Test Methods To Quantify Core Loss At 100 KHz And Above For Amorphous Soft Magnetic Alloys In High-Frequency Power Electronics

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Frequency Core Loss Testing Background and Objectives

The evolution of power electronics has been marked by a continuous pursuit of higher efficiency, smaller form factors, and increased power density. Since the 1970s, magnetic components have been critical elements in power conversion systems, with core losses representing a significant portion of overall energy losses. The emergence of wide bandgap semiconductors like SiC and GaN in the early 2000s has enabled switching frequencies to exceed 100 kHz, dramatically reducing the size of magnetic components but introducing new challenges in core loss characterization.

Amorphous soft magnetic alloys, first developed commercially in the 1980s, have gained significant attention for high-frequency applications due to their unique microstructure that minimizes eddy current losses. However, accurately quantifying core losses at frequencies above 100 kHz remains problematic due to limitations in conventional testing methodologies that were primarily designed for lower frequency ranges (typically below 20 kHz).

The traditional Steinmetz equation and its derivatives become increasingly inaccurate at higher frequencies, where non-sinusoidal waveforms and complex magnetization processes dominate. Industry standards such as IEC 60404 and IEEE 393 provide guidelines for core loss measurement, but these standards have not been fully adapted for the ultra-high frequency domain relevant to modern power electronics.

This technical research aims to comprehensively evaluate existing test methods for quantifying core losses in amorphous soft magnetic alloys at frequencies of 100 kHz and above, while identifying their limitations and potential improvements. The primary objective is to establish reliable, reproducible, and practical testing protocols that accurately characterize core losses under conditions representative of actual high-frequency power electronic applications.

Secondary objectives include developing mathematical models that can accurately predict core losses across various operating conditions, creating standardized testing procedures that can be widely adopted by the industry, and exploring the correlation between material microstructure and high-frequency magnetic performance in amorphous alloys.

The research will focus particularly on non-sinusoidal excitation conditions typical in switch-mode power supplies, wireless power transfer systems, and electric vehicle charging infrastructure, where accurate core loss prediction is essential for optimal design. By addressing these challenges, this research aims to accelerate the adoption of advanced magnetic materials in next-generation power electronics, contributing to improved energy efficiency and reduced environmental impact across multiple industries.

Amorphous soft magnetic alloys, first developed commercially in the 1980s, have gained significant attention for high-frequency applications due to their unique microstructure that minimizes eddy current losses. However, accurately quantifying core losses at frequencies above 100 kHz remains problematic due to limitations in conventional testing methodologies that were primarily designed for lower frequency ranges (typically below 20 kHz).

The traditional Steinmetz equation and its derivatives become increasingly inaccurate at higher frequencies, where non-sinusoidal waveforms and complex magnetization processes dominate. Industry standards such as IEC 60404 and IEEE 393 provide guidelines for core loss measurement, but these standards have not been fully adapted for the ultra-high frequency domain relevant to modern power electronics.

This technical research aims to comprehensively evaluate existing test methods for quantifying core losses in amorphous soft magnetic alloys at frequencies of 100 kHz and above, while identifying their limitations and potential improvements. The primary objective is to establish reliable, reproducible, and practical testing protocols that accurately characterize core losses under conditions representative of actual high-frequency power electronic applications.

Secondary objectives include developing mathematical models that can accurately predict core losses across various operating conditions, creating standardized testing procedures that can be widely adopted by the industry, and exploring the correlation between material microstructure and high-frequency magnetic performance in amorphous alloys.

The research will focus particularly on non-sinusoidal excitation conditions typical in switch-mode power supplies, wireless power transfer systems, and electric vehicle charging infrastructure, where accurate core loss prediction is essential for optimal design. By addressing these challenges, this research aims to accelerate the adoption of advanced magnetic materials in next-generation power electronics, contributing to improved energy efficiency and reduced environmental impact across multiple industries.

Market Demand Analysis for High-Frequency Magnetic Materials

The global market for high-frequency magnetic materials, particularly amorphous soft magnetic alloys, is experiencing robust growth driven by the increasing demand for efficient power electronics across multiple industries. The market size for soft magnetic materials was valued at approximately $25 billion in 2022 and is projected to grow at a CAGR of 7.8% through 2030, with high-frequency applications representing the fastest-growing segment.

