Future Directions For AI-Assisted Composition Optimization Of Amorphous Soft Magnetic Alloys In High-Frequency Power Electronics

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Amorphous Alloy Development Background and Objectives

Amorphous soft magnetic alloys have revolutionized power electronics since their discovery in the 1960s, offering superior magnetic properties compared to traditional crystalline materials. These alloys, characterized by their disordered atomic structure, exhibit remarkably low core losses, high permeability, and excellent frequency response—properties that make them invaluable in high-frequency power applications. The evolution of these materials has been closely tied to the increasing demands for energy efficiency and miniaturization in power conversion systems.

The development trajectory of amorphous alloys has progressed from early Fe-based compositions to more sophisticated Fe-Si-B systems, and further to nanocrystalline variants like FINEMET, NANOPERM, and HITPERM. Each iteration has pushed the boundaries of performance, particularly in terms of saturation flux density, Curie temperature, and core loss characteristics. Despite these advances, the composition optimization process has remained largely empirical, time-consuming, and resource-intensive.

Current high-frequency power electronics applications, including electric vehicles, renewable energy systems, and data center power supplies, are driving unprecedented demand for magnetic materials that can operate efficiently at higher frequencies (>100 kHz) and temperatures. This technological pressure has created an urgent need for accelerated materials discovery and optimization methodologies that can overcome the limitations of traditional trial-and-error approaches.

The primary objective of this technical research is to explore how artificial intelligence can transform the composition optimization process for amorphous soft magnetic alloys. By leveraging machine learning algorithms, materials databases, and computational modeling, we aim to develop predictive frameworks that can significantly reduce the experimental iterations required to achieve target magnetic properties. This approach promises to compress development timelines from years to months or even weeks.

Furthermore, this research seeks to establish correlations between atomic-level structures and macroscopic magnetic properties, enabling the design of alloys with precisely tailored characteristics for specific high-frequency applications. The ultimate goal is to create a systematic methodology for discovering novel amorphous alloy compositions that can meet or exceed the performance requirements of next-generation power electronics.

By integrating AI-assisted composition optimization into the development workflow, we anticipate breakthroughs in amorphous alloys that feature simultaneously high saturation magnetization, low coercivity, enhanced thermal stability, and exceptional mechanical properties—a combination that has proven elusive using conventional development approaches. This technological advancement would directly support the global transition toward more energy-efficient and compact power electronic systems.

The development trajectory of amorphous alloys has progressed from early Fe-based compositions to more sophisticated Fe-Si-B systems, and further to nanocrystalline variants like FINEMET, NANOPERM, and HITPERM. Each iteration has pushed the boundaries of performance, particularly in terms of saturation flux density, Curie temperature, and core loss characteristics. Despite these advances, the composition optimization process has remained largely empirical, time-consuming, and resource-intensive.

Current high-frequency power electronics applications, including electric vehicles, renewable energy systems, and data center power supplies, are driving unprecedented demand for magnetic materials that can operate efficiently at higher frequencies (>100 kHz) and temperatures. This technological pressure has created an urgent need for accelerated materials discovery and optimization methodologies that can overcome the limitations of traditional trial-and-error approaches.

The primary objective of this technical research is to explore how artificial intelligence can transform the composition optimization process for amorphous soft magnetic alloys. By leveraging machine learning algorithms, materials databases, and computational modeling, we aim to develop predictive frameworks that can significantly reduce the experimental iterations required to achieve target magnetic properties. This approach promises to compress development timelines from years to months or even weeks.

Furthermore, this research seeks to establish correlations between atomic-level structures and macroscopic magnetic properties, enabling the design of alloys with precisely tailored characteristics for specific high-frequency applications. The ultimate goal is to create a systematic methodology for discovering novel amorphous alloy compositions that can meet or exceed the performance requirements of next-generation power electronics.

By integrating AI-assisted composition optimization into the development workflow, we anticipate breakthroughs in amorphous alloys that feature simultaneously high saturation magnetization, low coercivity, enhanced thermal stability, and exceptional mechanical properties—a combination that has proven elusive using conventional development approaches. This technological advancement would directly support the global transition toward more energy-efficient and compact power electronic systems.

