Surface Coating Methods For Corrosion Protection Of Amorphous Soft Magnetic Alloys In High-Frequency Power Electronics

AUG 26, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Corrosion Protection Coating Background and Objectives

Amorphous soft magnetic alloys have emerged as critical materials in high-frequency power electronics due to their superior magnetic properties, including high permeability, low coercivity, and minimal core losses. These characteristics make them ideal for applications in power transformers, inductors, and various electronic components operating at high frequencies. The evolution of these materials began in the 1970s with the development of metal glass technology, progressing significantly through the 1990s and 2000s with improved manufacturing techniques and material compositions.

Despite their excellent magnetic properties, amorphous soft magnetic alloys face a significant challenge: susceptibility to corrosion. When exposed to moisture, oxygen, and other environmental factors, these alloys can deteriorate rapidly, compromising their magnetic performance and structural integrity. This vulnerability stems from their unique atomic structure, which lacks the crystalline order that provides natural corrosion resistance in conventional magnetic materials.

The corrosion issue becomes particularly critical in high-frequency power electronics applications, where these materials operate under demanding conditions including thermal cycling, electromagnetic stress, and potential exposure to various environmental factors. As power electronics continue to advance toward higher frequencies, greater power densities, and more compact designs, the need for effective corrosion protection becomes increasingly urgent.

Traditional coating methods developed for crystalline magnetic materials often prove inadequate for amorphous alloys due to differences in surface chemistry, thermal expansion characteristics, and mechanical properties. This has necessitated the development of specialized coating technologies specifically tailored to the unique properties of amorphous soft magnetic materials.

The primary objective of this technical research is to comprehensively evaluate existing and emerging surface coating methods for corrosion protection of amorphous soft magnetic alloys in high-frequency power electronics. We aim to identify coating technologies that not only provide effective corrosion resistance but also maintain or enhance the desirable magnetic properties of these materials without introducing significant losses at high frequencies.

Secondary objectives include assessing the scalability and cost-effectiveness of various coating methods for industrial implementation, evaluating their long-term reliability under typical operating conditions, and identifying promising research directions for next-generation protective coatings. The ultimate goal is to extend the service life of amorphous soft magnetic components in power electronic systems, thereby improving overall system reliability and performance while reducing maintenance requirements and lifecycle costs.

Despite their excellent magnetic properties, amorphous soft magnetic alloys face a significant challenge: susceptibility to corrosion. When exposed to moisture, oxygen, and other environmental factors, these alloys can deteriorate rapidly, compromising their magnetic performance and structural integrity. This vulnerability stems from their unique atomic structure, which lacks the crystalline order that provides natural corrosion resistance in conventional magnetic materials.

The corrosion issue becomes particularly critical in high-frequency power electronics applications, where these materials operate under demanding conditions including thermal cycling, electromagnetic stress, and potential exposure to various environmental factors. As power electronics continue to advance toward higher frequencies, greater power densities, and more compact designs, the need for effective corrosion protection becomes increasingly urgent.

Traditional coating methods developed for crystalline magnetic materials often prove inadequate for amorphous alloys due to differences in surface chemistry, thermal expansion characteristics, and mechanical properties. This has necessitated the development of specialized coating technologies specifically tailored to the unique properties of amorphous soft magnetic materials.

The primary objective of this technical research is to comprehensively evaluate existing and emerging surface coating methods for corrosion protection of amorphous soft magnetic alloys in high-frequency power electronics. We aim to identify coating technologies that not only provide effective corrosion resistance but also maintain or enhance the desirable magnetic properties of these materials without introducing significant losses at high frequencies.

Secondary objectives include assessing the scalability and cost-effectiveness of various coating methods for industrial implementation, evaluating their long-term reliability under typical operating conditions, and identifying promising research directions for next-generation protective coatings. The ultimate goal is to extend the service life of amorphous soft magnetic components in power electronic systems, thereby improving overall system reliability and performance while reducing maintenance requirements and lifecycle costs.

Market Analysis for Protected Magnetic Alloys in Power Electronics

The global market for protected amorphous soft magnetic alloys in power electronics is experiencing robust growth, driven primarily by the increasing demand for energy-efficient power conversion systems. Current market valuations indicate that the power electronics segment utilizing these specialized magnetic materials reached approximately 2.5 billion USD in 2023, with a projected compound annual growth rate of 7.8% through 2030.

The demand is particularly strong in renewable energy applications, where high-frequency power electronics are essential for efficient energy conversion. Solar inverters and wind power systems represent the largest application segments, collectively accounting for over 40% of the market share. This trend aligns with global sustainability initiatives and governmental regulations promoting energy efficiency.

