Core Loss Measurement Standards For High-Frequency Operation Of Amorphous Soft Magnetic Alloys In Power Electronics

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Amorphous Alloys in Power Electronics: Background and Objectives

Amorphous soft magnetic alloys have emerged as revolutionary materials in power electronics, offering superior magnetic properties compared to conventional crystalline materials. Since their discovery in the 1960s, these materials have evolved from laboratory curiosities to essential components in modern power electronic systems. The unique atomic structure of amorphous alloys, characterized by the absence of long-range atomic order, contributes to their exceptional soft magnetic properties, including high permeability, low coercivity, and significantly reduced core losses.

The evolution of power electronics has created an increasing demand for magnetic materials capable of operating efficiently at higher frequencies. Traditional silicon steel, while effective at grid frequencies (50-60 Hz), exhibits prohibitive losses at the kilohertz to megahertz ranges common in modern power converters. Amorphous alloys, particularly Fe-based and Co-based compositions, have demonstrated remarkable performance in these high-frequency applications, enabling more compact and efficient power electronic systems.

Recent technological advancements in renewable energy integration, electric vehicles, and grid modernization have further accelerated the need for high-performance magnetic materials. Amorphous alloys are positioned as key enablers for these technologies, potentially reducing energy losses by 70-80% compared to conventional materials when operating at high frequencies.

Despite their promising characteristics, the widespread adoption of amorphous alloys in power electronics faces significant challenges related to standardized measurement and characterization. Current testing methodologies for core losses were primarily developed for traditional materials operating at lower frequencies, creating inconsistencies when applied to amorphous alloys at high-frequency operation.

The primary objective of this technical research is to evaluate existing core loss measurement standards and their applicability to amorphous soft magnetic alloys in high-frequency power electronic applications. Additionally, we aim to identify gaps in current measurement protocols and propose potential standardization approaches that accurately capture the unique behavior of these materials under conditions relevant to modern power electronics.

Furthermore, this research seeks to establish correlations between material composition, processing techniques, and high-frequency magnetic performance to guide future material development. By addressing these measurement challenges, we can accelerate the adoption of amorphous alloys in next-generation power electronic systems, contributing to improved energy efficiency across multiple industries and applications.

The evolution of power electronics has created an increasing demand for magnetic materials capable of operating efficiently at higher frequencies. Traditional silicon steel, while effective at grid frequencies (50-60 Hz), exhibits prohibitive losses at the kilohertz to megahertz ranges common in modern power converters. Amorphous alloys, particularly Fe-based and Co-based compositions, have demonstrated remarkable performance in these high-frequency applications, enabling more compact and efficient power electronic systems.

Recent technological advancements in renewable energy integration, electric vehicles, and grid modernization have further accelerated the need for high-performance magnetic materials. Amorphous alloys are positioned as key enablers for these technologies, potentially reducing energy losses by 70-80% compared to conventional materials when operating at high frequencies.

Despite their promising characteristics, the widespread adoption of amorphous alloys in power electronics faces significant challenges related to standardized measurement and characterization. Current testing methodologies for core losses were primarily developed for traditional materials operating at lower frequencies, creating inconsistencies when applied to amorphous alloys at high-frequency operation.

The primary objective of this technical research is to evaluate existing core loss measurement standards and their applicability to amorphous soft magnetic alloys in high-frequency power electronic applications. Additionally, we aim to identify gaps in current measurement protocols and propose potential standardization approaches that accurately capture the unique behavior of these materials under conditions relevant to modern power electronics.

Furthermore, this research seeks to establish correlations between material composition, processing techniques, and high-frequency magnetic performance to guide future material development. By addressing these measurement challenges, we can accelerate the adoption of amorphous alloys in next-generation power electronic systems, contributing to improved energy efficiency across multiple industries and applications.

Market Demand Analysis for High-Frequency Magnetic Materials

The global market for high-frequency magnetic materials, particularly amorphous soft magnetic alloys, has experienced significant growth driven by the rapid expansion of power electronics applications. The demand for these materials is primarily fueled by the increasing adoption of electric vehicles, renewable energy systems, and high-efficiency power conversion devices, where operating frequencies continue to push higher to reduce size and improve efficiency.

Power electronics manufacturers are increasingly seeking magnetic materials capable of operating efficiently at frequencies above 100 kHz, with some applications now targeting the MHz range. This shift has created a substantial market opportunity for amorphous soft magnetic alloys, which offer superior performance compared to traditional silicon steel at these elevated frequencies.