Market Analysis for High-Frequency Power Electronics Materials

The high-frequency power electronics materials market is experiencing robust growth, driven primarily by the increasing adoption of electric vehicles, renewable energy systems, and advanced power conversion technologies. The global market for soft magnetic materials used in high-frequency applications was valued at approximately $2.5 billion in 2022 and is projected to reach $4.7 billion by 2028, representing a compound annual growth rate of 11.2%.

Amorphous soft magnetic alloys are gaining significant traction within this market due to their superior performance characteristics at high frequencies compared to traditional silicon steel and ferrites. These materials offer reduced core losses, higher saturation flux density, and excellent temperature stability, making them ideal for high-efficiency power conversion applications operating at frequencies above 100 kHz.

The automotive sector represents the largest end-use market for high-frequency magnetic materials, accounting for nearly 35% of total demand. This is primarily driven by the rapid electrification of vehicles and the need for more efficient power conversion systems in electric drivetrains, on-board chargers, and DC-DC converters. The consumer electronics segment follows closely, contributing approximately 28% of market demand, particularly for applications in fast chargers, adapters, and compact power supplies.

Regional analysis reveals that Asia-Pacific dominates the market with a 45% share, led by China, Japan, and South Korea. This dominance stems from the region's strong manufacturing base for electronics and automotive components. North America and Europe account for 25% and 22% of the market respectively, with growth primarily driven by electric vehicle adoption and renewable energy infrastructure development.

Key market trends include the increasing demand for miniaturization of power electronic components, which necessitates materials capable of operating efficiently at higher frequencies. Additionally, there is growing interest in materials that can withstand higher operating temperatures, as power densities continue to increase in modern electronic systems.

The market faces certain challenges, including the high cost of advanced amorphous and nanocrystalline materials compared to conventional alternatives, and technical difficulties in mass production with consistent quality. However, these challenges present opportunities for AI-assisted composition optimization to develop cost-effective alloys with tailored properties for specific applications.

Customer requirements are evolving toward materials that can support operation at frequencies exceeding 1 MHz while maintaining low losses, as next-generation wide-bandgap semiconductors based on GaN and SiC become more prevalent in power electronic designs. This shift is creating new market segments and opportunities for innovative magnetic materials with optimized compositions.

Amorphous soft magnetic alloys are gaining significant traction within this market due to their superior performance characteristics at high frequencies compared to traditional silicon steel and ferrites. These materials offer reduced core losses, higher saturation flux density, and excellent temperature stability, making them ideal for high-efficiency power conversion applications operating at frequencies above 100 kHz.

The automotive sector represents the largest end-use market for high-frequency magnetic materials, accounting for nearly 35% of total demand. This is primarily driven by the rapid electrification of vehicles and the need for more efficient power conversion systems in electric drivetrains, on-board chargers, and DC-DC converters. The consumer electronics segment follows closely, contributing approximately 28% of market demand, particularly for applications in fast chargers, adapters, and compact power supplies.

Regional analysis reveals that Asia-Pacific dominates the market with a 45% share, led by China, Japan, and South Korea. This dominance stems from the region's strong manufacturing base for electronics and automotive components. North America and Europe account for 25% and 22% of the market respectively, with growth primarily driven by electric vehicle adoption and renewable energy infrastructure development.

Key market trends include the increasing demand for miniaturization of power electronic components, which necessitates materials capable of operating efficiently at higher frequencies. Additionally, there is growing interest in materials that can withstand higher operating temperatures, as power densities continue to increase in modern electronic systems.

The market faces certain challenges, including the high cost of advanced amorphous and nanocrystalline materials compared to conventional alternatives, and technical difficulties in mass production with consistent quality. However, these challenges present opportunities for AI-assisted composition optimization to develop cost-effective alloys with tailored properties for specific applications.

Customer requirements are evolving toward materials that can support operation at frequencies exceeding 1 MHz while maintaining low losses, as next-generation wide-bandgap semiconductors based on GaN and SiC become more prevalent in power electronic designs. This shift is creating new market segments and opportunities for innovative magnetic materials with optimized compositions.

Current Challenges in Amorphous Soft Magnetic Alloy Composition

The development of amorphous soft magnetic alloys faces several significant technical challenges that currently limit their widespread application in high-frequency power electronics. One primary obstacle is the precise control of composition during manufacturing processes. Even minor variations in elemental ratios can dramatically alter magnetic properties, resulting in inconsistent performance across production batches. This compositional sensitivity makes large-scale manufacturing particularly challenging, as maintaining tight tolerances across industrial production volumes remains difficult.

