Measure Outgassing Properties in High-Performance Conformal Coating

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conformal Coating Outgassing Background and Objectives

Conformal coating technology has evolved significantly over the past five decades, transitioning from simple protective layers to sophisticated engineered materials with multiple functionalities. Originally developed for military and aerospace applications in the 1960s, these coatings have become essential components in modern electronics manufacturing across diverse industries including automotive, medical devices, and consumer electronics. The evolution has been driven by increasingly demanding operating environments and the miniaturization of electronic components, requiring enhanced protection against moisture, chemicals, temperature extremes, and mechanical stress.

Outgassing—the release of trapped gases or volatile compounds from materials under vacuum or elevated temperatures—represents a critical challenge in high-performance conformal coating applications. This phenomenon can lead to serious reliability issues including delamination, bubble formation, and contamination of sensitive components. The aerospace industry first documented systematic studies of outgassing effects in the 1970s, but comprehensive measurement methodologies remained inconsistent until standardization efforts began in the 1990s.

Current industry standards such as ASTM E595 and NASA SP-R-0022A provide baseline testing protocols, but these were primarily developed for space applications and may not fully address the specific requirements of modern electronics manufacturing environments. The increasing complexity of electronic assemblies and the introduction of new substrate materials have created a need for more sophisticated and application-specific outgassing measurement techniques.

The primary objective of this technical research is to develop comprehensive methodologies for measuring outgassing properties in high-performance conformal coatings that accurately predict real-world performance across diverse operating conditions. This includes establishing correlations between laboratory measurements and field performance, identifying key outgassing compounds and their sources, and determining threshold values for different application scenarios.

Secondary objectives include investigating the relationship between coating formulation parameters and outgassing behavior, evaluating the impact of curing conditions on volatile content retention, and developing accelerated testing protocols that can reliably predict long-term outgassing characteristics. These objectives align with industry trends toward higher reliability requirements and increasing regulatory pressure regarding volatile organic compounds (VOCs) and hazardous air pollutants.

The technological goal is to establish a standardized framework for outgassing measurement that enables meaningful comparison between different coating formulations and application methods, ultimately supporting more informed material selection decisions and process optimizations. This framework must balance scientific rigor with practical implementation considerations to ensure adoption across the electronics manufacturing ecosystem.

Outgassing—the release of trapped gases or volatile compounds from materials under vacuum or elevated temperatures—represents a critical challenge in high-performance conformal coating applications. This phenomenon can lead to serious reliability issues including delamination, bubble formation, and contamination of sensitive components. The aerospace industry first documented systematic studies of outgassing effects in the 1970s, but comprehensive measurement methodologies remained inconsistent until standardization efforts began in the 1990s.

Current industry standards such as ASTM E595 and NASA SP-R-0022A provide baseline testing protocols, but these were primarily developed for space applications and may not fully address the specific requirements of modern electronics manufacturing environments. The increasing complexity of electronic assemblies and the introduction of new substrate materials have created a need for more sophisticated and application-specific outgassing measurement techniques.

The primary objective of this technical research is to develop comprehensive methodologies for measuring outgassing properties in high-performance conformal coatings that accurately predict real-world performance across diverse operating conditions. This includes establishing correlations between laboratory measurements and field performance, identifying key outgassing compounds and their sources, and determining threshold values for different application scenarios.

Secondary objectives include investigating the relationship between coating formulation parameters and outgassing behavior, evaluating the impact of curing conditions on volatile content retention, and developing accelerated testing protocols that can reliably predict long-term outgassing characteristics. These objectives align with industry trends toward higher reliability requirements and increasing regulatory pressure regarding volatile organic compounds (VOCs) and hazardous air pollutants.

The technological goal is to establish a standardized framework for outgassing measurement that enables meaningful comparison between different coating formulations and application methods, ultimately supporting more informed material selection decisions and process optimizations. This framework must balance scientific rigor with practical implementation considerations to ensure adoption across the electronics manufacturing ecosystem.

Market Demand Analysis for Low-Outgassing Coatings

The global market for low-outgassing conformal coatings has experienced significant growth in recent years, driven primarily by the expanding aerospace, electronics, and medical device industries. These sectors demand materials that maintain stability in vacuum or high-temperature environments without releasing volatile compounds that could compromise system performance or safety.

