Conformal Coating Vs Soft Touch Solutions: Hardness Testing

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conformal Coating and Soft Touch Technology Evolution

The evolution of conformal coating and soft touch technologies represents a fascinating journey of materials science innovation driven by electronics protection needs and consumer experience enhancement. Conformal coating technology emerged in the 1940s during World War II, primarily developed for military applications to protect sensitive electronic components from harsh environmental conditions. These early coatings were basic acrylic and epoxy formulations applied through rudimentary dipping processes.

By the 1960s and 1970s, conformal coating technology expanded into commercial electronics, with the introduction of silicone and polyurethane variants offering improved flexibility and thermal resistance. The miniaturization trend in electronics during the 1980s necessitated more precise application methods, leading to the development of selective spray systems and automated robotic application technologies.

Soft touch materials followed a different evolutionary path, originating in the 1980s primarily as aesthetic enhancements for consumer products. Initially limited to basic rubber overmolding techniques, these materials were valued for their tactile properties rather than protective capabilities. The 1990s saw significant advancement with the introduction of two-shot molding processes and specialized thermoplastic elastomers (TPEs) that could be directly integrated into product designs.

The 2000s marked a convergence point where both technologies began to influence each other. Conformal coatings evolved to incorporate UV-curable formulations that reduced curing times from hours to seconds, while also improving environmental credentials through reduced volatile organic compound (VOC) emissions. Simultaneously, soft touch materials advanced to include antimicrobial properties and improved chemical resistance.

The 2010s witnessed the emergence of nano-enhanced formulations in both technologies. Conformal coatings incorporated nanoparticles to improve moisture resistance and dielectric properties, while soft touch materials integrated nanomaterials to enhance durability without compromising tactile qualities. This period also saw increased focus on environmental sustainability, with bio-based alternatives being developed for both coating types.

Most recently, adaptive and smart coatings represent the cutting edge of both technologies. These include self-healing conformal coatings that can repair minor damage automatically and responsive soft touch materials that can change properties based on environmental conditions or user interaction. The hardness testing methodologies have similarly evolved from basic Shore durometer measurements to sophisticated instrumented indentation techniques that can measure properties at the nanoscale.

The technological trajectory suggests future developments will focus on multifunctional coatings that combine protective and interactive capabilities, potentially incorporating elements of both conformal coating durability and soft touch sensory appeal in unified solutions.

By the 1960s and 1970s, conformal coating technology expanded into commercial electronics, with the introduction of silicone and polyurethane variants offering improved flexibility and thermal resistance. The miniaturization trend in electronics during the 1980s necessitated more precise application methods, leading to the development of selective spray systems and automated robotic application technologies.

Soft touch materials followed a different evolutionary path, originating in the 1980s primarily as aesthetic enhancements for consumer products. Initially limited to basic rubber overmolding techniques, these materials were valued for their tactile properties rather than protective capabilities. The 1990s saw significant advancement with the introduction of two-shot molding processes and specialized thermoplastic elastomers (TPEs) that could be directly integrated into product designs.

The 2000s marked a convergence point where both technologies began to influence each other. Conformal coatings evolved to incorporate UV-curable formulations that reduced curing times from hours to seconds, while also improving environmental credentials through reduced volatile organic compound (VOC) emissions. Simultaneously, soft touch materials advanced to include antimicrobial properties and improved chemical resistance.

The 2010s witnessed the emergence of nano-enhanced formulations in both technologies. Conformal coatings incorporated nanoparticles to improve moisture resistance and dielectric properties, while soft touch materials integrated nanomaterials to enhance durability without compromising tactile qualities. This period also saw increased focus on environmental sustainability, with bio-based alternatives being developed for both coating types.

Most recently, adaptive and smart coatings represent the cutting edge of both technologies. These include self-healing conformal coatings that can repair minor damage automatically and responsive soft touch materials that can change properties based on environmental conditions or user interaction. The hardness testing methodologies have similarly evolved from basic Shore durometer measurements to sophisticated instrumented indentation techniques that can measure properties at the nanoscale.

The technological trajectory suggests future developments will focus on multifunctional coatings that combine protective and interactive capabilities, potentially incorporating elements of both conformal coating durability and soft touch sensory appeal in unified solutions.

