CSAC Thermal Isolation: Materials And Mechanical Design Options

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CSAC Thermal Isolation Background and Objectives

Chip-Scale Atomic Clocks (CSACs) represent a significant advancement in precision timing technology, miniaturizing atomic clock capabilities into remarkably compact form factors. The development of CSACs began in the early 2000s, primarily driven by DARPA's initiatives to create highly accurate timing devices for military and aerospace applications. The evolution of this technology has been characterized by continuous efforts to reduce size, weight, and power consumption while maintaining exceptional timing accuracy.

Thermal isolation stands as a critical challenge in CSAC design, as atomic frequency references are highly sensitive to temperature fluctuations. Even minor thermal variations can significantly impact clock stability and accuracy. The physics underlying atomic clocks requires precise control of the atomic vapor cell temperature, typically maintained at elevated levels (70-80°C) to ensure optimal atomic behavior. This creates an inherent thermal management challenge within the confined dimensions of chip-scale devices.

The technical objectives for CSAC thermal isolation focus on several key parameters. First, achieving thermal stability of less than ±0.1°C at the physics package despite external temperature variations of ±50°C or more. Second, minimizing power consumption for heating elements to below 10mW, essential for portable applications. Third, developing isolation solutions that maintain the compact form factor, ideally keeping the overall device volume under 1cm³.

Historical approaches to thermal isolation have evolved from basic insulating materials to sophisticated multi-layer designs incorporating vacuum gaps and advanced composite materials. Early CSACs utilized simple polymer insulation, which proved inadequate for stringent performance requirements. The technology progression has seen the introduction of MEMS-based solutions, vacuum packaging techniques, and aerogel implementations, each offering incremental improvements in thermal efficiency.

Current research trends point toward hybrid approaches that combine multiple isolation strategies, including advanced materials science innovations such as nano-structured thermal barriers and active compensation systems. The goal is to develop solutions that not only provide superior thermal isolation but also remain compatible with mass production techniques and cost-effective manufacturing processes.

The technical trajectory suggests that future CSAC designs will likely incorporate increasingly sophisticated thermal management architectures, potentially leveraging developments from adjacent fields such as space technology and semiconductor packaging. The ultimate objective remains consistent: to create thermal isolation systems that enable atomic clock precision in increasingly challenging operational environments while supporting the continued miniaturization of these critical timing devices.

Thermal isolation stands as a critical challenge in CSAC design, as atomic frequency references are highly sensitive to temperature fluctuations. Even minor thermal variations can significantly impact clock stability and accuracy. The physics underlying atomic clocks requires precise control of the atomic vapor cell temperature, typically maintained at elevated levels (70-80°C) to ensure optimal atomic behavior. This creates an inherent thermal management challenge within the confined dimensions of chip-scale devices.

The technical objectives for CSAC thermal isolation focus on several key parameters. First, achieving thermal stability of less than ±0.1°C at the physics package despite external temperature variations of ±50°C or more. Second, minimizing power consumption for heating elements to below 10mW, essential for portable applications. Third, developing isolation solutions that maintain the compact form factor, ideally keeping the overall device volume under 1cm³.

Historical approaches to thermal isolation have evolved from basic insulating materials to sophisticated multi-layer designs incorporating vacuum gaps and advanced composite materials. Early CSACs utilized simple polymer insulation, which proved inadequate for stringent performance requirements. The technology progression has seen the introduction of MEMS-based solutions, vacuum packaging techniques, and aerogel implementations, each offering incremental improvements in thermal efficiency.

Current research trends point toward hybrid approaches that combine multiple isolation strategies, including advanced materials science innovations such as nano-structured thermal barriers and active compensation systems. The goal is to develop solutions that not only provide superior thermal isolation but also remain compatible with mass production techniques and cost-effective manufacturing processes.

The technical trajectory suggests that future CSAC designs will likely incorporate increasingly sophisticated thermal management architectures, potentially leveraging developments from adjacent fields such as space technology and semiconductor packaging. The ultimate objective remains consistent: to create thermal isolation systems that enable atomic clock precision in increasingly challenging operational environments while supporting the continued miniaturization of these critical timing devices.

