Surface Treatments To Improve Insulation And Thermal Dissipation Of Amorphous Soft Magnetic Alloys In High-Frequency Power Electronics

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Amorphous Alloy Surface Treatment Background and Objectives

Amorphous soft magnetic alloys have emerged as critical materials in high-frequency power electronics due to their superior magnetic properties, including high permeability, low coercivity, and minimal core losses. The evolution of these materials began in the 1970s with the development of metal glass technology, progressing significantly through the 1990s and 2000s as manufacturing techniques improved and applications expanded into power conversion systems.

The technological trajectory of amorphous alloys has been driven by increasing demands for energy efficiency in power electronics, particularly as switching frequencies continue to rise beyond the kilohertz range into megahertz domains. This progression has exposed limitations in traditional magnetic materials and created opportunities for amorphous alloys to fill performance gaps.

Despite their excellent magnetic characteristics, amorphous soft magnetic alloys face significant challenges related to thermal management and electrical insulation when deployed in high-frequency applications. The ribbon-like structure of these materials, typically produced through rapid solidification processes, creates unique surface properties that can lead to eddy current losses, inter-layer short circuits, and inadequate heat dissipation.

Current technical objectives in this field focus on developing advanced surface treatment methodologies that can simultaneously enhance electrical insulation between laminations while improving thermal conductivity to surrounding structures. These seemingly contradictory requirements represent a complex materials science challenge that requires innovative approaches to surface modification.

The primary goals for surface treatment development include: achieving uniform insulation coatings with thicknesses below 5 micrometers to maintain high stacking factors; creating thermally conductive pathways that do not compromise electrical isolation; ensuring coating adhesion under thermal cycling conditions; and maintaining compatibility with existing manufacturing processes to enable cost-effective implementation.

Additionally, there is growing interest in developing environmentally sustainable surface treatments that eliminate hazardous chemicals traditionally used in magnetic core processing. This aligns with global regulatory trends toward reducing environmental impact across the electronics manufacturing sector.

As power electronics continue to advance toward higher power densities and frequencies, the effective surface treatment of amorphous soft magnetic alloys represents a critical enabling technology for next-generation power conversion systems in electric vehicles, renewable energy interfaces, and advanced grid infrastructure.

The technological trajectory of amorphous alloys has been driven by increasing demands for energy efficiency in power electronics, particularly as switching frequencies continue to rise beyond the kilohertz range into megahertz domains. This progression has exposed limitations in traditional magnetic materials and created opportunities for amorphous alloys to fill performance gaps.

Despite their excellent magnetic characteristics, amorphous soft magnetic alloys face significant challenges related to thermal management and electrical insulation when deployed in high-frequency applications. The ribbon-like structure of these materials, typically produced through rapid solidification processes, creates unique surface properties that can lead to eddy current losses, inter-layer short circuits, and inadequate heat dissipation.

Current technical objectives in this field focus on developing advanced surface treatment methodologies that can simultaneously enhance electrical insulation between laminations while improving thermal conductivity to surrounding structures. These seemingly contradictory requirements represent a complex materials science challenge that requires innovative approaches to surface modification.

The primary goals for surface treatment development include: achieving uniform insulation coatings with thicknesses below 5 micrometers to maintain high stacking factors; creating thermally conductive pathways that do not compromise electrical isolation; ensuring coating adhesion under thermal cycling conditions; and maintaining compatibility with existing manufacturing processes to enable cost-effective implementation.

Additionally, there is growing interest in developing environmentally sustainable surface treatments that eliminate hazardous chemicals traditionally used in magnetic core processing. This aligns with global regulatory trends toward reducing environmental impact across the electronics manufacturing sector.

As power electronics continue to advance toward higher power densities and frequencies, the effective surface treatment of amorphous soft magnetic alloys represents a critical enabling technology for next-generation power conversion systems in electric vehicles, renewable energy interfaces, and advanced grid infrastructure.

Market Demand Analysis for High-Frequency Power Electronics

The high-frequency power electronics market is experiencing unprecedented growth, driven primarily by the increasing demand for efficient power conversion systems across multiple industries. The global market for high-frequency power electronics was valued at approximately $12.5 billion in 2022 and is projected to reach $18.7 billion by 2027, representing a compound annual growth rate (CAGR) of 8.4%. This growth trajectory is particularly significant for technologies that enhance the performance of magnetic components, such as amorphous soft magnetic alloys with improved surface treatments.