In the aerospace sector, the demand for low-outgassing coatings has grown at approximately 7% annually over the past five years. This growth is attributed to increasing satellite deployments and space exploration missions, where component reliability in vacuum environments is critical. The commercial space industry's expansion has further accelerated this demand, with private companies launching more satellites requiring specialized protective coatings.

The electronics industry represents the largest market segment for low-outgassing coatings, particularly in high-reliability applications such as military electronics, automotive control systems, and medical devices. Market analysis indicates that electronics manufacturers are increasingly specifying low-outgassing properties as standard requirements for conformal coatings, even in applications where they were previously considered optional.

Medical device manufacturing has emerged as a rapidly growing application area, with stringent requirements for materials used in implantable devices and diagnostic equipment. The need for biocompatible coatings that maintain stability without releasing potentially harmful compounds has created a specialized niche within the broader conformal coating market.

Regional market analysis shows North America and Europe currently dominating the low-outgassing coatings market, collectively accounting for over 60% of global demand. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by expanding electronics manufacturing and increasing adoption of high-reliability standards in countries like China, Japan, and South Korea.

Customer requirements are evolving toward more quantifiable outgassing specifications, with many industries now requiring detailed outgassing test data according to ASTM E595 or similar standards. This shift from general low-outgassing claims to specific performance metrics has created market opportunities for coating manufacturers who can provide comprehensive testing data and certification.

Price sensitivity varies significantly by application, with aerospace and medical applications demonstrating willingness to pay premium prices for coatings with proven low-outgassing properties and comprehensive documentation. In contrast, consumer electronics manufacturers remain more price-sensitive, creating demand for cost-effective solutions that still meet basic outgassing requirements.

Market forecasts project continued growth in the low-outgassing coatings sector, with an estimated compound annual growth rate of 8.5% through 2028, potentially creating a specialized market valued at several billion dollars globally as industries increasingly recognize the critical importance of controlling volatile emissions in sensitive applications.

In the aerospace sector, the demand for low-outgassing coatings has grown at approximately 7% annually over the past five years. This growth is attributed to increasing satellite deployments and space exploration missions, where component reliability in vacuum environments is critical. The commercial space industry's expansion has further accelerated this demand, with private companies launching more satellites requiring specialized protective coatings.

The electronics industry represents the largest market segment for low-outgassing coatings, particularly in high-reliability applications such as military electronics, automotive control systems, and medical devices. Market analysis indicates that electronics manufacturers are increasingly specifying low-outgassing properties as standard requirements for conformal coatings, even in applications where they were previously considered optional.

Medical device manufacturing has emerged as a rapidly growing application area, with stringent requirements for materials used in implantable devices and diagnostic equipment. The need for biocompatible coatings that maintain stability without releasing potentially harmful compounds has created a specialized niche within the broader conformal coating market.

Regional market analysis shows North America and Europe currently dominating the low-outgassing coatings market, collectively accounting for over 60% of global demand. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by expanding electronics manufacturing and increasing adoption of high-reliability standards in countries like China, Japan, and South Korea.

Customer requirements are evolving toward more quantifiable outgassing specifications, with many industries now requiring detailed outgassing test data according to ASTM E595 or similar standards. This shift from general low-outgassing claims to specific performance metrics has created market opportunities for coating manufacturers who can provide comprehensive testing data and certification.

Price sensitivity varies significantly by application, with aerospace and medical applications demonstrating willingness to pay premium prices for coatings with proven low-outgassing properties and comprehensive documentation. In contrast, consumer electronics manufacturers remain more price-sensitive, creating demand for cost-effective solutions that still meet basic outgassing requirements.

Market forecasts project continued growth in the low-outgassing coatings sector, with an estimated compound annual growth rate of 8.5% through 2028, potentially creating a specialized market valued at several billion dollars globally as industries increasingly recognize the critical importance of controlling volatile emissions in sensitive applications.

Current Measurement Techniques and Limitations

The measurement of outgassing properties in high-performance conformal coatings currently employs several established techniques, each with specific capabilities and limitations. The most widely used method is the ASTM E595 standard test, which measures Total Mass Loss (TML) and Collected Volatile Condensable Materials (CVCM) under vacuum conditions. This test operates at 125°C for 24 hours and provides quantitative data on material volatility, but fails to identify specific outgassing compounds or their release rates over time.