Electric vehicle (EV) infrastructure presents another significant market opportunity. The rapid expansion of EV charging networks globally has created substantial demand for high-performance magnetic components that can withstand harsh environmental conditions while maintaining optimal performance. Market research indicates that this segment is growing at nearly 12% annually, outpacing the overall market.

Regional analysis reveals that Asia-Pacific dominates the market with approximately 45% share, led by China, Japan, and South Korea. These countries have established robust manufacturing ecosystems for power electronics components. North America and Europe follow with 25% and 20% market shares respectively, with particular growth in renewable energy and automotive applications.

Consumer electronics represents another substantial market segment, particularly in applications requiring miniaturization and high efficiency. The trend toward smaller, more powerful electronic devices continues to drive demand for advanced magnetic materials that can operate efficiently at high frequencies while maintaining thermal stability.

Industry surveys indicate that end-users are increasingly prioritizing long-term reliability over initial cost, creating market opportunities for premium corrosion-protected magnetic alloys. This shift in purchasing behavior reflects the growing recognition of total cost of ownership rather than just acquisition costs.

The competitive landscape features both established materials manufacturers and emerging specialized coating technology providers. Strategic partnerships between magnetic alloy producers and surface treatment specialists are becoming more common, indicating a trend toward integrated solutions rather than separate component sourcing.

Market forecasts suggest that innovations in corrosion protection technologies could unlock additional market segments, particularly in marine, aerospace, and industrial applications where environmental exposure presents significant challenges to conventional magnetic materials.

The demand is particularly strong in renewable energy applications, where high-frequency power electronics are essential for efficient energy conversion. Solar inverters and wind power systems represent the largest application segments, collectively accounting for over 40% of the market share. This trend aligns with global sustainability initiatives and governmental regulations promoting energy efficiency.

Electric vehicle (EV) infrastructure presents another significant market opportunity. The rapid expansion of EV charging networks globally has created substantial demand for high-performance magnetic components that can withstand harsh environmental conditions while maintaining optimal performance. Market research indicates that this segment is growing at nearly 12% annually, outpacing the overall market.

Regional analysis reveals that Asia-Pacific dominates the market with approximately 45% share, led by China, Japan, and South Korea. These countries have established robust manufacturing ecosystems for power electronics components. North America and Europe follow with 25% and 20% market shares respectively, with particular growth in renewable energy and automotive applications.

Consumer electronics represents another substantial market segment, particularly in applications requiring miniaturization and high efficiency. The trend toward smaller, more powerful electronic devices continues to drive demand for advanced magnetic materials that can operate efficiently at high frequencies while maintaining thermal stability.

Industry surveys indicate that end-users are increasingly prioritizing long-term reliability over initial cost, creating market opportunities for premium corrosion-protected magnetic alloys. This shift in purchasing behavior reflects the growing recognition of total cost of ownership rather than just acquisition costs.

The competitive landscape features both established materials manufacturers and emerging specialized coating technology providers. Strategic partnerships between magnetic alloy producers and surface treatment specialists are becoming more common, indicating a trend toward integrated solutions rather than separate component sourcing.

Market forecasts suggest that innovations in corrosion protection technologies could unlock additional market segments, particularly in marine, aerospace, and industrial applications where environmental exposure presents significant challenges to conventional magnetic materials.

Current Challenges in Amorphous Alloy Surface Protection

Amorphous soft magnetic alloys face significant corrosion challenges that compromise their performance in high-frequency power electronics applications. The inherent metastable structure of these materials, characterized by the absence of grain boundaries, creates unique surface properties that traditional coating methods struggle to adequately protect. Environmental factors such as humidity, temperature fluctuations, and exposure to corrosive agents accelerate degradation processes, leading to premature failure of components.

The high silicon content in many amorphous alloys, while beneficial for magnetic properties, creates challenges for coating adhesion and uniformity. Conventional coating techniques often result in poor interfacial bonding, leading to delamination under thermal cycling conditions common in power electronic applications. This is particularly problematic as operating frequencies increase, generating more heat and thermal stress at material interfaces.

Current coating technologies face limitations in providing comprehensive protection while maintaining the superior magnetic properties of the base material. Thick protective layers can significantly reduce the effective cross-sectional area of magnetic cores, diminishing their performance advantages. Conversely, thin coatings often lack durability and complete surface coverage, allowing corrosion initiation at microscopic defect sites.

The complex geometry of wound cores and intricate component shapes presents additional challenges for uniform coating application. Edge coverage remains particularly problematic, with sharp corners and edges often receiving insufficient protection due to surface tension effects during coating processes. These areas become vulnerable points for corrosion initiation, which can rapidly propagate throughout the component.

