Manufacturing Scale-Up For Melt-Spun Ribbons Of Amorphous Soft Magnetic Alloys In High-Frequency Power Electronics

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Amorphous Magnetic Alloys Background and Objectives

Amorphous soft magnetic alloys emerged in the 1970s when researchers at Allied Signal discovered that rapidly quenching certain metal alloys could prevent crystallization, resulting in materials with unique magnetic properties. These amorphous metals, primarily composed of iron, boron, silicon, and other elements, exhibit significantly reduced core losses compared to traditional silicon steel, making them ideal for high-frequency power applications.

The evolution of these materials has been marked by continuous improvements in composition and processing techniques. Early amorphous alloys faced limitations in saturation magnetization and thermal stability. The subsequent development of nanocrystalline alloys in the 1980s, achieved through controlled crystallization of amorphous precursors, represented a significant advancement by combining the advantages of both amorphous and crystalline structures.

Recent technological trends show increasing focus on tailoring these materials for specific applications in renewable energy systems, electric vehicles, and advanced power electronics. The push toward higher switching frequencies in power conversion systems has intensified the demand for magnetic materials capable of operating efficiently at frequencies exceeding 100 kHz.

The primary objective of scaling up manufacturing for melt-spun amorphous ribbons is to bridge the gap between laboratory-scale production and commercial viability. This involves developing consistent, high-volume production methods that maintain the exceptional magnetic properties observed in smaller batches. Specific technical goals include achieving uniform ribbon thickness below 30 μm, consistent width control, and minimal surface defects across kilometers of continuous production.

Additional objectives include enhancing thermal stability for operation at temperatures up to 200°C, improving mechanical properties to facilitate handling during core manufacturing, and developing cost-effective production methods to compete with traditional magnetic materials. The ultimate aim is to enable widespread adoption of these advanced materials in next-generation power electronics.

Environmental considerations also factor into development objectives, with efforts directed toward reducing the energy intensity of the manufacturing process and minimizing the use of rare or toxic elements in alloy compositions. This aligns with global sustainability goals while ensuring long-term material availability.

Understanding the fundamental relationship between processing parameters, resulting microstructure, and magnetic performance remains a central research focus, as this knowledge is essential for optimizing large-scale production methods.

The evolution of these materials has been marked by continuous improvements in composition and processing techniques. Early amorphous alloys faced limitations in saturation magnetization and thermal stability. The subsequent development of nanocrystalline alloys in the 1980s, achieved through controlled crystallization of amorphous precursors, represented a significant advancement by combining the advantages of both amorphous and crystalline structures.

Recent technological trends show increasing focus on tailoring these materials for specific applications in renewable energy systems, electric vehicles, and advanced power electronics. The push toward higher switching frequencies in power conversion systems has intensified the demand for magnetic materials capable of operating efficiently at frequencies exceeding 100 kHz.

The primary objective of scaling up manufacturing for melt-spun amorphous ribbons is to bridge the gap between laboratory-scale production and commercial viability. This involves developing consistent, high-volume production methods that maintain the exceptional magnetic properties observed in smaller batches. Specific technical goals include achieving uniform ribbon thickness below 30 μm, consistent width control, and minimal surface defects across kilometers of continuous production.

Additional objectives include enhancing thermal stability for operation at temperatures up to 200°C, improving mechanical properties to facilitate handling during core manufacturing, and developing cost-effective production methods to compete with traditional magnetic materials. The ultimate aim is to enable widespread adoption of these advanced materials in next-generation power electronics.

Environmental considerations also factor into development objectives, with efforts directed toward reducing the energy intensity of the manufacturing process and minimizing the use of rare or toxic elements in alloy compositions. This aligns with global sustainability goals while ensuring long-term material availability.

Understanding the fundamental relationship between processing parameters, resulting microstructure, and magnetic performance remains a central research focus, as this knowledge is essential for optimizing large-scale production methods.

Market Analysis for High-Frequency Power Electronics Applications

The high-frequency power electronics market is experiencing unprecedented growth, driven by the increasing demand for efficient power conversion systems across multiple industries. The global market for high-frequency power electronics was valued at approximately $12 billion in 2022 and is projected to reach $20 billion by 2027, representing a compound annual growth rate (CAGR) of 10.8%. This growth trajectory is primarily fueled by the rapid expansion of electric vehicles, renewable energy systems, and advanced telecommunications infrastructure.

