Long-Term Aging Effects In CSACs: Causes And Mitigation Strategies

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CSAC Aging Background and Research Objectives

Chip-Scale Atomic Clocks (CSACs) represent a significant advancement in precision timing technology, offering unprecedented accuracy in a compact form factor. Since their commercial introduction in the early 2000s, CSACs have revolutionized applications requiring precise timing in space-constrained environments. These devices utilize the quantum properties of alkali metal atoms, typically rubidium or cesium, to maintain frequency stability that far exceeds traditional quartz oscillators.

The evolution of CSAC technology has been marked by continuous improvements in size reduction, power efficiency, and performance reliability. Initially developed for military and aerospace applications, CSACs have gradually expanded into telecommunications, navigation systems, and scientific instrumentation. Despite these advancements, long-term aging effects remain a persistent challenge that impacts the practical deployment and operational lifespan of these devices.

Aging in CSACs manifests as a gradual drift in frequency output over time, compromising the very precision these devices are designed to deliver. This phenomenon has been observed across various CSAC implementations, with aging rates typically ranging from 10^-10 to 10^-11 per day. While these values may seem minuscule, they accumulate significantly over months and years of operation, potentially leading to timing errors that exceed acceptable thresholds for critical applications.

The primary objective of this technical research is to comprehensively investigate the fundamental causes of aging effects in CSACs and develop effective mitigation strategies. We aim to identify the physical and chemical mechanisms responsible for performance degradation, including buffer gas absorption, light shift variations, cell wall interactions, and electronic component aging. Understanding these mechanisms at a molecular level is crucial for designing next-generation CSACs with enhanced long-term stability.

Additionally, this research seeks to establish standardized methodologies for accelerated aging tests that can reliably predict long-term performance. Current testing protocols often fail to account for the complex interplay of aging factors, leading to discrepancies between laboratory results and field performance. By developing more accurate predictive models, we can better estimate operational lifespans and maintenance requirements for deployed systems.

The ultimate goal is to propose innovative design modifications and operational practices that can significantly reduce aging effects without compromising the compact form factor or power efficiency that makes CSACs valuable. This includes exploring alternative materials for cell construction, refined manufacturing processes, advanced compensation algorithms, and novel calibration techniques that can be implemented in both existing and future CSAC designs.

Through this comprehensive investigation, we aim to extend the practical operational lifetime of CSACs from the current industry standard of 5-7 years to beyond 10 years, while maintaining frequency stability within 10^-12 range throughout this extended period.

The evolution of CSAC technology has been marked by continuous improvements in size reduction, power efficiency, and performance reliability. Initially developed for military and aerospace applications, CSACs have gradually expanded into telecommunications, navigation systems, and scientific instrumentation. Despite these advancements, long-term aging effects remain a persistent challenge that impacts the practical deployment and operational lifespan of these devices.

Aging in CSACs manifests as a gradual drift in frequency output over time, compromising the very precision these devices are designed to deliver. This phenomenon has been observed across various CSAC implementations, with aging rates typically ranging from 10^-10 to 10^-11 per day. While these values may seem minuscule, they accumulate significantly over months and years of operation, potentially leading to timing errors that exceed acceptable thresholds for critical applications.

The primary objective of this technical research is to comprehensively investigate the fundamental causes of aging effects in CSACs and develop effective mitigation strategies. We aim to identify the physical and chemical mechanisms responsible for performance degradation, including buffer gas absorption, light shift variations, cell wall interactions, and electronic component aging. Understanding these mechanisms at a molecular level is crucial for designing next-generation CSACs with enhanced long-term stability.

Additionally, this research seeks to establish standardized methodologies for accelerated aging tests that can reliably predict long-term performance. Current testing protocols often fail to account for the complex interplay of aging factors, leading to discrepancies between laboratory results and field performance. By developing more accurate predictive models, we can better estimate operational lifespans and maintenance requirements for deployed systems.

The ultimate goal is to propose innovative design modifications and operational practices that can significantly reduce aging effects without compromising the compact form factor or power efficiency that makes CSACs valuable. This includes exploring alternative materials for cell construction, refined manufacturing processes, advanced compensation algorithms, and novel calibration techniques that can be implemented in both existing and future CSAC designs.

Through this comprehensive investigation, we aim to extend the practical operational lifetime of CSACs from the current industry standard of 5-7 years to beyond 10 years, while maintaining frequency stability within 10^-12 range throughout this extended period.

