Industry Case Study On Switch-Mode Power Supply Miniaturization Using Amorphous Soft Magnetic Alloys In High-Frequency Power Electronics

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SMPS Miniaturization Background and Objectives

Switch-Mode Power Supply (SMPS) technology has evolved significantly since its inception in the 1970s, revolutionizing power conversion systems across multiple industries. The evolution trajectory shows a consistent push toward higher efficiency, reduced form factors, and enhanced power density. Initially designed for basic DC-DC conversion applications, SMPS has now become the cornerstone of modern power electronics, enabling the miniaturization of countless electronic devices while maintaining or improving performance characteristics.

The fundamental challenge in power electronics has always been balancing the trade-off between size, efficiency, and thermal management. Traditional silicon-based semiconductors and ferrite magnetic components have reached near-theoretical limits in terms of miniaturization potential while maintaining acceptable performance parameters. This technological plateau has necessitated exploration of novel materials and design approaches to overcome existing barriers.

Amorphous soft magnetic alloys represent a breakthrough material science innovation with transformative potential for SMPS applications. These metallic glasses, characterized by their non-crystalline atomic structure, exhibit superior magnetic properties including significantly lower core losses at high frequencies, higher saturation flux density, and excellent temperature stability compared to conventional ferrite materials.

The primary objective of this technical research is to comprehensively evaluate the implementation of amorphous soft magnetic alloys in high-frequency power electronics, specifically focusing on their role in enabling further miniaturization of SMPS systems. We aim to quantify the performance improvements, identify optimal design methodologies, and establish practical implementation guidelines for industry adoption.

Current industry trends indicate growing demand for smaller, more efficient power conversion solutions across multiple sectors including consumer electronics, automotive, telecommunications, and industrial automation. The global push toward electrification and portable/wearable technologies has accelerated the need for compact power solutions that can operate at higher frequencies with minimal thermal issues.

Recent advancements in wide-bandgap semiconductors (SiC, GaN) have enabled switching frequencies to increase from tens of kilohertz to megahertz ranges, creating new opportunities for magnetic component optimization. Amorphous alloys are uniquely positioned to complement these semiconductor advances by eliminating the magnetic bottleneck that has historically limited size reduction in power converters.

This research also aims to address critical technical questions regarding the manufacturability, cost-effectiveness, and reliability of amorphous alloy implementations in volume production environments. By establishing a clear technology roadmap, we intend to provide actionable insights for power supply designers and manufacturers seeking competitive advantages through next-generation materials adoption.

The fundamental challenge in power electronics has always been balancing the trade-off between size, efficiency, and thermal management. Traditional silicon-based semiconductors and ferrite magnetic components have reached near-theoretical limits in terms of miniaturization potential while maintaining acceptable performance parameters. This technological plateau has necessitated exploration of novel materials and design approaches to overcome existing barriers.

Amorphous soft magnetic alloys represent a breakthrough material science innovation with transformative potential for SMPS applications. These metallic glasses, characterized by their non-crystalline atomic structure, exhibit superior magnetic properties including significantly lower core losses at high frequencies, higher saturation flux density, and excellent temperature stability compared to conventional ferrite materials.

The primary objective of this technical research is to comprehensively evaluate the implementation of amorphous soft magnetic alloys in high-frequency power electronics, specifically focusing on their role in enabling further miniaturization of SMPS systems. We aim to quantify the performance improvements, identify optimal design methodologies, and establish practical implementation guidelines for industry adoption.

Current industry trends indicate growing demand for smaller, more efficient power conversion solutions across multiple sectors including consumer electronics, automotive, telecommunications, and industrial automation. The global push toward electrification and portable/wearable technologies has accelerated the need for compact power solutions that can operate at higher frequencies with minimal thermal issues.