High-temperature operation in power electronics creates another dimension of complexity, as coating materials must maintain their protective properties across wide temperature ranges. Many organic coatings degrade at elevated temperatures, while inorganic alternatives may crack due to thermal expansion mismatches with the substrate. This thermal cycling effect accelerates coating failure through the formation of microcracks that allow moisture and corrosive agents to penetrate.

The industry also faces challenges related to environmentally sustainable coating solutions. Traditional corrosion protection methods often rely on chromate conversion coatings or other environmentally problematic substances that face increasing regulatory restrictions. Developing effective, environmentally friendly alternatives that can be applied in cost-effective manufacturing processes remains a significant hurdle.

Electrical insulation requirements further complicate coating selection, as the protective layer must simultaneously prevent corrosion while maintaining specific electrical properties. This dual functionality requirement narrows the field of suitable coating materials and application methods, particularly for high-frequency applications where parasitic effects must be minimized.

The high silicon content in many amorphous alloys, while beneficial for magnetic properties, creates challenges for coating adhesion and uniformity. Conventional coating techniques often result in poor interfacial bonding, leading to delamination under thermal cycling conditions common in power electronic applications. This is particularly problematic as operating frequencies increase, generating more heat and thermal stress at material interfaces.

Current coating technologies face limitations in providing comprehensive protection while maintaining the superior magnetic properties of the base material. Thick protective layers can significantly reduce the effective cross-sectional area of magnetic cores, diminishing their performance advantages. Conversely, thin coatings often lack durability and complete surface coverage, allowing corrosion initiation at microscopic defect sites.

The complex geometry of wound cores and intricate component shapes presents additional challenges for uniform coating application. Edge coverage remains particularly problematic, with sharp corners and edges often receiving insufficient protection due to surface tension effects during coating processes. These areas become vulnerable points for corrosion initiation, which can rapidly propagate throughout the component.

High-temperature operation in power electronics creates another dimension of complexity, as coating materials must maintain their protective properties across wide temperature ranges. Many organic coatings degrade at elevated temperatures, while inorganic alternatives may crack due to thermal expansion mismatches with the substrate. This thermal cycling effect accelerates coating failure through the formation of microcracks that allow moisture and corrosive agents to penetrate.

The industry also faces challenges related to environmentally sustainable coating solutions. Traditional corrosion protection methods often rely on chromate conversion coatings or other environmentally problematic substances that face increasing regulatory restrictions. Developing effective, environmentally friendly alternatives that can be applied in cost-effective manufacturing processes remains a significant hurdle.

Electrical insulation requirements further complicate coating selection, as the protective layer must simultaneously prevent corrosion while maintaining specific electrical properties. This dual functionality requirement narrows the field of suitable coating materials and application methods, particularly for high-frequency applications where parasitic effects must be minimized.

Established Coating Solutions for Amorphous Soft Magnetic Alloys

01 Surface coating techniques for corrosion protection

Various surface coating techniques can be applied to amorphous soft magnetic alloys to enhance their corrosion resistance. These include the application of protective layers such as chromate coatings, polymer films, or metal oxide layers that act as barriers against corrosive environments. These coatings can significantly extend the service life of amorphous magnetic components while preserving their magnetic properties.- Surface coating techniques for corrosion protection: Various surface coating methods can be applied to amorphous soft magnetic alloys to enhance their corrosion resistance. These include applying protective layers such as chromate coatings, polymer films, or metal oxide layers that act as barriers against corrosive environments. These coatings create a physical barrier that prevents direct contact between the alloy surface and corrosive agents, significantly extending the service life of the magnetic components.

- Alloy composition modification for improved corrosion resistance: The corrosion resistance of amorphous soft magnetic alloys can be enhanced by modifying their chemical composition. Adding specific elements such as chromium, phosphorus, or molybdenum to the base alloy can significantly improve its inherent corrosion resistance without compromising the magnetic properties. These elements help form passive films on the alloy surface that protect against oxidation and other corrosion mechanisms.

- Heat treatment processes to enhance corrosion protection: Specialized heat treatment processes can be employed to improve the corrosion resistance of amorphous soft magnetic alloys. Controlled annealing in specific atmospheres can create protective oxide layers or modify the surface structure to enhance corrosion resistance. These thermal processes can also help relieve internal stresses in the material, which might otherwise serve as initiation sites for corrosion.