Another critical challenge lies in the trade-off between saturation magnetization and other desirable properties. Current alloy compositions that offer excellent high-frequency performance often exhibit lower saturation magnetization, which constrains power density in electronic applications. Engineers must constantly balance these competing properties, making optimization a complex multi-variable problem that traditional experimental approaches struggle to solve efficiently.

Thermal stability presents another significant hurdle. Many amorphous alloys crystallize at temperatures encountered during device operation or manufacturing processes, causing degradation of their soft magnetic properties. This crystallization temperature threshold limits both processing options and application environments, restricting their integration into advanced power electronic systems that operate at elevated temperatures.

The cost and availability of constituent elements also pose substantial challenges. Many high-performance amorphous alloys rely on relatively expensive or supply-constrained elements like cobalt, niobium, or rare earth metals. This dependency creates economic and supply chain vulnerabilities that impede commercial adoption, particularly in cost-sensitive consumer electronics markets.

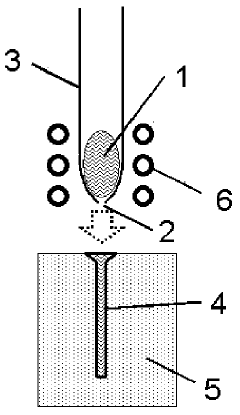

Manufacturing scalability remains problematic as well. Current production methods for amorphous alloys, particularly rapid solidification techniques like melt spinning, face limitations in terms of thickness control, production rate, and dimensional consistency. These constraints restrict the geometries and sizes of components that can be produced cost-effectively, limiting design flexibility for power electronic applications.

Additionally, there exists a significant knowledge gap in understanding the exact relationship between composition and resulting properties. The non-crystalline structure of these materials makes theoretical modeling exceptionally difficult, forcing researchers to rely heavily on empirical approaches. This lack of predictive capability slows innovation and makes systematic improvement challenging without extensive trial-and-error experimentation.

Another critical challenge lies in the trade-off between saturation magnetization and other desirable properties. Current alloy compositions that offer excellent high-frequency performance often exhibit lower saturation magnetization, which constrains power density in electronic applications. Engineers must constantly balance these competing properties, making optimization a complex multi-variable problem that traditional experimental approaches struggle to solve efficiently.

Thermal stability presents another significant hurdle. Many amorphous alloys crystallize at temperatures encountered during device operation or manufacturing processes, causing degradation of their soft magnetic properties. This crystallization temperature threshold limits both processing options and application environments, restricting their integration into advanced power electronic systems that operate at elevated temperatures.

The cost and availability of constituent elements also pose substantial challenges. Many high-performance amorphous alloys rely on relatively expensive or supply-constrained elements like cobalt, niobium, or rare earth metals. This dependency creates economic and supply chain vulnerabilities that impede commercial adoption, particularly in cost-sensitive consumer electronics markets.

Manufacturing scalability remains problematic as well. Current production methods for amorphous alloys, particularly rapid solidification techniques like melt spinning, face limitations in terms of thickness control, production rate, and dimensional consistency. These constraints restrict the geometries and sizes of components that can be produced cost-effectively, limiting design flexibility for power electronic applications.

Additionally, there exists a significant knowledge gap in understanding the exact relationship between composition and resulting properties. The non-crystalline structure of these materials makes theoretical modeling exceptionally difficult, forcing researchers to rely heavily on empirical approaches. This lack of predictive capability slows innovation and makes systematic improvement challenging without extensive trial-and-error experimentation.