Thermogravimetric Analysis (TGA) offers another approach by measuring weight changes as a function of temperature in controlled environments. While TGA provides valuable data on thermal stability and decomposition patterns, it typically operates at atmospheric pressure rather than vacuum conditions, limiting direct correlation to space applications. Additionally, TGA cannot distinguish between different volatile species released simultaneously.

Mass spectrometry techniques, particularly Residual Gas Analysis (RGA), enable real-time identification of outgassed species. However, these systems require complex vacuum setups and specialized expertise for proper interpretation. The sensitivity varies significantly between different molecular species, making absolute quantification challenging without extensive calibration.

Quartz Crystal Microbalance (QCM) technology offers high sensitivity for measuring mass deposition rates of condensable outgassing products. Modern QCM systems can detect nanogram-level mass changes but are limited to measuring only condensable species at the specific temperature of the crystal, potentially missing non-condensable outgassing products.

For conformal coatings specifically, the industry faces challenges with sample preparation consistency. Coating thickness variations and substrate interactions significantly influence outgassing behavior, yet standardized sample preparation protocols remain inadequately defined. This introduces variability in test results across different laboratories.

Current limitations also include the disconnect between accelerated testing and real-world performance. Most standard tests employ elevated temperatures to accelerate outgassing, but the correlation between these accelerated results and actual long-term performance under varying operational conditions remains poorly established. This creates uncertainty when predicting coating behavior over extended missions or in fluctuating environments.

Furthermore, existing techniques generally lack the capability to measure outgassing under dynamic conditions that simulate actual operational environments, including thermal cycling, radiation exposure, and mechanical stress. This gap between laboratory testing and real-world application scenarios represents a significant limitation in current measurement methodologies for high-performance conformal coatings.

Thermogravimetric Analysis (TGA) offers another approach by measuring weight changes as a function of temperature in controlled environments. While TGA provides valuable data on thermal stability and decomposition patterns, it typically operates at atmospheric pressure rather than vacuum conditions, limiting direct correlation to space applications. Additionally, TGA cannot distinguish between different volatile species released simultaneously.

Mass spectrometry techniques, particularly Residual Gas Analysis (RGA), enable real-time identification of outgassed species. However, these systems require complex vacuum setups and specialized expertise for proper interpretation. The sensitivity varies significantly between different molecular species, making absolute quantification challenging without extensive calibration.

Quartz Crystal Microbalance (QCM) technology offers high sensitivity for measuring mass deposition rates of condensable outgassing products. Modern QCM systems can detect nanogram-level mass changes but are limited to measuring only condensable species at the specific temperature of the crystal, potentially missing non-condensable outgassing products.

For conformal coatings specifically, the industry faces challenges with sample preparation consistency. Coating thickness variations and substrate interactions significantly influence outgassing behavior, yet standardized sample preparation protocols remain inadequately defined. This introduces variability in test results across different laboratories.

Current limitations also include the disconnect between accelerated testing and real-world performance. Most standard tests employ elevated temperatures to accelerate outgassing, but the correlation between these accelerated results and actual long-term performance under varying operational conditions remains poorly established. This creates uncertainty when predicting coating behavior over extended missions or in fluctuating environments.

Furthermore, existing techniques generally lack the capability to measure outgassing under dynamic conditions that simulate actual operational environments, including thermal cycling, radiation exposure, and mechanical stress. This gap between laboratory testing and real-world application scenarios represents a significant limitation in current measurement methodologies for high-performance conformal coatings.

Standard Test Methods for Outgassing Quantification

01 Low-outgassing conformal coating materials

Specific materials can be formulated to create conformal coatings with minimal outgassing properties, which is critical for applications in sensitive environments like aerospace and electronics. These materials include silicone-free formulations, fluoropolymers, and certain acrylics that have been specially designed to reduce volatile organic compound (VOC) emissions. The low-outgassing properties help prevent contamination of optical surfaces, sensors, and other sensitive components in enclosed environments.- Low-outgassing conformal coating materials: Specific materials can be formulated to create conformal coatings with minimal outgassing properties, which is crucial for applications in sensitive environments like aerospace and electronics. These materials include silicone-free formulations, fluoropolymers, and certain acrylics that have been specially designed to reduce volatile organic compound (VOC) emissions. These coatings maintain their protective properties while minimizing contamination risks in vacuum or sealed environments.

