accelerated the development of alternative formulations, including water-based coatings, high-solids formulations, and UV-curable systems that significantly reduce environmental impact while maintaining protective qualities for different PCB applications.

The sustainability profile of conformal coatings extends beyond their chemical composition to encompass their entire lifecycle. Energy consumption during application and curing processes varies significantly between coating types, with UV-curable coatings typically requiring less energy than thermal-cure alternatives. This consideration becomes particularly relevant when tailoring solutions for high-volume PCB production, where energy efficiency translates to both environmental benefits and cost savings.

Waste management represents another critical environmental factor in coating selection. Some formulations facilitate easier rework and repair processes, reducing waste generation throughout the PCB lifecycle. Additionally, coating removal methods must be evaluated for their environmental impact, as harsh solvents traditionally used for removal can introduce additional environmental concerns.

Regional regulatory variations further complicate formulation decisions. European markets typically enforce stricter environmental standards than other regions, necessitating different formulation approaches depending on the intended market for the finished PCB assembly. This regulatory fragmentation requires manufacturers to develop flexible formulation strategies that can adapt to diverse compliance requirements.

Emerging bio-based and renewable content conformal coatings represent the cutting edge of sustainability in this field. These formulations incorporate plant-derived components to reduce reliance on petrochemical feedstocks. While still evolving in terms of performance characteristics, they show particular promise for less demanding PCB applications where environmental credentials are prioritized over extreme protection requirements.

The environmental impact of packaging and transportation must also be considered in the overall sustainability assessment of conformal coating solutions. Concentrated formulations that require less packaging material and generate lower transportation emissions are gaining favor, particularly for global supply chains where logistics footprints are significant.

Performance Testing and Quality Assurance Protocols

Performance testing and quality assurance protocols are critical components in the development of tailored conformal coating formulations for specific PCB types. Establishing rigorous testing methodologies ensures that coatings meet the required protection standards while maintaining compatibility with the underlying PCB materials and components.

The testing protocol should begin with basic physical property assessments, including viscosity, surface tension, and cure time measurements. These parameters directly influence the coating's application characteristics and must be optimized for different PCB topographies. For high-density PCBs with fine-pitch components, lower viscosity formulations may be required, necessitating specific quality thresholds.

Environmental stress testing represents the next critical phase, where coated PCBs undergo accelerated aging in controlled chambers simulating extreme conditions. This includes thermal cycling (-65°C to +150°C), humidity exposure (85% RH at 85°C), and salt fog testing. The duration and intensity of these tests should be calibrated according to the intended operating environment of the specific PCB type.

Electrical property verification must be conducted to ensure the coating maintains its dielectric strength and insulation resistance after application. Standardized tests such as IPC-CC-830B provide baseline requirements, but additional customized testing may be necessary for specialized applications like high-frequency RF circuits or high-voltage power electronics.

Adhesion testing using cross-hatch and pull-off methods helps quantify the coating's mechanical bond to various substrate materials common in different PCB types. FR-4, ceramic, and flexible substrates each require different adhesion specifications, with ASTM D3359 serving as a common reference standard.

Chemical resistance evaluation should target industry-specific exposure risks. For automotive PCBs, resistance to fuels and oils is paramount, while medical device PCBs require biocompatibility and resistance to sterilization chemicals. Standardized immersion tests with subsequent visual inspection and electrical testing provide quantifiable results.

Documentation and traceability systems must be implemented throughout the testing process. Each batch of conformal coating should be assigned a unique identifier linked to its complete test results, enabling manufacturers to maintain consistent quality and troubleshoot any field failures that may occur.

Finally, accelerated life testing methodologies should be developed to predict long-term performance. These protocols typically combine multiple stressors (temperature, humidity, voltage) to force failures in a compressed timeframe, allowing manufacturers to estimate the coating's protection capabilities throughout the PCB's intended service life.

The testing protocol should begin with basic physical property assessments, including viscosity, surface tension, and cure time measurements. These parameters directly influence the coating's application characteristics and must be optimized for different PCB topographies. For high-density PCBs with fine-pitch components, lower viscosity formulations may be required, necessitating specific quality thresholds.

Environmental stress testing represents the next critical phase, where coated PCBs undergo accelerated aging in controlled chambers simulating extreme conditions. This includes thermal cycling (-65°C to +150°C), humidity exposure (85% RH at 85°C), and salt fog testing. The duration and intensity of these tests should be calibrated according to the intended operating environment of the specific PCB type.

Electrical property verification must be conducted to ensure the coating maintains its dielectric strength and insulation resistance after application. Standardized tests such as IPC-CC-830B provide baseline requirements, but additional customized testing may be necessary for specialized applications like high-frequency RF circuits or high-voltage power electronics.

Adhesion testing using cross-hatch and pull-off methods helps quantify the coating's mechanical bond to various substrate materials common in different PCB types. FR-4, ceramic, and flexible substrates each require different adhesion specifications, with ASTM D3359 serving as a common reference standard.

Chemical resistance evaluation should target industry-specific exposure risks. For automotive PCBs, resistance to fuels and oils is paramount, while medical device PCBs require biocompatibility and resistance to sterilization chemicals. Standardized immersion tests with subsequent visual inspection and electrical testing provide quantifiable results.

Documentation and traceability systems must be implemented throughout the testing process. Each batch of conformal coating should be assigned a unique identifier linked to its complete test results, enabling manufacturers to maintain consistent quality and troubleshoot any field failures that may occur.

Finally, accelerated life testing methodologies should be developed to predict long-term performance. These protocols typically combine multiple stressors (temperature, humidity, voltage) to force failures in a compressed timeframe, allowing manufacturers to estimate the coating's protection capabilities throughout the PCB's intended service life.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!