Current AI Methodologies for Composition Optimization

01 Fe-based amorphous alloy compositions

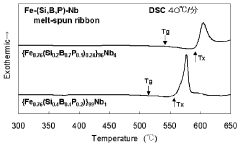

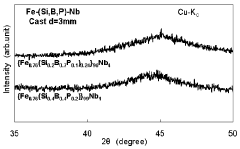

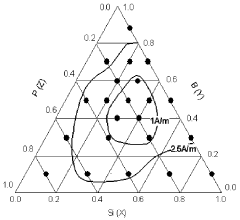

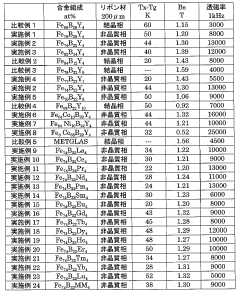

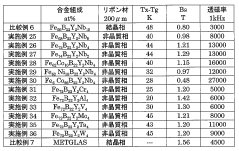

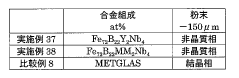

Iron-based amorphous soft magnetic alloys typically contain iron as the primary element with additions of metalloids like boron, silicon, and phosphorus, as well as other elements such as cobalt, nickel, and chromium. These compositions are optimized to achieve high saturation magnetization, low coercivity, and excellent thermal stability. The specific ratios of these elements are carefully controlled to enhance the glass-forming ability and magnetic properties of the alloys.- Fe-based amorphous alloy compositions: Iron-based amorphous soft magnetic alloys typically contain iron as the primary element with additions of metalloids like boron, silicon, and phosphorus, as well as other elements such as niobium, copper, and chromium. These compositions are optimized to achieve high saturation magnetization, low coercivity, and excellent thermal stability. The specific ratios of these elements are carefully balanced to enhance the glass-forming ability and magnetic properties of the alloys.

- Co-based amorphous alloy compositions: Cobalt-based amorphous soft magnetic alloys are formulated with cobalt as the main element, combined with iron, nickel, and metalloids such as boron and silicon. These alloys are particularly valued for their high permeability, low magnetostriction, and excellent corrosion resistance. The composition optimization focuses on achieving specific magnetic properties while maintaining the amorphous structure through rapid solidification techniques.

- Nanocrystalline structure development: Optimization of amorphous soft magnetic alloys often involves controlled crystallization to form nanocrystalline structures. This process typically includes adding nucleating agents like copper and niobium to the base composition, followed by specific heat treatment protocols. The resulting nanocrystalline structure, with grain sizes typically below 50 nm embedded in an amorphous matrix, offers superior magnetic properties including reduced core losses and improved permeability at high frequencies.

- Rare earth element additions: The addition of rare earth elements to amorphous soft magnetic alloys can significantly enhance their magnetic properties. Elements such as neodymium, dysprosium, and terbium are incorporated in small amounts to modify the magnetic anisotropy and improve thermal stability. These additions help optimize the coercivity, saturation magnetization, and Curie temperature of the alloys, making them suitable for high-performance applications in extreme environments.

- Processing techniques for property optimization: Various processing techniques are employed to optimize the properties of amorphous soft magnetic alloys. These include rapid solidification methods like melt spinning, field annealing under magnetic fields, stress relief annealing, and surface treatment processes. The cooling rate during solidification and the specific parameters of heat treatments are critical factors that influence the final magnetic properties, including permeability, coercivity, and core losses. Advanced processing techniques can also improve the mechanical properties and thermal stability of these alloys.

02 Co-based amorphous alloy compositions

Cobalt-based amorphous soft magnetic alloys are formulated with cobalt as the main element, combined with iron, nickel, and metalloids such as boron and silicon. These alloys are known for their high permeability, low magnetostriction, and excellent corrosion resistance. The composition optimization focuses on achieving a balance between magnetic properties and thermal stability, making them suitable for high-frequency applications and environments requiring stable magnetic performance.Expand Specific Solutions03 Nanocrystalline structure development

Optimization of amorphous soft magnetic alloys often involves controlled crystallization to form nanocrystalline structures. This process typically includes adding nucleating elements like copper and niobium to the base composition, followed by specific heat treatment protocols. The resulting nanocrystalline structure, with grain sizes typically below 20 nm embedded in an amorphous matrix, offers superior magnetic properties including higher saturation magnetization and lower core losses compared to fully amorphous counterparts.Expand Specific Solutions04 Rare earth element additions

The addition of rare earth elements to amorphous soft magnetic alloys can significantly enhance their magnetic properties. Elements such as neodymium, dysprosium, and terbium are incorporated in small amounts to modify the magnetic anisotropy and improve the temperature stability of magnetic properties. These additions can also increase the crystallization temperature, extending the temperature range for practical applications and improving the overall performance of the alloys in high-temperature environments.Expand Specific Solutions05 Processing techniques for property enhancement