Power electronics applications operating at frequencies of 100 kHz and above are becoming increasingly prevalent in renewable energy systems, electric vehicles, data centers, and industrial automation. This shift toward higher frequencies is primarily motivated by the need for smaller, lighter, and more efficient power conversion systems. Amorphous soft magnetic alloys are particularly well-positioned to meet these demands due to their superior performance characteristics at high frequencies.

The electric vehicle (EV) sector represents one of the most significant market drivers, with onboard chargers and DC-DC converters increasingly operating at frequencies above 100 kHz to reduce size and weight while improving efficiency. The global EV market is expected to grow at a CAGR of 21% through 2030, creating substantial demand for high-performance magnetic materials that can operate efficiently at high frequencies.

Renewable energy systems, particularly solar inverters and wind power converters, constitute another major market segment. The transition to silicon carbide (SiC) and gallium nitride (GaN) power semiconductors in these applications is enabling switching frequencies well above 100 kHz, necessitating magnetic materials with minimal core losses at these frequencies.

The telecommunications and data center industries are also driving demand for high-frequency magnetic materials, with power supplies and server power management systems requiring increasingly compact and efficient designs. The global data center power market is growing at approximately 6.5% annually, with efficiency requirements becoming more stringent.

Industry surveys indicate that manufacturers of power electronics are prioritizing efficiency improvements, with over 70% of respondents identifying core loss reduction as a critical factor in their design considerations. This has created a strong market pull for both improved magnetic materials and more accurate testing methods to quantify core losses at high frequencies.

The market demand for standardized and reliable test methods for quantifying core losses at high frequencies is particularly acute, as existing testing protocols often show significant variations between different measurement techniques. This inconsistency creates challenges for design engineers when selecting materials and dimensioning components, highlighting the commercial value of improved testing methodologies.

Power electronics applications operating at frequencies of 100 kHz and above are becoming increasingly prevalent in renewable energy systems, electric vehicles, data centers, and industrial automation. This shift toward higher frequencies is primarily motivated by the need for smaller, lighter, and more efficient power conversion systems. Amorphous soft magnetic alloys are particularly well-positioned to meet these demands due to their superior performance characteristics at high frequencies.

The electric vehicle (EV) sector represents one of the most significant market drivers, with onboard chargers and DC-DC converters increasingly operating at frequencies above 100 kHz to reduce size and weight while improving efficiency. The global EV market is expected to grow at a CAGR of 21% through 2030, creating substantial demand for high-performance magnetic materials that can operate efficiently at high frequencies.

Renewable energy systems, particularly solar inverters and wind power converters, constitute another major market segment. The transition to silicon carbide (SiC) and gallium nitride (GaN) power semiconductors in these applications is enabling switching frequencies well above 100 kHz, necessitating magnetic materials with minimal core losses at these frequencies.

The telecommunications and data center industries are also driving demand for high-frequency magnetic materials, with power supplies and server power management systems requiring increasingly compact and efficient designs. The global data center power market is growing at approximately 6.5% annually, with efficiency requirements becoming more stringent.

Industry surveys indicate that manufacturers of power electronics are prioritizing efficiency improvements, with over 70% of respondents identifying core loss reduction as a critical factor in their design considerations. This has created a strong market pull for both improved magnetic materials and more accurate testing methods to quantify core losses at high frequencies.

The market demand for standardized and reliable test methods for quantifying core losses at high frequencies is particularly acute, as existing testing protocols often show significant variations between different measurement techniques. This inconsistency creates challenges for design engineers when selecting materials and dimensioning components, highlighting the commercial value of improved testing methodologies.

Current Challenges in Amorphous Alloy Core Loss Measurement

The accurate measurement of core losses in amorphous soft magnetic alloys at frequencies above 100 kHz presents significant technical challenges that impede both research advancement and industrial application. Traditional measurement methods such as the Epstein frame and toroidal testing, which are standardized for lower frequencies (typically below 20 kHz), become increasingly unreliable as frequency increases due to skin and proximity effects, as well as parasitic impedances that distort readings.

One primary challenge is the separation of core losses from other system losses. At high frequencies, the measurement system's parasitic components—including lead inductance, capacitive coupling, and contact resistance—can contribute significantly to the total measured loss, sometimes exceeding the actual core loss. This makes it difficult to isolate and quantify the true material performance.