The automotive sector represents one of the largest growth segments, with the electric vehicle market expected to grow at a compound annual rate of over 20% through 2030. Each electric vehicle requires numerous power electronic components utilizing high-frequency magnetic materials, including DC-DC converters, onboard chargers, and motor drive inverters. This application alone is creating substantial demand for advanced magnetic materials with precisely characterized core loss properties.

Renewable energy systems constitute another major market driver. Solar inverters and wind power converters increasingly operate at higher switching frequencies to improve efficiency and reduce size. The global solar PV installed capacity continues to grow at double-digit rates annually, with each installation requiring power conversion systems that benefit from high-frequency magnetic components.

Consumer electronics and data center power supplies represent additional significant markets. The miniaturization trend in consumer devices demands smaller power adapters, achievable only through higher frequency operation. Meanwhile, data centers face mounting pressure to improve energy efficiency, driving adoption of high-frequency power conversion technologies.

A critical market challenge identified by industry stakeholders is the lack of standardized core loss measurement methodologies for high-frequency operation. This deficiency creates uncertainty in material selection and design processes, potentially limiting market growth. Engineering teams report spending excessive time characterizing materials themselves due to inconsistent or incomplete manufacturer data, particularly above 100 kHz.

Market research indicates that manufacturers who can provide comprehensive, standardized core loss data for their amorphous alloys at high frequencies gain significant competitive advantage. Customers demonstrate willingness to pay premium prices for materials with well-documented performance characteristics that reduce design uncertainty and time-to-market.

The geographical distribution of demand shows particular strength in regions with established electronics manufacturing bases and aggressive electrification policies, including East Asia, North America, and Europe. China currently represents the largest single market, followed by the United States and Germany.

Power electronics manufacturers are increasingly seeking magnetic materials capable of operating efficiently at frequencies above 100 kHz, with some applications now targeting the MHz range. This shift has created a substantial market opportunity for amorphous soft magnetic alloys, which offer superior performance compared to traditional silicon steel at these elevated frequencies.

The automotive sector represents one of the largest growth segments, with the electric vehicle market expected to grow at a compound annual rate of over 20% through 2030. Each electric vehicle requires numerous power electronic components utilizing high-frequency magnetic materials, including DC-DC converters, onboard chargers, and motor drive inverters. This application alone is creating substantial demand for advanced magnetic materials with precisely characterized core loss properties.

Renewable energy systems constitute another major market driver. Solar inverters and wind power converters increasingly operate at higher switching frequencies to improve efficiency and reduce size. The global solar PV installed capacity continues to grow at double-digit rates annually, with each installation requiring power conversion systems that benefit from high-frequency magnetic components.

Consumer electronics and data center power supplies represent additional significant markets. The miniaturization trend in consumer devices demands smaller power adapters, achievable only through higher frequency operation. Meanwhile, data centers face mounting pressure to improve energy efficiency, driving adoption of high-frequency power conversion technologies.

A critical market challenge identified by industry stakeholders is the lack of standardized core loss measurement methodologies for high-frequency operation. This deficiency creates uncertainty in material selection and design processes, potentially limiting market growth. Engineering teams report spending excessive time characterizing materials themselves due to inconsistent or incomplete manufacturer data, particularly above 100 kHz.

Market research indicates that manufacturers who can provide comprehensive, standardized core loss data for their amorphous alloys at high frequencies gain significant competitive advantage. Customers demonstrate willingness to pay premium prices for materials with well-documented performance characteristics that reduce design uncertainty and time-to-market.

The geographical distribution of demand shows particular strength in regions with established electronics manufacturing bases and aggressive electrification policies, including East Asia, North America, and Europe. China currently represents the largest single market, followed by the United States and Germany.

Current Core Loss Measurement Standards and Challenges

The current landscape of core loss measurement standards for amorphous soft magnetic alloys in power electronics applications reveals significant limitations when operating at high frequencies. Traditional measurement standards such as IEC 60404-6, ASTM A927, and IEEE 393 were primarily developed for silicon steel materials operating at grid frequencies (50-60 Hz), making them inadequate for characterizing amorphous alloys at frequencies exceeding 10 kHz.