The automotive sector represents one of the largest market segments, with electric vehicles (EVs) requiring advanced power electronics for efficient energy conversion. The number of EVs globally surpassed 10 million in 2022, with projections indicating this figure will reach 145 million by 2030. Each EV contains multiple high-frequency power conversion systems that could benefit from enhanced magnetic components, creating substantial market potential.

Renewable energy systems constitute another critical market segment. Solar inverters and wind power converters increasingly demand higher switching frequencies to reduce size and improve efficiency. The global solar inverter market alone is expected to grow at a CAGR of 8.8% through 2028, with similar growth patterns observed in wind power electronics.

Data centers represent a rapidly expanding application area, with power density requirements doubling approximately every four years. This trend necessitates more efficient power conversion technologies that can operate at higher frequencies while managing thermal challenges effectively. The global data center power market is projected to reach $15 billion by 2026, growing at a CAGR of 6.9%.

Consumer electronics manufacturers are also driving demand for miniaturized, efficient power supplies. The global market for smartphone chargers and adapters alone exceeds $5 billion annually, with fast-charging technologies creating specific requirements for high-frequency magnetic components with superior thermal management.

Industrial automation systems represent another significant market segment, with an increasing focus on energy efficiency and system miniaturization. The industrial power electronics market is expected to grow at a CAGR of 7.2% through 2028, with particular emphasis on components that can withstand harsh operating environments.

The market demand for surface-treated amorphous soft magnetic alloys is further amplified by regulatory pressures worldwide. Energy efficiency standards such as 80 PLUS Titanium for power supplies and the European Ecodesign Directive are pushing manufacturers toward higher-frequency operation, where improved insulation and thermal dissipation become critical performance factors.

The automotive sector represents one of the largest market segments, with electric vehicles (EVs) requiring advanced power electronics for efficient energy conversion. The number of EVs globally surpassed 10 million in 2022, with projections indicating this figure will reach 145 million by 2030. Each EV contains multiple high-frequency power conversion systems that could benefit from enhanced magnetic components, creating substantial market potential.

Renewable energy systems constitute another critical market segment. Solar inverters and wind power converters increasingly demand higher switching frequencies to reduce size and improve efficiency. The global solar inverter market alone is expected to grow at a CAGR of 8.8% through 2028, with similar growth patterns observed in wind power electronics.

Data centers represent a rapidly expanding application area, with power density requirements doubling approximately every four years. This trend necessitates more efficient power conversion technologies that can operate at higher frequencies while managing thermal challenges effectively. The global data center power market is projected to reach $15 billion by 2026, growing at a CAGR of 6.9%.

Consumer electronics manufacturers are also driving demand for miniaturized, efficient power supplies. The global market for smartphone chargers and adapters alone exceeds $5 billion annually, with fast-charging technologies creating specific requirements for high-frequency magnetic components with superior thermal management.

Industrial automation systems represent another significant market segment, with an increasing focus on energy efficiency and system miniaturization. The industrial power electronics market is expected to grow at a CAGR of 7.2% through 2028, with particular emphasis on components that can withstand harsh operating environments.

The market demand for surface-treated amorphous soft magnetic alloys is further amplified by regulatory pressures worldwide. Energy efficiency standards such as 80 PLUS Titanium for power supplies and the European Ecodesign Directive are pushing manufacturers toward higher-frequency operation, where improved insulation and thermal dissipation become critical performance factors.

Current Insulation and Thermal Dissipation Challenges

Amorphous soft magnetic alloys have emerged as critical materials in high-frequency power electronics due to their superior magnetic properties, including low core losses and high permeability. However, these materials face significant challenges related to insulation and thermal management that limit their full potential in advanced applications.

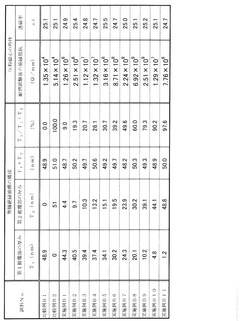

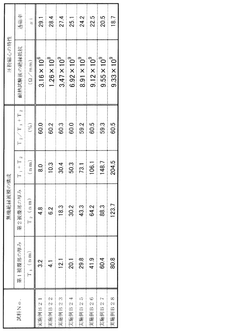

The primary insulation challenge stems from the metallic nature of these alloys, which can lead to eddy current losses when exposed to alternating magnetic fields. Traditional insulation methods such as organic coatings often prove inadequate at higher frequencies (>100 kHz) where these materials operate. The insulation layers must be extremely thin (typically <10 μm) to maintain the effective packing factor while providing sufficient electrical isolation between laminations.