Within this broader market, soft magnetic materials play a crucial role, with amorphous and nanocrystalline alloys capturing significant attention due to their superior performance characteristics. The market segment specifically for amorphous soft magnetic alloys in high-frequency applications currently stands at around $1.5 billion and is expected to grow at a CAGR of 12.3% through 2028.

Electric vehicle (EV) applications represent the fastest-growing segment for these materials, with on-board chargers and DC-DC converters requiring high-efficiency magnetic components that operate at frequencies above 100 kHz. The automotive sector's demand for these materials is expected to triple by 2030 as EV adoption accelerates globally.

Renewable energy systems, particularly solar inverters and wind power converters, constitute the second-largest application segment. The push for higher power density and efficiency in these systems is driving the adoption of amorphous soft magnetic materials, with the market in this sector growing at approximately 11% annually.

Data centers and telecommunications infrastructure represent another significant market opportunity, with the deployment of 5G networks and edge computing facilities requiring advanced power supplies with improved efficiency and reduced footprint. This segment is projected to grow at 9.5% annually through 2027.

Geographically, Asia-Pacific dominates the market consumption, accounting for 45% of global demand, followed by North America (28%) and Europe (22%). China, in particular, has emerged as both the largest consumer and producer of amorphous soft magnetic materials, with substantial government investments in manufacturing capabilities.

The market is characterized by increasing price sensitivity and growing demand for customized solutions that meet specific application requirements. End-users are increasingly focused on total cost of ownership rather than initial acquisition costs, creating opportunities for materials that offer superior lifetime performance despite higher upfront costs.

Within this broader market, soft magnetic materials play a crucial role, with amorphous and nanocrystalline alloys capturing significant attention due to their superior performance characteristics. The market segment specifically for amorphous soft magnetic alloys in high-frequency applications currently stands at around $1.5 billion and is expected to grow at a CAGR of 12.3% through 2028.

Electric vehicle (EV) applications represent the fastest-growing segment for these materials, with on-board chargers and DC-DC converters requiring high-efficiency magnetic components that operate at frequencies above 100 kHz. The automotive sector's demand for these materials is expected to triple by 2030 as EV adoption accelerates globally.

Renewable energy systems, particularly solar inverters and wind power converters, constitute the second-largest application segment. The push for higher power density and efficiency in these systems is driving the adoption of amorphous soft magnetic materials, with the market in this sector growing at approximately 11% annually.

Data centers and telecommunications infrastructure represent another significant market opportunity, with the deployment of 5G networks and edge computing facilities requiring advanced power supplies with improved efficiency and reduced footprint. This segment is projected to grow at 9.5% annually through 2027.

Geographically, Asia-Pacific dominates the market consumption, accounting for 45% of global demand, followed by North America (28%) and Europe (22%). China, in particular, has emerged as both the largest consumer and producer of amorphous soft magnetic materials, with substantial government investments in manufacturing capabilities.

The market is characterized by increasing price sensitivity and growing demand for customized solutions that meet specific application requirements. End-users are increasingly focused on total cost of ownership rather than initial acquisition costs, creating opportunities for materials that offer superior lifetime performance despite higher upfront costs.

Current Challenges in Melt-Spinning Scale-Up Technology

Despite significant advancements in melt-spinning technology for amorphous soft magnetic alloys, scaling up production from laboratory to industrial levels presents numerous technical challenges. The primary obstacle lies in maintaining consistent ribbon quality across larger production volumes. When scaling up, even minor variations in cooling rates can lead to partial crystallization, dramatically altering the magnetic properties that make these materials valuable for high-frequency power electronics applications.

Temperature control during the melt-spinning process becomes increasingly difficult at industrial scales. The molten alloy must be maintained within precise temperature ranges before ejection onto the cooling wheel. As production volumes increase, heat distribution becomes less uniform, creating inconsistencies in the final ribbon structure. These temperature fluctuations directly impact the amorphous nature of the material, potentially introducing unwanted crystalline phases.