Market Demand Analysis for Surface Protection Solutions

The global market for surface protection solutions has witnessed significant growth in recent years, driven by increasing demand across multiple industries including electronics, automotive, aerospace, medical devices, and consumer goods. The combined market value for conformal coatings and soft touch solutions reached approximately $15 billion in 2022, with projections indicating a compound annual growth rate of 5.7% through 2028.

Electronics manufacturing represents the largest market segment, accounting for nearly 40% of the total demand. This is primarily due to the proliferation of miniaturized electronic components and the growing need for protection against environmental factors such as moisture, dust, chemicals, and temperature fluctuations. The automotive industry follows closely, contributing about 25% of market demand, particularly for applications in electronic control units, sensors, and interior components requiring both protection and enhanced tactile experience.

Consumer preferences are increasingly driving market dynamics, with end-users demanding products that not only perform reliably but also offer superior tactile feedback and aesthetic appeal. This has led to a 32% increase in demand for soft touch solutions over the past three years, despite their generally lower protection capabilities compared to traditional conformal coatings.

Regional analysis reveals that Asia-Pacific dominates the market with a 45% share, followed by North America (28%) and Europe (20%). The rapid growth in Asia-Pacific is attributed to the concentration of electronics manufacturing facilities and automotive production centers in countries like China, Japan, South Korea, and Taiwan.

A significant market trend is the increasing demand for environmentally friendly and regulatory-compliant coating solutions. With stricter regulations regarding volatile organic compounds (VOCs) and hazardous air pollutants, manufacturers are investing in water-based and UV-curable coating technologies, which now represent 37% of the total market.

The hardness testing segment within the surface protection market has grown by 8.3% annually, exceeding the overall market growth rate. This acceleration reflects the industry's increasing focus on quantifiable quality metrics and standardized testing protocols to ensure consistent performance across applications.

Customer surveys indicate that 78% of industrial buyers consider hardness specifications as a critical factor in their purchasing decisions for surface protection solutions, highlighting the importance of reliable hardness testing methodologies and clear performance documentation in marketing materials.

Electronics manufacturing represents the largest market segment, accounting for nearly 40% of the total demand. This is primarily due to the proliferation of miniaturized electronic components and the growing need for protection against environmental factors such as moisture, dust, chemicals, and temperature fluctuations. The automotive industry follows closely, contributing about 25% of market demand, particularly for applications in electronic control units, sensors, and interior components requiring both protection and enhanced tactile experience.

Consumer preferences are increasingly driving market dynamics, with end-users demanding products that not only perform reliably but also offer superior tactile feedback and aesthetic appeal. This has led to a 32% increase in demand for soft touch solutions over the past three years, despite their generally lower protection capabilities compared to traditional conformal coatings.

Regional analysis reveals that Asia-Pacific dominates the market with a 45% share, followed by North America (28%) and Europe (20%). The rapid growth in Asia-Pacific is attributed to the concentration of electronics manufacturing facilities and automotive production centers in countries like China, Japan, South Korea, and Taiwan.

A significant market trend is the increasing demand for environmentally friendly and regulatory-compliant coating solutions. With stricter regulations regarding volatile organic compounds (VOCs) and hazardous air pollutants, manufacturers are investing in water-based and UV-curable coating technologies, which now represent 37% of the total market.

The hardness testing segment within the surface protection market has grown by 8.3% annually, exceeding the overall market growth rate. This acceleration reflects the industry's increasing focus on quantifiable quality metrics and standardized testing protocols to ensure consistent performance across applications.

Customer surveys indicate that 78% of industrial buyers consider hardness specifications as a critical factor in their purchasing decisions for surface protection solutions, highlighting the importance of reliable hardness testing methodologies and clear performance documentation in marketing materials.

Technical Challenges in Hardness Testing Methodologies

Hardness testing methodologies for conformal coatings and soft touch solutions present several significant technical challenges that impact measurement accuracy and reliability. The fundamental issue lies in the diverse material properties these coatings exhibit, ranging from extremely hard protective conformal coatings to deliberately soft tactile surfaces. This diversity necessitates different testing approaches, yet industry standards have not fully evolved to address these specialized needs.