Thermal dissipation presents another critical challenge. Despite their lower core losses compared to silicon steel, amorphous alloys still generate significant heat during operation, particularly in high-power density applications. The ribbon-like structure of these materials creates numerous interfaces that impede efficient heat transfer. Thermal conductivity values typically range from 10-18 W/m·K, significantly lower than crystalline counterparts, creating hotspots that can lead to premature aging and performance degradation.

Surface oxidation during manufacturing processes further complicates both insulation and thermal management. The native oxide layer, while providing some electrical insulation, is often inconsistent in thickness and quality. This inconsistency leads to unpredictable electrical performance and variable thermal contact resistance between layers in stacked configurations.

Environmental factors also pose challenges, as many existing surface treatments are susceptible to degradation under humidity and temperature cycling. This degradation compromises long-term reliability, particularly in automotive and industrial applications where operating conditions can be harsh and variable.

Current manufacturing limitations exacerbate these challenges. The extremely thin nature of amorphous ribbons (typically 15-35 μm) makes uniform application of surface treatments difficult to achieve at scale. Conventional coating methods often result in uneven coverage, creating weak points in the insulation system and inconsistent thermal interfaces.

The trade-off between insulation effectiveness and thermal conductivity represents perhaps the most fundamental challenge. Materials that provide excellent electrical insulation typically exhibit poor thermal conductivity, creating an inherent design conflict. This necessitates innovative approaches that can simultaneously address both requirements without compromising the magnetic performance of the core material.

The primary insulation challenge stems from the metallic nature of these alloys, which can lead to eddy current losses when exposed to alternating magnetic fields. Traditional insulation methods such as organic coatings often prove inadequate at higher frequencies (>100 kHz) where these materials operate. The insulation layers must be extremely thin (typically <10 μm) to maintain the effective packing factor while providing sufficient electrical isolation between laminations.

Thermal dissipation presents another critical challenge. Despite their lower core losses compared to silicon steel, amorphous alloys still generate significant heat during operation, particularly in high-power density applications. The ribbon-like structure of these materials creates numerous interfaces that impede efficient heat transfer. Thermal conductivity values typically range from 10-18 W/m·K, significantly lower than crystalline counterparts, creating hotspots that can lead to premature aging and performance degradation.

Surface oxidation during manufacturing processes further complicates both insulation and thermal management. The native oxide layer, while providing some electrical insulation, is often inconsistent in thickness and quality. This inconsistency leads to unpredictable electrical performance and variable thermal contact resistance between layers in stacked configurations.

Environmental factors also pose challenges, as many existing surface treatments are susceptible to degradation under humidity and temperature cycling. This degradation compromises long-term reliability, particularly in automotive and industrial applications where operating conditions can be harsh and variable.

Current manufacturing limitations exacerbate these challenges. The extremely thin nature of amorphous ribbons (typically 15-35 μm) makes uniform application of surface treatments difficult to achieve at scale. Conventional coating methods often result in uneven coverage, creating weak points in the insulation system and inconsistent thermal interfaces.

The trade-off between insulation effectiveness and thermal conductivity represents perhaps the most fundamental challenge. Materials that provide excellent electrical insulation typically exhibit poor thermal conductivity, creating an inherent design conflict. This necessitates innovative approaches that can simultaneously address both requirements without compromising the magnetic performance of the core material.

Current Surface Treatment Solutions and Implementation

01 Insulation coatings for amorphous soft magnetic alloys

Various insulation coatings can be applied to amorphous soft magnetic alloys to improve their electrical insulation properties while maintaining magnetic performance. These coatings typically include oxide layers, polymer films, or ceramic materials that provide electrical isolation between adjacent layers in magnetic cores. The insulation layers help reduce eddy current losses, which is crucial for high-frequency applications. These coatings are designed to be thin enough to maintain high stacking factors while providing sufficient electrical resistance.- Insulation coatings for amorphous soft magnetic alloys: Various insulation coatings can be applied to amorphous soft magnetic alloys to improve their electrical insulation properties while maintaining magnetic performance. These coatings typically include oxide layers, polymer-based insulations, or composite materials that provide electrical isolation between laminated layers. The insulation coatings help reduce eddy current losses in magnetic cores, improving overall efficiency while providing some degree of thermal protection.