Wheel speed consistency represents another significant challenge. Industrial-scale wheels must maintain precise rotational velocities over extended production runs. Any fluctuation in wheel speed alters the cooling rate and ribbon thickness, leading to inconsistent magnetic performance across batches. Current wheel drive systems struggle to maintain the necessary precision at higher production speeds.

The ejection mechanism for delivering molten alloy onto the cooling wheel faces scaling limitations. Laboratory-scale nozzles cannot simply be enlarged for industrial production, as fluid dynamics change dramatically with increased flow rates. Larger nozzles often create turbulence in the molten stream, resulting in ribbon thickness variations and edge defects that compromise magnetic performance and mechanical integrity.

Ribbon collection systems present additional complications at industrial scales. As production volumes increase, the continuous collection of fragile amorphous ribbons without introducing mechanical stress or deformation becomes problematic. Current collection methods often induce micro-stresses that can nucleate crystallization during subsequent processing steps.

Quality control methodologies that work effectively at laboratory scales become insufficient for industrial production. In-line monitoring of ribbon properties presents technical challenges, as many critical parameters cannot be measured in real-time during high-speed production. This creates quality assurance gaps that increase rejection rates and production costs.

Environmental control within larger production facilities introduces another layer of complexity. Dust particles, atmospheric variations, and vibrations from nearby equipment can all impact ribbon quality. Creating and maintaining the necessary controlled environment at industrial scales requires significant engineering solutions that are not fully developed in current production systems.

Temperature control during the melt-spinning process becomes increasingly difficult at industrial scales. The molten alloy must be maintained within precise temperature ranges before ejection onto the cooling wheel. As production volumes increase, heat distribution becomes less uniform, creating inconsistencies in the final ribbon structure. These temperature fluctuations directly impact the amorphous nature of the material, potentially introducing unwanted crystalline phases.

Wheel speed consistency represents another significant challenge. Industrial-scale wheels must maintain precise rotational velocities over extended production runs. Any fluctuation in wheel speed alters the cooling rate and ribbon thickness, leading to inconsistent magnetic performance across batches. Current wheel drive systems struggle to maintain the necessary precision at higher production speeds.

The ejection mechanism for delivering molten alloy onto the cooling wheel faces scaling limitations. Laboratory-scale nozzles cannot simply be enlarged for industrial production, as fluid dynamics change dramatically with increased flow rates. Larger nozzles often create turbulence in the molten stream, resulting in ribbon thickness variations and edge defects that compromise magnetic performance and mechanical integrity.

Ribbon collection systems present additional complications at industrial scales. As production volumes increase, the continuous collection of fragile amorphous ribbons without introducing mechanical stress or deformation becomes problematic. Current collection methods often induce micro-stresses that can nucleate crystallization during subsequent processing steps.

Quality control methodologies that work effectively at laboratory scales become insufficient for industrial production. In-line monitoring of ribbon properties presents technical challenges, as many critical parameters cannot be measured in real-time during high-speed production. This creates quality assurance gaps that increase rejection rates and production costs.

Environmental control within larger production facilities introduces another layer of complexity. Dust particles, atmospheric variations, and vibrations from nearby equipment can all impact ribbon quality. Creating and maintaining the necessary controlled environment at industrial scales requires significant engineering solutions that are not fully developed in current production systems.

Current Manufacturing Methods for Melt-Spun Ribbons

01 Alloy composition optimization for melt-spun ribbons

The composition of amorphous soft magnetic alloys significantly impacts the properties of melt-spun ribbons. By carefully selecting and optimizing the proportions of elements such as Fe, Co, Ni, B, Si, and rare earth metals, manufacturers can enhance magnetic properties like permeability, saturation magnetization, and coercivity. These optimized compositions also improve the amorphous structure formation during rapid solidification, which is crucial for achieving desired magnetic softness and thermal stability in scaled-up production.- Melt-spinning process optimization for scale-up: Optimization of the melt-spinning process is crucial for scaling up production of amorphous soft magnetic alloy ribbons. This involves controlling parameters such as wheel speed, melt temperature, nozzle design, and cooling rate to achieve consistent ribbon thickness and quality. Advanced process monitoring and control systems help maintain stable conditions during continuous production, ensuring uniform magnetic properties across large batches.

