Design Optimization For Miniaturized Inductors Using Amorphous Soft Magnetic Alloys In High-Frequency Power Electronics

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Miniaturized Inductor Technology Background and Objectives

Inductors have been fundamental components in power electronics since the early 20th century, with their miniaturization journey beginning in earnest during the 1970s with the advent of switched-mode power supplies. The evolution of inductor technology has been closely tied to advancements in magnetic materials, from traditional ferrites to modern nanocrystalline and amorphous alloys. This progression has been driven by the increasing demand for smaller, more efficient power electronic systems across various industries.

The past decade has witnessed an unprecedented acceleration in miniaturization requirements, particularly in consumer electronics, automotive systems, and renewable energy applications. Traditional inductor designs face fundamental limitations when scaled down, including increased core losses, reduced energy storage capacity, and thermal management challenges. These limitations have created a technological bottleneck in the further development of compact high-frequency power electronics.

Amorphous soft magnetic alloys emerged as promising materials for inductor cores in the 1980s but have gained renewed interest in recent years due to their exceptional magnetic properties at high frequencies. These materials, characterized by their non-crystalline atomic structure, offer significantly lower core losses and higher saturation flux densities compared to conventional ferrites, making them ideal candidates for miniaturized high-frequency applications.

The primary objective of this technical research is to systematically investigate design optimization strategies for miniaturized inductors utilizing amorphous soft magnetic alloys in high-frequency power electronics. Specifically, we aim to develop novel inductor architectures that leverage the unique properties of these materials to achieve at least a 40% reduction in inductor volume while maintaining or improving performance metrics such as quality factor, power density, and thermal stability.

Secondary objectives include establishing comprehensive design guidelines for engineers working with these materials, identifying optimal processing techniques to enhance material properties, and developing accurate modeling methodologies that account for the complex behavior of amorphous alloys at high frequencies. These objectives align with the broader industry trend toward more compact, efficient, and reliable power electronic systems.

The technological trajectory suggests that successful optimization of miniaturized inductors using amorphous soft magnetic alloys could enable significant advancements in several emerging fields, including wearable electronics, implantable medical devices, and compact renewable energy systems. Furthermore, this research aims to address current challenges in material cost and manufacturing complexity that have historically limited the widespread adoption of amorphous alloy-based inductors in commercial applications.

The past decade has witnessed an unprecedented acceleration in miniaturization requirements, particularly in consumer electronics, automotive systems, and renewable energy applications. Traditional inductor designs face fundamental limitations when scaled down, including increased core losses, reduced energy storage capacity, and thermal management challenges. These limitations have created a technological bottleneck in the further development of compact high-frequency power electronics.

Amorphous soft magnetic alloys emerged as promising materials for inductor cores in the 1980s but have gained renewed interest in recent years due to their exceptional magnetic properties at high frequencies. These materials, characterized by their non-crystalline atomic structure, offer significantly lower core losses and higher saturation flux densities compared to conventional ferrites, making them ideal candidates for miniaturized high-frequency applications.

The primary objective of this technical research is to systematically investigate design optimization strategies for miniaturized inductors utilizing amorphous soft magnetic alloys in high-frequency power electronics. Specifically, we aim to develop novel inductor architectures that leverage the unique properties of these materials to achieve at least a 40% reduction in inductor volume while maintaining or improving performance metrics such as quality factor, power density, and thermal stability.

Secondary objectives include establishing comprehensive design guidelines for engineers working with these materials, identifying optimal processing techniques to enhance material properties, and developing accurate modeling methodologies that account for the complex behavior of amorphous alloys at high frequencies. These objectives align with the broader industry trend toward more compact, efficient, and reliable power electronic systems.

The technological trajectory suggests that successful optimization of miniaturized inductors using amorphous soft magnetic alloys could enable significant advancements in several emerging fields, including wearable electronics, implantable medical devices, and compact renewable energy systems. Furthermore, this research aims to address current challenges in material cost and manufacturing complexity that have historically limited the widespread adoption of amorphous alloy-based inductors in commercial applications.

Market Demand Analysis for High-Frequency Power Electronics

The high-frequency power electronics market is experiencing unprecedented growth, driven primarily by the increasing demand for miniaturization and efficiency improvements across multiple industries. The global market for high-frequency power electronics was valued at approximately $18.5 billion in 2022 and is projected to reach $26.8 billion by 2028, representing a compound annual growth rate (CAGR) of 6.4%.