- Thermal dissipation structures for amorphous magnetic components: Specialized thermal dissipation structures can be integrated with amorphous soft magnetic components to manage heat generation during operation. These structures include heat sinks, cooling channels, thermal interface materials, and specialized housing designs that facilitate heat transfer away from the magnetic core. Effective thermal management prevents degradation of magnetic properties at elevated temperatures and extends the operational lifetime of the components.

- Composition modifications for improved thermal properties: The thermal and insulation properties of amorphous soft magnetic alloys can be enhanced through specific composition modifications. Adding elements such as Si, B, P, or rare earth metals in precise proportions can improve the thermal stability and Curie temperature of the alloys. These compositional adjustments help maintain magnetic performance at elevated temperatures while potentially improving the natural insulation characteristics of the material.

- Lamination techniques for enhanced insulation and cooling: Advanced lamination techniques can be employed to improve both the insulation and thermal dissipation properties of amorphous soft magnetic components. These techniques include specialized stacking methods, interleaving with thermally conductive but electrically insulating materials, and optimized lamination thickness. The resulting structures provide effective electrical isolation between layers while creating pathways for heat dissipation, reducing core losses and improving efficiency.

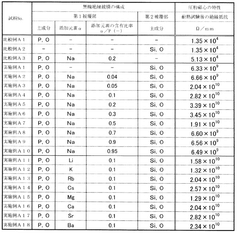

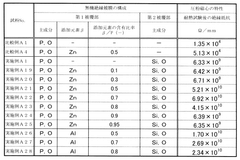

- Surface treatment methods for dual functionality: Various surface treatment methods can be applied to amorphous soft magnetic alloys to simultaneously enhance both insulation and thermal dissipation properties. These treatments include controlled oxidation, phosphating, nitriding, or application of specialized nano-coatings. The treated surfaces provide electrical insulation while maintaining or improving thermal conductivity, allowing for more efficient heat transfer while preventing unwanted electrical currents between layers.

02 Thermal dissipation structures for amorphous magnetic components

Specialized thermal dissipation structures can be integrated with amorphous soft magnetic components to manage heat generation during operation. These structures include heat sinks, cooling channels, thermal interface materials, and specialized housing designs that facilitate heat transfer away from the magnetic core. Effective thermal management is essential for maintaining the magnetic properties of amorphous alloys, as their performance can degrade at elevated temperatures. Some designs incorporate phase change materials or forced cooling mechanisms to handle high power applications.Expand Specific Solutions03 Composition modifications for improved thermal properties

The thermal properties of amorphous soft magnetic alloys can be enhanced through specific composition modifications. By adjusting the ratios of constituent elements such as Fe, Co, Ni, B, Si, and P, or by adding small amounts of elements like Cu, Nb, or rare earth metals, the thermal stability and Curie temperature of the alloys can be improved. These compositional adjustments help create materials that maintain their amorphous structure and magnetic properties at higher operating temperatures, which is crucial for applications in harsh environments or high-power density devices.Expand Specific Solutions04 Lamination techniques for enhanced insulation and cooling

Specialized lamination techniques are employed to enhance both electrical insulation and thermal dissipation in amorphous soft magnetic components. These techniques involve stacking thin layers of amorphous ribbons with insulating materials between them, creating pathways for heat dissipation while preventing electrical shorts. Advanced lamination methods include interleaved cooling layers, gradient stacking patterns, and pressure-bonded assemblies. These approaches help optimize the balance between magnetic performance, electrical isolation, and thermal management, particularly important for high-frequency transformer and inductor applications.Expand Specific Solutions05 Surface treatment methods for dual functionality

Various surface treatment methods can provide both insulation and thermal dissipation benefits to amorphous soft magnetic alloys. These treatments include controlled oxidation, phosphating, plasma treatment, and application of specialized nano-coatings. The treated surfaces create a thin layer that provides electrical insulation while facilitating thermal conduction through strategic material selection and structure design. Some treatments also improve corrosion resistance and mechanical stability of the amorphous ribbons, extending the lifetime of magnetic components in challenging operating conditions.Expand Specific Solutions