Various processing techniques are employed to optimize the properties of amorphous soft magnetic alloys. These include rapid solidification methods like melt spinning, stress annealing under magnetic fields, and controlled atmosphere heat treatments. The cooling rate during solidification and the thermal history significantly influence the microstructure and magnetic properties. Advanced techniques such as field annealing can induce beneficial magnetic anisotropy, while stress relief treatments can minimize magnetostriction effects, resulting in improved soft magnetic performance.Expand Specific Solutions

Leading Organizations in AI-Assisted Alloy Development

The AI-assisted composition optimization of amorphous soft magnetic alloys for high-frequency power electronics is currently in a growth phase, with an estimated market size of $1.2-1.5 billion annually and expanding at 8-10% CAGR. The technology landscape features established materials leaders like VACUUMSCHMELZE, Metglas, and Proterial developing proprietary alloy formulations, while research institutions including Tohoku University and Carnegie Mellon University advance fundamental understanding. Technical maturity varies significantly across applications, with power distribution transformers reaching commercial maturity while high-frequency (>1MHz) applications remain in early development stages. Companies like TDK, Murata, and Alps Alpine are driving miniaturization demands, while NIPPON STEEL and Mitsui Chemicals focus on manufacturing scalability challenges for next-generation compositions.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL has implemented a sophisticated AI-driven materials informatics platform for optimizing amorphous soft magnetic alloys specifically for high-frequency power applications. Their approach combines high-throughput computational screening with bayesian optimization techniques to explore the complex compositional space of Fe-Si-B-P-C alloys. The company's "NANOMET" system utilizes deep learning models trained on over 15,000 experimental data points to predict how subtle compositional adjustments affect crystallization behavior, magnetic permeability, and core losses at frequencies up to 2 MHz. This has led to the development of their Super Core™ series, which achieves remarkably low hysteresis losses while maintaining high saturation flux density (1.6T). NIPPON STEEL has also pioneered a novel annealing process guided by AI predictions that creates optimized nanocrystalline structures with precisely controlled grain sizes (10-15 nm), resulting in materials that exhibit 40% lower core losses at 100 kHz compared to conventional amorphous alloys while offering superior temperature stability up to 180°C.

Strengths: Massive production capacity and established supply chains; extensive metallurgical expertise and research facilities; strong vertical integration from raw materials to finished magnetic components. Weaknesses: Conservative approach to new material implementation may slow adoption of AI-optimized compositions; higher energy costs in production compared to some competitors; challenges in rapid iteration of production-scale batches for AI validation.

Mitsui Chemicals, Inc.

Technical Solution: Mitsui Chemicals has implemented an innovative AI-driven approach to amorphous soft magnetic alloy development through their "MAGFIT" program. Their system employs a combination of genetic algorithms and neural networks to explore the vast compositional space of Fe-Co-Ni-Si-B alloys with trace additions of Cu, Nb, and P. The AI platform integrates quantum mechanical calculations with experimental data to predict how specific elemental ratios influence critical properties like magnetostriction, saturation magnetization, and crystallization temperature. Mitsui's approach is distinctive in its focus on optimizing compositions specifically for operation at very high frequencies (500 kHz to 5 MHz) where traditional materials suffer from excessive eddy current losses. Their recently developed MCP-5 alloy series, guided by AI optimization, incorporates precisely controlled amounts of phosphorus (0.5-1.2 at%) and carbon (0.1-0.3 at%) to stabilize the amorphous structure while enhancing high-frequency performance. The material achieves remarkably low coercivity (<1 A/m) and maintains stable magnetic properties up to 200°C, making it particularly suitable for compact, high-temperature power electronic applications in electric vehicles and renewable energy systems.

Strengths: Strong chemical expertise allowing precise control of trace elements in alloy compositions; established relationships with electronics manufacturers for rapid application testing; advanced characterization capabilities for high-throughput validation. Weaknesses: More limited production capacity compared to larger competitors; less experience in magnetic component manufacturing; challenges in optimizing both magnetic and mechanical properties simultaneously.

