Reliability Testing Of Amorphous Soft Magnetic Alloys Under Cyclic High-Frequency Loads For Power Electronics

AUG 26, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Amorphous Alloy Evolution and Research Objectives

Amorphous soft magnetic alloys emerged in the 1970s when researchers at Allied Signal (now Honeywell) discovered that rapid solidification techniques could produce metallic glasses with unique magnetic properties. These materials represented a significant departure from traditional crystalline magnetic materials, offering substantially reduced core losses, higher permeability, and near-zero magnetostriction. The evolution of these materials has been marked by continuous improvements in composition, processing techniques, and application-specific optimizations.

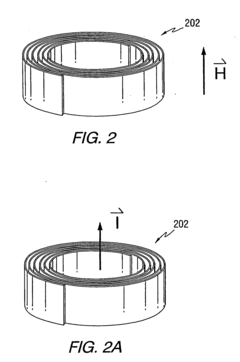

The development trajectory of amorphous soft magnetic alloys has seen several key phases. Initially, iron-based compositions (Fe-B-Si) dominated the landscape, followed by the introduction of cobalt-based alloys (Co-Fe-B-Si) in the 1980s, which offered higher saturation flux density and improved temperature stability. The 1990s witnessed the emergence of nanocrystalline alloys, representing a hybrid approach where controlled crystallization of amorphous precursors yielded enhanced magnetic properties.

Recent advancements have focused on tailoring these materials for high-frequency power electronic applications, where operating frequencies have increased dramatically from kilohertz to megahertz ranges. This shift has placed unprecedented demands on magnetic components, particularly regarding their reliability under cyclic high-frequency electromagnetic and thermal loads.

Despite their superior magnetic properties, the widespread adoption of amorphous alloys in power electronics has been hindered by concerns about their long-term reliability. The brittle nature of these materials, combined with the thermal cycling and high-frequency electromagnetic stresses present in modern power converters, raises questions about their durability and performance stability over time.

The primary research objective of this investigation is to establish comprehensive reliability testing methodologies specifically designed for amorphous soft magnetic alloys under conditions that accurately simulate real-world power electronic applications. This includes developing accelerated testing protocols that can predict lifetime performance under cyclic high-frequency loads ranging from 100 kHz to 5 MHz, with varying duty cycles and operating temperatures.

Secondary objectives include identifying failure mechanisms unique to amorphous alloys in high-frequency applications, establishing correlations between material composition, processing parameters, and reliability metrics, and developing predictive models that can inform both material design and application engineering decisions. The ultimate goal is to enable confident specification of amorphous magnetic materials in next-generation power electronic systems where efficiency, power density, and reliability are paramount considerations.

The development trajectory of amorphous soft magnetic alloys has seen several key phases. Initially, iron-based compositions (Fe-B-Si) dominated the landscape, followed by the introduction of cobalt-based alloys (Co-Fe-B-Si) in the 1980s, which offered higher saturation flux density and improved temperature stability. The 1990s witnessed the emergence of nanocrystalline alloys, representing a hybrid approach where controlled crystallization of amorphous precursors yielded enhanced magnetic properties.

Recent advancements have focused on tailoring these materials for high-frequency power electronic applications, where operating frequencies have increased dramatically from kilohertz to megahertz ranges. This shift has placed unprecedented demands on magnetic components, particularly regarding their reliability under cyclic high-frequency electromagnetic and thermal loads.

Despite their superior magnetic properties, the widespread adoption of amorphous alloys in power electronics has been hindered by concerns about their long-term reliability. The brittle nature of these materials, combined with the thermal cycling and high-frequency electromagnetic stresses present in modern power converters, raises questions about their durability and performance stability over time.

The primary research objective of this investigation is to establish comprehensive reliability testing methodologies specifically designed for amorphous soft magnetic alloys under conditions that accurately simulate real-world power electronic applications. This includes developing accelerated testing protocols that can predict lifetime performance under cyclic high-frequency loads ranging from 100 kHz to 5 MHz, with varying duty cycles and operating temperatures.