Miniaturized inductors using amorphous soft magnetic alloys are becoming critical components in this expanding market. The automotive sector represents one of the largest demand drivers, with electric vehicles requiring compact, efficient power conversion systems. The EV market alone is expected to grow at a CAGR of 21.7% through 2030, directly influencing the demand for advanced inductor technologies.

Consumer electronics constitutes another significant market segment, with smartphones, laptops, and wearable devices all requiring smaller form factors while maintaining or improving performance. The trend toward faster charging technologies has particularly accelerated the need for high-frequency power components that can handle increased power densities without thermal issues.

Industrial automation and robotics applications are also creating substantial demand for miniaturized power electronics. As factories implement more sophisticated automation systems, the need for compact, reliable power components continues to rise. This sector is expected to grow at 9.2% annually through 2027.

Renewable energy systems represent an emerging but rapidly growing application area. Solar inverters and wind power converters benefit significantly from high-frequency operation enabled by advanced magnetic materials, improving efficiency and reducing size. The renewable energy electronics market is projected to double in size by 2026.

Telecommunications infrastructure, particularly with the ongoing 5G rollout, requires more compact power solutions for base stations and network equipment. The density of these installations necessitates smaller components with higher efficiency to manage thermal constraints in limited spaces.

Market research indicates that customers across these segments prioritize three key factors: power density (watts per cubic centimeter), efficiency (reduced losses), and reliability (consistent performance over time and temperature ranges). Amorphous soft magnetic alloys address these needs by enabling operation at higher frequencies with lower core losses compared to traditional materials.

Regional analysis shows Asia-Pacific leading the market with 42% share, followed by North America (28%) and Europe (23%). China, Japan, and South Korea are particularly significant manufacturing hubs for high-frequency power electronics components, while research and development activities are strong in the United States, Germany, and Japan.

Miniaturized inductors using amorphous soft magnetic alloys are becoming critical components in this expanding market. The automotive sector represents one of the largest demand drivers, with electric vehicles requiring compact, efficient power conversion systems. The EV market alone is expected to grow at a CAGR of 21.7% through 2030, directly influencing the demand for advanced inductor technologies.

Consumer electronics constitutes another significant market segment, with smartphones, laptops, and wearable devices all requiring smaller form factors while maintaining or improving performance. The trend toward faster charging technologies has particularly accelerated the need for high-frequency power components that can handle increased power densities without thermal issues.

Industrial automation and robotics applications are also creating substantial demand for miniaturized power electronics. As factories implement more sophisticated automation systems, the need for compact, reliable power components continues to rise. This sector is expected to grow at 9.2% annually through 2027.

Renewable energy systems represent an emerging but rapidly growing application area. Solar inverters and wind power converters benefit significantly from high-frequency operation enabled by advanced magnetic materials, improving efficiency and reducing size. The renewable energy electronics market is projected to double in size by 2026.

Telecommunications infrastructure, particularly with the ongoing 5G rollout, requires more compact power solutions for base stations and network equipment. The density of these installations necessitates smaller components with higher efficiency to manage thermal constraints in limited spaces.

Market research indicates that customers across these segments prioritize three key factors: power density (watts per cubic centimeter), efficiency (reduced losses), and reliability (consistent performance over time and temperature ranges). Amorphous soft magnetic alloys address these needs by enabling operation at higher frequencies with lower core losses compared to traditional materials.

Regional analysis shows Asia-Pacific leading the market with 42% share, followed by North America (28%) and Europe (23%). China, Japan, and South Korea are particularly significant manufacturing hubs for high-frequency power electronics components, while research and development activities are strong in the United States, Germany, and Japan.

Amorphous Soft Magnetic Alloys: Current Status and Challenges

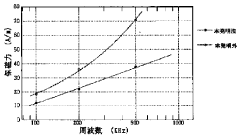

Amorphous soft magnetic alloys represent a significant advancement in magnetic material technology, offering superior magnetic properties compared to traditional crystalline materials. Currently, these alloys are primarily produced through rapid solidification techniques, with melt spinning being the dominant commercial method. This process creates ribbons with thicknesses ranging from 15-35 μm, which are then typically laminated or powdered for various applications.