Key Industry Players in Soft Magnetic Materials

The surface treatment technology for amorphous soft magnetic alloys in high-frequency power electronics is currently in a growth phase, with the market expanding rapidly due to increasing demand for efficient power conversion systems. The global market size for these specialized materials is projected to reach significant value as industries transition toward higher frequency operation and miniaturization. Technologically, the field shows varying maturity levels across competitors. Companies like TDK Corp., Hitachi Industrial Equipment Systems, and Sumitomo Electric Industries lead with advanced insulation and thermal management solutions, while VACUUMSCHMELZE and Proterial Ltd. demonstrate strong innovation in specialized surface treatments. Academic institutions including Tongji University and Nanchang University contribute fundamental research, creating a competitive ecosystem where industrial-academic partnerships drive technological advancement in addressing thermal challenges in high-frequency applications.

TDK Corp.

Technical Solution: TDK has pioneered an advanced surface treatment technology called "AMOCOAT" specifically designed for their amorphous and nanocrystalline soft magnetic materials used in high-frequency power electronics. This technology employs a hybrid organic-inorganic coating system that combines the benefits of both material types. The base layer consists of an aluminum oxide coating applied through atomic layer deposition (ALD), providing excellent electrical insulation with minimal thickness (typically 50-100nm). This is followed by a proprietary polymer-ceramic composite coating that enhances thermal conductivity while maintaining the insulation properties. TDK has also developed a specialized edge treatment process that prevents edge shorting in stacked core configurations, a common failure point in high-frequency applications. Their research demonstrates that cores treated with AMOCOAT technology can operate at frequencies up to 500 kHz with significantly reduced eddy current losses compared to conventional coatings, while also showing improved thermal dissipation capabilities that allow for up to 30% higher power density in converter applications.

Strengths: Ultra-thin coating maintains excellent magnetic properties while providing superior insulation; specialized edge treatment prevents a common failure mode; enables higher power density in converter applications. Weaknesses: ALD process is relatively slow and increases production costs; requires specialized equipment and clean room conditions; potential for coating damage during core assembly.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has developed a comprehensive surface treatment solution called "ThermoInsul" for their amorphous soft magnetic alloys used in high-frequency power electronics. Their approach involves a multi-step process beginning with surface preparation using plasma etching to create a nanoscale roughened surface that improves coating adhesion. This is followed by application of a proprietary silicon-aluminum oxide composite coating using magnetron sputtering technology, which provides excellent electrical insulation while maintaining high thermal conductivity. The coating thickness is precisely controlled between 1-3 μm to minimize impact on the core's magnetic properties. Mitsubishi has also implemented a post-coating thermal annealing process in a controlled atmosphere that optimizes the crystalline structure of the coating for improved thermal performance. Their research indicates that this treatment can improve thermal dissipation by up to 35% compared to conventional insulation methods while maintaining insulation resistance above 50 MΩ at operating temperatures up to 180°C. The company has successfully implemented this technology in their latest generation of high-efficiency power converters, demonstrating a 15% reduction in core temperature during operation.

Strengths: Excellent balance between thermal conductivity and electrical insulation; precise thickness control minimizes impact on magnetic properties; proven performance in commercial power converter applications. Weaknesses: Magnetron sputtering process is relatively expensive and time-consuming; requires specialized equipment; potential for coating cracking under mechanical stress during core assembly.

Core Patents and Technical Literature on Amorphous Alloy Treatments

Soft magnetic powder, magnetic core, and electronic component

PatentWO2021015206A1

Innovation

- A soft magnetic powder with a multilayer inorganic insulating coating comprising a phosphorus-based first coating and a silicon-based second coating, along with an optional intermediate layer, is applied to the surface of soft magnetic metal particles, maintaining high insulation resistance and magnetic permeability even at elevated temperatures.