Secondary objectives include identifying failure mechanisms unique to amorphous alloys in high-frequency applications, establishing correlations between material composition, processing parameters, and reliability metrics, and developing predictive models that can inform both material design and application engineering decisions. The ultimate goal is to enable confident specification of amorphous magnetic materials in next-generation power electronic systems where efficiency, power density, and reliability are paramount considerations.

Market Demand Analysis for High-Frequency Power Electronics

The global power electronics market is experiencing robust growth, with a market size reaching $41.1 billion in 2022 and projected to expand to $65.7 billion by 2028. This growth is primarily driven by the increasing demand for energy-efficient power conversion systems across various industries including automotive, renewable energy, industrial automation, and consumer electronics. High-frequency power electronics, in particular, represent a rapidly growing segment due to their ability to enable smaller, lighter, and more efficient power conversion systems.

The transition toward electric vehicles (EVs) has emerged as a significant market driver for high-frequency power electronics. With global EV sales surpassing 10 million units in 2022, the demand for efficient power conversion components has surged. These vehicles require advanced power electronics for battery management systems, motor drives, and charging infrastructure, creating substantial market opportunities for high-performance magnetic materials.

Renewable energy systems constitute another major market segment, with global renewable capacity additions reaching 295 GW in 2022. Solar inverters and wind power converters increasingly utilize high-frequency operation to improve efficiency and reduce size. This trend has intensified the need for reliable magnetic components capable of operating under demanding conditions without performance degradation.

Data centers and telecommunications infrastructure represent a growing application area for high-frequency power electronics. With global data center power consumption exceeding 200 TWh annually, there is significant pressure to improve power conversion efficiency. The shift toward higher switching frequencies in power supplies has created demand for magnetic materials that can maintain performance under continuous high-frequency operation.

Consumer electronics and industrial automation sectors are also driving market growth, with requirements for miniaturized power supplies operating at frequencies exceeding 100 kHz. This miniaturization trend has accelerated the adoption of advanced magnetic materials capable of efficient operation at high frequencies.

Market research indicates that end-users are increasingly prioritizing reliability and longevity in power electronic components, with 78% of procurement managers citing reliability as a critical selection factor. This shift has created a growing demand for comprehensive reliability testing methodologies for magnetic components, particularly for amorphous soft magnetic alloys that offer superior performance at high frequencies.

The geographical distribution of market demand shows Asia-Pacific leading with 45% market share, followed by North America (27%) and Europe (21%). China, Japan, and South Korea have emerged as manufacturing hubs for high-frequency power electronics, while North America and Europe lead in research and development of advanced materials and testing methodologies.

The transition toward electric vehicles (EVs) has emerged as a significant market driver for high-frequency power electronics. With global EV sales surpassing 10 million units in 2022, the demand for efficient power conversion components has surged. These vehicles require advanced power electronics for battery management systems, motor drives, and charging infrastructure, creating substantial market opportunities for high-performance magnetic materials.

Renewable energy systems constitute another major market segment, with global renewable capacity additions reaching 295 GW in 2022. Solar inverters and wind power converters increasingly utilize high-frequency operation to improve efficiency and reduce size. This trend has intensified the need for reliable magnetic components capable of operating under demanding conditions without performance degradation.

Data centers and telecommunications infrastructure represent a growing application area for high-frequency power electronics. With global data center power consumption exceeding 200 TWh annually, there is significant pressure to improve power conversion efficiency. The shift toward higher switching frequencies in power supplies has created demand for magnetic materials that can maintain performance under continuous high-frequency operation.

Consumer electronics and industrial automation sectors are also driving market growth, with requirements for miniaturized power supplies operating at frequencies exceeding 100 kHz. This miniaturization trend has accelerated the adoption of advanced magnetic materials capable of efficient operation at high frequencies.

Market research indicates that end-users are increasingly prioritizing reliability and longevity in power electronic components, with 78% of procurement managers citing reliability as a critical selection factor. This shift has created a growing demand for comprehensive reliability testing methodologies for magnetic components, particularly for amorphous soft magnetic alloys that offer superior performance at high frequencies.