The global market for these materials has seen steady growth, with major manufacturers concentrated in Japan, China, the United States, and Europe. Leading companies include Hitachi Metals (Japan), Advanced Technology & Materials (China), Vacuumschmelze GmbH (Germany), and Metglas Inc. (USA). These manufacturers have established robust production capabilities, though supply chain vulnerabilities were exposed during recent global disruptions.

Despite their promising properties, amorphous soft magnetic alloys face several significant challenges. Temperature stability remains a critical issue, as these materials typically exhibit degraded performance above 150°C, limiting their application in high-temperature power electronics environments. The mechanical brittleness of amorphous ribbons presents manufacturing difficulties, particularly when attempting to form complex geometries required for miniaturized inductors.

Production scalability represents another major challenge. Current manufacturing methods struggle to produce consistent material properties at high volumes, leading to batch-to-batch variations that complicate design optimization. Additionally, the relatively high cost compared to traditional silicon steel or ferrite materials creates market entry barriers, especially for cost-sensitive applications.

Recent research has focused on addressing these limitations through compositional modifications and processing improvements. Fe-based amorphous alloys with additions of Co, Ni, and other elements have shown improved temperature stability, while advances in casting techniques are gradually enhancing production consistency. Nanocrystalline variants, created through controlled crystallization of amorphous precursors, offer promising improvements in saturation flux density while maintaining low core losses.

For miniaturized inductor applications specifically, the challenge of integrating these materials into semiconductor manufacturing processes remains substantial. Current deposition methods for thin-film amorphous layers lack the precision and uniformity required for reliable mass production. Furthermore, the interface between amorphous materials and other components in integrated circuits often suffers from adhesion issues and thermal expansion mismatches.

Despite these challenges, the unique combination of high permeability, low coercivity, and excellent high-frequency performance continues to drive research interest in these materials for next-generation power electronics applications.

The global market for these materials has seen steady growth, with major manufacturers concentrated in Japan, China, the United States, and Europe. Leading companies include Hitachi Metals (Japan), Advanced Technology & Materials (China), Vacuumschmelze GmbH (Germany), and Metglas Inc. (USA). These manufacturers have established robust production capabilities, though supply chain vulnerabilities were exposed during recent global disruptions.

Despite their promising properties, amorphous soft magnetic alloys face several significant challenges. Temperature stability remains a critical issue, as these materials typically exhibit degraded performance above 150°C, limiting their application in high-temperature power electronics environments. The mechanical brittleness of amorphous ribbons presents manufacturing difficulties, particularly when attempting to form complex geometries required for miniaturized inductors.

Production scalability represents another major challenge. Current manufacturing methods struggle to produce consistent material properties at high volumes, leading to batch-to-batch variations that complicate design optimization. Additionally, the relatively high cost compared to traditional silicon steel or ferrite materials creates market entry barriers, especially for cost-sensitive applications.

Recent research has focused on addressing these limitations through compositional modifications and processing improvements. Fe-based amorphous alloys with additions of Co, Ni, and other elements have shown improved temperature stability, while advances in casting techniques are gradually enhancing production consistency. Nanocrystalline variants, created through controlled crystallization of amorphous precursors, offer promising improvements in saturation flux density while maintaining low core losses.

For miniaturized inductor applications specifically, the challenge of integrating these materials into semiconductor manufacturing processes remains substantial. Current deposition methods for thin-film amorphous layers lack the precision and uniformity required for reliable mass production. Furthermore, the interface between amorphous materials and other components in integrated circuits often suffers from adhesion issues and thermal expansion mismatches.

Despite these challenges, the unique combination of high permeability, low coercivity, and excellent high-frequency performance continues to drive research interest in these materials for next-generation power electronics applications.

Current Design Solutions for Miniaturized High-Frequency Inductors

01 Core material composition and structure

Amorphous soft magnetic alloys with specific compositions are used to optimize the performance of miniaturized inductors. These materials typically contain iron, cobalt, or nickel combined with metalloids like boron, silicon, or phosphorus. The amorphous structure provides high permeability, low coercivity, and reduced core losses at high frequencies. By carefully selecting the alloy composition and controlling the manufacturing process, the magnetic properties can be tailored for specific inductor applications, resulting in improved power density and efficiency.- Core material composition and structure: Amorphous soft magnetic alloys with specific compositions are used to optimize the performance of miniaturized inductors. These materials typically contain iron, cobalt, or nickel combined with metalloids like boron, silicon, and phosphorus. The amorphous structure provides high permeability, low coercivity, and reduced eddy current losses. By carefully selecting the alloy composition and controlling the manufacturing process, the magnetic properties can be tailored for specific inductor applications, resulting in improved power density and efficiency.