Market Analysis for CSAC Thermal Solutions

The CSAC (Chip-Scale Atomic Clock) thermal solutions market is experiencing significant growth driven by expanding applications in telecommunications, defense, aerospace, and scientific research. The global market for CSAC thermal management solutions is currently valued at approximately $320 million and is projected to grow at a CAGR of 8.7% through 2028, reaching an estimated $485 million by the end of the forecast period.

The demand for CSAC thermal solutions is primarily fueled by the increasing adoption of precision timing devices in critical infrastructure, autonomous systems, and secure communications networks. Military and defense sectors represent the largest market segment, accounting for roughly 42% of the total market share, followed by telecommunications at 28%, aerospace at 17%, and scientific research at 13%.

Regional analysis indicates North America dominates the market with 38% share due to substantial defense investments and presence of major CSAC manufacturers. Asia-Pacific represents the fastest-growing region with a 10.2% growth rate, driven by expanding telecommunications infrastructure and increasing defense modernization programs in countries like China, India, and South Korea.

The market for advanced thermal isolation materials specifically designed for CSACs is growing at an accelerated rate of 11.3% annually, outpacing the overall market. This sub-segment is valued at approximately $85 million currently, with ceramic-based solutions commanding the largest share at 45%, followed by advanced polymer composites at 32% and aerogel-based solutions at 18%.

Customer requirements are increasingly focused on solutions that can maintain temperature stability within ±0.01°C while minimizing power consumption and physical footprint. The market shows a clear premium pricing trend for solutions that can achieve superior thermal isolation with minimal size and weight penalties, with customers willing to pay 30-40% more for solutions that reduce power consumption by at least 25%.

Emerging market opportunities include the growing demand for CSACs in autonomous vehicles, smart grid infrastructure, and next-generation mobile networks. These applications are expected to create a new market segment worth approximately $75 million by 2026, with thermal management being a critical differentiator for product success.

Market challenges include increasing price pressure from emerging competitors, particularly from Asian manufacturers offering lower-cost alternatives, and the technical complexity of balancing thermal isolation with size constraints. The average development cycle for new thermal isolation solutions remains lengthy at 18-24 months, creating opportunities for companies that can accelerate innovation timelines.

The demand for CSAC thermal solutions is primarily fueled by the increasing adoption of precision timing devices in critical infrastructure, autonomous systems, and secure communications networks. Military and defense sectors represent the largest market segment, accounting for roughly 42% of the total market share, followed by telecommunications at 28%, aerospace at 17%, and scientific research at 13%.

Regional analysis indicates North America dominates the market with 38% share due to substantial defense investments and presence of major CSAC manufacturers. Asia-Pacific represents the fastest-growing region with a 10.2% growth rate, driven by expanding telecommunications infrastructure and increasing defense modernization programs in countries like China, India, and South Korea.

The market for advanced thermal isolation materials specifically designed for CSACs is growing at an accelerated rate of 11.3% annually, outpacing the overall market. This sub-segment is valued at approximately $85 million currently, with ceramic-based solutions commanding the largest share at 45%, followed by advanced polymer composites at 32% and aerogel-based solutions at 18%.

Customer requirements are increasingly focused on solutions that can maintain temperature stability within ±0.01°C while minimizing power consumption and physical footprint. The market shows a clear premium pricing trend for solutions that can achieve superior thermal isolation with minimal size and weight penalties, with customers willing to pay 30-40% more for solutions that reduce power consumption by at least 25%.

Emerging market opportunities include the growing demand for CSACs in autonomous vehicles, smart grid infrastructure, and next-generation mobile networks. These applications are expected to create a new market segment worth approximately $75 million by 2026, with thermal management being a critical differentiator for product success.

Market challenges include increasing price pressure from emerging competitors, particularly from Asian manufacturers offering lower-cost alternatives, and the technical complexity of balancing thermal isolation with size constraints. The average development cycle for new thermal isolation solutions remains lengthy at 18-24 months, creating opportunities for companies that can accelerate innovation timelines.