The geographical distribution of market demand shows Asia-Pacific leading with 45% market share, followed by North America (27%) and Europe (21%). China, Japan, and South Korea have emerged as manufacturing hubs for high-frequency power electronics, while North America and Europe lead in research and development of advanced materials and testing methodologies.

Current Challenges in Soft Magnetic Alloy Reliability Testing

Despite significant advancements in amorphous soft magnetic alloys for power electronics applications, reliability testing under cyclic high-frequency loads presents several formidable challenges. The non-crystalline structure that gives these materials their superior magnetic properties also creates unique testing complexities that conventional methods struggle to address adequately.

One primary challenge is the development of standardized testing protocols specifically designed for amorphous alloys. Current testing methodologies were largely developed for traditional crystalline materials and fail to account for the distinct mechanical and magnetic behavior of amorphous structures under high-frequency operation. This lack of standardization leads to inconsistent reliability assessments across the industry and hinders meaningful comparison between different alloy formulations.

Temperature management during high-frequency testing represents another significant obstacle. Amorphous alloys exhibit different thermal expansion characteristics compared to crystalline counterparts, and their magnetic properties demonstrate heightened temperature sensitivity. Testing equipment must precisely control and monitor temperature fluctuations to prevent thermal artifacts from contaminating reliability data, a requirement that exceeds the capabilities of many conventional testing setups.

The simulation of real-world operating conditions poses additional difficulties. Power electronic applications subject these materials to complex combinations of electrical, magnetic, thermal, and mechanical stresses simultaneously. Current testing approaches often isolate these factors rather than evaluating their combined effects, resulting in reliability predictions that may not accurately reflect field performance.

Accelerated aging methodologies present particular challenges for amorphous alloys. The relationship between accelerated test conditions and actual degradation mechanisms remains poorly understood, making it difficult to extrapolate long-term reliability from short-duration tests. This uncertainty is compounded by the relatively limited field data available for these newer materials compared to traditional magnetic alloys.

Microstructural characterization during and after reliability testing represents another frontier challenge. Non-destructive evaluation techniques capable of detecting early-stage degradation in amorphous structures are still evolving. The subtle structural changes that precede performance deterioration often go undetected until failure occurs, limiting the predictive power of current testing approaches.

Finally, there exists a significant gap between laboratory testing and manufacturing quality control. Translating sophisticated reliability testing protocols into practical, cost-effective quality assurance measures for high-volume production environments remains problematic, creating barriers to wider industrial adoption of these advanced materials.

One primary challenge is the development of standardized testing protocols specifically designed for amorphous alloys. Current testing methodologies were largely developed for traditional crystalline materials and fail to account for the distinct mechanical and magnetic behavior of amorphous structures under high-frequency operation. This lack of standardization leads to inconsistent reliability assessments across the industry and hinders meaningful comparison between different alloy formulations.

Temperature management during high-frequency testing represents another significant obstacle. Amorphous alloys exhibit different thermal expansion characteristics compared to crystalline counterparts, and their magnetic properties demonstrate heightened temperature sensitivity. Testing equipment must precisely control and monitor temperature fluctuations to prevent thermal artifacts from contaminating reliability data, a requirement that exceeds the capabilities of many conventional testing setups.

The simulation of real-world operating conditions poses additional difficulties. Power electronic applications subject these materials to complex combinations of electrical, magnetic, thermal, and mechanical stresses simultaneously. Current testing approaches often isolate these factors rather than evaluating their combined effects, resulting in reliability predictions that may not accurately reflect field performance.

Accelerated aging methodologies present particular challenges for amorphous alloys. The relationship between accelerated test conditions and actual degradation mechanisms remains poorly understood, making it difficult to extrapolate long-term reliability from short-duration tests. This uncertainty is compounded by the relatively limited field data available for these newer materials compared to traditional magnetic alloys.