- Multilayer and 3D design approaches: Multilayer and three-dimensional design approaches enable significant miniaturization of inductors using amorphous soft magnetic alloys. These designs incorporate multiple layers of magnetic materials and conductive windings to increase inductance density while maintaining a small footprint. Advanced fabrication techniques allow for complex 3D structures that optimize the magnetic flux path and reduce electromagnetic interference. These approaches are particularly valuable for high-frequency applications where space constraints are critical.

- Heat treatment and annealing processes: Specific heat treatment and annealing processes are crucial for optimizing the magnetic properties of amorphous soft magnetic alloys used in miniaturized inductors. These thermal processes help to relieve internal stresses, control crystallization, and enhance magnetic permeability while maintaining low core losses. Parameters such as temperature, duration, cooling rate, and the presence of magnetic fields during annealing significantly impact the final performance of the inductor. Properly optimized heat treatment can substantially improve the quality factor and energy storage capability of miniaturized inductors.

- Nanocrystalline and composite structures: Nanocrystalline and composite structures combining amorphous and crystalline phases offer enhanced performance for miniaturized inductors. These structures feature nanoscale crystallites embedded within an amorphous matrix, providing a balance between high saturation flux density and low core losses. By controlling the size, distribution, and volume fraction of nanocrystals, the magnetic properties can be precisely tuned. Composite structures may also incorporate non-magnetic layers or particles to further optimize performance characteristics such as frequency response and temperature stability.

- Thin film deposition techniques: Advanced thin film deposition techniques enable the fabrication of ultra-miniaturized inductors with amorphous soft magnetic alloys. Methods such as sputtering, electroplating, and chemical vapor deposition allow for precise control over film thickness, composition, and microstructure. These techniques facilitate the integration of magnetic cores with semiconductor processes, enabling on-chip inductors with high performance. The thin film approach minimizes eddy current losses at high frequencies and allows for complex patterning to optimize magnetic flux paths and reduce parasitic effects.

02 Multilayer and thin-film design approaches

Miniaturized inductors can be optimized through multilayer and thin-film design approaches using amorphous soft magnetic alloys. These designs involve depositing thin layers of magnetic materials alternating with conductive layers to create compact inductor structures. The thickness of the magnetic layers is carefully controlled to balance performance parameters such as inductance density, quality factor, and frequency response. This approach enables significant size reduction while maintaining or improving electrical performance, making it suitable for integrated circuit applications.Expand Specific Solutions03 Heat treatment and annealing processes

Heat treatment and annealing processes are crucial for optimizing the magnetic properties of amorphous soft magnetic alloys used in miniaturized inductors. Controlled heating under specific temperature profiles and magnetic field conditions can reduce internal stresses, induce beneficial magnetic anisotropy, and improve the overall magnetic performance. These processes can enhance permeability, reduce core losses, and increase the saturation flux density of the magnetic materials, resulting in inductors with higher efficiency and power handling capability.Expand Specific Solutions04 3D geometric optimization techniques

Three-dimensional geometric optimization techniques are employed to maximize the performance of miniaturized inductors using amorphous soft magnetic alloys. These techniques involve innovative shapes and structures such as solenoid, toroidal, spiral, and custom geometries that optimize the magnetic flux path and minimize leakage flux. Computer-aided design and simulation tools are used to analyze and optimize parameters such as winding configuration, core shape, and air gap dimensions, resulting in compact inductors with improved inductance density and quality factor.Expand Specific Solutions05 Integration with semiconductor manufacturing processes

Integration of amorphous soft magnetic alloys with semiconductor manufacturing processes enables the production of highly miniaturized inductors for system-on-chip applications. This involves developing compatible deposition techniques, such as sputtering or electroplating, that can be incorporated into standard semiconductor fabrication flows. Challenges related to thermal budget constraints, material interface issues, and patterning techniques are addressed to ensure reliable performance. This integration approach allows for mass production of miniaturized inductors with consistent properties and reduced manufacturing costs.Expand Specific Solutions

Key Industry Players in Soft Magnetic Materials and Power Electronics

The miniaturized inductor design optimization market using amorphous soft magnetic alloys is currently in a growth phase, with increasing adoption in high-frequency power electronics applications. The market is expanding rapidly due to demands for smaller, more efficient power components, with an estimated global value exceeding $2 billion. Leading players include established materials manufacturers like Metglas, Inc., VACUUMSCHMELZE, and Proterial Ltd., who possess advanced amorphous alloy fabrication capabilities. Technology innovators such as TDK Corp., Murata Manufacturing, and Alps Alpine are driving miniaturization breakthroughs, while academic institutions including Tohoku University and Beihang University contribute fundamental research. The technology is approaching commercial maturity with several companies offering market-ready solutions, though optimization challenges remain in balancing size reduction with performance and thermal management.