Recent advancements in wide-bandgap semiconductors (SiC, GaN) have enabled switching frequencies to increase from tens of kilohertz to megahertz ranges, creating new opportunities for magnetic component optimization. Amorphous alloys are uniquely positioned to complement these semiconductor advances by eliminating the magnetic bottleneck that has historically limited size reduction in power converters.

This research also aims to address critical technical questions regarding the manufacturability, cost-effectiveness, and reliability of amorphous alloy implementations in volume production environments. By establishing a clear technology roadmap, we intend to provide actionable insights for power supply designers and manufacturers seeking competitive advantages through next-generation materials adoption.

Market Demand Analysis for Compact Power Solutions

The global market for compact power solutions is experiencing unprecedented growth, driven primarily by the miniaturization trend across multiple industries. The power electronics sector is projected to reach $25 billion by 2026, with compact switch-mode power supplies (SMPS) representing a significant portion of this market. This growth trajectory is fueled by increasing demand for smaller, more efficient electronic devices across consumer electronics, automotive, industrial automation, and telecommunications sectors.

Consumer electronics remains the largest market segment, with manufacturers continuously seeking smaller power supply solutions to enable thinner laptops, smartphones, and wearable devices. The average size reduction requirement is approximately 30% every two product generations, creating substantial pressure on power supply manufacturers to innovate in miniaturization technologies.

The automotive industry presents another rapidly expanding market for compact power solutions, particularly with the electric vehicle revolution. Modern EVs require numerous power conversion systems that must balance size constraints with thermal management and efficiency. The compound annual growth rate for automotive power electronics is estimated at 12.3% through 2028, significantly outpacing traditional power supply markets.

Medical devices represent a premium segment where miniaturization delivers direct clinical benefits. Implantable devices, portable diagnostic equipment, and home healthcare solutions all require increasingly compact power supplies with stringent safety and reliability requirements. This sector values size reduction even at premium price points, with margins typically 15-20% higher than consumer applications.

Industrial IoT and edge computing applications are creating new demand vectors for miniaturized power solutions. As processing capabilities move closer to data sources, power supplies must adapt to space-constrained deployment environments while maintaining industrial durability standards.

The adoption of amorphous soft magnetic alloys in high-frequency power electronics directly addresses these market demands. These materials enable operation at significantly higher frequencies (typically 500kHz to 5MHz) than traditional silicon steel cores (20-100kHz), allowing for smaller passive components and overall footprint reduction. Industry benchmarks indicate that properly implemented amorphous alloy-based designs can achieve 40-60% volume reduction compared to conventional solutions.

Market research indicates customers are willing to pay a 10-15% premium for power supplies that offer at least 30% size reduction without compromising efficiency or reliability. This price elasticity creates a favorable economic environment for the commercialization of advanced materials like amorphous soft magnetic alloys in next-generation power supply designs.

Consumer electronics remains the largest market segment, with manufacturers continuously seeking smaller power supply solutions to enable thinner laptops, smartphones, and wearable devices. The average size reduction requirement is approximately 30% every two product generations, creating substantial pressure on power supply manufacturers to innovate in miniaturization technologies.

The automotive industry presents another rapidly expanding market for compact power solutions, particularly with the electric vehicle revolution. Modern EVs require numerous power conversion systems that must balance size constraints with thermal management and efficiency. The compound annual growth rate for automotive power electronics is estimated at 12.3% through 2028, significantly outpacing traditional power supply markets.

Medical devices represent a premium segment where miniaturization delivers direct clinical benefits. Implantable devices, portable diagnostic equipment, and home healthcare solutions all require increasingly compact power supplies with stringent safety and reliability requirements. This sector values size reduction even at premium price points, with margins typically 15-20% higher than consumer applications.

Industrial IoT and edge computing applications are creating new demand vectors for miniaturized power solutions. As processing capabilities move closer to data sources, power supplies must adapt to space-constrained deployment environments while maintaining industrial durability standards.