Microstructural characterization during and after reliability testing represents another frontier challenge. Non-destructive evaluation techniques capable of detecting early-stage degradation in amorphous structures are still evolving. The subtle structural changes that precede performance deterioration often go undetected until failure occurs, limiting the predictive power of current testing approaches.

Finally, there exists a significant gap between laboratory testing and manufacturing quality control. Translating sophisticated reliability testing protocols into practical, cost-effective quality assurance measures for high-volume production environments remains problematic, creating barriers to wider industrial adoption of these advanced materials.

Established Methodologies for High-Frequency Cyclic Load Testing

01 Composition optimization for reliability enhancement

Specific elemental compositions in amorphous soft magnetic alloys can significantly improve their reliability. By carefully controlling the ratios of elements such as Fe, Co, Ni, B, Si, and rare earth additions, manufacturers can enhance thermal stability, mechanical strength, and magnetic performance consistency over time. These optimized compositions reduce crystallization tendencies under thermal stress and improve resistance to environmental factors that could degrade magnetic properties.- Composition optimization for enhanced reliability: Specific elemental compositions in amorphous soft magnetic alloys can significantly improve their reliability. By carefully controlling the ratios of elements such as Fe, Co, Ni, B, Si, and rare earth additions, manufacturers can create alloys with superior thermal stability, corrosion resistance, and consistent magnetic properties over time. These optimized compositions help prevent crystallization during operation and maintain performance under thermal cycling and mechanical stress conditions.

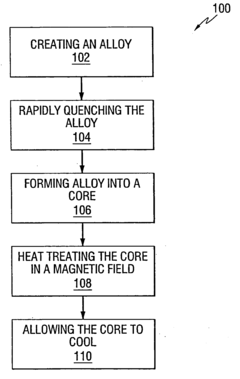

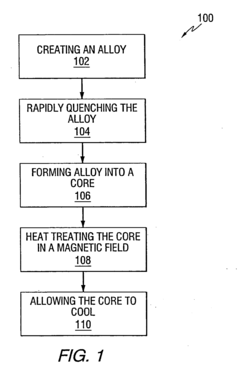

- Heat treatment processes for stability improvement: Specialized heat treatment processes can enhance the reliability of amorphous soft magnetic alloys. Controlled annealing under specific temperature profiles and magnetic fields helps relieve internal stresses, optimize domain structures, and stabilize magnetic properties. These treatments can be tailored to improve the alloy's resistance to environmental factors and mechanical stresses while maintaining its amorphous structure, resulting in more consistent performance over extended operational lifetimes.

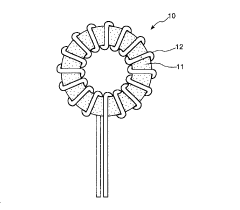

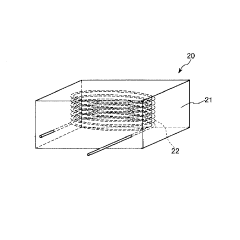

- Structural design for mechanical reliability: The mechanical reliability of amorphous soft magnetic alloys can be enhanced through innovative structural designs. Laminated structures, composite configurations, and specialized core geometries help distribute mechanical stresses, reduce eddy current losses, and improve thermal management. These design approaches address the inherent brittleness of amorphous materials while maintaining their superior magnetic properties, resulting in components that can withstand operational vibrations and thermal cycling without degradation.

- Surface treatment and coating technologies: Surface treatments and protective coatings significantly improve the reliability of amorphous soft magnetic alloys by enhancing corrosion resistance and mechanical durability. Techniques such as passivation, oxide layer formation, and application of specialized polymer or ceramic coatings create barriers against environmental degradation. These treatments preserve the magnetic properties of the alloys while extending their operational lifetime in harsh environments, including high humidity, temperature fluctuations, and exposure to corrosive substances.