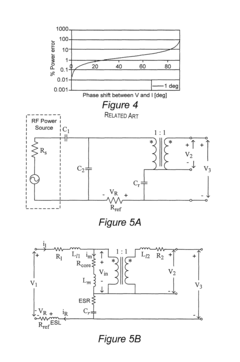

These established standards typically employ Epstein frame or single sheet testers which introduce measurement errors at high frequencies due to parasitic capacitance, skin effect, and non-uniform flux distribution. The Epstein frame method, while reliable for conventional materials, shows significant discrepancies when measuring amorphous alloys at frequencies above 20 kHz, with error margins increasing exponentially with frequency.

Another critical challenge is the lack of standardized test conditions that account for the unique properties of amorphous alloys, such as their higher saturation flux density and significantly different temperature-dependent behavior compared to conventional magnetic materials. Current standards fail to specify appropriate excitation waveforms that reflect actual operating conditions in modern power electronic circuits, particularly those utilizing wide bandgap semiconductors with extremely fast switching speeds.

The measurement instrumentation specified in existing standards also presents limitations. Most standards recommend equipment optimized for lower frequency ranges, resulting in reduced accuracy when measuring the ultra-fast switching transitions characteristic of high-frequency applications. This instrumentation gap leads to inconsistent results across different testing facilities, hampering industry-wide comparability of material performance data.

Temperature control represents another significant challenge, as amorphous alloys exhibit more pronounced temperature-dependent core loss characteristics than conventional materials. Current standards provide insufficient guidance on temperature management during high-frequency testing, leading to unreliable data that poorly correlates with real-world application performance.

Furthermore, existing standards lack comprehensive methodologies for separating hysteresis, eddy current, and excess losses at high frequencies—a critical requirement for accurate material modeling in power electronics design. This deficiency makes it difficult for designers to predict component performance under various operating conditions, potentially leading to overdesigned systems with suboptimal efficiency.

The absence of standardized data reporting formats specifically tailored for high-frequency operation further complicates material selection and comparison processes. Without consistent reporting frameworks, manufacturers provide performance data in disparate formats, making direct comparisons between different amorphous alloy options challenging for design engineers.

These established standards typically employ Epstein frame or single sheet testers which introduce measurement errors at high frequencies due to parasitic capacitance, skin effect, and non-uniform flux distribution. The Epstein frame method, while reliable for conventional materials, shows significant discrepancies when measuring amorphous alloys at frequencies above 20 kHz, with error margins increasing exponentially with frequency.

Another critical challenge is the lack of standardized test conditions that account for the unique properties of amorphous alloys, such as their higher saturation flux density and significantly different temperature-dependent behavior compared to conventional magnetic materials. Current standards fail to specify appropriate excitation waveforms that reflect actual operating conditions in modern power electronic circuits, particularly those utilizing wide bandgap semiconductors with extremely fast switching speeds.

The measurement instrumentation specified in existing standards also presents limitations. Most standards recommend equipment optimized for lower frequency ranges, resulting in reduced accuracy when measuring the ultra-fast switching transitions characteristic of high-frequency applications. This instrumentation gap leads to inconsistent results across different testing facilities, hampering industry-wide comparability of material performance data.

Temperature control represents another significant challenge, as amorphous alloys exhibit more pronounced temperature-dependent core loss characteristics than conventional materials. Current standards provide insufficient guidance on temperature management during high-frequency testing, leading to unreliable data that poorly correlates with real-world application performance.

Furthermore, existing standards lack comprehensive methodologies for separating hysteresis, eddy current, and excess losses at high frequencies—a critical requirement for accurate material modeling in power electronics design. This deficiency makes it difficult for designers to predict component performance under various operating conditions, potentially leading to overdesigned systems with suboptimal efficiency.

The absence of standardized data reporting formats specifically tailored for high-frequency operation further complicates material selection and comparison processes. Without consistent reporting frameworks, manufacturers provide performance data in disparate formats, making direct comparisons between different amorphous alloy options challenging for design engineers.