One primary challenge is the thin-film nature of these coatings, typically ranging from 25 to 250 microns for conformal coatings and 50 to 500 microns for soft touch solutions. Traditional hardness testing methods like Rockwell or Brinell are unsuitable as they require material thicknesses significantly greater than these coatings provide. While micro-indentation techniques such as Vickers and Knoop offer better alternatives, they still struggle with ultra-thin applications where substrate effects can significantly influence readings.

The viscoelastic behavior of soft touch coatings presents another substantial challenge. These materials often demonstrate time-dependent recovery after indentation, making standard hardness measurements problematic. The rate of indentation and dwell time become critical parameters that can dramatically affect results, yet standardization of these parameters across the industry remains inconsistent.

Environmental factors introduce additional complexity to hardness testing. Both coating types exhibit property changes with temperature and humidity variations. Conformal coatings may become more brittle at low temperatures or soften at elevated temperatures, while soft touch solutions can show even more dramatic property shifts. Testing protocols rarely account for these environmental dependencies, leading to inconsistent results across different testing conditions.

Surface texture variations further complicate measurements. Soft touch coatings often intentionally incorporate textured surfaces for enhanced tactile properties, making it difficult to obtain consistent indentation measurements. The surface irregularities create challenges in establishing a reliable reference plane for depth measurements, introducing significant variability in test results.

Aging effects represent another critical challenge, as both coating types undergo property changes over time. Conformal coatings may harden further through continued curing or degrade through UV exposure, while soft touch solutions might experience plasticizer migration or oxidation. Current testing methodologies rarely account for these temporal changes, potentially leading to misleading conclusions about long-term performance.

Correlation between laboratory hardness measurements and real-world performance remains perhaps the most significant challenge. The relationship between measured hardness values and practical attributes like scratch resistance, wear performance, and tactile sensation is not straightforward, requiring extensive empirical testing to establish meaningful correlations for specific applications.

One primary challenge is the thin-film nature of these coatings, typically ranging from 25 to 250 microns for conformal coatings and 50 to 500 microns for soft touch solutions. Traditional hardness testing methods like Rockwell or Brinell are unsuitable as they require material thicknesses significantly greater than these coatings provide. While micro-indentation techniques such as Vickers and Knoop offer better alternatives, they still struggle with ultra-thin applications where substrate effects can significantly influence readings.

The viscoelastic behavior of soft touch coatings presents another substantial challenge. These materials often demonstrate time-dependent recovery after indentation, making standard hardness measurements problematic. The rate of indentation and dwell time become critical parameters that can dramatically affect results, yet standardization of these parameters across the industry remains inconsistent.

Environmental factors introduce additional complexity to hardness testing. Both coating types exhibit property changes with temperature and humidity variations. Conformal coatings may become more brittle at low temperatures or soften at elevated temperatures, while soft touch solutions can show even more dramatic property shifts. Testing protocols rarely account for these environmental dependencies, leading to inconsistent results across different testing conditions.

Surface texture variations further complicate measurements. Soft touch coatings often intentionally incorporate textured surfaces for enhanced tactile properties, making it difficult to obtain consistent indentation measurements. The surface irregularities create challenges in establishing a reliable reference plane for depth measurements, introducing significant variability in test results.

Aging effects represent another critical challenge, as both coating types undergo property changes over time. Conformal coatings may harden further through continued curing or degrade through UV exposure, while soft touch solutions might experience plasticizer migration or oxidation. Current testing methodologies rarely account for these temporal changes, potentially leading to misleading conclusions about long-term performance.

Correlation between laboratory hardness measurements and real-world performance remains perhaps the most significant challenge. The relationship between measured hardness values and practical attributes like scratch resistance, wear performance, and tactile sensation is not straightforward, requiring extensive empirical testing to establish meaningful correlations for specific applications.

Current Hardness Testing Methods and Standards

01 Conformal coating materials with varying hardness properties

Various materials can be used for conformal coatings with different hardness characteristics. These include polyurethane, acrylic, silicone, and epoxy-based formulations that offer a range of Shore hardness values. The selection of coating material depends on the specific application requirements, with some formulations providing softer, more flexible coatings while others offer harder, more durable protection for electronic components.- Conformal coating materials with varying hardness properties: Conformal coatings can be formulated with different hardness properties to meet specific application requirements. These coatings can range from soft and flexible to hard and rigid, depending on the polymer base used. The hardness can be adjusted by modifying the chemical composition, curing conditions, and additives incorporated into the coating formulation. This allows for customization of the coating's mechanical properties while maintaining its protective function against environmental factors.