- Testing and reliability assessment methods: Advanced testing methodologies have been developed to accurately assess and predict the reliability of amorphous soft magnetic alloys. These include accelerated aging tests, thermal cycling evaluations, mechanical stress testing, and magnetic property stability measurements under various environmental conditions. Non-destructive evaluation techniques allow for quality control during manufacturing and in-service monitoring, helping to identify potential failure mechanisms before they affect performance and ensuring consistent magnetic properties throughout the component's operational lifetime.

02 Heat treatment processes for stability

Specialized heat treatment protocols are crucial for enhancing the reliability of amorphous soft magnetic alloys. Controlled annealing under specific temperature profiles, magnetic fields, and atmospheric conditions can relieve internal stresses, optimize domain structures, and stabilize magnetic properties. These processes improve the long-term performance consistency of the alloys by creating more uniform amorphous structures with fewer defects that could lead to performance degradation over time.Expand Specific Solutions03 Surface treatment and protective coatings

Surface treatments and protective coatings significantly enhance the reliability of amorphous soft magnetic alloys by preventing oxidation and corrosion. Various coating technologies including oxide layers, polymer films, and metallic overlays can be applied to protect the alloy surface from environmental degradation. These protective measures maintain the magnetic and electrical properties of the alloys over extended periods, even in harsh operating conditions, thereby improving overall system reliability.Expand Specific Solutions04 Structural design for mechanical reliability

The mechanical reliability of amorphous soft magnetic alloys can be enhanced through innovative structural designs. Lamination techniques, edge conditioning, stress-relief patterns, and strategic reinforcement can mitigate the inherent brittleness of these materials. These design approaches distribute mechanical stresses more evenly, prevent crack propagation, and improve vibration resistance, resulting in components that maintain their magnetic performance despite mechanical challenges in various applications.Expand Specific Solutions05 Testing and qualification methods

Advanced testing and qualification methods are essential for ensuring the reliability of amorphous soft magnetic alloys in practical applications. Accelerated aging tests, thermal cycling, vibration analysis, and magnetic property stability measurements help predict long-term performance. These methodologies enable manufacturers to identify potential failure modes, establish reliability metrics, and develop quality control standards that ensure consistent performance throughout the intended service life of components made from these specialized alloys.Expand Specific Solutions

Key Industry Players in Soft Magnetic Alloy Manufacturing

The reliability testing of amorphous soft magnetic alloys under cyclic high-frequency loads for power electronics is currently in a growth phase, with the market expanding due to increasing demand for efficient power conversion systems. The global market size is projected to reach significant volumes as power electronics applications proliferate across renewable energy, electric vehicles, and industrial sectors. From a technological maturity perspective, companies like Metglas, VACUUMSCHMELZE, and Hitachi Industrial Equipment Systems lead with established testing protocols, while Proterial Ltd. and Advanced Technology & Materials Co. are advancing novel reliability assessment methodologies. TDK, Qingdao Yunlu, and TOKIN are focusing on high-frequency performance optimization, with academic-industrial collaborations from institutions like Tsinghua University and Carnegie Mellon University accelerating standardization efforts for reliability metrics.

Metglas, Inc.

Technical Solution: Metglas has pioneered a multi-parameter reliability testing framework for their POWERLITE® amorphous metal cores used in high-frequency power electronics. Their methodology focuses on evaluating core performance under combined stressors including thermal cycling (−55°C to +200°C), mechanical vibration (10-2000 Hz), and high-frequency electromagnetic excitation up to 100 kHz. The company employs custom-designed test chambers that can simultaneously apply these stressors while measuring key performance indicators such as core loss, permeability stability, and temperature rise. Metglas has developed proprietary surface treatment technologies that enhance the interfacial adhesion between amorphous ribbons, significantly improving mechanical stability under cyclic loading conditions. Their testing data shows that properly treated POWERLITE® cores maintain over 95% of initial performance after 50,000 hours of operation at frequencies up to 50 kHz. The company has established a comprehensive database correlating material composition, processing parameters, and long-term reliability metrics, enabling them to continuously optimize their amorphous alloy formulations for specific application requirements.