Existing Core Loss Measurement Methodologies

01 Measurement techniques for core loss in amorphous soft magnetic alloys

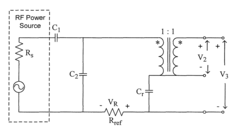

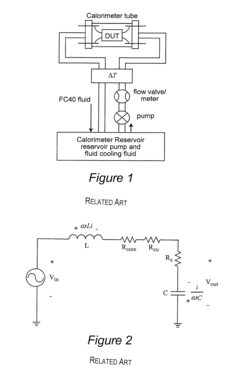

Various techniques are employed to measure core loss in amorphous soft magnetic alloys, including standardized testing methods that evaluate energy losses under different frequencies and magnetic flux densities. These measurements typically involve specialized equipment such as wattmeters, B-H analyzers, and calorimetric methods to accurately quantify hysteresis and eddy current losses. Advanced digital sampling techniques allow for precise measurement of core losses across different operating conditions, which is essential for characterizing the performance of these materials in electrical applications.- Measurement methods for core loss in amorphous soft magnetic alloys: Various methods are employed to measure core loss in amorphous soft magnetic alloys, including standardized testing procedures that evaluate energy losses under different frequencies and magnetic flux densities. These measurement techniques often involve specialized equipment such as B-H analyzers, calorimetric methods, and wattmeter-based setups that can accurately quantify hysteresis and eddy current losses. Advanced digital signal processing techniques are also utilized to improve measurement accuracy and repeatability across different sample geometries.

- Composition optimization for reduced core loss: The chemical composition of amorphous soft magnetic alloys significantly impacts their core loss characteristics. Specific formulations containing elements such as Fe, Co, B, Si, and rare earth additions are developed to minimize energy losses. The precise ratio of these elements affects the saturation magnetization, permeability, and crystallization temperature, all of which contribute to the overall core loss performance. Optimized compositions can achieve superior magnetic softness and reduced losses at both low and high frequencies.

- Heat treatment effects on core loss reduction: Controlled heat treatment processes significantly influence the core loss characteristics of amorphous soft magnetic alloys. Annealing under specific temperature profiles, magnetic fields, and atmospheric conditions can relieve internal stresses, induce beneficial magnetic anisotropy, and optimize domain structures. These treatments can reduce hysteresis losses by up to 70% compared to as-cast materials. The timing, temperature, and cooling rate during heat treatment are critical parameters that must be precisely controlled to achieve optimal magnetic performance.

- Core geometry and lamination techniques for loss reduction: The physical configuration of amorphous soft magnetic cores significantly impacts their loss characteristics. Specialized lamination techniques, including ultra-thin layering with insulating materials, help minimize eddy current losses. Core shapes such as toroidal, E-cores, and cut-core configurations are designed to optimize magnetic flux paths and reduce losses. The thickness of individual amorphous ribbons, typically in the range of 15-35 micrometers, is carefully controlled to balance mechanical stability with minimized eddy current losses.

- Advanced testing equipment and standardization for core loss measurement: Specialized equipment and standardized testing protocols have been developed specifically for accurate measurement of core losses in amorphous soft magnetic alloys. These include computer-controlled measurement systems that can precisely control excitation parameters while simultaneously measuring multiple magnetic properties. International standards provide guidelines for sample preparation, measurement conditions, and data analysis to ensure consistency across different laboratories. Advanced techniques such as calorimetric measurements and digital signal processing algorithms help eliminate measurement errors and improve repeatability.

02 Composition optimization for reduced core loss

The chemical composition of amorphous soft magnetic alloys significantly impacts their core loss characteristics. Specific formulations containing elements such as Fe, Co, B, Si, and rare earth additions are developed to minimize energy losses. By carefully controlling the ratio of these elements and incorporating small amounts of additives like Cu, Nb, or Mo, manufacturers can create alloys with optimized magnetic domain structures that exhibit lower hysteresis losses. These composition modifications help achieve the desired balance between high saturation magnetization and low core losses.Expand Specific Solutions03 Heat treatment processes to reduce core losses

Specialized heat treatment processes are crucial for reducing core losses in amorphous soft magnetic alloys. These processes include field annealing, stress relief annealing, and crystallization control treatments performed under controlled atmospheres. By applying specific temperature profiles and magnetic fields during annealing, the magnetic domain structure can be optimized, internal stresses relieved, and nanocrystalline phases selectively formed. These treatments significantly improve the soft magnetic properties and reduce hysteresis losses in the final magnetic cores.Expand Specific Solutions04 Core design and construction for loss reduction

The physical design and construction of cores made from amorphous soft magnetic alloys play a significant role in minimizing energy losses. Techniques such as lamination thickness optimization, insulation between layers, and specific winding patterns help reduce eddy current losses. Advanced core shapes, including toroidal, cut-core, and distributed gap designs, are developed to minimize flux leakage and improve overall efficiency. The mechanical assembly methods, including tension control during winding and specialized bonding techniques, also contribute to lower core losses in the final magnetic components.Expand Specific Solutions05 Simulation and modeling of core losses