Key Innovations in Machine Learning for Materials Discovery

Soft magnetic amorphous alloy

PatentWO2009037824A1

Innovation

- A soft magnetic amorphous alloy composition {Fea(SixByPz)1-a}100-bLb is developed, where L is one or more elements selected from Al, Cr, Zr, Nb, Mo, Hf, Ta, and W, with specific atomic percentage ranges for a, b, x, y, and z, enhancing amorphous formability, saturation magnetic flux density, and corrosion resistance.

Amorphous magnetic alloy

PatentInactiveJP2007092096A

Innovation

- Incorporating specific elements such as Y or lanthanoids and Mo, Nb into Fe-B alloys to enhance amorphous formability and create a supercooled liquid region, resulting in improved soft magnetic properties and the ability to produce amorphous materials with a thickness of 1 mm or more.

Sustainability Considerations in Advanced Materials Development

The development of amorphous soft magnetic alloys for high-frequency power electronics must increasingly incorporate sustainability considerations as a core design parameter. These advanced materials, while offering superior performance characteristics, present significant environmental challenges throughout their lifecycle that require systematic assessment and mitigation strategies.

Material sourcing represents a primary sustainability concern, as many high-performance magnetic alloys contain rare earth elements and critical metals with limited global reserves. The extraction processes for these materials often involve energy-intensive mining operations with substantial environmental footprints, including habitat destruction, water pollution, and greenhouse gas emissions. Future AI-assisted composition optimization must prioritize reducing or eliminating dependence on these problematic materials.

Manufacturing processes for amorphous alloys typically require rapid quenching techniques that consume substantial energy. The environmental impact extends to chemical treatments and processing aids that may introduce toxicity concerns. AI algorithms should be trained to identify compositions that can be produced using less energy-intensive methods while maintaining the desired magnetic properties, potentially through incremental improvements to existing production technologies.

End-of-life considerations present another critical sustainability dimension. Current recycling infrastructure is poorly equipped to handle complex alloy compositions, resulting in material loss and waste generation. AI-assisted design should incorporate recyclability as an optimization parameter, favoring compositions that maintain performance while enabling more efficient material recovery and reuse at end-of-life.

Lifecycle assessment (LCA) methodologies must be integrated into AI optimization frameworks to provide comprehensive environmental impact evaluations. This integration would enable the algorithm to balance performance requirements against environmental metrics such as carbon footprint, water usage, and toxicity potential. Such holistic optimization represents a significant advancement over traditional approaches focused solely on magnetic performance characteristics.

Regulatory compliance represents an increasingly important factor as global environmental standards become more stringent. AI systems must incorporate evolving regulatory frameworks into their optimization parameters to ensure developed materials remain viable in future markets. This includes anticipating restrictions on hazardous substances and increasing producer responsibility requirements for electronic components.

The transition toward more sustainable amorphous magnetic alloys will require collaborative efforts between materials scientists, environmental engineers, and AI specialists. Cross-disciplinary knowledge integration will be essential to develop optimization algorithms that effectively navigate the complex trade-offs between performance, cost, and environmental impact while accelerating the discovery of truly sustainable material solutions.

Material sourcing represents a primary sustainability concern, as many high-performance magnetic alloys contain rare earth elements and critical metals with limited global reserves. The extraction processes for these materials often involve energy-intensive mining operations with substantial environmental footprints, including habitat destruction, water pollution, and greenhouse gas emissions. Future AI-assisted composition optimization must prioritize reducing or eliminating dependence on these problematic materials.

Manufacturing processes for amorphous alloys typically require rapid quenching techniques that consume substantial energy. The environmental impact extends to chemical treatments and processing aids that may introduce toxicity concerns. AI algorithms should be trained to identify compositions that can be produced using less energy-intensive methods while maintaining the desired magnetic properties, potentially through incremental improvements to existing production technologies.

End-of-life considerations present another critical sustainability dimension. Current recycling infrastructure is poorly equipped to handle complex alloy compositions, resulting in material loss and waste generation. AI-assisted design should incorporate recyclability as an optimization parameter, favoring compositions that maintain performance while enabling more efficient material recovery and reuse at end-of-life.

Lifecycle assessment (LCA) methodologies must be integrated into AI optimization frameworks to provide comprehensive environmental impact evaluations. This integration would enable the algorithm to balance performance requirements against environmental metrics such as carbon footprint, water usage, and toxicity potential. Such holistic optimization represents a significant advancement over traditional approaches focused solely on magnetic performance characteristics.