- Multilayer protective systems for harsh environments: For amorphous soft magnetic alloys used in particularly harsh or corrosive environments, multilayer protective systems can be implemented. These systems typically combine different protective mechanisms, such as an inner passivation layer, a middle barrier coating, and an outer sacrificial layer. This comprehensive approach provides redundant protection against various corrosion mechanisms and significantly extends the service life of the magnetic components.

- Nanostructured surface treatments for enhanced protection: Advanced nanostructured surface treatments can be applied to amorphous soft magnetic alloys to provide superior corrosion protection while maintaining their magnetic properties. These treatments include the application of nanocomposite coatings, nanoscale surface patterning, or the incorporation of nanoparticles into protective layers. The nanoscale features create highly effective barriers against corrosion while adding minimal thickness to the components, which is crucial for maintaining magnetic performance.

02 Composition modification for improved corrosion resistance

The corrosion resistance of amorphous soft magnetic alloys can be enhanced by modifying their chemical composition. Adding specific elements such as chromium, phosphorus, or molybdenum to the alloy formulation can create passive films that protect against corrosion. These compositional adjustments are designed to maintain the desirable magnetic properties while simultaneously improving the material's resistance to oxidation and other corrosive processes.Expand Specific Solutions03 Heat treatment processes for corrosion protection

Specialized heat treatment processes can be employed to improve the corrosion resistance of amorphous soft magnetic alloys. These thermal treatments can include annealing in controlled atmospheres, crystallization treatments, or surface oxidation processes that create protective oxide layers. The carefully controlled thermal processing helps to develop specific microstructures that enhance corrosion resistance while maintaining the desired magnetic properties.Expand Specific Solutions04 Multilayer protective systems

Multilayer protective systems can provide enhanced corrosion protection for amorphous soft magnetic alloys. These systems typically consist of different functional layers, such as adhesion promoters, barrier layers, and top coats, each serving a specific protective purpose. The combination of multiple protective layers creates a synergistic effect that provides superior corrosion resistance compared to single-layer protection methods.Expand Specific Solutions05 Encapsulation and packaging solutions

Encapsulation and specialized packaging solutions can effectively protect amorphous soft magnetic alloys from corrosive environments. These approaches involve completely sealing the magnetic components within protective materials such as resins, glasses, or hermetic packages. The encapsulation prevents direct contact between the amorphous alloy and potentially corrosive agents, thereby extending the component's operational lifetime and reliability in harsh environments.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The surface coating market for corrosion protection of amorphous soft magnetic alloys is in a growth phase, driven by expanding high-frequency power electronics applications. The market is estimated to reach significant value as industries prioritize efficiency and durability in electronic components. Technologically, the field shows varying maturity levels across players. Advanced Technology & Materials and TDK lead with specialized magnetic alloy expertise, while established chemical companies like Henkel, MacDermid Enthone, and Chemetall bring advanced surface treatment technologies. Research institutions including Kyushu University and Fraunhofer-Gesellschaft are advancing novel coating methods. The competitive landscape features collaboration between materials specialists and coating technology providers, with automotive and electronics manufacturers driving application-specific innovations.

MacDermid Enthone, Inc.

Technical Solution: MacDermid Enthone has developed the Guardian™ series of protective coatings specifically engineered for amorphous soft magnetic alloys in high-frequency power electronics. Their approach combines electrochemical surface modification with advanced polymer science to create multi-functional coatings that address the unique challenges of these materials. The process begins with a proprietary micro-etching step that creates controlled surface topography without compromising the amorphous structure, followed by application of a nano-ceramic conversion coating that serves as both a corrosion barrier and adhesion promoter. The final layer consists of a specialized polymer with high dielectric strength and thermal stability up to 200°C. This system provides a total coating thickness of 5-12 μm while maintaining the magnetic permeability critical for high-frequency applications. MacDermid Enthone's coatings incorporate self-stratifying technology that automatically forms distinct functional layers during the curing process, optimizing both adhesion and surface properties[5]. Their latest innovation includes the integration of graphene nanoplatelets that enhance both corrosion resistance and thermal conductivity, addressing the dual challenges of protection and heat management in compact power electronics.

Strengths: Excellent adhesion to difficult-to-coat amorphous surfaces; superior edge coverage for complex geometries; demonstrated salt spray resistance exceeding 1,000 hours; maintains performance after thermal cycling. Weaknesses: More complex application process compared to simple dip coatings; requires careful control of bath chemistry; higher material costs compared to conventional coatings; limited field repairability.