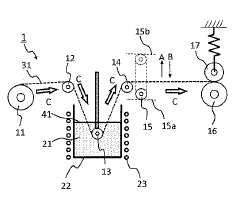

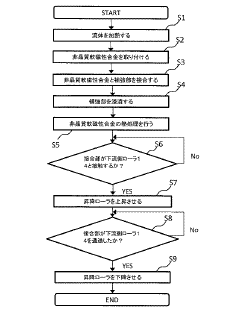

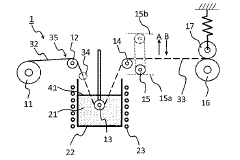

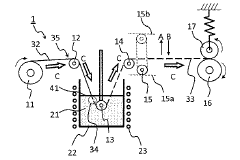

Heat treatment method for amorphous soft magnetic alloy and heat treatment device for amorphous soft magnetic alloy

PatentInactiveJP2016160497A

Innovation

- A heat treatment method involving a guide portion and a reinforcing portion for the amorphous soft magnetic alloy, where only the reinforcing portion is immersed in a fluid maintained at a predetermined temperature, guiding the alloy through the fluid while minimizing contact with guide rollers to prevent breakage.

Environmental Impact and Sustainability Considerations

The environmental impact of surface treatments for amorphous soft magnetic alloys represents a critical consideration in the sustainable development of high-frequency power electronics. Traditional coating processes often involve hazardous chemicals, high energy consumption, and significant waste generation. Recent life cycle assessments indicate that conventional insulation treatments can contribute up to 15% of the total environmental footprint of magnetic components in power electronic systems.

Water-based coating technologies have emerged as environmentally preferable alternatives to solvent-based systems, reducing volatile organic compound (VOC) emissions by approximately 80%. These aqueous solutions minimize air pollution and occupational health risks while maintaining comparable insulation performance. Additionally, sol-gel derived ceramic coatings offer biodegradable precursors with reduced toxicity profiles compared to conventional epoxy-based insulation materials.

Energy consumption during surface treatment processes presents another significant environmental concern. Thermal curing of insulation coatings typically requires temperatures between 150-300°C, contributing substantially to the carbon footprint of component manufacturing. Recent innovations in UV-curable and room-temperature curing formulations have demonstrated energy savings of up to 60% while reducing processing time by 75%, thereby enhancing production efficiency while decreasing environmental impact.

End-of-life considerations for treated amorphous alloys have gained increasing attention as electronic waste volumes continue to rise globally. Surface treatments that enable component disassembly and material recovery facilitate circular economy principles. Phosphate-based coatings, for instance, can be chemically dissolved without damaging the underlying magnetic material, allowing for more effective recycling of valuable metals compared to permanently bonded epoxy systems.

The thermal dissipation properties of surface treatments directly impact the operational efficiency and lifespan of power electronic devices. Enhanced thermal management through optimized surface treatments can reduce energy consumption during operation by 5-12%, translating to significant carbon emission reductions over product lifetimes. Moreover, improved thermal performance extends component service life, reducing replacement frequency and associated resource consumption.

Regulatory frameworks increasingly influence surface treatment selection, with restrictions on substances of very high concern (SVHCs) under REACH legislation and RoHS directives limiting heavy metal content. Forward-thinking manufacturers are proactively adopting compliant technologies such as nano-ceramic dispersions and bio-based polymers that meet both technical requirements and environmental standards, positioning themselves advantageously for future regulatory developments.

Water-based coating technologies have emerged as environmentally preferable alternatives to solvent-based systems, reducing volatile organic compound (VOC) emissions by approximately 80%. These aqueous solutions minimize air pollution and occupational health risks while maintaining comparable insulation performance. Additionally, sol-gel derived ceramic coatings offer biodegradable precursors with reduced toxicity profiles compared to conventional epoxy-based insulation materials.

Energy consumption during surface treatment processes presents another significant environmental concern. Thermal curing of insulation coatings typically requires temperatures between 150-300°C, contributing substantially to the carbon footprint of component manufacturing. Recent innovations in UV-curable and room-temperature curing formulations have demonstrated energy savings of up to 60% while reducing processing time by 75%, thereby enhancing production efficiency while decreasing environmental impact.

End-of-life considerations for treated amorphous alloys have gained increasing attention as electronic waste volumes continue to rise globally. Surface treatments that enable component disassembly and material recovery facilitate circular economy principles. Phosphate-based coatings, for instance, can be chemically dissolved without damaging the underlying magnetic material, allowing for more effective recycling of valuable metals compared to permanently bonded epoxy systems.

The thermal dissipation properties of surface treatments directly impact the operational efficiency and lifespan of power electronic devices. Enhanced thermal management through optimized surface treatments can reduce energy consumption during operation by 5-12%, translating to significant carbon emission reductions over product lifetimes. Moreover, improved thermal performance extends component service life, reducing replacement frequency and associated resource consumption.