Strengths: Pioneer in amorphous metal technology with extensive material science expertise; comprehensive reliability database spanning decades of field applications; advanced surface treatment technologies that enhance mechanical stability. Weaknesses: Testing capabilities limited to lower frequencies compared to some competitors; less experience with newer power electronic topologies like wide-bandgap semiconductor applications.

Hitachi Industrial Equipment Systems Co., Ltd.

Technical Solution: Hitachi Industrial Equipment Systems has developed a comprehensive reliability assessment framework for their FINEMET® series of nanocrystalline soft magnetic materials used in high-frequency power electronic applications. Their approach integrates accelerated life testing with in-situ monitoring of microstructural evolution using advanced characterization techniques. Hitachi's testing methodology employs custom-designed electromagnetic excitation systems capable of generating precisely controlled flux waveforms at frequencies up to 300 kHz while simultaneously applying thermal cycling between −40°C and +180°C. The company has pioneered the use of high-resolution thermal imaging combined with impedance spectroscopy to detect localized heating and early signs of degradation in magnetic cores under cyclic loading. Hitachi has established correlations between processing parameters during rapid solidification and subsequent heat treatment with long-term reliability metrics, enabling them to optimize material composition and manufacturing processes for specific application requirements. Their reliability testing includes evaluation under various cooling conditions, recognizing that thermal management significantly impacts the long-term stability of magnetic components in power electronic systems. Hitachi's research has demonstrated that properly optimized FINEMET® cores can maintain stable performance for over 100,000 hours of operation at frequencies up to 100 kHz with less than 10% degradation in core loss characteristics.

Strengths: Advanced in-situ monitoring techniques for detecting early degradation; strong integration with thermal management considerations; extensive experience in industrial power electronic applications. Weaknesses: Testing methodologies heavily focused on their proprietary materials; limited published data on correlation between accelerated testing and actual field performance in newer applications.

Critical Patents in Amorphous Alloy Reliability Assessment

Amorphous alloy soft magnetic powder, powder magnetic core, magnetic element and electronic device

PatentPendingJP2023109412A

Innovation

- The amorphous alloy soft magnetic powder with a composition of (Fe x Co 1-x) 100-(a+b) (Si y B 1-y) a M b, where M is C, S, P, Sn, Mo, Cu, or Nb, and specific intensity ratios of XANES and EXAFS peaks, optimized for high amorphization, is used to enhance magnetic properties.

Soft magnetic alloy and uses thereof

PatentActiveUS20100265028A1

Innovation

- A soft magnetic nanocomposite alloy comprising an amorphous phase and a crystalline phase, specifically an Fe1-x-yCoxMy)100-a-b-cTaBbNc composition, where M is Ni or Mn, T includes Nb, W, Ta, Hf, Ti, Cr, Cu, Mo, and N is Si, Ge, C, P, or Al, with controlled atomic percentages to form fine crystalline particles embedded in an amorphous matrix, enhancing magnetic properties.

Thermal Management Considerations for High-Frequency Applications

Thermal management represents a critical consideration in the reliability testing of amorphous soft magnetic alloys under cyclic high-frequency loads for power electronics applications. As operating frequencies increase in modern power electronic systems, the thermal behavior of magnetic components becomes increasingly significant in determining their long-term performance and reliability.

Amorphous soft magnetic alloys, while offering superior magnetic properties compared to traditional silicon steel, present unique thermal challenges when subjected to high-frequency operation. These materials experience two primary heating mechanisms: hysteresis losses and eddy current losses, both of which intensify at higher frequencies. The amorphous structure that provides excellent magnetic properties also influences thermal conductivity characteristics, typically resulting in lower thermal conductivity compared to crystalline counterparts.

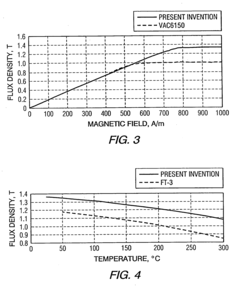

Temperature rise during operation directly impacts the magnetic properties of these alloys. Research indicates that core losses increase approximately 0.5-1% per degree Celsius above ambient temperature, creating a potential thermal runaway scenario if heat dissipation is inadequate. Furthermore, repeated thermal cycling can induce structural changes in the amorphous matrix, potentially leading to crystallization and permanent degradation of magnetic properties.