Metglas, Inc.

Technical Solution: Metglas has pioneered the development and commercialization of METGLAS® amorphous metal alloys specifically optimized for high-frequency power electronic applications. Their approach to miniaturized inductor design centers on Fe-based amorphous ribbons produced through rapid solidification technology, creating a non-crystalline atomic structure that eliminates magnetocrystalline anisotropy and minimizes eddy current losses. Their proprietary 2605SA1 alloy achieves saturation inductions of approximately 1.56T while maintaining excellent high-frequency characteristics up to several hundred kHz. Metglas employs precision winding techniques to create toroidal cores with distributed air gaps that optimize energy storage capability while minimizing core losses. Their design methodology incorporates sophisticated 3D electromagnetic field simulation to predict and mitigate proximity effects and optimize flux distribution. Recent innovations include their POWERLITE® C-cores that feature a unique cut-core configuration allowing for simplified assembly around pre-wound copper windings, facilitating higher copper fill factors and improved thermal management. Metglas has also developed specialized surface treatments and inter-laminar coatings that enhance insulation properties while maintaining excellent thermal conductivity.

Strengths: Market-leading expertise in amorphous alloy production with consistent quality; excellent high-frequency performance with superior saturation flux density; established global supply chain and manufacturing capacity. Weaknesses: Limited shape formability compared to powder-based materials; relatively higher cost than conventional silicon steel; requires specialized handling due to ribbon brittleness.

VACUUMSCHMELZE GmbH & Co. KG

Technical Solution: VACUUMSCHMELZE (VAC) has developed advanced nanocrystalline soft magnetic materials like VITROPERM® specifically for miniaturized inductor applications in high-frequency power electronics. Their design optimization approach focuses on tailored material compositions with Fe-based amorphous precursors that undergo controlled crystallization to achieve grain sizes below 20 nm. This nanostructure enables exceptional high-frequency performance with saturation flux densities reaching 1.2T while maintaining low core losses (< 50 W/kg at 100 kHz, 0.3T). VAC employs proprietary rapid solidification techniques to produce ultra-thin ribbons (down to 15μm) that are subsequently wound into toroidal cores with optimized dimensions. Their VITROPERM® 500F material demonstrates permeability values adjustable between 15,000 and 150,000 through specific annealing processes, allowing customization for different power conversion applications. VAC has also pioneered specialized coating technologies that provide electrical insulation while enhancing thermal conductivity, addressing a critical challenge in miniaturized inductor design.

Strengths: Industry-leading expertise in nanocrystalline materials with superior magnetic properties; comprehensive vertical integration from material development to component manufacturing; extensive application engineering support. Weaknesses: Higher cost compared to ferrite alternatives; limited shape flexibility due to ribbon-based manufacturing process; requires specialized handling during assembly due to mechanical brittleness.

Core Technical Innovations in Amorphous Alloy Inductor Design

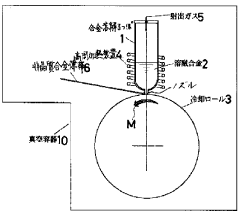

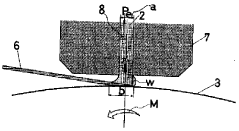

Production of amorphous alloy thin strip having excellent high-frequency magnetic characteristic

PatentInactiveJP1992309442A

Innovation

- A manufacturing method involving high-speed injection of molten alloy onto a rotating cooling roll under reduced pressure, with precise control of nozzle spacing, injection pressure, and atmospheric conditions to produce amorphous alloy strips with thicknesses between 5-13 μm, optimizing coercive force and magnetic properties.

Nitrogen-added amorphous soft magnetic alloy and manufacturing method therefor

PatentWO2018030582A1

Innovation

- The development of a nitrogen-added amorphous soft magnetic alloy with a composition formula Fe100-a-b-c-d-eBPaXcCde, where X is Hf or Co, and specific atomic percentage ranges for a, b, c, d, and e, which includes a method of manufacturing through rapid solidification and heat treatment to achieve high saturation magnetic flux density and soft magnetic properties.