- Curing methods to reduce outgassing: Various curing techniques can significantly reduce outgassing in conformal coatings. UV curing, thermal curing at optimized temperatures, and multi-stage curing processes help ensure complete polymerization of coating materials, minimizing residual solvents and unreacted components that could later outgas. Advanced curing methods can achieve more complete cross-linking of polymers, resulting in more stable coatings with reduced outgassing potential over time.

- Testing and measurement of outgassing properties: Specialized testing methods are employed to evaluate the outgassing characteristics of conformal coatings. These include thermal vacuum outgassing tests, gas chromatography-mass spectrometry analysis, and weight loss measurements under controlled conditions. Testing protocols often follow industry standards such as ASTM E595, which measures total mass loss and collected volatile condensable materials. These measurements help in selecting appropriate coatings for specific applications where outgassing must be minimized.

- Outgassing-resistant coatings for electronic applications: Specialized conformal coatings have been developed specifically for electronic components where outgassing can cause circuit failure or contamination. These formulations provide necessary protection against moisture and environmental factors while ensuring minimal release of volatile compounds that could condense on sensitive components. These coatings are particularly important in high-reliability electronics for aerospace, medical devices, and telecommunications equipment where component failure is not acceptable.

- Environmental and vacuum performance of conformal coatings: The behavior of conformal coatings in vacuum and extreme environmental conditions is critical for many applications. Coatings must maintain their protective properties while minimizing outgassing that could contaminate optical surfaces or other sensitive components. Formulations specifically designed for space applications or vacuum chambers incorporate materials that remain stable under reduced pressure and temperature cycling. These specialized coatings often balance multiple performance requirements including outgassing resistance, thermal stability, and protection against radiation.

02 Thermal curing techniques to reduce outgassing

Thermal curing processes can significantly reduce outgassing in conformal coatings by ensuring complete polymerization and removal of volatile components before the coated product enters service. These techniques involve carefully controlled temperature profiles that allow solvents and other volatile compounds to evaporate fully during the curing process. Advanced thermal curing methods may include multi-stage temperature ramping and extended bake times to minimize residual outgassing during the product's operational life.Expand Specific Solutions03 UV-curable conformal coatings with reduced outgassing

UV-curable conformal coating formulations offer advantages for applications requiring minimal outgassing. These coatings typically contain fewer solvents than traditional formulations and cure rapidly under UV exposure, reducing the time available for volatile components to be trapped in the coating. The rapid polymerization process creates a tightly cross-linked structure that inherently reduces outgassing potential. Some advanced UV-curable systems incorporate dual-cure mechanisms (UV plus moisture or heat) to ensure complete curing throughout the coating thickness.Expand Specific Solutions04 Testing and measurement of outgassing properties

Various methods and equipment have been developed to accurately measure and characterize the outgassing properties of conformal coatings. These include thermal vacuum outgassing tests, gas chromatography-mass spectrometry analysis, and collected volatile condensable materials (CVCM) testing. These testing protocols help manufacturers quantify total mass loss (TML) and identify specific outgassed compounds, enabling the development of coatings that meet stringent outgassing specifications for aerospace, medical, and high-reliability electronics applications.Expand Specific Solutions05 Parylene coatings for ultra-low outgassing applications

Parylene conformal coatings are deposited through a unique vapor deposition polymerization process that inherently produces extremely low outgassing characteristics. The solvent-free application method eliminates the primary source of outgassing present in liquid-applied coatings. Parylene forms a pinhole-free, uniform coating even on complex geometries and provides excellent barrier properties against moisture and gases. These properties make parylene particularly suitable for space applications, medical implants, and other environments where outgassing must be minimized to prevent contamination or degradation of sensitive components.Expand Specific Solutions

Critical Parameters and Analytical Techniques

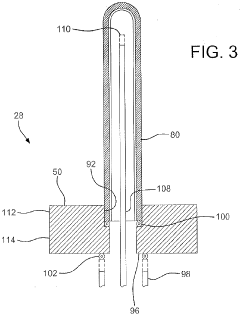

Outgassing method for inspecting a coated surface

PatentActiveEP2251671A3

Innovation

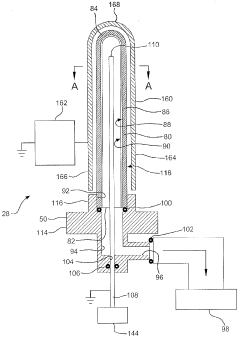

- A method using plasma-enhanced chemical vapor deposition (PECVD) to apply organosilicon precursor-based coatings, including lubricity, barrier, and hydrophobic coatings on the interior surfaces of vessels, which reduces friction, prevents material leaching, and inhibits blood clotting, while maintaining vacuum integrity.