- Soft touch coatings with tactile properties: Soft touch solutions provide a pleasant tactile feel while maintaining protective properties. These coatings typically utilize elastomeric materials or polyurethane-based formulations that create a soft, velvety surface texture. The hardness of soft touch coatings can be precisely controlled through the ratio of hard and soft segments in the polymer structure. These coatings are commonly applied to consumer electronics, automotive interiors, and handheld devices to enhance user experience while providing protection against wear and environmental factors.

- Hardness measurement and testing methods: Various methods are employed to measure and test the hardness of conformal coatings and soft touch solutions. These include Shore durometer tests (Shore A and Shore D scales), pencil hardness tests, and nanoindentation techniques. The hardness measurement provides critical information about the coating's resistance to scratching, abrasion, and deformation. Testing protocols often involve standardized procedures to ensure consistency and comparability of results across different coating formulations and applications.

- Application techniques for consistent hardness: Achieving consistent hardness in conformal coatings and soft touch solutions requires specific application techniques. Methods such as spraying, dipping, brushing, and automated selective coating are used depending on the substrate geometry and coating requirements. The thickness control, curing parameters, and environmental conditions during application significantly impact the final hardness properties. Multi-layer approaches may be employed to achieve an optimal balance between surface softness and underlying protection, with each layer contributing specific properties to the overall coating system.

- Electronic protection with optimized hardness: Conformal coatings for electronic components require carefully balanced hardness properties to provide protection without causing stress on delicate components. These coatings must be hard enough to resist physical damage while remaining flexible enough to accommodate thermal expansion and contraction of the substrate. Advanced formulations incorporate specialized additives that enhance protective properties against moisture, chemicals, and temperature extremes while maintaining appropriate hardness levels. The coating hardness must be optimized to prevent cracking during thermal cycling while still providing adequate mechanical protection.

02 Soft touch coating technologies and applications

Soft touch coatings provide tactile comfort and aesthetic appeal while maintaining protective properties. These coatings typically utilize elastomeric materials or specialized polymer blends that create a pleasant feel while still offering resistance to environmental factors. Applications include consumer electronics, automotive interiors, and medical devices where user comfort and grip are important considerations alongside protection requirements.Expand Specific Solutions03 Hardness measurement and testing methods for coatings

Various methods are employed to measure and test the hardness of conformal and soft touch coatings. These include Shore durometer testing (Shore A and Shore D scales), pencil hardness tests, and nanoindentation techniques. The hardness measurements help determine the coating's resistance to scratching, abrasion, and deformation, which are critical parameters for ensuring proper protection and durability in various environmental conditions.Expand Specific Solutions04 Electronic component protection with conformal coatings

Conformal coatings provide essential protection for electronic components against moisture, dust, chemicals, and mechanical stress. The hardness of these coatings is carefully balanced to ensure they can withstand environmental challenges while maintaining flexibility to accommodate thermal expansion and contraction of components. Advanced formulations offer enhanced protection for sensitive electronics in harsh environments while maintaining appropriate hardness characteristics.Expand Specific Solutions05 Manufacturing processes for applying conformal and soft touch coatings

Various manufacturing processes are used to apply conformal and soft touch coatings with controlled hardness properties. These include spray coating, dipping, brushing, and automated selective coating systems. The application method significantly impacts the final hardness and performance characteristics of the coating. Process parameters such as curing temperature, humidity, and application thickness must be carefully controlled to achieve the desired hardness specifications and ensure consistent coating quality.Expand Specific Solutions

Key Industry Players in Coating Materials Manufacturing

The conformal coating vs soft touch solutions market is in a growth phase, with increasing demand driven by electronics and automotive applications. The market size is expanding due to the need for protective coatings in harsh environments and consumer preference for soft-touch finishes. Technologically, the field shows moderate maturity with established players like PPG Industries, 3M, and Arkema leading innovation in hardness testing methodologies. Companies including Apple, Samsung, and Toyota are driving application-specific requirements, while specialized testing equipment manufacturers such as Bruker Nano and KLA Corp provide advanced hardness measurement solutions. Nordson and AKZO Nobel are developing hybrid solutions that balance protection with tactile qualities, indicating a trend toward multifunctional coating systems.