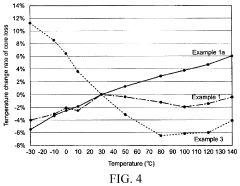

Temperature control represents another critical challenge. Amorphous alloys exhibit temperature-dependent magnetic properties, with core losses varying substantially across operating temperatures. During high-frequency testing, localized heating can occur rapidly, creating thermal gradients within the sample that lead to non-uniform magnetic performance and measurement inconsistencies.

The waveform integrity issue becomes particularly problematic above 100 kHz. Sinusoidal excitation waveforms tend to distort at high frequencies due to core nonlinearities and measurement circuit limitations. Since core loss is highly dependent on the excitation waveform shape, maintaining controlled test conditions becomes extremely difficult, leading to poor reproducibility between different test setups and laboratories.

Calibration standards for high-frequency measurements represent a significant gap in the industry. While low-frequency calibration materials and methods are well-established, reference materials and standardized procedures for frequencies above 100 kHz remain underdeveloped, creating uncertainty in measurement accuracy and hindering meaningful comparison between different research results.

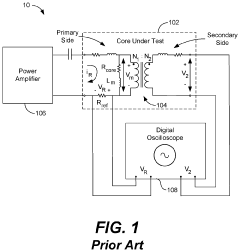

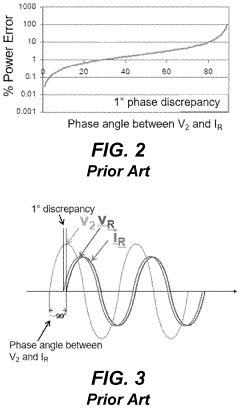

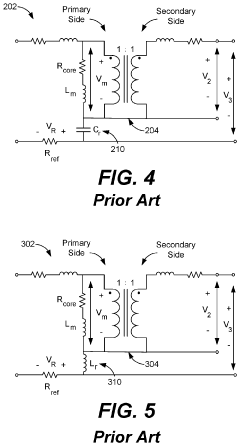

The dynamic B-H loop measurement, crucial for understanding energy loss mechanisms, becomes increasingly challenging at high frequencies due to phase errors between measured voltage and current signals. Even minor phase discrepancies of less than one degree can lead to substantial errors in loss calculation, requiring extremely precise instrumentation and careful signal processing techniques.

Additionally, the physical sample preparation for high-frequency testing introduces variables that affect measurement consistency. Mechanical stress during sample handling, cutting, or mounting can alter the magnetic properties of amorphous alloys, which are particularly sensitive to stress conditions. This creates difficulties in establishing repeatable test protocols that yield consistent results across different laboratories and testing facilities.

One primary challenge is the separation of core losses from other system losses. At high frequencies, the measurement system's parasitic components—including lead inductance, capacitive coupling, and contact resistance—can contribute significantly to the total measured loss, sometimes exceeding the actual core loss. This makes it difficult to isolate and quantify the true material performance.

Temperature control represents another critical challenge. Amorphous alloys exhibit temperature-dependent magnetic properties, with core losses varying substantially across operating temperatures. During high-frequency testing, localized heating can occur rapidly, creating thermal gradients within the sample that lead to non-uniform magnetic performance and measurement inconsistencies.

The waveform integrity issue becomes particularly problematic above 100 kHz. Sinusoidal excitation waveforms tend to distort at high frequencies due to core nonlinearities and measurement circuit limitations. Since core loss is highly dependent on the excitation waveform shape, maintaining controlled test conditions becomes extremely difficult, leading to poor reproducibility between different test setups and laboratories.

Calibration standards for high-frequency measurements represent a significant gap in the industry. While low-frequency calibration materials and methods are well-established, reference materials and standardized procedures for frequencies above 100 kHz remain underdeveloped, creating uncertainty in measurement accuracy and hindering meaningful comparison between different research results.

The dynamic B-H loop measurement, crucial for understanding energy loss mechanisms, becomes increasingly challenging at high frequencies due to phase errors between measured voltage and current signals. Even minor phase discrepancies of less than one degree can lead to substantial errors in loss calculation, requiring extremely precise instrumentation and careful signal processing techniques.

Additionally, the physical sample preparation for high-frequency testing introduces variables that affect measurement consistency. Mechanical stress during sample handling, cutting, or mounting can alter the magnetic properties of amorphous alloys, which are particularly sensitive to stress conditions. This creates difficulties in establishing repeatable test protocols that yield consistent results across different laboratories and testing facilities.