Current Thermal Isolation Challenges in CSAC Technology

Chip-Scale Atomic Clocks (CSACs) face significant thermal isolation challenges that directly impact their performance, stability, and power consumption. The physics package of a CSAC requires precise temperature control of the atomic vapor cell, typically maintained at 70-90°C, while the surrounding electronics must operate at much lower temperatures. This thermal gradient creates fundamental engineering challenges that current solutions address with varying degrees of success.

The primary challenge lies in minimizing heat transfer between the heated physics package and surrounding components. Conductive heat loss through structural supports represents the most significant thermal pathway, requiring materials with low thermal conductivity yet sufficient mechanical strength to maintain structural integrity. Current solutions typically employ thin-walled structures made from materials like glass, ceramics, or specialized polymers, but these often present trade-offs between thermal isolation and mechanical robustness.

Convective heat transfer presents another significant challenge, particularly in miniaturized CSAC designs where internal air gaps are minimal. Vacuum packaging has emerged as a potential solution, but introduces manufacturing complexity and reliability concerns, especially regarding long-term vacuum integrity in field deployments. Some designs utilize low-pressure inert gas fills as a compromise between thermal isolation and manufacturing feasibility.

Radiative heat transfer becomes increasingly dominant as conductive and convective pathways are minimized. Current designs employ reflective coatings and radiation shields, but these add complexity and can interfere with optical pathways necessary for atomic interrogation. Multi-layer insulation techniques borrowed from aerospace applications show promise but require adaptation for the microscale dimensions of CSACs.

Power efficiency represents a critical challenge, as thermal control systems typically consume 30-50% of a CSAC's total power budget. Current heating approaches using resistive elements suffer from inefficient heat distribution and power consumption. Alternative heating technologies like microheaters and thin-film resistive elements offer improved efficiency but present integration challenges with existing manufacturing processes.

Thermal transient response also poses significant difficulties, particularly in applications requiring rapid warm-up or those experiencing frequent environmental temperature fluctuations. Current designs struggle to maintain atomic resonance stability during thermal transitions, leading to frequency drift and reduced timing accuracy during these periods. Advanced thermal modeling and active compensation algorithms help mitigate these effects but add computational overhead.

Material compatibility issues further complicate thermal isolation strategies, as materials must simultaneously satisfy thermal, mechanical, chemical, and magnetic requirements. Many excellent thermal insulators exhibit outgassing properties that can contaminate the atomic vapor, while others introduce magnetic field distortions that degrade clock performance.

The primary challenge lies in minimizing heat transfer between the heated physics package and surrounding components. Conductive heat loss through structural supports represents the most significant thermal pathway, requiring materials with low thermal conductivity yet sufficient mechanical strength to maintain structural integrity. Current solutions typically employ thin-walled structures made from materials like glass, ceramics, or specialized polymers, but these often present trade-offs between thermal isolation and mechanical robustness.

Convective heat transfer presents another significant challenge, particularly in miniaturized CSAC designs where internal air gaps are minimal. Vacuum packaging has emerged as a potential solution, but introduces manufacturing complexity and reliability concerns, especially regarding long-term vacuum integrity in field deployments. Some designs utilize low-pressure inert gas fills as a compromise between thermal isolation and manufacturing feasibility.

Radiative heat transfer becomes increasingly dominant as conductive and convective pathways are minimized. Current designs employ reflective coatings and radiation shields, but these add complexity and can interfere with optical pathways necessary for atomic interrogation. Multi-layer insulation techniques borrowed from aerospace applications show promise but require adaptation for the microscale dimensions of CSACs.

Power efficiency represents a critical challenge, as thermal control systems typically consume 30-50% of a CSAC's total power budget. Current heating approaches using resistive elements suffer from inefficient heat distribution and power consumption. Alternative heating technologies like microheaters and thin-film resistive elements offer improved efficiency but present integration challenges with existing manufacturing processes.