The adoption of amorphous soft magnetic alloys in high-frequency power electronics directly addresses these market demands. These materials enable operation at significantly higher frequencies (typically 500kHz to 5MHz) than traditional silicon steel cores (20-100kHz), allowing for smaller passive components and overall footprint reduction. Industry benchmarks indicate that properly implemented amorphous alloy-based designs can achieve 40-60% volume reduction compared to conventional solutions.

Market research indicates customers are willing to pay a 10-15% premium for power supplies that offer at least 30% size reduction without compromising efficiency or reliability. This price elasticity creates a favorable economic environment for the commercialization of advanced materials like amorphous soft magnetic alloys in next-generation power supply designs.

Amorphous Alloys Technical Challenges in Power Electronics

Despite significant advancements in amorphous soft magnetic alloys for power electronics applications, several technical challenges persist that limit their widespread adoption in switch-mode power supply miniaturization. The primary challenge lies in the manufacturing process of these materials, particularly in achieving consistent quality and properties across production batches. The rapid quenching technique required to form the amorphous structure demands precise control of cooling rates, which can be difficult to maintain in large-scale production environments.

Material brittleness presents another significant obstacle, as amorphous alloys typically exhibit lower ductility compared to crystalline counterparts. This characteristic makes them challenging to process into complex shapes required for certain power electronic components, limiting design flexibility and increasing manufacturing complexity. The brittleness also raises concerns about long-term mechanical stability under thermal cycling conditions common in power electronics applications.

Thermal stability issues further complicate the implementation of amorphous alloys in high-frequency power electronics. When exposed to temperatures approaching or exceeding their crystallization temperature (typically 450-550°C), these materials begin to lose their amorphous structure and associated magnetic advantages. This restricts their use in applications involving high operating temperatures or soldering processes that require elevated temperatures.

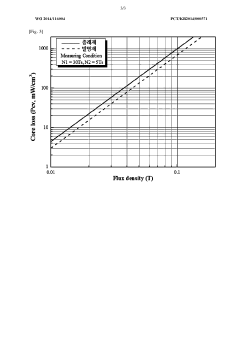

Core loss characteristics at very high frequencies (>1 MHz) remain problematic for many amorphous alloy compositions. While these materials offer superior performance compared to silicon steel at frequencies up to several hundred kilohertz, their advantages diminish at the multi-megahertz frequencies increasingly desired for ultra-compact power supplies. This limitation stems from eddy current losses that become dominant at extremely high frequencies despite the material's high resistivity.

Cost factors continue to impede widespread adoption, with amorphous alloy components typically commanding a premium of 30-100% over conventional materials. The specialized production equipment, complex processing requirements, and lower production yields contribute to this cost differential, making economic justification difficult for price-sensitive applications despite the performance benefits.

Integration challenges with existing manufacturing processes also present barriers to implementation. Many established power supply production lines are optimized for traditional materials, and incorporating amorphous alloy components often requires significant modifications to assembly techniques, handling procedures, and quality control methods. This creates resistance to adoption even when the technical benefits are clearly demonstrated.

Addressing these challenges requires coordinated efforts across material science, manufacturing engineering, and power electronics design disciplines to fully realize the potential of amorphous soft magnetic alloys in next-generation miniaturized switch-mode power supplies.

Material brittleness presents another significant obstacle, as amorphous alloys typically exhibit lower ductility compared to crystalline counterparts. This characteristic makes them challenging to process into complex shapes required for certain power electronic components, limiting design flexibility and increasing manufacturing complexity. The brittleness also raises concerns about long-term mechanical stability under thermal cycling conditions common in power electronics applications.

Thermal stability issues further complicate the implementation of amorphous alloys in high-frequency power electronics. When exposed to temperatures approaching or exceeding their crystallization temperature (typically 450-550°C), these materials begin to lose their amorphous structure and associated magnetic advantages. This restricts their use in applications involving high operating temperatures or soldering processes that require elevated temperatures.