Pecvd coating using an organosilicon precursor

PatentActiveCA2761872A1

Innovation

- A method using plasma-enhanced chemical vapor deposition (PECVD) to coat vessel interiors with organosilicon precursors, creating lubricity, hydrophobic, or barrier coatings that reduce friction, prevent chemical interactions, and maintain vacuum integrity, employing a gaseous reactant mixture with organosilicon compounds and optional oxidizing or hydrocarbon gases to set coating properties.

Regulatory Compliance and Industry Standards

Regulatory compliance and industry standards play a crucial role in the development and implementation of high-performance conformal coating outgassing measurement methodologies. The aerospace industry follows ASTM E595, which specifies the standard test method for total mass loss (TML) and collected volatile condensable materials (CVCM) from outgassing in a vacuum environment. This standard requires materials to have less than 1.0% TML and less than 0.1% CVCM to be considered space-qualified.

For electronics manufacturing, IPC-CC-830 and IPC-J-STD-001 establish requirements for conformal coatings, including outgassing properties that might affect long-term reliability. These standards define acceptable levels of outgassing for various application environments and provide guidelines for testing methodologies.

The automotive industry adheres to standards such as USCAR-2 for electronic components, which includes specifications for outgassing properties under high-temperature conditions. Similarly, military applications follow MIL-STD-883 Method 5011 for evaluating the effects of outgassing on microelectronic devices.

International standards organizations have also developed relevant guidelines. ISO 14644 addresses cleanroom environments where outgassing control is critical, while IEC 61189-2 provides test methods for materials used in electronic assemblies, including outgassing evaluation procedures.

Regulatory bodies like the European Chemicals Agency (ECHA) under REACH regulations and the United States Environmental Protection Agency (EPA) impose restrictions on volatile organic compounds (VOCs) that directly impact conformal coating formulations and their outgassing characteristics. Manufacturers must ensure their products comply with these regulations, which vary by region and application domain.

Recent updates to these standards reflect the industry's move toward more environmentally friendly coatings with lower outgassing profiles. For instance, NASA's updated outgassing database now includes more rigorous testing protocols for modern conformal coating materials used in sensitive optical and electronic systems.

Compliance certification processes typically require third-party laboratory testing using standardized equipment such as thermogravimetric analyzers (TGA) and mass spectrometers. Documentation of these test results must be maintained according to quality management systems like ISO 9001 or AS9100 for aerospace applications.

Industry working groups, including the IPC Conformal Coating Task Group, continuously review and update standards to address emerging technologies and environmental concerns. Their work ensures that measurement methodologies remain relevant as new coating formulations enter the market with improved outgassing properties.

For electronics manufacturing, IPC-CC-830 and IPC-J-STD-001 establish requirements for conformal coatings, including outgassing properties that might affect long-term reliability. These standards define acceptable levels of outgassing for various application environments and provide guidelines for testing methodologies.

The automotive industry adheres to standards such as USCAR-2 for electronic components, which includes specifications for outgassing properties under high-temperature conditions. Similarly, military applications follow MIL-STD-883 Method 5011 for evaluating the effects of outgassing on microelectronic devices.

International standards organizations have also developed relevant guidelines. ISO 14644 addresses cleanroom environments where outgassing control is critical, while IEC 61189-2 provides test methods for materials used in electronic assemblies, including outgassing evaluation procedures.

Regulatory bodies like the European Chemicals Agency (ECHA) under REACH regulations and the United States Environmental Protection Agency (EPA) impose restrictions on volatile organic compounds (VOCs) that directly impact conformal coating formulations and their outgassing characteristics. Manufacturers must ensure their products comply with these regulations, which vary by region and application domain.

Recent updates to these standards reflect the industry's move toward more environmentally friendly coatings with lower outgassing profiles. For instance, NASA's updated outgassing database now includes more rigorous testing protocols for modern conformal coating materials used in sensitive optical and electronic systems.