Regulatory frameworks increasingly influence surface treatment selection, with restrictions on substances of very high concern (SVHCs) under REACH legislation and RoHS directives limiting heavy metal content. Forward-thinking manufacturers are proactively adopting compliant technologies such as nano-ceramic dispersions and bio-based polymers that meet both technical requirements and environmental standards, positioning themselves advantageously for future regulatory developments.

Cost-Benefit Analysis of Advanced Surface Treatments

The implementation of advanced surface treatments for amorphous soft magnetic alloys requires careful economic evaluation to determine their viability in high-frequency power electronics applications. When analyzing the cost-benefit ratio of these treatments, initial investment costs must be weighed against long-term operational advantages and performance improvements.

Primary investment costs include specialized equipment for plasma treatment, chemical vapor deposition, or nano-coating application, which typically range from $200,000 to $1.5 million depending on production scale and precision requirements. Additionally, high-purity materials for coatings such as aluminum oxide, silicon nitride, or specialized polymer composites represent recurring expenses that can significantly impact unit economics.

Labor costs constitute another substantial component, as these advanced treatments often require skilled technicians and engineers with specialized training. The implementation of quality control systems for ensuring coating uniformity and adherence adds further to the overall investment.

Against these costs, several quantifiable benefits emerge. Enhanced insulation properties from advanced surface treatments can reduce eddy current losses by 15-30%, directly improving energy efficiency in power conversion applications. This translates to energy savings of approximately 5-12% in typical high-frequency converter systems, representing significant operational cost reductions over device lifetime.

Improved thermal dissipation capabilities enable higher power density designs, allowing manufacturers to reduce overall material usage by 10-20% while maintaining performance specifications. This material reduction compounds into savings across the supply chain and manufacturing process.

Extended component lifespan represents perhaps the most significant long-term benefit. Surface-treated amorphous alloys demonstrate 30-50% longer operational lifetimes in high-stress applications, reducing replacement frequency and associated maintenance costs. For industrial applications, this can translate to thousands of operational hours gained before replacement becomes necessary.

The return on investment timeline varies by application, with consumer electronics typically seeing ROI within 1-2 years, while industrial power systems may require 2-4 years to fully realize economic benefits. However, as production scales increase and treatment technologies mature, these timelines are expected to shorten significantly.

Environmental considerations also factor into the cost-benefit equation, as improved efficiency reduces lifetime carbon footprint, potentially qualifying products for environmental certifications and incentives in certain markets.

Primary investment costs include specialized equipment for plasma treatment, chemical vapor deposition, or nano-coating application, which typically range from $200,000 to $1.5 million depending on production scale and precision requirements. Additionally, high-purity materials for coatings such as aluminum oxide, silicon nitride, or specialized polymer composites represent recurring expenses that can significantly impact unit economics.

Labor costs constitute another substantial component, as these advanced treatments often require skilled technicians and engineers with specialized training. The implementation of quality control systems for ensuring coating uniformity and adherence adds further to the overall investment.

Against these costs, several quantifiable benefits emerge. Enhanced insulation properties from advanced surface treatments can reduce eddy current losses by 15-30%, directly improving energy efficiency in power conversion applications. This translates to energy savings of approximately 5-12% in typical high-frequency converter systems, representing significant operational cost reductions over device lifetime.

Improved thermal dissipation capabilities enable higher power density designs, allowing manufacturers to reduce overall material usage by 10-20% while maintaining performance specifications. This material reduction compounds into savings across the supply chain and manufacturing process.

Extended component lifespan represents perhaps the most significant long-term benefit. Surface-treated amorphous alloys demonstrate 30-50% longer operational lifetimes in high-stress applications, reducing replacement frequency and associated maintenance costs. For industrial applications, this can translate to thousands of operational hours gained before replacement becomes necessary.

The return on investment timeline varies by application, with consumer electronics typically seeing ROI within 1-2 years, while industrial power systems may require 2-4 years to fully realize economic benefits. However, as production scales increase and treatment technologies mature, these timelines are expected to shorten significantly.

Environmental considerations also factor into the cost-benefit equation, as improved efficiency reduces lifetime carbon footprint, potentially qualifying products for environmental certifications and incentives in certain markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!