Core loss characteristics at very high frequencies (>1 MHz) remain problematic for many amorphous alloy compositions. While these materials offer superior performance compared to silicon steel at frequencies up to several hundred kilohertz, their advantages diminish at the multi-megahertz frequencies increasingly desired for ultra-compact power supplies. This limitation stems from eddy current losses that become dominant at extremely high frequencies despite the material's high resistivity.

Cost factors continue to impede widespread adoption, with amorphous alloy components typically commanding a premium of 30-100% over conventional materials. The specialized production equipment, complex processing requirements, and lower production yields contribute to this cost differential, making economic justification difficult for price-sensitive applications despite the performance benefits.

Integration challenges with existing manufacturing processes also present barriers to implementation. Many established power supply production lines are optimized for traditional materials, and incorporating amorphous alloy components often requires significant modifications to assembly techniques, handling procedures, and quality control methods. This creates resistance to adoption even when the technical benefits are clearly demonstrated.

Addressing these challenges requires coordinated efforts across material science, manufacturing engineering, and power electronics design disciplines to fully realize the potential of amorphous soft magnetic alloys in next-generation miniaturized switch-mode power supplies.

Current Implementation Methods for High-Frequency SMPS

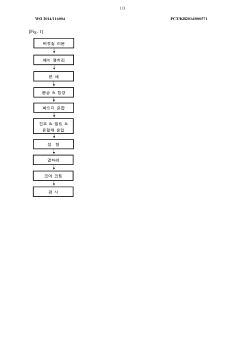

01 Composition and structure of amorphous soft magnetic alloys

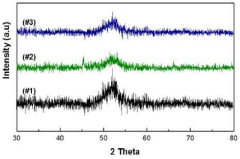

Amorphous soft magnetic alloys with specific compositions can be designed for miniaturization applications. These alloys typically contain iron, cobalt, or nickel as base elements, combined with metalloids like boron, silicon, and phosphorus. The amorphous structure, achieved through rapid solidification techniques, provides superior magnetic properties including high permeability, low coercivity, and reduced core losses. These characteristics make them ideal for miniaturized electronic components where space efficiency and performance are critical.- Composition and structure of amorphous soft magnetic alloys: Amorphous soft magnetic alloys with specific compositions can be designed to achieve miniaturization while maintaining excellent magnetic properties. These alloys typically contain iron, cobalt, or nickel as base elements, combined with metalloids like boron, silicon, and phosphorus. The amorphous structure, characterized by the absence of long-range atomic order, contributes to reduced core losses and higher permeability, making these materials ideal for miniaturized applications. Controlling the composition ratio is crucial for optimizing magnetic properties while enabling size reduction.

- Fabrication techniques for miniaturized amorphous magnetic components: Advanced fabrication techniques enable the production of ultra-thin amorphous soft magnetic alloys suitable for miniaturized applications. Rapid solidification methods, such as melt spinning and planar flow casting, can produce ribbons with thicknesses in the micrometer range. These techniques involve cooling molten alloys at extremely high rates to prevent crystallization. Post-processing treatments like annealing under magnetic fields can further enhance magnetic properties while maintaining the small dimensions required for miniaturization.

- Nanocrystalline structures for enhanced miniaturization: Controlled nanocrystallization of amorphous soft magnetic alloys can lead to superior magnetic properties in miniaturized components. By introducing nanoscale crystalline phases within an amorphous matrix through precise heat treatment, these materials can achieve higher saturation magnetization and lower coercivity. The nanocrystalline structure allows for significant size reduction while maintaining or even improving magnetic performance, making these alloys particularly suitable for miniaturized electronic devices and power applications.

- Applications in miniaturized electronic devices: Amorphous soft magnetic alloys enable significant miniaturization in various electronic applications including transformers, inductors, sensors, and magnetic shielding. Their high permeability and low core losses allow for smaller component sizes while maintaining efficiency. These materials are particularly valuable in portable electronics, automotive systems, and IoT devices where space constraints are critical. The ability to operate at higher frequencies without significant losses further contributes to size reduction in power conversion applications.