Existing High-Frequency Core Loss Measurement Techniques

01 Composition optimization for reduced core loss

Specific elemental compositions in amorphous soft magnetic alloys can significantly reduce core loss. By carefully controlling the ratios of elements such as Fe, Co, B, Si, and adding trace elements like Cu, Nb, or rare earth metals, manufacturers can create alloys with optimized magnetic domain structures. These compositions promote smaller magnetic domains and reduced magnetostriction, which directly contributes to lower hysteresis losses and eddy current losses during magnetization cycles.- Composition optimization for reduced core loss: Specific elemental compositions in amorphous soft magnetic alloys can significantly reduce core loss. By carefully adjusting the ratios of elements such as Fe, Co, B, Si, and adding trace elements like Cu, Nb, or rare earth metals, manufacturers can create alloys with optimized magnetic domain structures. These compositions promote smaller magnetic domains and reduce eddy current losses, resulting in lower core loss at both low and high frequencies.

- Heat treatment processes to minimize core loss: Various heat treatment methods can be applied to amorphous soft magnetic alloys to reduce core loss. These include annealing in magnetic fields, stress-relief annealing, and crystallization control treatments. Optimized heat treatment protocols can refine the microstructure, relieve internal stresses, and create beneficial nanocrystalline phases within the amorphous matrix, all contributing to lower hysteresis losses and improved magnetic performance.

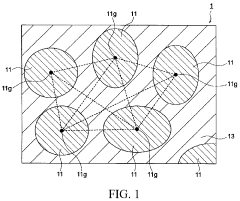

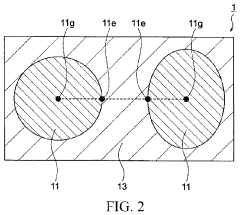

- Core design and lamination techniques: The physical design of amorphous soft magnetic cores significantly impacts core loss. Techniques such as using thinner laminations, optimizing core shapes, and implementing special stacking methods can reduce eddy currents. Advanced lamination techniques with improved insulation between layers and novel core geometries help minimize magnetic flux leakage and decrease overall core losses, particularly in high-frequency applications.

- Surface treatment and coating technologies: Surface treatments and specialized coatings can be applied to amorphous soft magnetic alloy cores to reduce core loss. These treatments include chemical etching, mechanical polishing, and application of insulating coatings. Such processes help to eliminate surface defects that can act as pinning sites for domain walls, reduce inter-laminar eddy currents, and improve the overall magnetic performance by creating smoother surfaces with fewer stress concentrations.

- Nanocrystalline phase control for loss reduction: Controlling the formation of nanocrystalline phases within the amorphous matrix can significantly reduce core loss in soft magnetic alloys. By precisely managing the size, distribution, and volume fraction of nanocrystalline phases through composition adjustments and specialized heat treatments, manufacturers can create materials with excellent soft magnetic properties. These nanocrystalline structures help to refine magnetic domains, reduce magnetostriction, and decrease both hysteresis and anomalous losses.

02 Heat treatment processes to minimize core loss

Various heat treatment methods can be applied to amorphous soft magnetic alloys to reduce core loss. These include annealing in magnetic fields, stress-relief annealing, and crystallization control treatments. The thermal processing helps to relieve internal stresses, optimize domain wall movement, and create nanocrystalline structures within the amorphous matrix. Properly controlled heat treatment can significantly improve the magnetic softness and reduce energy losses during magnetization cycles.Expand Specific Solutions03 Core design and lamination techniques

The physical design and construction of amorphous cores significantly impact core loss performance. Techniques such as ultra-thin lamination, special winding methods, and optimized core shapes can minimize eddy current losses. By reducing the effective cross-sectional area perpendicular to induced currents and implementing insulation between layers, these design approaches limit the pathways for eddy currents while maintaining the magnetic flux capacity of the core.Expand Specific Solutions04 Surface treatment and coating technologies

Surface modifications and specialized coatings can be applied to amorphous soft magnetic alloy cores to reduce core losses. These treatments include insulative coatings, surface oxidation control, and stress-relieving surface processing. By modifying the surface properties, these techniques help to reduce eddy current formation at the material boundaries, improve thermal stability, and maintain consistent magnetic properties throughout the operational lifetime of the core.Expand Specific Solutions05 Nanocrystalline structure development

Controlled partial crystallization of amorphous alloys can create nanocrystalline structures that significantly reduce core losses. By developing nanoscale crystalline regions within the amorphous matrix, these materials combine the high resistivity of amorphous alloys with the superior magnetic properties of crystalline materials. The nanocrystalline structure disrupts the formation of large magnetic domains and provides pinning sites that reduce domain wall movement losses during magnetization cycles.Expand Specific Solutions