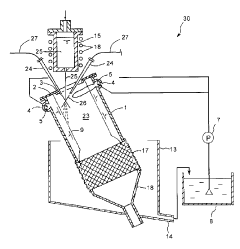

Effective thermal management strategies must address both steady-state and transient thermal behaviors. Computational fluid dynamics (CFD) modeling has emerged as an essential tool for predicting temperature distributions within amorphous cores under various operating conditions. These models must account for the anisotropic thermal conductivity often observed in laminated amorphous structures, where heat transfer perpendicular to laminations can be 5-10 times lower than parallel conduction paths.

Cooling solutions for high-frequency applications utilizing amorphous alloys range from passive approaches, such as optimized core geometries and enhanced surface area designs, to active cooling systems incorporating forced air or liquid cooling. Novel thermal interface materials with high thermal conductivity and electrical isolation properties are being developed specifically for these applications, with some recent formulations achieving thermal conductivities exceeding 5 W/m·K while maintaining dielectric strength.

Temperature monitoring during reliability testing presents additional challenges, as conventional contact sensors may alter the electromagnetic field distribution. Advanced infrared thermography and fiber-optic temperature sensing technologies offer non-intrusive alternatives, capable of capturing thermal transients with sub-millisecond resolution and temperature accuracy within ±1°C.

Accelerated thermal aging protocols have been established to evaluate long-term reliability, typically subjecting test specimens to temperatures 20-40°C above maximum rated operating temperature while maintaining representative electromagnetic conditions. These tests have revealed that thermal management effectiveness can extend the useful life of amorphous magnetic components by factors of 3-5 compared to inadequately cooled counterparts.

Amorphous soft magnetic alloys, while offering superior magnetic properties compared to traditional silicon steel, present unique thermal challenges when subjected to high-frequency operation. These materials experience two primary heating mechanisms: hysteresis losses and eddy current losses, both of which intensify at higher frequencies. The amorphous structure that provides excellent magnetic properties also influences thermal conductivity characteristics, typically resulting in lower thermal conductivity compared to crystalline counterparts.

Temperature rise during operation directly impacts the magnetic properties of these alloys. Research indicates that core losses increase approximately 0.5-1% per degree Celsius above ambient temperature, creating a potential thermal runaway scenario if heat dissipation is inadequate. Furthermore, repeated thermal cycling can induce structural changes in the amorphous matrix, potentially leading to crystallization and permanent degradation of magnetic properties.

Effective thermal management strategies must address both steady-state and transient thermal behaviors. Computational fluid dynamics (CFD) modeling has emerged as an essential tool for predicting temperature distributions within amorphous cores under various operating conditions. These models must account for the anisotropic thermal conductivity often observed in laminated amorphous structures, where heat transfer perpendicular to laminations can be 5-10 times lower than parallel conduction paths.

Cooling solutions for high-frequency applications utilizing amorphous alloys range from passive approaches, such as optimized core geometries and enhanced surface area designs, to active cooling systems incorporating forced air or liquid cooling. Novel thermal interface materials with high thermal conductivity and electrical isolation properties are being developed specifically for these applications, with some recent formulations achieving thermal conductivities exceeding 5 W/m·K while maintaining dielectric strength.

Temperature monitoring during reliability testing presents additional challenges, as conventional contact sensors may alter the electromagnetic field distribution. Advanced infrared thermography and fiber-optic temperature sensing technologies offer non-intrusive alternatives, capable of capturing thermal transients with sub-millisecond resolution and temperature accuracy within ±1°C.