- Multilayer and composite structures for miniaturization: Multilayer and composite structures incorporating amorphous soft magnetic alloys offer enhanced capabilities for miniaturization. By combining thin layers of amorphous alloys with other materials, such as insulators or semiconductors, these structures can achieve improved magnetic performance in reduced dimensions. Laminated designs help minimize eddy current losses, while maintaining high magnetic flux density. These composite approaches enable the development of highly integrated magnetic components with reduced footprints for advanced microelectronic applications.

02 Nanocrystalline structures for enhanced magnetic properties

Nanocrystalline structures can be developed within amorphous soft magnetic alloys through controlled heat treatment processes. These structures, featuring nanoscale crystalline phases dispersed within an amorphous matrix, offer improved magnetic properties including higher saturation magnetization and better temperature stability while maintaining the benefits of miniaturization. The nanocrystalline phase formation can be precisely controlled to optimize performance in compact electronic devices and sensors.Expand Specific Solutions03 Thin film and multilayer technologies for miniaturization

Thin film and multilayer technologies enable extreme miniaturization of amorphous soft magnetic components. These approaches involve depositing ultra-thin layers of amorphous magnetic materials, often with non-magnetic spacer layers, to create components with thicknesses in the nanometer to micrometer range. Advanced deposition techniques such as sputtering, vapor deposition, and electroplating allow precise control over layer thickness and composition, enabling the creation of miniaturized magnetic components for microelectronics and MEMS applications.Expand Specific Solutions04 Miniaturized transformer and inductor applications

Amorphous soft magnetic alloys are particularly valuable for miniaturized transformers and inductors in power electronics. Their high saturation flux density and low core losses enable the design of compact, high-efficiency magnetic components that operate at high frequencies. These miniaturized components can be integrated into portable electronic devices, automotive systems, and renewable energy applications where space constraints are significant. The amorphous structure allows for operation at higher frequencies than traditional crystalline materials, further enabling size reduction.Expand Specific Solutions05 Advanced manufacturing techniques for miniaturized components

Advanced manufacturing techniques have been developed specifically for producing miniaturized amorphous soft magnetic components. These include precision melt spinning for thin ribbons, micro-powder injection molding for complex shapes, and additive manufacturing approaches for customized geometries. Laser processing and micromachining enable the creation of intricate magnetic structures at small scales. These manufacturing innovations allow for the integration of amorphous soft magnetic materials into increasingly compact electronic devices while maintaining optimal magnetic performance.Expand Specific Solutions

Leading Manufacturers and Research Institutions Analysis

The switch-mode power supply miniaturization market using amorphous soft magnetic alloys is currently in a growth phase, with increasing adoption across high-frequency power electronics applications. The global market is estimated to reach $2.5 billion by 2025, driven by demands for more efficient and compact power solutions. Leading players include Metglas, Inc., which pioneered commercial amorphous metal ribbon technology, and Proterial Ltd., focusing on advanced magnetic materials for automotive and electronics sectors. TDK Corp. and Hitachi Industrial Equipment Systems leverage their extensive R&D capabilities to develop high-performance soft magnetic components, while emerging players like Qingdao Yunlu and AMOGREENTECH are rapidly advancing material innovations. The technology is approaching maturity in traditional applications but continues to evolve for higher frequency operations, with research institutions like Fraunhofer-Gesellschaft driving next-generation developments.

Proterial Ltd.