Thermal transient response also poses significant difficulties, particularly in applications requiring rapid warm-up or those experiencing frequent environmental temperature fluctuations. Current designs struggle to maintain atomic resonance stability during thermal transitions, leading to frequency drift and reduced timing accuracy during these periods. Advanced thermal modeling and active compensation algorithms help mitigate these effects but add computational overhead.

Material compatibility issues further complicate thermal isolation strategies, as materials must simultaneously satisfy thermal, mechanical, chemical, and magnetic requirements. Many excellent thermal insulators exhibit outgassing properties that can contaminate the atomic vapor, while others introduce magnetic field distortions that degrade clock performance.

Existing Thermal Isolation Materials and Design Approaches

01 Vacuum packaging for thermal isolation in CSACs

Vacuum packaging techniques are employed to provide thermal isolation in chip-scale atomic clocks. By creating a vacuum environment around the atomic clock components, heat transfer through conduction and convection is minimized, resulting in improved thermal stability. This isolation method helps maintain precise operating temperatures for the atomic resonance cells and reduces power consumption by preventing heat loss to the surrounding environment.- Vacuum packaging for thermal isolation in CSACs: Vacuum packaging techniques are employed to provide thermal isolation in chip-scale atomic clocks. By creating a vacuum environment around the atomic clock components, heat transfer through conduction and convection is minimized, resulting in improved thermal stability. This approach helps maintain precise operating temperatures for the atomic resonance cell while reducing power consumption required for heating elements. The vacuum encapsulation also protects sensitive components from environmental factors that could affect clock performance.

- MEMS-based thermal isolation structures: Microelectromechanical systems (MEMS) technology is utilized to create specialized thermal isolation structures for chip-scale atomic clocks. These structures include suspended platforms, thin bridges, and micromachined supports that minimize thermal conductivity paths between the heated atomic cell and surrounding components. By reducing thermal mass and creating air gaps, these MEMS structures provide effective thermal barriers while maintaining mechanical stability. This approach enables efficient temperature control of the atomic resonance cell with minimal power consumption.

- Multi-layer thermal isolation techniques: Multi-layer thermal isolation approaches incorporate various materials with different thermal properties to create effective insulation barriers in chip-scale atomic clocks. These designs utilize alternating layers of high and low thermal conductivity materials, reflective coatings, and specialized thermal interface materials. The layered structure creates thermal resistance paths that minimize heat transfer between critical components. This technique helps maintain temperature stability of the atomic resonance cell while preventing thermal interference with surrounding electronics.

- Active thermal management systems: Active thermal management systems employ temperature sensors, control circuits, and heating elements to dynamically regulate the thermal environment of chip-scale atomic clocks. These systems continuously monitor temperature variations and make real-time adjustments to maintain optimal operating conditions. Sophisticated algorithms optimize power consumption while ensuring temperature stability. The active approach compensates for environmental changes and aging effects, providing consistent performance across varying conditions and extending the operational lifetime of the atomic clock.

- Advanced materials for thermal isolation: Specialized materials with extremely low thermal conductivity are incorporated into chip-scale atomic clocks to achieve superior thermal isolation. These materials include aerogels, ceramic composites, and engineered polymers that provide exceptional insulating properties while meeting size constraints. Some designs utilize phase-change materials to absorb thermal fluctuations and maintain stable temperatures. The strategic placement of these advanced materials around critical components minimizes heat transfer and improves the overall energy efficiency of the atomic clock system.