Bruker Nano, Inc.

Technical Solution: Bruker Nano has developed advanced nanoindentation systems specifically designed for hardness testing of conformal coatings and soft touch solutions. Their Hysitron TI Premier Nanoindenter utilizes dynamic mechanical analysis capabilities to precisely measure the mechanical properties of both rigid conformal coatings and compliant soft touch materials. The system employs a patented electromagnetic transducer that allows for controlled force application ranging from micronewtons to millinewtons, enabling accurate hardness measurements across various coating thicknesses (from nanometers to micrometers). Their proprietary QuasistaTic® measurement technique allows for continuous measurement of hardness and elastic modulus as a function of indentation depth, providing comprehensive characterization of coating performance and durability under different environmental conditions.

Strengths: Superior precision in measuring nanoscale mechanical properties; ability to test both hard conformal coatings and soft touch materials with the same instrument; advanced data analysis software for comprehensive material characterization. Weaknesses: High equipment cost; requires specialized training for operation; limited throughput for high-volume production testing.

Nordson Corp.

Technical Solution: Nordson has pioneered integrated testing solutions for conformal coating quality assessment through their Asymtek Selective Coating product line. Their approach combines automated optical inspection (AOI) with mechanical testing capabilities to evaluate coating thickness uniformity and hardness characteristics. The system utilizes precision dispensing technology coupled with in-line hardness testing that employs modified Shore durometer principles adapted for thin films. Their proprietary Coating Process Quality (CPQ) software correlates visual inspection data with hardness measurements to create comprehensive coating quality profiles. Nordson's technology enables real-time monitoring of coating hardness variations across complex electronic assemblies, allowing manufacturers to optimize their conformal coating processes for consistent protection while maintaining the desired tactile properties for soft touch applications. The system can detect subtle hardness variations that might indicate curing issues or contamination problems before they impact product reliability.

Strengths: Integrated inspection and testing solution; high throughput suitable for production environments; excellent correlation between visual and mechanical property data. Weaknesses: Less precise than dedicated laboratory instruments; primarily designed for production monitoring rather than fundamental materials research.

Critical Patents in Conformal Coating and Soft Touch Materials

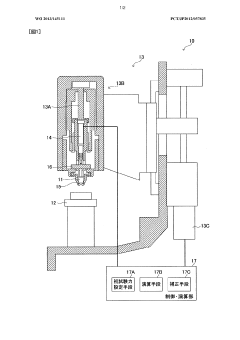

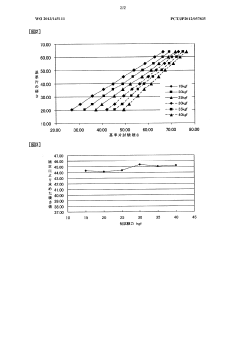

Hardness testing device and hardness testing method

PatentWO2013145111A1

Innovation

- A hardness tester and method that allows for arbitrary adjustment of the initial test force, enabling the indenter to penetrate through surface layers, with a correction mechanism to account for deviations in hardness calculations based on the Rockwell hardness formula, using a depth detection system and control unit to calculate hardness from the difference in indenter penetration depths before and after applying the initial and final forces.

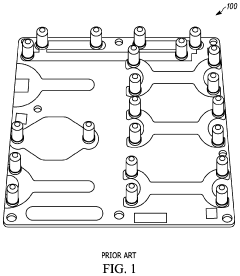

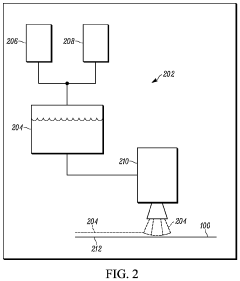

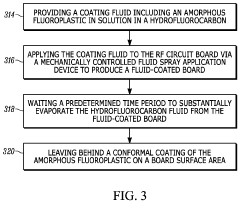

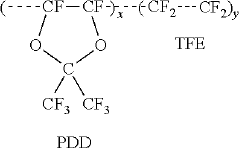

Method of conformal coating

PatentActiveUS10485108B1

Innovation

- A method using a mechanically controlled fluid spray application of an amorphous fluorinated polymer dissolved in a fluorinated solvent, such as Teflon™ AF in Vertrel™ XF, to apply a thin, conformal coating to RF circuit boards, which evaporates, leaving behind a protective layer that adheres without degrading RF performance.