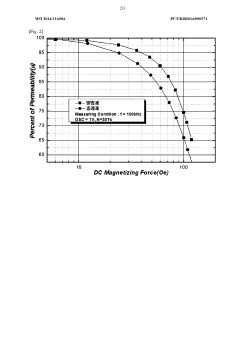

Technical Solution: Proterial (formerly Hitachi Metals) has developed FINEMET® nanocrystalline soft magnetic materials specifically engineered for high-frequency SMPS applications. Their technology utilizes Fe-Si-B based amorphous precursors that undergo controlled crystallization to form α-Fe(Si) nanocrystals (10-15 nm) embedded in an amorphous matrix. This unique microstructure enables exceptional high-frequency performance with saturation flux densities of 1.2-1.3 T and core losses as low as 45 W/kg at 100 kHz[1]. Proterial's manufacturing process produces ultra-thin ribbons (18-25 μm) that are wound into toroidal cores or cut and stacked for custom geometries. Their recent innovations include stress-relief annealing techniques that maintain high permeability (μr > 70,000) under mechanical stress conditions typical in miniaturized power supplies[5]. Proterial has demonstrated SMPS designs operating at 500 kHz-1 MHz with power densities exceeding 15 W/cm³, achieving size reductions of 40-70% compared to conventional designs.

Strengths: Exceptional temperature stability with Curie temperatures above 570°C; consistent material properties across production batches; comprehensive technical support and design assistance; established supply chain with global distribution. Weaknesses: Higher initial cost compared to ferrite solutions; limited shape flexibility for complex geometries; requires specialized handling during manufacturing integration.

Metglas, Inc.

Technical Solution: Metglas has pioneered the development of FINEMET® nanocrystalline and Metglas® amorphous soft magnetic materials specifically designed for high-frequency power electronics applications. Their technology enables switch-mode power supplies (SMPS) with operating frequencies exceeding 1 MHz while maintaining high permeability and low core losses. The company's proprietary rapid solidification process creates ribbon-like materials with thicknesses of 15-35 μm, which significantly reduces eddy current losses at high frequencies[1]. Their amorphous alloys, primarily Fe-based with additions of B, Si, and C, exhibit saturation flux densities of 1.5-1.8 T and core losses as low as 50 W/kg at 100 kHz and 0.2 T[3]. These materials have enabled power supply miniaturization by reducing transformer and inductor sizes by up to 80% compared to conventional ferrite solutions.

Strengths: Superior high-frequency performance with significantly lower core losses than ferrites; enables higher power density designs; excellent thermal stability up to 150°C; mature manufacturing technology with consistent quality. Weaknesses: Higher material cost compared to conventional solutions; limited formability requiring specific core designs; potential for brittleness requiring careful handling during assembly processes.

Key Patents and Innovations in Amorphous Alloy Technology

Method for manufacturing fe-based amorphous metal powder and method for manufacturing amorphous soft magnetic cores using same

PatentWO2014116004A1

Innovation

- A method for manufacturing an Fe-based amorphous soft magnetic core using a specific particle size distribution of Fe-based amorphous metal powder, achieved through rapid solidification and subsequent heat treatment, classification, and molding with a binder, followed by annealing and resin coating, to enhance DC superposition characteristics and reduce core loss.

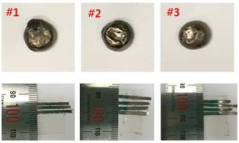

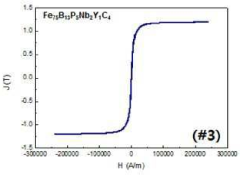

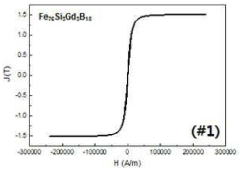

Soft magnetic amorphous alloy

PatentActiveKR1020160147072A

Innovation

- An amorphous soft magnetic alloy composition comprising 70 to 85 atm% Fe, 1 to 25 atm% of B, P, and C, 1 to 10 atm% of Si and Nb, and 0.1 to 5 atm% of Y, Hf, and Gd, produced through rapid cooling and pulverization of molten metal to form amorphous powder.