02 MEMS-based thermal isolation structures

Microelectromechanical systems (MEMS) technology is utilized to create specialized thermal isolation structures for chip-scale atomic clocks. These structures include suspended platforms, thin bridges, and microfabricated support arms that minimize thermal conductivity paths between the heated atomic cell and the surrounding substrate. The MEMS-based approach allows for precise control of thermal isolation while maintaining the compact form factor required for chip-scale devices.Expand Specific Solutions03 Multi-layer thermal isolation materials and coatings

Advanced materials and multi-layer coatings are implemented to enhance thermal isolation in chip-scale atomic clocks. These include low thermal conductivity materials, reflective coatings to minimize radiative heat transfer, and specialized insulating layers. The strategic placement of these materials creates effective thermal barriers that help maintain temperature stability of the atomic resonance cell while reducing power requirements for heating elements.Expand Specific Solutions04 Active thermal management systems

Active thermal management systems are incorporated into chip-scale atomic clocks to maintain precise temperature control despite external environmental variations. These systems include miniaturized temperature sensors, feedback control circuits, and precision heating elements that work together to actively regulate the temperature of critical components. The active approach enables rapid warm-up times, stable operation across a wide ambient temperature range, and improved frequency stability of the atomic clock.Expand Specific Solutions05 Hermetic sealing and packaging techniques

Hermetic sealing and advanced packaging techniques are employed to provide thermal isolation in chip-scale atomic clocks. These methods include specialized bonding processes, gas-filled cavities with low thermal conductivity gases, and multi-chamber designs that create thermal barriers. The hermetic packaging not only provides thermal isolation but also protects sensitive atomic components from environmental contaminants that could affect clock performance and long-term stability.Expand Specific Solutions

Leading CSAC Manufacturers and Research Institutions

The CSAC Thermal Isolation market is in its growth phase, characterized by increasing demand for high-precision atomic clock technologies across aerospace, defense, and telecommunications sectors. The competitive landscape features established industrial conglomerates like Siemens AG, General Electric, and Rolls-Royce alongside specialized technology providers. From a technical maturity perspective, companies demonstrate varying capabilities: Siemens Energy and GE lead in thermal management systems, while Darchem Engineering and KGT Graphit Technologie offer specialized thermal isolation materials. Asian manufacturers like Shanghai Huali Microelectronics and BOE Technology are advancing in miniaturization and integration technologies, while research institutions such as Japan Fine Ceramics Center and Southern University of Science & Technology drive fundamental materials innovation for next-generation CSAC thermal isolation solutions.

Darchem Engineering Ltd.

Technical Solution: Darchem Engineering has leveraged their expertise in high-performance thermal insulation systems to develop specialized solutions for CSAC thermal isolation. Their approach centers on a proprietary multi-layer metallic and ceramic composite structure that combines extremely low thermal conductivity with excellent mechanical properties. The system utilizes thin-walled stainless steel honeycomb structures filled with ceramic fiber insulation, creating an effective thermal barrier with minimal mass. Darchem's design incorporates precision-engineered thermal standoffs manufactured from titanium alloys with complex geometries that maximize the conductive path length while maintaining structural integrity. Their solution also features specialized surface treatments that reduce radiative heat transfer by up to 90% compared to untreated surfaces. For CSAC applications, they've developed miniaturized versions of their aerospace-grade multi-layer insulation systems, achieving thermal conductivities as low as 0.005 W/mK while maintaining the mechanical robustness needed for portable applications.

Strengths: Extensive experience in designing thermal isolation systems for extreme environments, with proven manufacturing capabilities for high-reliability components used in aerospace and nuclear industries. Weaknesses: Their solutions may be more focused on industrial applications and might require significant adaptation for the miniaturized scale required by modern CSAC devices.

The Regents of the University of California

Technical Solution: The University of California has developed advanced thermal isolation solutions for Chip-Scale Atomic Clocks (CSACs) using multi-layered vacuum packaging technology. Their approach incorporates a vacuum-sealed cavity with specialized getter materials to maintain ultra-high vacuum levels (10^-6 Torr or better) around the physics package. The design employs a combination of ceramic substrates (typically aluminum nitride or aluminum oxide) with low thermal conductivity pathways and strategically placed thermal breaks. Their research has demonstrated that implementing multiple radiation shields with gold-plated surfaces can reduce radiative heat transfer by up to 85%. Additionally, they've pioneered the use of aerogel-based insulators with thermal conductivities as low as 0.015 W/mK, providing exceptional thermal isolation while maintaining mechanical stability. The University has also developed proprietary MEMS-based suspension systems that minimize conductive heat paths while providing sufficient mechanical support for the sensitive atomic reference cell.