Chemetall GmbH

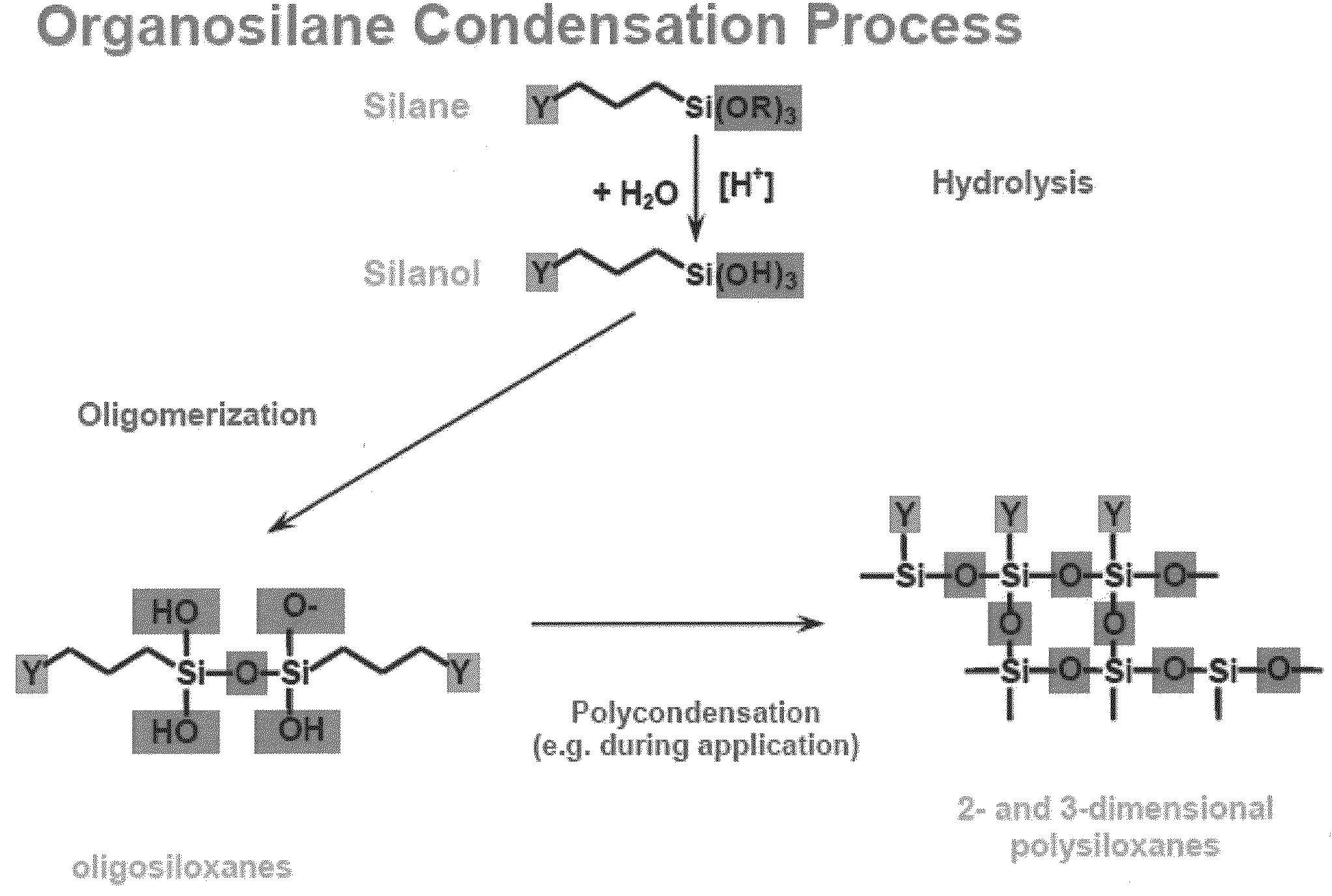

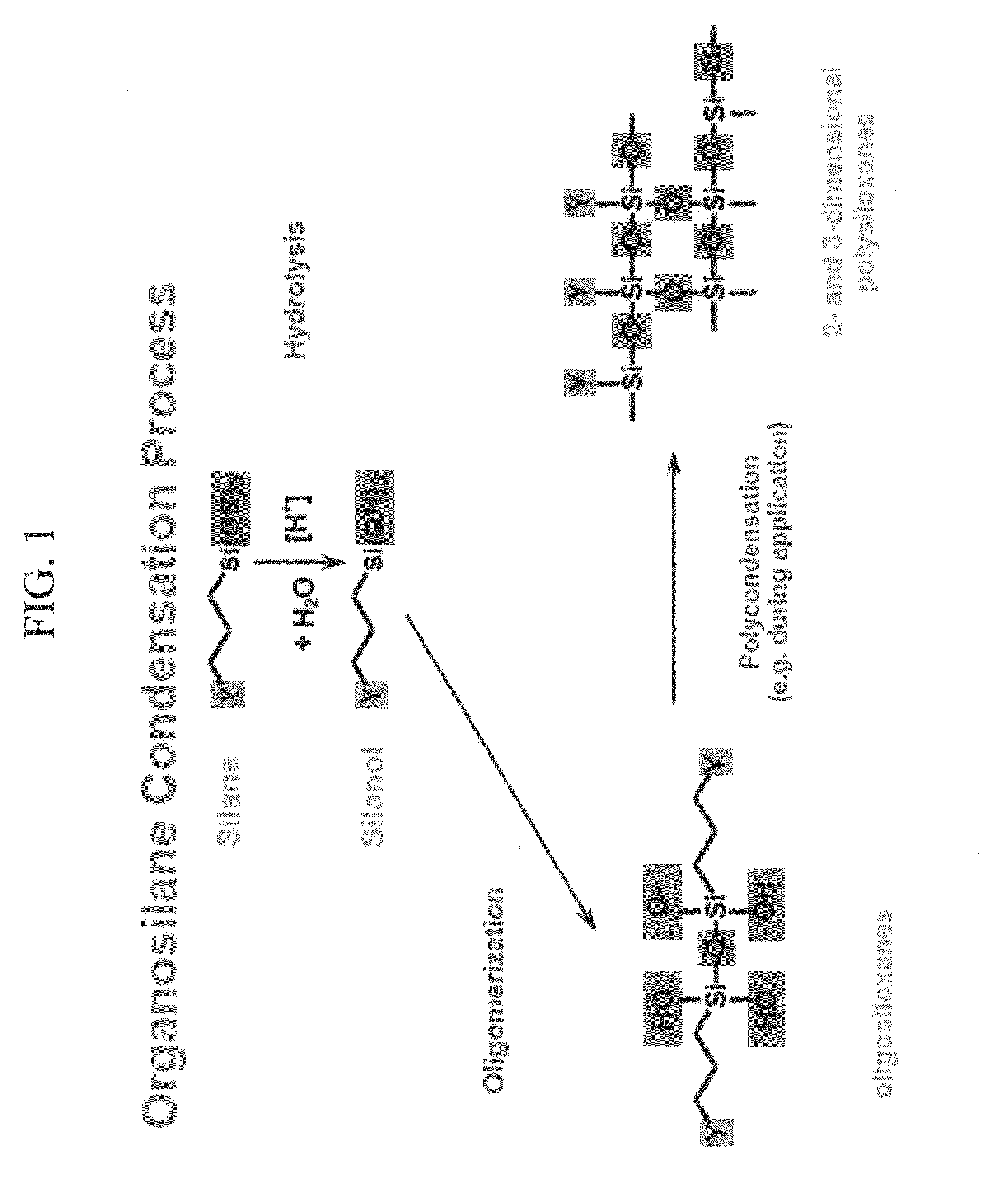

Technical Solution: Chemetall has pioneered advanced surface treatment technologies specifically for amorphous soft magnetic alloys used in high-frequency power electronics. Their flagship Oxsilan® technology represents a significant breakthrough, utilizing silane-based chemistry to create a nanoscale conversion coating that forms covalent bonds with the amorphous metal substrate. This approach provides superior corrosion protection while maintaining the electromagnetic properties essential for high-frequency applications. The coating process involves a multi-stage treatment that includes surface preparation using specialized cleaners that remove contaminants without etching the sensitive amorphous structure, followed by the application of the proprietary silane formulation that creates a 0.5-2 μm protective layer. Chemetall has further enhanced this technology with their Gardobond® additive packages that incorporate rare earth compounds to provide active corrosion inhibition through self-healing mechanisms[4]. Their coatings demonstrate excellent edge coverage—a critical factor for the thin laminations used in high-frequency transformers and inductors—and maintain performance integrity even after thermal cycling between -55°C and 200°C.

Strengths: Extremely thin coatings (0.5-2 μm) that minimize impact on magnetic properties; excellent adhesion to amorphous surfaces; environmentally compliant formulations free from heavy metals; compatible with existing manufacturing processes. Weaknesses: Requires precise process control parameters; higher initial implementation costs compared to conventional phosphate treatments; may require specialized equipment for optimal application in high-volume production.

Key Patents and Innovations in Corrosion-Resistant Coatings

Silane-containing corrosion protection coatings

PatentInactiveUS20100015339A1

Innovation

- A low-temperature curing process using hydrolyzed and condensed oligomers or polymers of functionalized silanes, which are formulated to reduce alcohol content and allow for aqueous systems that can be cured between 20 to 120°C, providing effective corrosion protection without the need for hazardous metals.