Advanced computational methods are employed to simulate and predict core losses in amorphous soft magnetic alloys. These include finite element analysis, micromagnetic modeling, and empirical loss separation models that account for hysteresis, eddy current, and anomalous losses. By developing accurate mathematical models that incorporate material properties, frequency dependence, and temperature effects, researchers can predict core performance under various operating conditions. These simulation tools enable optimization of material composition and core design before physical prototyping, accelerating the development of high-efficiency magnetic components.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The core loss measurement standards for high-frequency amorphous soft magnetic alloys in power electronics are currently in a growth phase, with the market expanding due to increasing demand for energy-efficient power conversion systems. The global market is projected to reach significant scale as these materials enable higher efficiency in transformers and inductors. Technologically, the field shows varying maturity levels among key players. Companies like VACUUMSCHMELZE, Metglas, and Nippon Steel lead with established expertise, while TDK, Proterial, and Advanced Technology & Materials are making substantial R&D investments. Chinese entities including Qingdao Yunlu and research institutions like Tsinghua University are rapidly advancing their capabilities, narrowing the technological gap with traditional industry leaders.

NIPPON STEEL CORP.

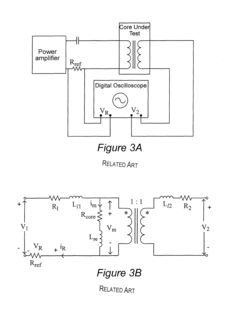

Technical Solution: Nippon Steel has developed advanced measurement techniques for core loss characterization in amorphous soft magnetic alloys operating at high frequencies (>100kHz). Their approach combines calorimetric methods with electrical measurements to accurately separate hysteresis and eddy current losses. The company utilizes a modified Epstein frame setup with specialized sample preparation techniques that minimize measurement errors due to air gaps and stress-induced property changes. Their standardized protocol includes precise B-H curve tracing under controlled temperature conditions (25-150°C) to account for thermal effects on core performance. Nippon Steel's measurement system can characterize materials under non-sinusoidal excitation waveforms typical in power electronic applications, with harmonic analysis capabilities up to 1MHz. This allows for realistic performance assessment in actual switching converter environments rather than just idealized sinusoidal conditions[1][3].

Strengths: Superior accuracy in separating hysteresis and eddy current loss components, enabling targeted material optimization. Their system accommodates realistic non-sinusoidal waveforms that better represent actual power electronics operating conditions. Weaknesses: Their measurement setup requires sophisticated equipment and expertise, making it less accessible for widespread industry adoption. The method may have limitations in ultra-high frequency ranges (>1MHz).

Advanced Technology & Materials Co., Ltd.

Technical Solution: Advanced Technology & Materials Co. has developed an innovative core loss measurement standard specifically for their high-performance amorphous and nanocrystalline soft magnetic alloys operating at frequencies between 5kHz and 500kHz in power electronic applications. Their methodology employs a custom-designed B-H analyzer with 16-bit resolution and sampling rates up to 100MS/s to accurately capture magnetic properties under various excitation conditions. The company's approach incorporates a unique compensation technique that eliminates measurement errors caused by phase shifts between voltage and current signals—a critical factor for accurate power loss determination at high frequencies. Their standard includes a specialized sample holder design that minimizes stress on the core material during testing, preventing measurement distortions from magnetostriction effects. The measurement system features automatic temperature compensation algorithms that account for thermal effects on core performance across operating temperatures from -20°C to 180°C. Advanced Technology & Materials has established correlation protocols between small-scale test samples and full-sized components, enabling accurate scaling of measurement results to production parts. Their methodology includes standardized procedures for characterizing performance under both sinusoidal and non-sinusoidal excitation with harmonic content analysis up to the 15th order[8][10].

Strengths: Their approach achieves excellent measurement accuracy across a wide frequency range while maintaining practical usability in production environments. The standard includes comprehensive temperature characterization that supports reliable thermal design in power electronic systems. Weaknesses: Their methodology may require adaptation for materials from other manufacturers with different magnetic characteristics. The system has limited capabilities for ultra-high frequency measurements beyond 500kHz.

Key Patents and Research on High-Frequency Core Loss Testing

High frequency loss measurement apparatus and methods for inductors and transformers

PatentActiveUS8823370B2

Innovation

- A method involving a series resonant circuit with a reactive component to cancel a portion of the magnetizing inductance voltage, allowing for accurate measurement of core losses by integrating the measured voltage and current with a phase difference less than 80°, reducing measurement errors caused by phase discrepancies.