- Alloy composition engineering for industrial production: Engineering specific alloy compositions is essential for industrial-scale production of amorphous soft magnetic ribbons. Formulations typically include iron, cobalt, or nickel as base elements with additions of boron, silicon, phosphorus, and other elements to enhance glass-forming ability and magnetic properties. Precise control of elemental ratios and purity levels is necessary to maintain consistent performance when scaling from laboratory to commercial production.

- Equipment design for high-volume manufacturing: Specialized equipment design is required for high-volume manufacturing of melt-spun amorphous ribbons. This includes custom melting chambers, precision nozzles, large-diameter cooling wheels with enhanced thermal management, and automated handling systems. Industrial-scale equipment must address challenges such as wheel wear, thermal stability, and ribbon collection to enable continuous operation and consistent quality across extended production runs.

- Post-processing techniques for enhanced properties: Various post-processing techniques are employed to enhance the properties of melt-spun amorphous ribbons during scale-up. These include controlled annealing treatments to relieve internal stresses, surface treatments to improve corrosion resistance, and precision cutting methods to produce cores with specific dimensions. Heat treatment under magnetic fields can also be used to induce beneficial anisotropy for specific applications while maintaining the amorphous structure.

- Quality control and characterization methods: Robust quality control and characterization methods are essential for scaled-up production of amorphous soft magnetic ribbons. This includes in-line monitoring of ribbon dimensions, surface quality, and magnetic properties, as well as advanced analytical techniques such as X-ray diffraction, electron microscopy, and magnetic testing. Statistical process control methods help identify variations in production parameters that affect ribbon quality, enabling continuous improvement of manufacturing processes.

02 Rapid solidification process control for industrial scale

Scaling up the melt-spinning process requires precise control of rapid solidification parameters. This includes optimizing wheel speed, melt temperature, ejection pressure, and nozzle-to-wheel distance to maintain consistent ribbon thickness and quality at higher production volumes. Advanced cooling techniques and temperature gradient management systems are implemented to ensure uniform amorphous structure formation across wider ribbons. These process controls are essential for transitioning from laboratory-scale to industrial-scale production while maintaining the magnetic properties of the alloys.Expand Specific Solutions03 Equipment modifications for large-scale production

Specialized equipment modifications are necessary for scaling up melt-spun ribbon production. These include designing larger crucibles with precise temperature control, developing wider cooling wheels with enhanced surface treatments, and implementing automated handling systems for continuous production. Advanced nozzle designs with multiple ejection points allow for wider ribbon formation, while modified tension control systems maintain ribbon quality during collection. These equipment adaptations address the challenges of increased production volume while ensuring consistent ribbon quality.Expand Specific Solutions04 Post-processing techniques for enhanced properties

Various post-processing techniques are employed to enhance the properties of melt-spun amorphous ribbons in large-scale production. These include controlled annealing processes to relieve internal stresses and optimize magnetic domains, surface treatments to improve corrosion resistance, and precision cutting methods for specific applications. Additional techniques such as lamination, stacking, and encapsulation are used to create composite cores with reduced eddy current losses. These post-processing steps are crucial for achieving the desired magnetic performance in final applications.Expand Specific Solutions05 Quality control and characterization methods for scaled production

Implementing robust quality control and characterization methods is essential for consistent large-scale production of amorphous soft magnetic ribbons. Advanced techniques include in-line monitoring of ribbon thickness and width, real-time magnetic property testing, and automated defect detection systems. Non-destructive testing methods such as eddy current analysis, X-ray diffraction, and magnetic domain imaging are employed to verify amorphous structure and magnetic properties. Statistical process control methodologies help maintain consistency across production batches and identify optimization opportunities.Expand Specific Solutions

Leading Manufacturers and Research Institutions Analysis

The manufacturing scale-up for melt-spun ribbons of amorphous soft magnetic alloys is currently in a growth phase, with the market expanding due to increasing demand in high-frequency power electronics applications. The global market is projected to grow significantly as these materials offer superior performance in energy efficiency and miniaturization. Technologically, the field shows varying maturity levels across players. Companies like Metglas, Proterial, and NIPPON STEEL have established advanced manufacturing capabilities, while newer entrants such as Qingdao Yunlu and Jiangsu Xuanyuan are rapidly developing their technologies. Academic-industry partnerships, particularly involving Tohoku University and Dalian University of Technology, are accelerating innovation in manufacturing processes, addressing challenges in consistent quality and volume production for commercial applications.