Strengths: Exceptional research capabilities with access to advanced materials science expertise and fabrication facilities. Their solutions achieve industry-leading thermal isolation performance while maintaining long-term vacuum integrity. Weaknesses: Their designs may be more academically focused and potentially more expensive to implement in mass production environments compared to industry-developed solutions.

Critical Patents in CSAC Thermal Management

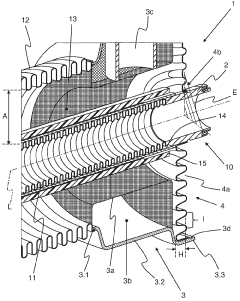

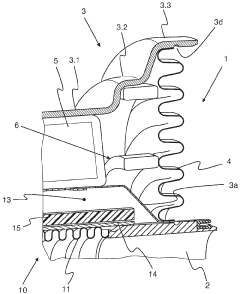

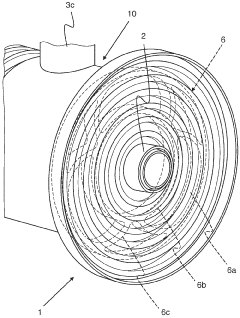

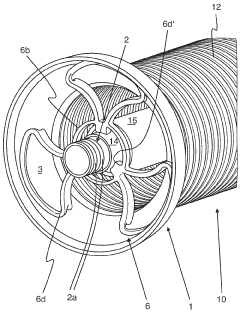

Connection assembly for a cryogenic line and cryogenic line

PatentWO2023213493A1

Innovation

- A connection arrangement featuring an inner and outer line element with a grooved membrane disk spacer, which creates a long heat conduction path transverse to the longitudinal axis, reducing axial length without compromising thermal insulation, and includes features like multi-layer insulation, adsorbers, and support elements for enhanced sealing and stability.

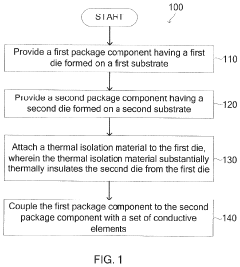

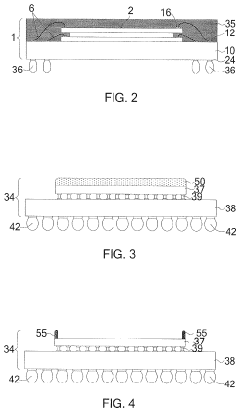

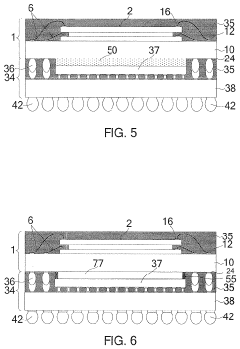

Package-on-Package Structure Including a Thermal Isolation Material

PatentPendingUS20230378153A1

Innovation

- Incorporating a thermal isolation material with low thermal conductivity, such as a porous film or seal ring with an air gap, to insulate the top die from the heat generated by the bottom die, thereby controlling warpage and enhancing mechanical strength.

Environmental Impact of Thermal Isolation Materials

The environmental impact of thermal isolation materials used in Chip-Scale Atomic Clocks (CSACs) represents a critical consideration in the development and deployment of these precision instruments. Traditional thermal isolation materials often contain compounds that pose significant environmental challenges throughout their lifecycle, from production to disposal.

Manufacturing processes for high-performance thermal insulators frequently involve energy-intensive methods and potentially hazardous chemicals. Ceramic-based insulators require high-temperature firing, consuming substantial energy and generating considerable carbon emissions. Similarly, aerogels and vacuum insulation panels (VIPs) utilize specialized production techniques that may incorporate environmentally problematic solvents and blowing agents.

The carbon footprint associated with thermal isolation materials varies significantly across different options. Polymer-based insulators generally exhibit lower production-phase emissions compared to their ceramic counterparts but may present greater end-of-life challenges. Recent life cycle assessments indicate that advanced multi-layer insulation systems can reduce overall environmental impact by 30-45% compared to conventional single-material approaches when considering the entire product lifecycle.