Anti-tarnish coating

PatentActiveEP2220009A1

Innovation

- A method and composition involving organic molecules with specific functional groups that interact with precious metal and copper surfaces, forming a protective self-assembled film to enhance corrosion resistance and solderability, using thiols, disulfides, amines, and aromatic heterocycles, along with a surfactant, to create a hydrophobic layer that inhibits copper creep corrosion and environmental exposure.

Environmental Impact and Sustainability Considerations

The environmental impact of surface coating methods for amorphous soft magnetic alloys represents a critical consideration in the sustainable development of high-frequency power electronics. Traditional coating processes often involve hazardous chemicals such as chromates, phosphates, and heavy metals that pose significant environmental risks through soil contamination, water pollution, and air emissions. These substances can persist in ecosystems for extended periods, potentially causing long-term ecological damage and human health concerns.

Recent regulatory frameworks, including RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), have accelerated the transition toward more environmentally benign coating technologies. This shift has prompted the development of water-based coating systems, powder coatings, and UV-curable formulations that significantly reduce volatile organic compound (VOC) emissions compared to conventional solvent-based alternatives.

Life cycle assessment (LCA) studies of various coating methods reveal substantial differences in environmental footprints. Sol-gel coatings and plasma electrolytic oxidation processes demonstrate reduced energy consumption and waste generation compared to traditional electroplating techniques. Additionally, atomic layer deposition (ALD) offers exceptional material efficiency by enabling precise nanometer-scale coatings that minimize resource utilization while maintaining optimal performance characteristics.

The recyclability of coated amorphous soft magnetic components presents another sustainability challenge. Certain coating materials can complicate end-of-life processing and material recovery. Research indicates that silane-based coatings and some organic polymer systems offer improved compatibility with recycling processes, allowing for more effective separation and reclamation of valuable magnetic materials.

Energy efficiency considerations extend beyond manufacturing to the operational phase of coated components. Advanced ceramic and composite coatings can enhance the thermal management properties of magnetic components, potentially improving energy efficiency in power electronic systems by 3-7% over uncoated alternatives. This operational efficiency gain represents a significant sustainability benefit when considered across the product lifecycle.

Emerging bio-based coating alternatives derived from renewable resources show promising environmental profiles. Chitosan-based coatings, lignin derivatives, and cellulose-reinforced systems demonstrate effective corrosion protection while reducing dependence on petrochemical feedstocks. Though currently limited in commercial applications, these bio-inspired approaches represent an important frontier in sustainable coating development for specialized electronic applications.

Water consumption and wastewater management remain significant concerns, particularly for wet chemical processes. Closed-loop water systems and advanced filtration technologies have been implemented to reduce freshwater requirements by up to 80% in modern coating facilities. Additionally, dry coating methods such as physical vapor deposition offer substantially reduced water footprints compared to conventional techniques.

Recent regulatory frameworks, including RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), have accelerated the transition toward more environmentally benign coating technologies. This shift has prompted the development of water-based coating systems, powder coatings, and UV-curable formulations that significantly reduce volatile organic compound (VOC) emissions compared to conventional solvent-based alternatives.

Life cycle assessment (LCA) studies of various coating methods reveal substantial differences in environmental footprints. Sol-gel coatings and plasma electrolytic oxidation processes demonstrate reduced energy consumption and waste generation compared to traditional electroplating techniques. Additionally, atomic layer deposition (ALD) offers exceptional material efficiency by enabling precise nanometer-scale coatings that minimize resource utilization while maintaining optimal performance characteristics.

The recyclability of coated amorphous soft magnetic components presents another sustainability challenge. Certain coating materials can complicate end-of-life processing and material recovery. Research indicates that silane-based coatings and some organic polymer systems offer improved compatibility with recycling processes, allowing for more effective separation and reclamation of valuable magnetic materials.

Energy efficiency considerations extend beyond manufacturing to the operational phase of coated components. Advanced ceramic and composite coatings can enhance the thermal management properties of magnetic components, potentially improving energy efficiency in power electronic systems by 3-7% over uncoated alternatives. This operational efficiency gain represents a significant sustainability benefit when considered across the product lifecycle.

Emerging bio-based coating alternatives derived from renewable resources show promising environmental profiles. Chitosan-based coatings, lignin derivatives, and cellulose-reinforced systems demonstrate effective corrosion protection while reducing dependence on petrochemical feedstocks. Though currently limited in commercial applications, these bio-inspired approaches represent an important frontier in sustainable coating development for specialized electronic applications.