Proterial Ltd.

Technical Solution: Proterial (formerly Hitachi Metals) has developed an advanced manufacturing system for amorphous and nanocrystalline soft magnetic ribbons focused on high-volume production for power electronics applications. Their approach utilizes a modified planar flow casting technique with precisely controlled nozzle geometry to achieve uniform ribbon thickness down to 15μm. The company has implemented a proprietary wheel cooling system that maintains consistent thermal conditions during extended production runs, addressing one of the key challenges in scaling up melt spinning operations. Proterial's manufacturing line incorporates real-time monitoring of ribbon dimensions and surface quality using laser scanning and machine vision systems, enabling immediate process adjustments to maintain quality. For high-frequency applications, they've developed specialized Fe-based alloy compositions with reduced magnetostriction and optimized electrical resistivity. Their scale-up strategy includes parallel processing lines with synchronized operations to increase production volume while maintaining quality consistency. The company has also pioneered advanced winding and core assembly techniques that preserve the magnetic properties of the ribbons when formed into final components.

Strengths: Highly automated production system enabling consistent quality at scale; advanced process monitoring and control systems; integrated approach from material production to component manufacturing. Weaknesses: High capital investment requirements for production facilities; challenges in maintaining consistent ribbon edge quality at higher production speeds; limited flexibility to quickly change alloy compositions between production runs.

Qingdao Yunlu Advanced Materials Technology Co., Ltd.

Technical Solution: Qingdao Yunlu has developed a comprehensive manufacturing approach for amorphous and nanocrystalline soft magnetic ribbons targeting high-frequency power electronics applications. Their technology centers on a modified single-roller melt spinning process with proprietary nozzle designs that enable precise control of ribbon dimensions and cooling rates. The company has implemented specialized alloy preparation systems that ensure homogeneous melt composition and minimize impurities that could degrade magnetic performance. Their manufacturing scale-up strategy incorporates parallel casting units with synchronized control systems to increase production volume while maintaining quality consistency. Yunlu has developed custom wheel materials and surface treatments that optimize thermal transfer during quenching while extending wheel lifetime in production environments. Their process includes in-line annealing capabilities with precisely controlled temperature profiles for nanocrystallization, achieving grain sizes of approximately 10-20nm for optimal high-frequency performance. The company has also implemented automated handling and winding systems specifically designed for the brittle amorphous ribbons, minimizing mechanical damage during processing.

Strengths: Cost-effective manufacturing approach enabling competitive pricing; vertically integrated production from raw materials to finished components; flexible production capabilities accommodating various alloy compositions. Weaknesses: Relatively newer entrant to the market compared to established players; challenges in achieving the tightest thickness tolerances consistently at scale; ongoing development of proprietary alloy compositions.

Key Technical Innovations in Ribbon Production Processes

Soft magnetic thin strip, process for production of the same, magnetic parts, and amorphous thin strip

PatentWO2008133302A1

Innovation

- A soft magnetic ribbon with a composition formula like Fe 100-x-y-z A x My X z-a Pa, where A is Cu or Au, M is Ti, Zr, Hf, V, Nb, Ta, Cr, Mo, and W, and X is B or Si, is produced with a heat treatment that forms nanoscale crystal grains dispersed in an amorphous phase, achieving high saturation magnetic flux density and low coercive force.

Soft magnetic alloy ribbon and manufacturing method thereof, and magnetic device using the soft magnetic alloy ribbon

PatentPendingDE112010000836T5

Innovation

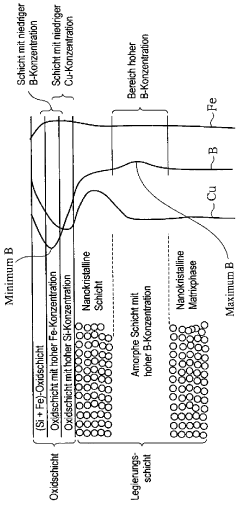

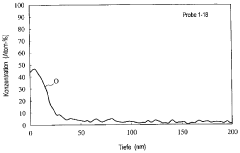

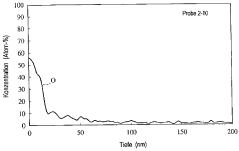

- A soft magnetic alloy ribbon with a specific composition and manufacturing process involving controlled oxygen concentration during annealing, forming a layered structure with fine crystal grains and high B concentration amorphous layers, enhancing insulation and corrosion resistance.