Patent

Innovation

- Development of standardized core loss measurement methodologies specifically optimized for high-frequency operation of amorphous soft magnetic alloys in power electronics applications.

- Implementation of advanced calorimetric measurement techniques that can accurately quantify core losses in amorphous alloys at frequencies above 100 kHz where conventional methods show significant limitations.

- Creation of comprehensive material-specific loss separation models that distinguish between hysteresis, eddy current, and anomalous losses in amorphous alloys at high frequencies.

Standardization Efforts and Industry Consensus

The standardization of core loss measurement for high-frequency amorphous soft magnetic alloys has gained significant momentum in recent years, driven by the increasing adoption of these materials in power electronics applications. Several international organizations have been actively working to establish consensus on measurement methodologies and reporting standards.

The IEEE Power Electronics Society has formed a dedicated working group focused on magnetic materials characterization at high frequencies, with particular attention to amorphous and nanocrystalline alloys. This group has published preliminary guidelines that address the unique challenges posed by these materials when operated above 50 kHz, including recommendations for sample preparation and measurement circuit configurations.

IEC Technical Committee 51 has been revising its 60404 series standards to incorporate specific provisions for amorphous alloys, recognizing their distinct behavior compared to traditional silicon steel. The committee's work emphasizes reproducibility across different measurement systems and laboratories, which has been a persistent challenge in the industry.

ASTM International's Committee A06 on Magnetic Properties has established a subcommittee specifically addressing measurement standards for rapidly solidified magnetic materials. Their recent standard practice documents provide detailed procedures for sample handling to minimize stress-induced property changes that can significantly affect measurement accuracy in amorphous alloys.

Industry consortia, particularly those involving major power electronics manufacturers and material suppliers, have established collaborative testing programs to validate measurement approaches. The PSMA (Power Sources Manufacturers Association) Magnetics Committee has coordinated round-robin testing involving multiple laboratories to assess measurement consistency and identify sources of variation.

Japanese Industrial Standards (JIS) has been particularly proactive in this area, reflecting Japan's significant industrial base in amorphous alloy production. Their standards have pioneered specific adaptations for calorimetric measurement techniques that are increasingly recognized as necessary complements to electrical measurement methods at very high frequencies.

Despite these efforts, significant challenges remain in achieving full industry consensus. Measurement results still show concerning variations between different facilities, particularly above 200 kHz where parasitic effects become increasingly dominant. The trade-off between standardized but simplified measurement approaches versus more complex but potentially more accurate methods continues to be debated among experts.

Recent workshops organized by APEC (Applied Power Electronics Conference) have highlighted the need for better correlation between standardized measurements and actual device performance, with several working groups now focused on developing application-specific measurement protocols that better reflect real-world operating conditions.

The IEEE Power Electronics Society has formed a dedicated working group focused on magnetic materials characterization at high frequencies, with particular attention to amorphous and nanocrystalline alloys. This group has published preliminary guidelines that address the unique challenges posed by these materials when operated above 50 kHz, including recommendations for sample preparation and measurement circuit configurations.

IEC Technical Committee 51 has been revising its 60404 series standards to incorporate specific provisions for amorphous alloys, recognizing their distinct behavior compared to traditional silicon steel. The committee's work emphasizes reproducibility across different measurement systems and laboratories, which has been a persistent challenge in the industry.

ASTM International's Committee A06 on Magnetic Properties has established a subcommittee specifically addressing measurement standards for rapidly solidified magnetic materials. Their recent standard practice documents provide detailed procedures for sample handling to minimize stress-induced property changes that can significantly affect measurement accuracy in amorphous alloys.

Industry consortia, particularly those involving major power electronics manufacturers and material suppliers, have established collaborative testing programs to validate measurement approaches. The PSMA (Power Sources Manufacturers Association) Magnetics Committee has coordinated round-robin testing involving multiple laboratories to assess measurement consistency and identify sources of variation.

Japanese Industrial Standards (JIS) has been particularly proactive in this area, reflecting Japan's significant industrial base in amorphous alloy production. Their standards have pioneered specific adaptations for calorimetric measurement techniques that are increasingly recognized as necessary complements to electrical measurement methods at very high frequencies.