Market Analysis for Long-Term CSAC Applications

The Chip-Scale Atomic Clock (CSAC) market has experienced significant growth over the past decade, driven primarily by applications requiring precise timing in compact form factors. The global CSAC market is currently valued at approximately 300 million USD, with projections indicating growth to reach 550 million USD by 2028, representing a compound annual growth rate of 10.6%. This growth trajectory is supported by increasing demand across multiple sectors where long-term stability is critical.

Military and defense applications continue to dominate the CSAC market, accounting for roughly 40% of total demand. The need for reliable navigation systems in GPS-denied environments and secure communications infrastructure has positioned CSACs as essential components in modern defense technology. The long-term aging effects of these devices directly impact mission-critical operations, making reliability improvements a key market driver.

Telecommunications represents the second-largest market segment at 25%, where network synchronization demands increasingly stable timing references. As 5G infrastructure continues to expand globally, the requirement for precise timing synchronization across distributed networks has intensified interest in aging-resistant CSAC technology. Telecom operators are particularly concerned with reducing maintenance cycles and replacement costs associated with timing degradation.

Space applications constitute a rapidly growing segment (15% market share) where the harsh radiation environment accelerates aging effects in conventional timing devices. Satellite operators are increasingly adopting CSACs for their superior size-to-performance ratio, but remain concerned about long-term reliability in orbit where servicing is impossible or prohibitively expensive.

Industrial and scientific applications represent the remaining 20% of the market, spanning sectors from energy grid synchronization to scientific instrumentation. These applications typically have lower volume requirements but demand exceptional long-term stability characteristics.

Market research indicates that customers across all segments are willing to pay a premium of 15-30% for CSACs with demonstrated improvements in long-term aging characteristics. This price elasticity reflects the high downstream costs associated with timing failures and maintenance operations, particularly in remote or inaccessible installations.

Regional analysis shows North America leading CSAC adoption (45% market share), followed by Europe (30%) and Asia-Pacific (20%). However, the Asia-Pacific region is experiencing the fastest growth rate at 12.8% annually, driven by expanding telecommunications infrastructure and increasing defense modernization programs in countries like China, India, and South Korea.

Military and defense applications continue to dominate the CSAC market, accounting for roughly 40% of total demand. The need for reliable navigation systems in GPS-denied environments and secure communications infrastructure has positioned CSACs as essential components in modern defense technology. The long-term aging effects of these devices directly impact mission-critical operations, making reliability improvements a key market driver.

Telecommunications represents the second-largest market segment at 25%, where network synchronization demands increasingly stable timing references. As 5G infrastructure continues to expand globally, the requirement for precise timing synchronization across distributed networks has intensified interest in aging-resistant CSAC technology. Telecom operators are particularly concerned with reducing maintenance cycles and replacement costs associated with timing degradation.

Space applications constitute a rapidly growing segment (15% market share) where the harsh radiation environment accelerates aging effects in conventional timing devices. Satellite operators are increasingly adopting CSACs for their superior size-to-performance ratio, but remain concerned about long-term reliability in orbit where servicing is impossible or prohibitively expensive.

Industrial and scientific applications represent the remaining 20% of the market, spanning sectors from energy grid synchronization to scientific instrumentation. These applications typically have lower volume requirements but demand exceptional long-term stability characteristics.

Market research indicates that customers across all segments are willing to pay a premium of 15-30% for CSACs with demonstrated improvements in long-term aging characteristics. This price elasticity reflects the high downstream costs associated with timing failures and maintenance operations, particularly in remote or inaccessible installations.

Regional analysis shows North America leading CSAC adoption (45% market share), followed by Europe (30%) and Asia-Pacific (20%). However, the Asia-Pacific region is experiencing the fastest growth rate at 12.8% annually, driven by expanding telecommunications infrastructure and increasing defense modernization programs in countries like China, India, and South Korea.

Current Challenges in CSAC Aging Mechanisms

Chip-Scale Atomic Clocks (CSACs) face significant aging challenges that impact their long-term performance and reliability. The primary aging mechanism involves the physics package, where alkali metal vapor cells experience gradual degradation. This degradation manifests as frequency drift, typically ranging from 10^-10 to 10^-9 per day in early deployment, with rates generally decreasing over time but remaining unpredictable across individual units.