Material Characterization and Quality Control Strategies

Material characterization and quality control are critical components in the successful scale-up of melt-spun ribbon production for amorphous soft magnetic alloys used in high-frequency power electronics. Comprehensive characterization techniques must be employed to ensure consistent material properties across production batches, particularly as manufacturing volumes increase.

X-ray diffraction (XRD) analysis serves as a primary method for confirming the amorphous structure of the ribbons, with the absence of sharp crystalline peaks indicating successful formation of the desired non-crystalline state. This technique must be integrated into regular production monitoring protocols to detect any unintended crystallization that could compromise magnetic performance.

Magnetic property assessment through vibrating sample magnetometry (VSM) and B-H loop tracers provides essential data on core loss, permeability, and saturation magnetization. These parameters directly influence the performance of power electronic components and must be tightly controlled during scale-up operations. Statistical process control methods should be implemented to track these properties across production runs.

Surface and cross-sectional morphology evaluation using scanning electron microscopy (SEM) enables detection of defects such as surface irregularities, inclusions, or thickness variations that can significantly impact magnetic performance. As production scales up, automated vision systems can be deployed for real-time inspection of ribbon surfaces during manufacturing.

Thermal analysis techniques, particularly differential scanning calorimetry (DSC), are vital for determining crystallization temperatures and thermal stability of the amorphous alloys. This information guides processing parameters and helps establish quality control thresholds for heat treatment operations in downstream processing.

Mechanical property testing, including tensile strength and hardness measurements, provides insights into ribbon durability and handling characteristics during core assembly processes. These properties must remain consistent as production volumes increase to ensure reliable component manufacturing.

Compositional analysis through techniques such as energy-dispersive X-ray spectroscopy (EDX) or inductively coupled plasma mass spectrometry (ICP-MS) verifies elemental composition consistency, which is crucial for maintaining magnetic properties. Slight variations in critical elements like Fe, Co, B, or Si can significantly alter performance characteristics.

Implementation of statistical quality control methodologies becomes increasingly important during scale-up, with control charts and capability indices providing quantitative measures of process stability and product consistency. Advanced data analytics can identify correlations between processing parameters and final material properties, enabling predictive quality control approaches.

X-ray diffraction (XRD) analysis serves as a primary method for confirming the amorphous structure of the ribbons, with the absence of sharp crystalline peaks indicating successful formation of the desired non-crystalline state. This technique must be integrated into regular production monitoring protocols to detect any unintended crystallization that could compromise magnetic performance.

Magnetic property assessment through vibrating sample magnetometry (VSM) and B-H loop tracers provides essential data on core loss, permeability, and saturation magnetization. These parameters directly influence the performance of power electronic components and must be tightly controlled during scale-up operations. Statistical process control methods should be implemented to track these properties across production runs.

Surface and cross-sectional morphology evaluation using scanning electron microscopy (SEM) enables detection of defects such as surface irregularities, inclusions, or thickness variations that can significantly impact magnetic performance. As production scales up, automated vision systems can be deployed for real-time inspection of ribbon surfaces during manufacturing.

Thermal analysis techniques, particularly differential scanning calorimetry (DSC), are vital for determining crystallization temperatures and thermal stability of the amorphous alloys. This information guides processing parameters and helps establish quality control thresholds for heat treatment operations in downstream processing.

Mechanical property testing, including tensile strength and hardness measurements, provides insights into ribbon durability and handling characteristics during core assembly processes. These properties must remain consistent as production volumes increase to ensure reliable component manufacturing.