Key Players in Magnetic Materials and Test Equipment Industry

The high-frequency core loss quantification market for amorphous soft magnetic alloys is in a growth phase, driven by increasing demand for efficient power electronics. The global market is expanding rapidly as industries seek energy-efficient solutions, with significant research activity across academic and industrial sectors. Leading companies like Metglas, Inc., TDK Corp., and Proterial Ltd. have established strong positions through specialized expertise in amorphous materials, while AMOGREENTECH and Advanced Technology & Materials Co. are emerging as innovative competitors. Research institutions including Harbin Institute of Technology and Zhejiang University are advancing testing methodologies. The technology is approaching maturity for lower frequencies but remains in development for applications above 100 kHz, creating opportunities for companies with advanced measurement capabilities and material science expertise.

Proterial Ltd.

Technical Solution: Proterial (formerly Hitachi Metals) has developed a comprehensive test methodology for quantifying core losses in amorphous soft magnetic alloys at frequencies of 100 kHz and above. Their approach centers on a dual-measurement system that combines electrical and thermal techniques. The electrical method utilizes a high-precision wattmeter with specialized compensation circuits to account for phase errors that become critical at high frequencies. Their test fixtures employ Litz wire windings with optimized geometry to minimize proximity effects and stray inductance. Proterial's system includes custom-designed signal conditioning and data acquisition hardware capable of accurately capturing voltage and current waveforms with minimal phase distortion up to several megahertz. For thermal verification, they employ a gradient-layer calorimeter that directly measures heat generated by core losses. Their methodology also incorporates a unique deconvolution algorithm that can separate hysteresis, classical eddy current, and excess losses even at high frequencies where traditional models break down. This allows for more accurate material characterization and optimization for specific power electronics applications.

Strengths: Their dual-measurement approach provides exceptional accuracy through cross-validation between electrical and thermal methods; their system can test under various excitation conditions including non-sinusoidal waveforms common in power electronics. Weaknesses: The complex test setup requires significant expertise to operate correctly; their methodology demands expensive, specialized equipment that limits accessibility for smaller research facilities.

NIPPON STEEL CORP.

Technical Solution: Nippon Steel has developed sophisticated test methodologies for measuring core losses in amorphous soft magnetic alloys at frequencies exceeding 100 kHz. Their approach centers on a custom-designed ring sample test system that minimizes measurement errors associated with high-frequency testing. The system employs specialized sensing coils with precise geometric positioning to account for non-uniform flux distribution within the core. Nippon Steel's methodology incorporates digital signal processing techniques with high sampling rates (>100 MS/s) and 16-bit resolution to accurately capture B-H loop characteristics even at frequencies approaching 1 MHz. Their test fixtures utilize advanced thermal management to maintain consistent sample temperatures during testing, as thermal variations can significantly impact measured losses. Additionally, they've developed proprietary algorithms to compensate for phase shifts between voltage and current measurements that become increasingly problematic at higher frequencies. Nippon Steel's approach also includes a comparative analysis framework that correlates electrical measurements with calorimetric verification to ensure accuracy across different operating conditions and material compositions.

Strengths: Their methodology provides exceptional measurement accuracy (±2.5%) even at very high frequencies; their system can characterize materials under various excitation conditions including non-sinusoidal waveforms typical in power electronics applications. Weaknesses: The test equipment requires significant capital investment and specialized expertise; their approach necessitates careful sample preparation that may be difficult to standardize across different material batches.

Critical Patents and Research in Core Loss Quantification

Core loss characterization and measurement

PatentActiveUS11307266B2

Innovation

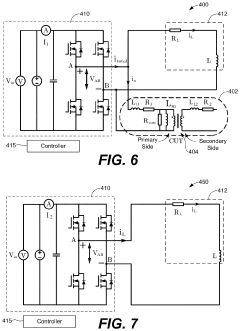

- A two-test parallel inductance method is developed, which involves a soft-switching circuit topology and two-test process to accurately measure core loss by disconnecting the core under test and applying excitation waveforms to both test configurations, allowing for the calculation of core loss without phase discrepancies and enabling the use of high amplitude excitation for a wide range of core sizes and waveforms.