Environmental Impact and Sustainability Considerations

The environmental impact of protective coatings for electronic components has become increasingly significant as sustainability considerations gain prominence in manufacturing decisions. Conformal coatings and soft touch solutions present different ecological footprints throughout their lifecycle, from raw material extraction to end-of-life disposal.

Conformal coatings, particularly those based on acrylic, silicone, and polyurethane chemistries, often contain volatile organic compounds (VOCs) that contribute to air pollution and potential health hazards during application. Traditional solvent-based conformal coatings can release significant amounts of VOCs during curing processes, though water-based alternatives have emerged to address this concern. The hardness testing methods for these coatings typically involve minimal additional environmental impact, as they are non-destructive and require little energy consumption.

Soft touch solutions, while providing enhanced tactile properties, frequently incorporate plasticizers and additives that may present environmental challenges. The manufacturing processes for soft touch coatings often require higher energy inputs compared to standard conformal coatings, resulting in greater carbon emissions. However, recent innovations in bio-based soft touch materials offer promising reductions in environmental impact while maintaining performance characteristics.

Waste management represents another critical environmental consideration. Conformal coatings generally create less waste during application due to their precision application methods, whereas soft touch solutions may generate more overspray and material waste. The hardness testing procedures for both coating types generate minimal waste, though the disposal of test samples and chemicals used in certain testing protocols requires proper hazardous waste management.

Recyclability presents distinct challenges for both coating types. Electronics protected with conformal coatings may be more difficult to recycle due to the chemical bonding between the coating and substrate. Soft touch solutions, particularly those incorporating rubber-like materials, can complicate separation processes in recycling facilities. The hardness characteristics of both coating types influence their end-of-life management, with softer materials generally being more challenging to separate from base materials.

Recent regulatory developments have pushed manufacturers toward more sustainable formulations. RoHS and REACH compliance has become standard for both coating types, with increasing focus on eliminating persistent environmental pollutants. Several manufacturers have developed hardness testing protocols that specifically evaluate environmental resistance while minimizing ecological impact during the testing process itself.

Life cycle assessment (LCA) studies comparing these coating technologies indicate that the environmental impact varies significantly based on specific formulations and application methods. The durability resulting from appropriate hardness characteristics directly influences product lifespan, potentially offsetting initial environmental costs through extended service life and reduced replacement frequency.

Conformal coatings, particularly those based on acrylic, silicone, and polyurethane chemistries, often contain volatile organic compounds (VOCs) that contribute to air pollution and potential health hazards during application. Traditional solvent-based conformal coatings can release significant amounts of VOCs during curing processes, though water-based alternatives have emerged to address this concern. The hardness testing methods for these coatings typically involve minimal additional environmental impact, as they are non-destructive and require little energy consumption.

Soft touch solutions, while providing enhanced tactile properties, frequently incorporate plasticizers and additives that may present environmental challenges. The manufacturing processes for soft touch coatings often require higher energy inputs compared to standard conformal coatings, resulting in greater carbon emissions. However, recent innovations in bio-based soft touch materials offer promising reductions in environmental impact while maintaining performance characteristics.

Waste management represents another critical environmental consideration. Conformal coatings generally create less waste during application due to their precision application methods, whereas soft touch solutions may generate more overspray and material waste. The hardness testing procedures for both coating types generate minimal waste, though the disposal of test samples and chemicals used in certain testing protocols requires proper hazardous waste management.

Recyclability presents distinct challenges for both coating types. Electronics protected with conformal coatings may be more difficult to recycle due to the chemical bonding between the coating and substrate. Soft touch solutions, particularly those incorporating rubber-like materials, can complicate separation processes in recycling facilities. The hardness characteristics of both coating types influence their end-of-life management, with softer materials generally being more challenging to separate from base materials.

Recent regulatory developments have pushed manufacturers toward more sustainable formulations. RoHS and REACH compliance has become standard for both coating types, with increasing focus on eliminating persistent environmental pollutants. Several manufacturers have developed hardness testing protocols that specifically evaluate environmental resistance while minimizing ecological impact during the testing process itself.