Compositional analysis through techniques such as energy-dispersive X-ray spectroscopy (EDX) or inductively coupled plasma mass spectrometry (ICP-MS) verifies elemental composition consistency, which is crucial for maintaining magnetic properties. Slight variations in critical elements like Fe, Co, B, or Si can significantly alter performance characteristics.

Implementation of statistical quality control methodologies becomes increasingly important during scale-up, with control charts and capability indices providing quantitative measures of process stability and product consistency. Advanced data analytics can identify correlations between processing parameters and final material properties, enabling predictive quality control approaches.

Economic Feasibility and Cost Optimization Approaches

The economic feasibility of scaling up manufacturing for melt-spun ribbons of amorphous soft magnetic alloys presents significant challenges and opportunities. Initial capital investment requirements are substantial, with specialized equipment costs ranging from $5-15 million for industrial-scale melt-spinning facilities. This includes high-precision rapid solidification systems, controlled atmosphere chambers, and precision winding mechanisms that maintain ribbon quality at higher production volumes.

Production economics improve considerably with scale, as demonstrated by recent industry analyses showing unit cost reductions of 30-45% when transitioning from pilot to full-scale production. However, these economies of scale are only realized after overcoming the steep learning curve associated with process optimization and yield improvement, typically requiring 12-18 months of continuous refinement.

Raw material costs represent 40-60% of total production expenses, with rare earth elements and high-purity transition metals contributing significantly to this proportion. Strategic approaches to cost optimization include developing alloy formulations with reduced dependence on volatile-priced elements while maintaining magnetic performance characteristics. Several manufacturers have successfully implemented recycling systems that recover up to 25% of waste material generated during edge trimming and quality control rejections.

Energy consumption optimization presents another critical cost factor, as the rapid quenching process is inherently energy-intensive. Advanced facilities have implemented regenerative heating systems and precision power control algorithms, achieving energy efficiency improvements of 15-20% compared to conventional methods. These innovations directly translate to operational cost reductions while simultaneously reducing carbon footprint.

Yield management represents perhaps the most significant economic lever in scale-up operations. Current industry benchmarks indicate that top-performing facilities achieve consistent yields of 85-90%, compared to 60-70% in less optimized operations. This differential dramatically impacts unit economics, as each percentage point of yield improvement typically translates to a 1.2-1.5% reduction in total production costs.

Labor costs vary significantly by region but generally constitute 15-25% of production expenses. Automation of ribbon handling, inspection, and packaging processes has proven effective in reducing labor intensity while improving consistency. The most advanced facilities maintain production rates of 50-80 kg/hour with minimal manual intervention, representing a 3-4x improvement over previous generation manufacturing approaches.

Production economics improve considerably with scale, as demonstrated by recent industry analyses showing unit cost reductions of 30-45% when transitioning from pilot to full-scale production. However, these economies of scale are only realized after overcoming the steep learning curve associated with process optimization and yield improvement, typically requiring 12-18 months of continuous refinement.

Raw material costs represent 40-60% of total production expenses, with rare earth elements and high-purity transition metals contributing significantly to this proportion. Strategic approaches to cost optimization include developing alloy formulations with reduced dependence on volatile-priced elements while maintaining magnetic performance characteristics. Several manufacturers have successfully implemented recycling systems that recover up to 25% of waste material generated during edge trimming and quality control rejections.

Energy consumption optimization presents another critical cost factor, as the rapid quenching process is inherently energy-intensive. Advanced facilities have implemented regenerative heating systems and precision power control algorithms, achieving energy efficiency improvements of 15-20% compared to conventional methods. These innovations directly translate to operational cost reductions while simultaneously reducing carbon footprint.

Yield management represents perhaps the most significant economic lever in scale-up operations. Current industry benchmarks indicate that top-performing facilities achieve consistent yields of 85-90%, compared to 60-70% in less optimized operations. This differential dramatically impacts unit economics, as each percentage point of yield improvement typically translates to a 1.2-1.5% reduction in total production costs.

Labor costs vary significantly by region but generally constitute 15-25% of production expenses. Automation of ribbon handling, inspection, and packaging processes has proven effective in reducing labor intensity while improving consistency. The most advanced facilities maintain production rates of 50-80 kg/hour with minimal manual intervention, representing a 3-4x improvement over previous generation manufacturing approaches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!