Compliance certification processes typically require third-party laboratory testing using standardized equipment such as thermogravimetric analyzers (TGA) and mass spectrometers. Documentation of these test results must be maintained according to quality management systems like ISO 9001 or AS9100 for aerospace applications.

Industry working groups, including the IPC Conformal Coating Task Group, continuously review and update standards to address emerging technologies and environmental concerns. Their work ensures that measurement methodologies remain relevant as new coating formulations enter the market with improved outgassing properties.

Environmental Impact of Coating Outgassing

The environmental impact of conformal coating outgassing represents a significant concern for industries utilizing these protective materials, particularly in sensitive applications such as aerospace, electronics, and medical devices. Outgassing—the release of trapped gases or volatile compounds from coating materials—can contribute to various environmental issues that extend beyond immediate application environments.

Volatile Organic Compounds (VOCs) released during outgassing processes constitute a primary environmental concern. These compounds can contribute to atmospheric pollution, potentially leading to ground-level ozone formation when they react with nitrogen oxides in the presence of sunlight. Many high-performance conformal coatings contain solvents and additives that release VOCs during curing and throughout their service life, with potential impacts on air quality in both indoor manufacturing environments and the broader atmosphere.

The persistence of outgassed compounds presents another environmental challenge. Some compounds released from conformal coatings demonstrate remarkable environmental stability, remaining in ecosystems for extended periods. This persistence increases the potential for bioaccumulation in living organisms and biomagnification through food chains, particularly for compounds with lipophilic properties that can concentrate in fatty tissues.

Regulatory frameworks worldwide have increasingly recognized these environmental concerns. The European Union's Restriction of Hazardous Substances (RoHS) directive and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have placed restrictions on certain compounds commonly found in conformal coatings. Similarly, the United States Environmental Protection Agency has established guidelines for VOC emissions from industrial processes, including coating applications.

Industry response has focused on developing environmentally friendly alternatives with reduced outgassing profiles. Water-based conformal coatings have emerged as alternatives to traditional solvent-based formulations, offering significantly reduced VOC emissions. Additionally, UV-curable coatings provide environmental benefits through their solvent-free formulations and energy-efficient curing processes, which minimize both emissions and energy consumption.

Measurement and quantification of outgassing properties have become essential for environmental impact assessment. Techniques such as Thermal Desorption Gas Chromatography-Mass Spectrometry (TD-GC-MS) enable precise identification and quantification of outgassed compounds, facilitating more accurate environmental impact evaluations. This data supports both regulatory compliance and the development of more environmentally sustainable coating formulations.

Volatile Organic Compounds (VOCs) released during outgassing processes constitute a primary environmental concern. These compounds can contribute to atmospheric pollution, potentially leading to ground-level ozone formation when they react with nitrogen oxides in the presence of sunlight. Many high-performance conformal coatings contain solvents and additives that release VOCs during curing and throughout their service life, with potential impacts on air quality in both indoor manufacturing environments and the broader atmosphere.

The persistence of outgassed compounds presents another environmental challenge. Some compounds released from conformal coatings demonstrate remarkable environmental stability, remaining in ecosystems for extended periods. This persistence increases the potential for bioaccumulation in living organisms and biomagnification through food chains, particularly for compounds with lipophilic properties that can concentrate in fatty tissues.

Regulatory frameworks worldwide have increasingly recognized these environmental concerns. The European Union's Restriction of Hazardous Substances (RoHS) directive and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have placed restrictions on certain compounds commonly found in conformal coatings. Similarly, the United States Environmental Protection Agency has established guidelines for VOC emissions from industrial processes, including coating applications.

Industry response has focused on developing environmentally friendly alternatives with reduced outgassing profiles. Water-based conformal coatings have emerged as alternatives to traditional solvent-based formulations, offering significantly reduced VOC emissions. Additionally, UV-curable coatings provide environmental benefits through their solvent-free formulations and energy-efficient curing processes, which minimize both emissions and energy consumption.

Measurement and quantification of outgassing properties have become essential for environmental impact assessment. Techniques such as Thermal Desorption Gas Chromatography-Mass Spectrometry (TD-GC-MS) enable precise identification and quantification of outgassed compounds, facilitating more accurate environmental impact evaluations. This data supports both regulatory compliance and the development of more environmentally sustainable coating formulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!