The vapor cell's internal environment presents a complex challenge, as buffer gases slowly react with cell walls or become absorbed into them. This chemical interaction alters the internal pressure and composition, directly affecting the hyperfine transition frequency that serves as the clock's reference. Additionally, the diffusion of alkali metals into cell walls creates another degradation pathway that progressively reduces vapor density and signal strength.

Temperature cycling exacerbates these issues by accelerating chemical reactions and creating mechanical stresses at material interfaces. The miniaturized nature of CSACs means even nanoscale changes can produce measurable frequency shifts, making them particularly vulnerable to aging effects compared to larger atomic clock technologies.

Electronic component aging introduces another layer of complexity. The local oscillator experiences drift from crystal aging, while analog components in control loops show parameter shifts over time. These electronic aging effects can cascade through the system, amplifying frequency instabilities and reducing overall performance predictability.

Power supply fluctuations and environmental radiation present additional challenges, as they can accelerate aging processes or create temporary performance anomalies that are difficult to distinguish from permanent aging effects. The radiation-induced degradation is particularly concerning for space applications where CSACs may encounter higher radiation levels.

Manufacturing variations further complicate aging management, as seemingly identical units can exhibit significantly different aging profiles. This variability stems from microscopic differences in material composition, surface treatments, and assembly processes that are difficult to control at scale. The lack of standardized accelerated aging protocols makes it challenging to predict long-term performance during qualification testing.

Current measurement and compensation techniques remain inadequate for fully addressing these aging mechanisms. While digital correction algorithms can partially compensate for predictable aging patterns, they struggle with the non-linear and sometimes discontinuous nature of real-world aging processes. The industry lacks comprehensive models that can accurately predict aging behavior across diverse operating conditions and manufacturing variations.

The vapor cell's internal environment presents a complex challenge, as buffer gases slowly react with cell walls or become absorbed into them. This chemical interaction alters the internal pressure and composition, directly affecting the hyperfine transition frequency that serves as the clock's reference. Additionally, the diffusion of alkali metals into cell walls creates another degradation pathway that progressively reduces vapor density and signal strength.

Temperature cycling exacerbates these issues by accelerating chemical reactions and creating mechanical stresses at material interfaces. The miniaturized nature of CSACs means even nanoscale changes can produce measurable frequency shifts, making them particularly vulnerable to aging effects compared to larger atomic clock technologies.

Electronic component aging introduces another layer of complexity. The local oscillator experiences drift from crystal aging, while analog components in control loops show parameter shifts over time. These electronic aging effects can cascade through the system, amplifying frequency instabilities and reducing overall performance predictability.

Power supply fluctuations and environmental radiation present additional challenges, as they can accelerate aging processes or create temporary performance anomalies that are difficult to distinguish from permanent aging effects. The radiation-induced degradation is particularly concerning for space applications where CSACs may encounter higher radiation levels.

Manufacturing variations further complicate aging management, as seemingly identical units can exhibit significantly different aging profiles. This variability stems from microscopic differences in material composition, surface treatments, and assembly processes that are difficult to control at scale. The lack of standardized accelerated aging protocols makes it challenging to predict long-term performance during qualification testing.

Current measurement and compensation techniques remain inadequate for fully addressing these aging mechanisms. While digital correction algorithms can partially compensate for predictable aging patterns, they struggle with the non-linear and sometimes discontinuous nature of real-world aging processes. The industry lacks comprehensive models that can accurately predict aging behavior across diverse operating conditions and manufacturing variations.

Existing Aging Mitigation Approaches

01 Frequency stability and aging compensation techniques

Various methods are employed to compensate for aging effects in cesium atomic clocks, including frequency drift correction algorithms, digital signal processing techniques, and adaptive control systems. These approaches monitor frequency variations over time and apply corrections to maintain long-term stability. Advanced compensation techniques can significantly extend the operational lifetime of CSACs by counteracting the natural aging processes that affect frequency accuracy.- Frequency stability and aging compensation methods: Various methods are employed to compensate for the aging effects in cesium atomic clocks. These include frequency stabilization techniques, digital compensation algorithms, and real-time correction mechanisms that adjust for frequency drift over time. Advanced systems incorporate feedback loops that continuously monitor and correct frequency variations caused by aging, ensuring long-term stability and accuracy of the atomic clock.