Toxicity concerns emerge particularly with flame retardants and processing additives commonly incorporated into thermal isolation materials. Halogenated compounds, while effective for enhancing fire resistance, persist in the environment and bioaccumulate in living organisms. Several materials traditionally used in CSACs contain substances now restricted under regulations such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals).

Disposal and recyclability present additional environmental challenges. The complex, multi-material nature of high-performance thermal isolation systems often complicates end-of-life processing. Ceramic-based insulators typically offer better recyclability than composite polymer systems, though the specialized nature of CSAC components may limit practical recovery options regardless of material selection.

Emerging eco-friendly alternatives show promising developments. Bio-based aerogels derived from cellulose and other renewable resources demonstrate thermal performance approaching that of synthetic counterparts while reducing environmental impact. Similarly, vacuum insulation technologies utilizing recycled content and non-toxic materials are advancing rapidly, offering potential pathways to more sustainable CSAC designs.

Regulatory frameworks increasingly influence material selection for thermal isolation. The European Union's Ecodesign Directive and similar initiatives worldwide are driving manufacturers toward more environmentally responsible choices. Companies developing CSACs must now balance thermal performance requirements against growing environmental compliance demands, creating both challenges and opportunities for innovation in thermal management approaches.

Manufacturing processes for high-performance thermal insulators frequently involve energy-intensive methods and potentially hazardous chemicals. Ceramic-based insulators require high-temperature firing, consuming substantial energy and generating considerable carbon emissions. Similarly, aerogels and vacuum insulation panels (VIPs) utilize specialized production techniques that may incorporate environmentally problematic solvents and blowing agents.

The carbon footprint associated with thermal isolation materials varies significantly across different options. Polymer-based insulators generally exhibit lower production-phase emissions compared to their ceramic counterparts but may present greater end-of-life challenges. Recent life cycle assessments indicate that advanced multi-layer insulation systems can reduce overall environmental impact by 30-45% compared to conventional single-material approaches when considering the entire product lifecycle.

Toxicity concerns emerge particularly with flame retardants and processing additives commonly incorporated into thermal isolation materials. Halogenated compounds, while effective for enhancing fire resistance, persist in the environment and bioaccumulate in living organisms. Several materials traditionally used in CSACs contain substances now restricted under regulations such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals).

Disposal and recyclability present additional environmental challenges. The complex, multi-material nature of high-performance thermal isolation systems often complicates end-of-life processing. Ceramic-based insulators typically offer better recyclability than composite polymer systems, though the specialized nature of CSAC components may limit practical recovery options regardless of material selection.

Emerging eco-friendly alternatives show promising developments. Bio-based aerogels derived from cellulose and other renewable resources demonstrate thermal performance approaching that of synthetic counterparts while reducing environmental impact. Similarly, vacuum insulation technologies utilizing recycled content and non-toxic materials are advancing rapidly, offering potential pathways to more sustainable CSAC designs.

Regulatory frameworks increasingly influence material selection for thermal isolation. The European Union's Ecodesign Directive and similar initiatives worldwide are driving manufacturers toward more environmentally responsible choices. Companies developing CSACs must now balance thermal performance requirements against growing environmental compliance demands, creating both challenges and opportunities for innovation in thermal management approaches.

Reliability Testing Standards for CSAC Thermal Solutions

Reliability testing standards for CSAC (Chip-Scale Atomic Clock) thermal solutions must be comprehensive and rigorous to ensure these critical components perform consistently under various environmental conditions. Industry standards such as MIL-STD-810G for environmental testing and MIL-STD-883 for microelectronic device testing provide foundational frameworks, but CSAC-specific thermal solution testing requires additional specialized protocols.

Temperature cycling tests represent a cornerstone of reliability assessment, typically requiring CSACs to withstand 500-1000 cycles between temperature extremes (-40°C to +85°C) with controlled ramp rates of 10-15°C per minute. Dwell times at temperature extremes should be sufficient to allow complete thermal stabilization, generally 15-30 minutes depending on the thermal mass of the specific CSAC design.