Thermal Management Strategies for High-Frequency Inductors

Thermal management is a critical aspect in the design optimization of miniaturized inductors using amorphous soft magnetic alloys for high-frequency power electronics. As power densities increase and form factors decrease, heat generation becomes a significant limiting factor affecting both performance and reliability of these components.

The thermal challenges specific to amorphous soft magnetic alloy inductors stem from their unique material properties. While these alloys offer superior magnetic performance at high frequencies, they typically exhibit lower thermal conductivity compared to traditional silicon steel or ferrite materials. This creates localized hotspots that can accelerate aging and potentially lead to thermal runaway conditions.

Effective thermal management strategies must address both active and passive cooling mechanisms. Passive approaches include optimized geometric designs that maximize surface area to volume ratios, facilitating natural convection cooling. Strategic placement of thermal vias and heat-spreading layers can direct heat away from critical components. Advanced thermal interface materials (TIMs) with high thermal conductivity can significantly improve heat transfer between the inductor and cooling structures.

Active cooling solutions become necessary for high-power density applications. Forced-air cooling remains the most cost-effective approach, though liquid cooling systems offer superior thermal performance for extreme conditions. The integration of microfluidic channels directly into inductor substrates represents an emerging solution for ultra-compact designs, though manufacturing complexity remains a challenge.

Thermal simulation and modeling play an essential role in optimizing these strategies. Finite element analysis (FEA) and computational fluid dynamics (CFD) enable accurate prediction of temperature distributions and hotspots before physical prototyping. These tools allow designers to evaluate various cooling strategies and material configurations virtually, reducing development cycles.

Recent innovations include phase-change materials (PCMs) embedded within inductor structures to absorb thermal energy during peak loads. These materials provide thermal buffering, reducing temperature fluctuations and extending component lifespan. Additionally, thermally conductive encapsulants specifically formulated for compatibility with amorphous alloys offer improved heat dissipation while providing environmental protection.

The trade-off between thermal performance and electromagnetic characteristics requires careful consideration. Cooling structures containing metallic elements can introduce eddy current losses, while certain thermal interface materials may affect the magnetic flux distribution. Holistic design approaches that simultaneously optimize both thermal and electromagnetic parameters are essential for achieving optimal performance in miniaturized high-frequency inductors.

The thermal challenges specific to amorphous soft magnetic alloy inductors stem from their unique material properties. While these alloys offer superior magnetic performance at high frequencies, they typically exhibit lower thermal conductivity compared to traditional silicon steel or ferrite materials. This creates localized hotspots that can accelerate aging and potentially lead to thermal runaway conditions.

Effective thermal management strategies must address both active and passive cooling mechanisms. Passive approaches include optimized geometric designs that maximize surface area to volume ratios, facilitating natural convection cooling. Strategic placement of thermal vias and heat-spreading layers can direct heat away from critical components. Advanced thermal interface materials (TIMs) with high thermal conductivity can significantly improve heat transfer between the inductor and cooling structures.

Active cooling solutions become necessary for high-power density applications. Forced-air cooling remains the most cost-effective approach, though liquid cooling systems offer superior thermal performance for extreme conditions. The integration of microfluidic channels directly into inductor substrates represents an emerging solution for ultra-compact designs, though manufacturing complexity remains a challenge.

Thermal simulation and modeling play an essential role in optimizing these strategies. Finite element analysis (FEA) and computational fluid dynamics (CFD) enable accurate prediction of temperature distributions and hotspots before physical prototyping. These tools allow designers to evaluate various cooling strategies and material configurations virtually, reducing development cycles.

Recent innovations include phase-change materials (PCMs) embedded within inductor structures to absorb thermal energy during peak loads. These materials provide thermal buffering, reducing temperature fluctuations and extending component lifespan. Additionally, thermally conductive encapsulants specifically formulated for compatibility with amorphous alloys offer improved heat dissipation while providing environmental protection.

The trade-off between thermal performance and electromagnetic characteristics requires careful consideration. Cooling structures containing metallic elements can introduce eddy current losses, while certain thermal interface materials may affect the magnetic flux distribution. Holistic design approaches that simultaneously optimize both thermal and electromagnetic parameters are essential for achieving optimal performance in miniaturized high-frequency inductors.