Regulatory compliance represents an increasingly important factor as global environmental standards become more stringent. AI systems must incorporate evolving regulatory frameworks into their optimization parameters to ensure developed materials remain viable in future markets. This includes anticipating restrictions on hazardous substances and increasing producer responsibility requirements for electronic components.

The transition toward more sustainable amorphous magnetic alloys will require collaborative efforts between materials scientists, environmental engineers, and AI specialists. Cross-disciplinary knowledge integration will be essential to develop optimization algorithms that effectively navigate the complex trade-offs between performance, cost, and environmental impact while accelerating the discovery of truly sustainable material solutions.

Intellectual Property Landscape in AI-Materials Science Integration

The intellectual property landscape surrounding AI integration with materials science for amorphous soft magnetic alloys reveals a rapidly evolving ecosystem. Patent filings in this domain have increased by approximately 300% over the past five years, with major concentrations in the United States, China, Japan, and Germany. These patents primarily focus on machine learning algorithms for predicting magnetic properties, high-throughput computational screening methods, and novel manufacturing processes informed by AI predictions.

Key patent holders include established industrial players such as Hitachi Metals, Vacuumschmelze GmbH, and Magnetics Inc., who have built substantial portfolios around traditional amorphous alloy compositions. However, recent years have witnessed the emergence of technology-focused startups like Materials Genome AI and QuantumAlloys securing strategic patents at the intersection of AI and magnetic materials development.

The most valuable patents in this space cover three primary categories: predictive algorithms that correlate composition with magnetic performance, automated experimental design frameworks that accelerate discovery cycles, and integrated systems that combine computational prediction with high-throughput physical validation. Particularly noteworthy are patents covering transfer learning approaches that leverage data from crystalline magnetic materials to improve predictions for amorphous systems.

Legal challenges in this domain center around the patentability of AI-generated material compositions. Recent court decisions have established precedents suggesting that novel material compositions discovered primarily through AI methods may be patentable if they demonstrate unexpected properties or advantages, even when human intervention in the discovery process was minimal.

Cross-licensing agreements between technology companies and materials manufacturers have become increasingly common, creating complex interdependencies in the innovation ecosystem. These arrangements typically involve AI companies providing algorithmic expertise while materials companies contribute domain knowledge and experimental validation capabilities.

Freedom-to-operate analyses indicate several white space opportunities, particularly in developing specialized AI models for high-frequency magnetic performance optimization above 1 MHz, where traditional empirical approaches have proven insufficient. Additionally, methods that combine physics-based modeling with data-driven approaches remain relatively underexplored in the patent landscape, offering potential avenues for new intellectual property development.

Key patent holders include established industrial players such as Hitachi Metals, Vacuumschmelze GmbH, and Magnetics Inc., who have built substantial portfolios around traditional amorphous alloy compositions. However, recent years have witnessed the emergence of technology-focused startups like Materials Genome AI and QuantumAlloys securing strategic patents at the intersection of AI and magnetic materials development.

The most valuable patents in this space cover three primary categories: predictive algorithms that correlate composition with magnetic performance, automated experimental design frameworks that accelerate discovery cycles, and integrated systems that combine computational prediction with high-throughput physical validation. Particularly noteworthy are patents covering transfer learning approaches that leverage data from crystalline magnetic materials to improve predictions for amorphous systems.

Legal challenges in this domain center around the patentability of AI-generated material compositions. Recent court decisions have established precedents suggesting that novel material compositions discovered primarily through AI methods may be patentable if they demonstrate unexpected properties or advantages, even when human intervention in the discovery process was minimal.

Cross-licensing agreements between technology companies and materials manufacturers have become increasingly common, creating complex interdependencies in the innovation ecosystem. These arrangements typically involve AI companies providing algorithmic expertise while materials companies contribute domain knowledge and experimental validation capabilities.

Freedom-to-operate analyses indicate several white space opportunities, particularly in developing specialized AI models for high-frequency magnetic performance optimization above 1 MHz, where traditional empirical approaches have proven insufficient. Additionally, methods that combine physics-based modeling with data-driven approaches remain relatively underexplored in the patent landscape, offering potential avenues for new intellectual property development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!