Thermal shock testing evaluates the resilience of materials and mechanical interfaces when subjected to rapid temperature changes. For CSAC thermal isolation systems, standards typically mandate survival of 100-200 cycles between temperature extremes with transition times under 10 seconds. This test specifically targets the integrity of material interfaces and bonding mechanisms within the thermal isolation structure.

Long-term thermal aging tests assess performance degradation over time, with CSACs subjected to elevated temperatures (typically 125°C) for 1000+ hours while periodically measuring frequency stability and power consumption. These tests help predict the long-term reliability of thermal isolation materials, particularly polymer-based solutions that may experience outgassing or mechanical property changes over time.

Humidity resistance testing combines elevated temperature (85°C) with high humidity (85% RH) for 1000 hours to evaluate moisture penetration and its effects on thermal isolation materials. This test is particularly important for CSACs deployed in maritime or tropical environments where moisture ingress could compromise thermal isolation performance.

Mechanical shock and vibration testing standards for CSAC thermal solutions must verify that the thermal isolation structures maintain their integrity during and after exposure to operational stresses. Random vibration profiles typically range from 20-2000 Hz at 7.5g RMS for operational conditions and up to 14g RMS for transportation scenarios, while mechanical shock testing requires survival of 100g, 6ms half-sine pulses in multiple orientations.

Thermal vacuum testing is essential for space applications, requiring CSACs to maintain performance through multiple thermal cycles in vacuum conditions below 10^-5 Torr. This test specifically evaluates outgassing characteristics of thermal isolation materials and their performance in the absence of convective heat transfer.

Combined environment testing represents the most comprehensive reliability assessment, subjecting CSACs to simultaneous thermal cycling, vibration, and humidity to identify potential interaction effects that might not be apparent in single-environment tests.

Temperature cycling tests represent a cornerstone of reliability assessment, typically requiring CSACs to withstand 500-1000 cycles between temperature extremes (-40°C to +85°C) with controlled ramp rates of 10-15°C per minute. Dwell times at temperature extremes should be sufficient to allow complete thermal stabilization, generally 15-30 minutes depending on the thermal mass of the specific CSAC design.

Thermal shock testing evaluates the resilience of materials and mechanical interfaces when subjected to rapid temperature changes. For CSAC thermal isolation systems, standards typically mandate survival of 100-200 cycles between temperature extremes with transition times under 10 seconds. This test specifically targets the integrity of material interfaces and bonding mechanisms within the thermal isolation structure.

Long-term thermal aging tests assess performance degradation over time, with CSACs subjected to elevated temperatures (typically 125°C) for 1000+ hours while periodically measuring frequency stability and power consumption. These tests help predict the long-term reliability of thermal isolation materials, particularly polymer-based solutions that may experience outgassing or mechanical property changes over time.

Humidity resistance testing combines elevated temperature (85°C) with high humidity (85% RH) for 1000 hours to evaluate moisture penetration and its effects on thermal isolation materials. This test is particularly important for CSACs deployed in maritime or tropical environments where moisture ingress could compromise thermal isolation performance.

Mechanical shock and vibration testing standards for CSAC thermal solutions must verify that the thermal isolation structures maintain their integrity during and after exposure to operational stresses. Random vibration profiles typically range from 20-2000 Hz at 7.5g RMS for operational conditions and up to 14g RMS for transportation scenarios, while mechanical shock testing requires survival of 100g, 6ms half-sine pulses in multiple orientations.

Thermal vacuum testing is essential for space applications, requiring CSACs to maintain performance through multiple thermal cycles in vacuum conditions below 10^-5 Torr. This test specifically evaluates outgassing characteristics of thermal isolation materials and their performance in the absence of convective heat transfer.

Combined environment testing represents the most comprehensive reliability assessment, subjecting CSACs to simultaneous thermal cycling, vibration, and humidity to identify potential interaction effects that might not be apparent in single-environment tests.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!