Soft magnetic alloy, soft magnetic alloy ribbon, soft magnetic powder, and magnetic component

PatentActiveUS20220328224A1

Innovation

- A soft magnetic alloy with a specific composition and microstructure, including crystallites and an amorphous phase, is developed, where the total area ratio of crystallites is between 40% and 60%, the average thickness of the amorphous phase is between 3.0 nm and 10.0 nm, and the standard deviation is 10.0 nm or less, along with controlled content of elements like Nb, Hf, Zr, Ta, Mo, V, Ti, W, P, Cu, and Co, to stabilize magnetic anisotropy and improve temperature stability.

Standardization Efforts for High-Frequency Core Loss Testing

The standardization of test methods for high-frequency core loss measurement represents a critical advancement in the field of power electronics, particularly for amorphous soft magnetic alloys operating at frequencies of 100 kHz and above. Several international organizations have been actively working to establish unified testing protocols that ensure consistency and reliability in core loss quantification.

IEEE Power Electronics Society has formed a dedicated working group (WG P2166) focused on standardizing test methods for magnetic materials at high frequencies. This initiative aims to address the significant variations in measurement techniques currently employed across the industry, which often lead to discrepancies in reported core loss values for identical materials.

The International Electrotechnical Commission (IEC) has also made substantial progress through its Technical Committee 51, which is developing standards specifically for measuring magnetic properties at frequencies exceeding 100 kHz. Their work includes defining precise measurement conditions, equipment specifications, and data processing methodologies to ensure reproducibility of results across different laboratories.

ASTM International's Committee A06 on Magnetic Properties has been revising existing standards to incorporate high-frequency testing protocols. Their approach emphasizes the unique challenges posed by amorphous alloys, including the need for specialized sample preparation techniques and consideration of skin effect phenomena at elevated frequencies.

Japan's Industrial Standards Committee (JISC) has pioneered several testing methodologies specifically designed for amorphous and nanocrystalline materials, contributing valuable insights to global standardization efforts. Their standards have gained recognition for addressing the temperature-dependent behavior of core losses at high frequencies.

The European Committee for Electrotechnical Standardization (CENELEC) has established a harmonization program to align European standards with international protocols, focusing particularly on calorimetric measurement techniques that offer advantages for high-frequency loss determination in amorphous materials.

Collaborative round-robin testing programs involving multiple research institutions and industrial partners have been instrumental in validating proposed standards. These programs have highlighted the importance of accounting for measurement uncertainties and establishing clear calibration procedures for test equipment operating at frequencies above 100 kHz.

Recent standardization efforts have increasingly incorporated digital twin modeling approaches, allowing for virtual validation of physical test methods and expanding the applicability of standards across diverse material compositions and core geometries used in modern power electronic applications.

IEEE Power Electronics Society has formed a dedicated working group (WG P2166) focused on standardizing test methods for magnetic materials at high frequencies. This initiative aims to address the significant variations in measurement techniques currently employed across the industry, which often lead to discrepancies in reported core loss values for identical materials.

The International Electrotechnical Commission (IEC) has also made substantial progress through its Technical Committee 51, which is developing standards specifically for measuring magnetic properties at frequencies exceeding 100 kHz. Their work includes defining precise measurement conditions, equipment specifications, and data processing methodologies to ensure reproducibility of results across different laboratories.

ASTM International's Committee A06 on Magnetic Properties has been revising existing standards to incorporate high-frequency testing protocols. Their approach emphasizes the unique challenges posed by amorphous alloys, including the need for specialized sample preparation techniques and consideration of skin effect phenomena at elevated frequencies.

Japan's Industrial Standards Committee (JISC) has pioneered several testing methodologies specifically designed for amorphous and nanocrystalline materials, contributing valuable insights to global standardization efforts. Their standards have gained recognition for addressing the temperature-dependent behavior of core losses at high frequencies.

The European Committee for Electrotechnical Standardization (CENELEC) has established a harmonization program to align European standards with international protocols, focusing particularly on calorimetric measurement techniques that offer advantages for high-frequency loss determination in amorphous materials.

Collaborative round-robin testing programs involving multiple research institutions and industrial partners have been instrumental in validating proposed standards. These programs have highlighted the importance of accounting for measurement uncertainties and establishing clear calibration procedures for test equipment operating at frequencies above 100 kHz.

Recent standardization efforts have increasingly incorporated digital twin modeling approaches, allowing for virtual validation of physical test methods and expanding the applicability of standards across diverse material compositions and core geometries used in modern power electronic applications.