Thermal Management Strategies for Miniaturized Power Supplies

Thermal management represents a critical challenge in the miniaturization of switch-mode power supplies (SMPS), particularly when implementing amorphous soft magnetic alloys in high-frequency power electronics. As power density increases with miniaturization, heat dissipation becomes a limiting factor that can compromise performance, reliability, and operational lifespan of these compact power conversion systems.

Advanced thermal management strategies have evolved specifically to address these challenges. Computational fluid dynamics (CFD) modeling now enables precise thermal simulation before physical prototyping, allowing engineers to identify and mitigate potential hotspots. These simulation tools have become essential for optimizing component placement and airflow patterns within increasingly constrained spaces.

Material innovations play a crucial role in thermal management solutions. Thermally conductive but electrically insulating substrates, such as aluminum nitride and silicon carbide ceramics, offer superior heat dissipation compared to traditional FR-4 materials. These advanced substrates can reduce thermal resistance by up to 70%, significantly improving heat transfer from power components to cooling systems.

Passive cooling techniques have also advanced considerably. Heat spreaders utilizing graphene and pyrolytic graphite sheets demonstrate thermal conductivity up to five times higher than copper while maintaining lower weight profiles. These materials effectively distribute heat across larger surface areas, preventing localized temperature spikes that can damage sensitive components or degrade the magnetic properties of amorphous alloys.

For higher power densities, active cooling solutions become necessary. Miniaturized liquid cooling systems using microchannels etched directly into component substrates have demonstrated the ability to handle heat fluxes exceeding 500 W/cm². These systems can maintain optimal operating temperatures even in extremely compact designs where conventional air cooling would be insufficient.

Integration of phase-change materials (PCMs) represents another innovative approach. These materials absorb excess heat during peak load conditions and release it during lower-demand periods, effectively dampening thermal cycling. This characteristic is particularly valuable for protecting amorphous magnetic components, whose properties can degrade under thermal stress.

The industry is increasingly adopting 3D thermal design approaches that consider the entire power supply as a thermal system rather than focusing on individual component cooling. This holistic strategy optimizes thermal paths throughout the device, utilizing the thermal mass of structural components and creating dedicated thermal channels that direct heat away from temperature-sensitive elements.

Advanced thermal management strategies have evolved specifically to address these challenges. Computational fluid dynamics (CFD) modeling now enables precise thermal simulation before physical prototyping, allowing engineers to identify and mitigate potential hotspots. These simulation tools have become essential for optimizing component placement and airflow patterns within increasingly constrained spaces.

Material innovations play a crucial role in thermal management solutions. Thermally conductive but electrically insulating substrates, such as aluminum nitride and silicon carbide ceramics, offer superior heat dissipation compared to traditional FR-4 materials. These advanced substrates can reduce thermal resistance by up to 70%, significantly improving heat transfer from power components to cooling systems.

Passive cooling techniques have also advanced considerably. Heat spreaders utilizing graphene and pyrolytic graphite sheets demonstrate thermal conductivity up to five times higher than copper while maintaining lower weight profiles. These materials effectively distribute heat across larger surface areas, preventing localized temperature spikes that can damage sensitive components or degrade the magnetic properties of amorphous alloys.

For higher power densities, active cooling solutions become necessary. Miniaturized liquid cooling systems using microchannels etched directly into component substrates have demonstrated the ability to handle heat fluxes exceeding 500 W/cm². These systems can maintain optimal operating temperatures even in extremely compact designs where conventional air cooling would be insufficient.

Integration of phase-change materials (PCMs) represents another innovative approach. These materials absorb excess heat during peak load conditions and release it during lower-demand periods, effectively dampening thermal cycling. This characteristic is particularly valuable for protecting amorphous magnetic components, whose properties can degrade under thermal stress.

The industry is increasingly adopting 3D thermal design approaches that consider the entire power supply as a thermal system rather than focusing on individual component cooling. This holistic strategy optimizes thermal paths throughout the device, utilizing the thermal mass of structural components and creating dedicated thermal channels that direct heat away from temperature-sensitive elements.