Life cycle assessment (LCA) studies comparing these coating technologies indicate that the environmental impact varies significantly based on specific formulations and application methods. The durability resulting from appropriate hardness characteristics directly influences product lifespan, potentially offsetting initial environmental costs through extended service life and reduced replacement frequency.

Comparative Cost-Benefit Analysis of Coating Solutions

When evaluating conformal coating versus soft touch solutions, cost-benefit analysis reveals significant economic implications across multiple dimensions. Initial implementation costs for conformal coating typically range from $0.05 to $0.30 per square inch, depending on material selection (acrylic, silicone, polyurethane, or epoxy). Soft touch solutions generally command a premium of 15-25% over standard conformal coatings due to specialized materials and application processes.

Equipment investment presents another critical cost factor. Conformal coating requires spray systems, curing ovens, and inspection equipment, representing capital expenditures of $50,000-$200,000 for production-scale operations. Soft touch application often necessitates additional specialized equipment for consistent tactile properties, potentially increasing initial investment by 30-40%.

Operational expenses differ substantially between these technologies. Conformal coating typically achieves higher throughput rates, processing 300-500 units per hour in automated systems. Soft touch solutions generally operate at 200-350 units per hour due to more complex application requirements and longer curing times, resulting in approximately 20% higher labor costs per unit.

Maintenance considerations favor conformal coating, which requires routine equipment cleaning and occasional recalibration, typically costing 3-5% of initial equipment investment annually. Soft touch solutions demand more frequent maintenance interventions and specialized cleaning protocols, with annual maintenance costs reaching 7-10% of equipment value.

Longevity analysis demonstrates that standard conformal coatings provide 5-10 years of protection in normal operating conditions, while premium soft touch solutions offer comparable protection but with potential degradation of tactile properties after 3-5 years. This differential creates replacement cycle implications affecting total ownership costs.

Environmental compliance costs increasingly impact economic calculations. Traditional solvent-based conformal coatings incur regulatory compliance costs of approximately $5,000-$15,000 annually for medium-sized operations. Water-based and UV-curable alternatives reduce these costs by 40-60% but may require process modifications. Soft touch solutions generally utilize more environmentally friendly formulations but may require specialized disposal protocols for certain components.

Return on investment calculations indicate conformal coating typically achieves ROI within 12-18 months for high-volume applications, while soft touch solutions require 18-30 months to reach break-even, primarily justified through premium product positioning and enhanced user experience rather than pure cost efficiency.

Equipment investment presents another critical cost factor. Conformal coating requires spray systems, curing ovens, and inspection equipment, representing capital expenditures of $50,000-$200,000 for production-scale operations. Soft touch application often necessitates additional specialized equipment for consistent tactile properties, potentially increasing initial investment by 30-40%.

Operational expenses differ substantially between these technologies. Conformal coating typically achieves higher throughput rates, processing 300-500 units per hour in automated systems. Soft touch solutions generally operate at 200-350 units per hour due to more complex application requirements and longer curing times, resulting in approximately 20% higher labor costs per unit.

Maintenance considerations favor conformal coating, which requires routine equipment cleaning and occasional recalibration, typically costing 3-5% of initial equipment investment annually. Soft touch solutions demand more frequent maintenance interventions and specialized cleaning protocols, with annual maintenance costs reaching 7-10% of equipment value.

Longevity analysis demonstrates that standard conformal coatings provide 5-10 years of protection in normal operating conditions, while premium soft touch solutions offer comparable protection but with potential degradation of tactile properties after 3-5 years. This differential creates replacement cycle implications affecting total ownership costs.

Environmental compliance costs increasingly impact economic calculations. Traditional solvent-based conformal coatings incur regulatory compliance costs of approximately $5,000-$15,000 annually for medium-sized operations. Water-based and UV-curable alternatives reduce these costs by 40-60% but may require process modifications. Soft touch solutions generally utilize more environmentally friendly formulations but may require specialized disposal protocols for certain components.

Return on investment calculations indicate conformal coating typically achieves ROI within 12-18 months for high-volume applications, while soft touch solutions require 18-30 months to reach break-even, primarily justified through premium product positioning and enhanced user experience rather than pure cost efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!