Thermal Management Considerations in High-Frequency Testing

Thermal management is a critical consideration in high-frequency testing of amorphous soft magnetic alloys, particularly when operating at frequencies of 100 kHz and above. As testing frequencies increase, the heat generated during measurement can significantly impact the accuracy of core loss quantification and potentially alter the magnetic properties of the material under test.

The primary challenge in thermal management stems from the rapid heat generation in the core material during high-frequency excitation. Amorphous soft magnetic alloys, while exhibiting superior performance at high frequencies compared to traditional silicon steel, still generate considerable heat due to hysteresis and eddy current losses. This heat generation increases exponentially with frequency, making thermal considerations paramount above 100 kHz.

Temperature rise during testing can introduce several measurement errors. First, the magnetic properties of amorphous alloys are temperature-dependent, with permeability and saturation flux density typically decreasing as temperature increases. Second, increased temperature can accelerate the crystallization process in amorphous materials, potentially causing irreversible changes to the core properties during extended testing periods.

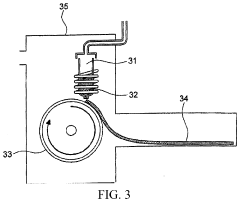

Effective thermal management strategies must be implemented to maintain measurement accuracy. Active cooling systems, such as forced air or liquid cooling, have proven effective in dissipating heat during high-frequency testing. These systems must be carefully designed to avoid introducing electromagnetic interference that could affect measurement accuracy.

Temperature monitoring is equally important, with strategically placed thermocouples or infrared sensors providing real-time feedback on core temperature. Advanced testing protocols often incorporate temperature compensation algorithms that adjust for the effects of temperature on measured core losses.

The physical design of test fixtures also plays a crucial role in thermal management. Minimizing thermal resistance between the core and cooling medium, while maintaining electrical isolation, represents a significant engineering challenge. Materials with high thermal conductivity but low electrical conductivity are preferred for test fixtures.

For extremely high-frequency testing (above 500 kHz), pulsed testing methods may be employed to reduce average power dissipation and associated heating. These methods apply test signals in short bursts, allowing cooling periods between measurements while still capturing the high-frequency behavior of the material.

Standardization of thermal management protocols remains an ongoing challenge in the industry, with different laboratories employing varied approaches. This lack of standardization contributes to discrepancies in reported core loss values across different testing facilities, highlighting the need for comprehensive thermal management guidelines specific to high-frequency testing of amorphous soft magnetic alloys.

The primary challenge in thermal management stems from the rapid heat generation in the core material during high-frequency excitation. Amorphous soft magnetic alloys, while exhibiting superior performance at high frequencies compared to traditional silicon steel, still generate considerable heat due to hysteresis and eddy current losses. This heat generation increases exponentially with frequency, making thermal considerations paramount above 100 kHz.

Temperature rise during testing can introduce several measurement errors. First, the magnetic properties of amorphous alloys are temperature-dependent, with permeability and saturation flux density typically decreasing as temperature increases. Second, increased temperature can accelerate the crystallization process in amorphous materials, potentially causing irreversible changes to the core properties during extended testing periods.

Effective thermal management strategies must be implemented to maintain measurement accuracy. Active cooling systems, such as forced air or liquid cooling, have proven effective in dissipating heat during high-frequency testing. These systems must be carefully designed to avoid introducing electromagnetic interference that could affect measurement accuracy.

Temperature monitoring is equally important, with strategically placed thermocouples or infrared sensors providing real-time feedback on core temperature. Advanced testing protocols often incorporate temperature compensation algorithms that adjust for the effects of temperature on measured core losses.

The physical design of test fixtures also plays a crucial role in thermal management. Minimizing thermal resistance between the core and cooling medium, while maintaining electrical isolation, represents a significant engineering challenge. Materials with high thermal conductivity but low electrical conductivity are preferred for test fixtures.

For extremely high-frequency testing (above 500 kHz), pulsed testing methods may be employed to reduce average power dissipation and associated heating. These methods apply test signals in short bursts, allowing cooling periods between measurements while still capturing the high-frequency behavior of the material.

Standardization of thermal management protocols remains an ongoing challenge in the industry, with different laboratories employing varied approaches. This lack of standardization contributes to discrepancies in reported core loss values across different testing facilities, highlighting the need for comprehensive thermal management guidelines specific to high-frequency testing of amorphous soft magnetic alloys.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!