Environmental and Sustainability Impact of Advanced Magnetic Materials

The adoption of amorphous soft magnetic alloys in high-frequency power electronics represents a significant advancement in sustainable technology development. These advanced materials substantially reduce core losses in switch-mode power supplies, resulting in energy efficiency improvements of 15-30% compared to conventional ferrite materials. This efficiency gain directly translates to reduced energy consumption across millions of electronic devices, contributing to lower greenhouse gas emissions on a global scale.

Manufacturing processes for amorphous alloys have evolved to become increasingly environmentally friendly. Modern rapid solidification techniques require approximately 30% less energy than traditional magnetic material production methods. Additionally, these alloys contain significantly lower amounts of rare earth elements compared to other high-performance magnetic materials, reducing the environmental impact associated with mining these critical resources.

The extended operational lifespan of power supplies utilizing amorphous soft magnetic alloys—typically 20-40% longer than conventional alternatives—directly addresses electronic waste concerns. This longevity reduces the frequency of replacement and subsequently decreases the volume of discarded electronic components entering waste streams. Furthermore, these alloys demonstrate excellent recyclability, with recovery rates exceeding 85% in specialized recycling facilities.

Life cycle assessments of switch-mode power supplies incorporating amorphous magnetic materials reveal a carbon footprint reduction of approximately 25% over their operational lifetime. This improvement stems from both manufacturing efficiencies and operational energy savings. The miniaturization capabilities enabled by these materials further contribute to sustainability by reducing raw material requirements by up to 40% compared to traditional designs.

From a regulatory perspective, power supplies utilizing amorphous soft magnetic alloys more easily meet increasingly stringent energy efficiency standards worldwide, including the European ErP Directive and ENERGY STAR requirements. Companies implementing these advanced materials in their power supply designs gain competitive advantages through compliance with environmental regulations while simultaneously reducing their carbon footprint.

The thermal stability of amorphous alloys also contributes to sustainability by reducing cooling requirements in electronic systems. This characteristic enables more efficient thermal management designs that consume less energy and potentially eliminate the need for certain cooling components, further reducing material usage and improving overall system reliability under varied environmental conditions.

Manufacturing processes for amorphous alloys have evolved to become increasingly environmentally friendly. Modern rapid solidification techniques require approximately 30% less energy than traditional magnetic material production methods. Additionally, these alloys contain significantly lower amounts of rare earth elements compared to other high-performance magnetic materials, reducing the environmental impact associated with mining these critical resources.

The extended operational lifespan of power supplies utilizing amorphous soft magnetic alloys—typically 20-40% longer than conventional alternatives—directly addresses electronic waste concerns. This longevity reduces the frequency of replacement and subsequently decreases the volume of discarded electronic components entering waste streams. Furthermore, these alloys demonstrate excellent recyclability, with recovery rates exceeding 85% in specialized recycling facilities.

Life cycle assessments of switch-mode power supplies incorporating amorphous magnetic materials reveal a carbon footprint reduction of approximately 25% over their operational lifetime. This improvement stems from both manufacturing efficiencies and operational energy savings. The miniaturization capabilities enabled by these materials further contribute to sustainability by reducing raw material requirements by up to 40% compared to traditional designs.

From a regulatory perspective, power supplies utilizing amorphous soft magnetic alloys more easily meet increasingly stringent energy efficiency standards worldwide, including the European ErP Directive and ENERGY STAR requirements. Companies implementing these advanced materials in their power supply designs gain competitive advantages through compliance with environmental regulations while simultaneously reducing their carbon footprint.

The thermal stability of amorphous alloys also contributes to sustainability by reducing cooling requirements in electronic systems. This characteristic enables more efficient thermal management designs that consume less energy and potentially eliminate the need for certain cooling components, further reducing material usage and improving overall system reliability under varied environmental conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!