Accelerated thermal aging protocols have been established to evaluate long-term reliability, typically subjecting test specimens to temperatures 20-40°C above maximum rated operating temperature while maintaining representative electromagnetic conditions. These tests have revealed that thermal management effectiveness can extend the useful life of amorphous magnetic components by factors of 3-5 compared to inadequately cooled counterparts.

Standardization Requirements for Reliability Test Protocols

The standardization of reliability test protocols for amorphous soft magnetic alloys is crucial for ensuring consistent evaluation methodologies across the industry. Currently, there exists significant variation in testing approaches, making it difficult to compare results between different research institutions and manufacturers. A comprehensive standardization framework must address multiple dimensions of reliability testing, including sample preparation, test conditions, measurement techniques, and data analysis methods.

Test sample specifications need standardization regarding dimensions, surface finish, and pre-test treatments. The industry requires clear guidelines on minimum sample quantities for statistical validity and reference samples for calibration purposes. Additionally, standardized documentation of material composition and processing history is essential for reproducibility of test results.

Environmental test conditions represent another critical area requiring standardization. Protocols must specify temperature ranges (typically -40°C to 150°C for power electronics applications), humidity levels, and magnetic field exposure parameters. High-frequency testing conditions need particular attention, with standardized frequencies (typically 10kHz to 2MHz), waveforms, and duty cycles that accurately represent real-world power electronic applications.

Measurement methodologies require standardization of instrumentation specifications, calibration procedures, and data acquisition rates. The protocols should establish minimum requirements for measurement accuracy and precision, particularly for detecting subtle degradation in magnetic properties under cyclic loading. Standardized methods for separating core losses from other system losses are especially important for accurate characterization.

Failure criteria and definitions must be clearly established across the industry. This includes standardized thresholds for performance degradation that constitute failure, such as percentage increases in core loss or decreases in permeability. Time-to-failure analysis methods should be standardized to enable meaningful comparison of results from accelerated life tests.

Data reporting formats need standardization to facilitate information sharing and meta-analysis across the industry. This includes statistical analysis methods, confidence interval calculations, and presentation of Weibull or other reliability distribution parameters. Standardized formats would significantly enhance the value of published reliability data and accelerate industry-wide learning.

Implementation of these standardization requirements would benefit from collaboration between industry consortia, academic institutions, and standards organizations such as IEEE, IEC, and ASTM. The development of round-robin testing programs would help validate proposed standards and ensure their practical applicability across different testing facilities.

Test sample specifications need standardization regarding dimensions, surface finish, and pre-test treatments. The industry requires clear guidelines on minimum sample quantities for statistical validity and reference samples for calibration purposes. Additionally, standardized documentation of material composition and processing history is essential for reproducibility of test results.

Environmental test conditions represent another critical area requiring standardization. Protocols must specify temperature ranges (typically -40°C to 150°C for power electronics applications), humidity levels, and magnetic field exposure parameters. High-frequency testing conditions need particular attention, with standardized frequencies (typically 10kHz to 2MHz), waveforms, and duty cycles that accurately represent real-world power electronic applications.

Measurement methodologies require standardization of instrumentation specifications, calibration procedures, and data acquisition rates. The protocols should establish minimum requirements for measurement accuracy and precision, particularly for detecting subtle degradation in magnetic properties under cyclic loading. Standardized methods for separating core losses from other system losses are especially important for accurate characterization.

Failure criteria and definitions must be clearly established across the industry. This includes standardized thresholds for performance degradation that constitute failure, such as percentage increases in core loss or decreases in permeability. Time-to-failure analysis methods should be standardized to enable meaningful comparison of results from accelerated life tests.

Data reporting formats need standardization to facilitate information sharing and meta-analysis across the industry. This includes statistical analysis methods, confidence interval calculations, and presentation of Weibull or other reliability distribution parameters. Standardized formats would significantly enhance the value of published reliability data and accelerate industry-wide learning.

Implementation of these standardization requirements would benefit from collaboration between industry consortia, academic institutions, and standards organizations such as IEEE, IEC, and ASTM. The development of round-robin testing programs would help validate proposed standards and ensure their practical applicability across different testing facilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!