Despite these efforts, significant challenges remain in achieving full industry consensus. Measurement results still show concerning variations between different facilities, particularly above 200 kHz where parasitic effects become increasingly dominant. The trade-off between standardized but simplified measurement approaches versus more complex but potentially more accurate methods continues to be debated among experts.

Recent workshops organized by APEC (Applied Power Electronics Conference) have highlighted the need for better correlation between standardized measurements and actual device performance, with several working groups now focused on developing application-specific measurement protocols that better reflect real-world operating conditions.

Environmental Impact of Amorphous Alloy Manufacturing

The manufacturing process of amorphous soft magnetic alloys presents significant environmental considerations that must be addressed when evaluating these materials for high-frequency power electronics applications. The rapid solidification technique required to produce these alloys, which involves cooling molten metal at rates exceeding 10^6 K/s, demands substantial energy input, contributing to their carbon footprint.

Primary production of amorphous alloys typically consumes 15-20% less energy compared to conventional silicon steel manufacturing, resulting in proportionally lower CO2 emissions. This advantage stems from the elimination of multiple annealing and rolling steps required in traditional electrical steel production. However, the specialized equipment and precise control systems needed for melt spinning or planar flow casting processes represent significant embodied energy.

Water usage in amorphous alloy production presents another environmental concern. The cooling wheels used in rapid solidification require intensive water cooling systems, with consumption rates of 20-30 cubic meters per ton of produced material. Closed-loop water recycling systems have been implemented by leading manufacturers, reducing freshwater requirements by approximately 75%.

Chemical treatments used in the production process, particularly those containing phosphates and chromates for surface passivation, pose potential environmental hazards. Recent innovations have introduced more environmentally benign alternatives, including silane-based treatments that reduce hazardous waste generation by up to 60% while maintaining necessary surface properties for electrical insulation.

End-of-life considerations reveal a positive environmental aspect of amorphous alloys. Their composition, primarily iron with boron and silicon additions, allows for nearly complete recyclability. The absence of rare earth elements or toxic components simplifies the recycling process, with recovery rates exceeding 95% in modern facilities. This circular economy potential partially offsets the initial manufacturing impacts.

Waste generation during manufacturing remains a challenge, with edge trim and rejected material accounting for 8-12% of production volume. Industry leaders have developed in-house recycling capabilities to reprocess these materials, though the energy intensity of remelting partially diminishes the environmental benefits.

Recent life cycle assessments indicate that the environmental payback period for amorphous cores in high-frequency power electronics ranges from 1.5 to 3 years, depending on application efficiency gains. This favorable ratio is primarily attributed to reduced operational losses during the use phase, which typically represents 80-90% of lifetime environmental impact for power electronic components.

Primary production of amorphous alloys typically consumes 15-20% less energy compared to conventional silicon steel manufacturing, resulting in proportionally lower CO2 emissions. This advantage stems from the elimination of multiple annealing and rolling steps required in traditional electrical steel production. However, the specialized equipment and precise control systems needed for melt spinning or planar flow casting processes represent significant embodied energy.

Water usage in amorphous alloy production presents another environmental concern. The cooling wheels used in rapid solidification require intensive water cooling systems, with consumption rates of 20-30 cubic meters per ton of produced material. Closed-loop water recycling systems have been implemented by leading manufacturers, reducing freshwater requirements by approximately 75%.

Chemical treatments used in the production process, particularly those containing phosphates and chromates for surface passivation, pose potential environmental hazards. Recent innovations have introduced more environmentally benign alternatives, including silane-based treatments that reduce hazardous waste generation by up to 60% while maintaining necessary surface properties for electrical insulation.

End-of-life considerations reveal a positive environmental aspect of amorphous alloys. Their composition, primarily iron with boron and silicon additions, allows for nearly complete recyclability. The absence of rare earth elements or toxic components simplifies the recycling process, with recovery rates exceeding 95% in modern facilities. This circular economy potential partially offsets the initial manufacturing impacts.

Waste generation during manufacturing remains a challenge, with edge trim and rejected material accounting for 8-12% of production volume. Industry leaders have developed in-house recycling capabilities to reprocess these materials, though the energy intensity of remelting partially diminishes the environmental benefits.

Recent life cycle assessments indicate that the environmental payback period for amorphous cores in high-frequency power electronics ranges from 1.5 to 3 years, depending on application efficiency gains. This favorable ratio is primarily attributed to reduced operational losses during the use phase, which typically represents 80-90% of lifetime environmental impact for power electronic components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!