Manufacturing Processes and Scalability Considerations

The manufacturing processes for miniaturized inductors using amorphous soft magnetic alloys present unique challenges and opportunities in high-frequency power electronics applications. Traditional manufacturing methods often struggle with the delicate nature of these materials, which require specialized handling to maintain their superior magnetic properties.

Rapid solidification techniques, particularly melt spinning, remain the predominant method for producing amorphous soft magnetic ribbons. This process involves cooling molten metal at rates exceeding 10^6 K/s, creating the non-crystalline structure essential for high-frequency performance. However, the resulting ribbons typically range from 20-50 μm in thickness, creating limitations for ultra-miniaturized applications.

Post-processing steps significantly impact the final inductor performance. Annealing treatments under precise magnetic field conditions can tailor the magnetic anisotropy to specific application requirements. The temperature control during this process must remain within ±2°C to ensure consistent magnetic properties across production batches.

Lamination techniques have evolved to address eddy current losses at high frequencies. Advanced methods now incorporate automated stacking of ultra-thin layers with specialized insulating materials between layers. Recent developments in nano-insulation coatings have reduced the effective spacing between layers to less than 1 μm, maximizing the effective magnetic cross-section.

Scalability considerations present significant challenges for mass production. Current manufacturing processes show approximately 15-20% yield variation when transitioning from laboratory to industrial scale. This variability primarily stems from difficulties in maintaining uniform cooling rates across larger production volumes and consistent material handling procedures.

Integration with semiconductor manufacturing processes represents a critical frontier for widespread adoption. Sputtering and electrodeposition methods for amorphous alloy deposition directly onto semiconductor substrates have demonstrated promising results in research settings but face challenges in thickness control and adhesion when scaled to production volumes.

Cost considerations remain a significant barrier to widespread adoption. Current manufacturing costs for high-performance amorphous alloy inductors exceed those of conventional ferrite-based components by 2.5-3.5 times. However, economic modeling suggests this gap could narrow to 1.3-1.5 times with optimized manufacturing processes and increased production volumes exceeding 10 million units annually.

Environmental and sustainability factors are increasingly influencing manufacturing process development. The rare earth elements often incorporated in high-performance soft magnetic alloys face supply chain vulnerabilities, driving research into alternative compositions with reduced critical material content while maintaining comparable magnetic performance.

Rapid solidification techniques, particularly melt spinning, remain the predominant method for producing amorphous soft magnetic ribbons. This process involves cooling molten metal at rates exceeding 10^6 K/s, creating the non-crystalline structure essential for high-frequency performance. However, the resulting ribbons typically range from 20-50 μm in thickness, creating limitations for ultra-miniaturized applications.

Post-processing steps significantly impact the final inductor performance. Annealing treatments under precise magnetic field conditions can tailor the magnetic anisotropy to specific application requirements. The temperature control during this process must remain within ±2°C to ensure consistent magnetic properties across production batches.

Lamination techniques have evolved to address eddy current losses at high frequencies. Advanced methods now incorporate automated stacking of ultra-thin layers with specialized insulating materials between layers. Recent developments in nano-insulation coatings have reduced the effective spacing between layers to less than 1 μm, maximizing the effective magnetic cross-section.

Scalability considerations present significant challenges for mass production. Current manufacturing processes show approximately 15-20% yield variation when transitioning from laboratory to industrial scale. This variability primarily stems from difficulties in maintaining uniform cooling rates across larger production volumes and consistent material handling procedures.

Integration with semiconductor manufacturing processes represents a critical frontier for widespread adoption. Sputtering and electrodeposition methods for amorphous alloy deposition directly onto semiconductor substrates have demonstrated promising results in research settings but face challenges in thickness control and adhesion when scaled to production volumes.

Cost considerations remain a significant barrier to widespread adoption. Current manufacturing costs for high-performance amorphous alloy inductors exceed those of conventional ferrite-based components by 2.5-3.5 times. However, economic modeling suggests this gap could narrow to 1.3-1.5 times with optimized manufacturing processes and increased production volumes exceeding 10 million units annually.

Environmental and sustainability factors are increasingly influencing manufacturing process development. The rare earth elements often incorporated in high-performance soft magnetic alloys face supply chain vulnerabilities, driving research into alternative compositions with reduced critical material content while maintaining comparable magnetic performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!