Water consumption and wastewater management remain significant concerns, particularly for wet chemical processes. Closed-loop water systems and advanced filtration technologies have been implemented to reduce freshwater requirements by up to 80% in modern coating facilities. Additionally, dry coating methods such as physical vapor deposition offer substantially reduced water footprints compared to conventional techniques.

Performance Testing and Quality Assurance Methods

Performance testing and quality assurance are critical components in evaluating the effectiveness of surface coating methods for amorphous soft magnetic alloys used in high-frequency power electronics. These processes ensure that the applied coatings meet the required standards for corrosion protection while maintaining the essential magnetic properties of the underlying alloy.

Standard testing protocols typically begin with accelerated corrosion tests, including salt spray testing (ASTM B117), humidity chamber testing, and cyclic corrosion testing. These methods simulate harsh environmental conditions to evaluate coating durability and protective capabilities within compressed timeframes. For high-frequency power electronics applications, these tests must be modified to account for the specific operating environments, including elevated temperatures and potential exposure to cooling fluids.

Electrochemical impedance spectroscopy (EIS) has emerged as a particularly valuable technique for quantitative assessment of coating integrity. This non-destructive method measures the impedance of the coating system across a range of frequencies, providing insights into coating porosity, adhesion, and barrier properties. For amorphous soft magnetic alloys, EIS results must be carefully interpreted to distinguish between coating degradation and substrate-specific responses.

Magnetic property retention testing represents a unique quality assurance requirement for coated soft magnetic components. Core loss measurements before and after coating application, as well as after environmental exposure, are essential to verify that the coating process and subsequent corrosion protection do not compromise the alloy's magnetic performance. Standardized testing using toroidal test fixtures at application-relevant frequencies (typically 10 kHz to 1 MHz) provides quantifiable data on magnetic property preservation.

Adhesion testing, including cross-cut (ASTM D3359) and pull-off strength tests (ASTM D4541), evaluates the mechanical bond between coating and substrate. For amorphous alloys, these tests must be carefully calibrated to account for the unique surface characteristics and potential stress sensitivity of these materials. Poor adhesion can lead to coating delamination during thermal cycling, a common condition in power electronics applications.

Thickness measurement and uniformity assessment using techniques such as eddy current testing or magnetic induction methods provide critical quality control parameters. For optimal performance, coatings must maintain consistent thickness across complex component geometries, with variations typically limited to ±10% of the target specification.

Statistical process control methodologies are increasingly being implemented to monitor coating quality in production environments. These approaches establish control limits for key parameters such as thickness, adhesion strength, and electrochemical impedance, enabling early detection of process drift and ensuring consistent coating performance across production batches.

Standard testing protocols typically begin with accelerated corrosion tests, including salt spray testing (ASTM B117), humidity chamber testing, and cyclic corrosion testing. These methods simulate harsh environmental conditions to evaluate coating durability and protective capabilities within compressed timeframes. For high-frequency power electronics applications, these tests must be modified to account for the specific operating environments, including elevated temperatures and potential exposure to cooling fluids.

Electrochemical impedance spectroscopy (EIS) has emerged as a particularly valuable technique for quantitative assessment of coating integrity. This non-destructive method measures the impedance of the coating system across a range of frequencies, providing insights into coating porosity, adhesion, and barrier properties. For amorphous soft magnetic alloys, EIS results must be carefully interpreted to distinguish between coating degradation and substrate-specific responses.

Magnetic property retention testing represents a unique quality assurance requirement for coated soft magnetic components. Core loss measurements before and after coating application, as well as after environmental exposure, are essential to verify that the coating process and subsequent corrosion protection do not compromise the alloy's magnetic performance. Standardized testing using toroidal test fixtures at application-relevant frequencies (typically 10 kHz to 1 MHz) provides quantifiable data on magnetic property preservation.

Adhesion testing, including cross-cut (ASTM D3359) and pull-off strength tests (ASTM D4541), evaluates the mechanical bond between coating and substrate. For amorphous alloys, these tests must be carefully calibrated to account for the unique surface characteristics and potential stress sensitivity of these materials. Poor adhesion can lead to coating delamination during thermal cycling, a common condition in power electronics applications.

Thickness measurement and uniformity assessment using techniques such as eddy current testing or magnetic induction methods provide critical quality control parameters. For optimal performance, coatings must maintain consistent thickness across complex component geometries, with variations typically limited to ±10% of the target specification.

Statistical process control methodologies are increasingly being implemented to monitor coating quality in production environments. These approaches establish control limits for key parameters such as thickness, adhesion strength, and electrochemical impedance, enabling early detection of process drift and ensuring consistent coating performance across production batches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!