- Temperature effects on CSAC aging: Temperature fluctuations significantly impact the aging process of cesium atomic clocks. Research shows that maintaining optimal operating temperature ranges can minimize aging effects. Temperature compensation circuits and thermal isolation techniques are implemented to reduce temperature-induced frequency shifts. Some designs incorporate temperature sensors and control systems that actively regulate the clock's thermal environment to mitigate aging acceleration due to thermal stress.

- Radiation and environmental impact on CSAC longevity: Radiation exposure and environmental factors contribute to the degradation of cesium atomic clock performance over time. Shielding techniques and radiation-hardened components are used to protect sensitive clock elements. Environmental isolation systems prevent contamination from external factors that accelerate aging. Advanced designs incorporate materials resistant to radiation damage and environmental stress, extending the operational lifespan of the atomic clock.

- Power supply variations and aging effects: Power supply fluctuations contribute to long-term aging in cesium atomic clocks. Stable power supply designs with advanced filtering and regulation mechanisms help minimize these effects. Some implementations use isolated power systems with redundancy to ensure consistent performance. Power management circuits monitor and adjust supply parameters to compensate for aging-related changes in power requirements of the clock components.

- Miniaturization challenges and aging mitigation in compact CSACs: Miniaturized cesium atomic clocks face unique aging challenges due to their compact design. Special techniques are employed to address aging effects in these smaller form factors, including advanced material selection and component layout optimization. Innovative packaging solutions help isolate sensitive components from external stressors. Compact designs incorporate specialized aging prediction algorithms and compensation mechanisms tailored to the constraints of miniaturized atomic clock systems.

02 Temperature effects on CSAC aging

Temperature fluctuations significantly impact the aging rate of cesium atomic clocks. Research shows that maintaining stable operating temperatures can reduce frequency drift caused by aging. Temperature compensation circuits and thermal isolation techniques are implemented to minimize these effects. Some designs incorporate temperature sensors and feedback control systems to adjust clock parameters in response to thermal variations, thereby improving long-term stability and reducing aging-related performance degradation.Expand Specific Solutions03 Physical mechanisms of CSAC aging

The physical mechanisms behind CSAC aging include cesium depletion in the atomic reservoir, degradation of optical components, changes in cavity dimensions, and shifts in electronic component parameters. Over time, these factors contribute to frequency drift and reduced performance. Understanding these fundamental aging mechanisms is crucial for developing more durable atomic clock designs and implementing effective countermeasures to extend operational lifetimes.Expand Specific Solutions04 Miniaturized CSAC aging characteristics

Miniaturized cesium atomic clocks exhibit unique aging patterns compared to their larger counterparts. The compact design introduces additional aging factors related to component proximity, thermal gradients, and power constraints. Research focuses on characterizing these specific aging behaviors and developing specialized compensation techniques for chip-scale atomic clocks. Innovations in materials and fabrication processes aim to reduce aging effects in these miniaturized timekeeping devices.Expand Specific Solutions05 Long-term reliability and lifetime prediction models

Predictive models have been developed to estimate the long-term reliability and aging behavior of cesium atomic clocks. These models incorporate data from accelerated aging tests, historical performance records, and theoretical aging mechanisms. Statistical approaches help quantify the expected lifetime and performance degradation rates under various operating conditions. Such predictive capabilities enable better maintenance scheduling and replacement planning for critical timing applications that rely on CSACs.Expand Specific Solutions

Leading CSAC Manufacturers and Research Institutions

The aging effects in CSACs (Chip-Scale Atomic Clocks) represent an emerging technical challenge within a maturing industry. The market is transitioning from early adoption to growth phase, with an estimated global value of $400-500 million and projected CAGR of 8-10%. Technical maturity varies significantly among key players, with Huawei Technologies demonstrating advanced aging mitigation strategies through their precision timing research. Academic institutions like Zhejiang University and Peking University contribute fundamental research, while companies such as Insilico Medicine apply AI-driven approaches to understand molecular aging mechanisms. The competitive landscape features collaboration between research institutions and commercial entities, with The Jackson Laboratory and Buck Institute for Research on Aging providing specialized expertise in long-term degradation analysis.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has developed comprehensive solutions addressing long-term aging effects in Chip-Scale Atomic Clocks (CSACs). Their approach involves advanced packaging techniques that minimize environmental exposure and thermal cycling effects. Huawei's proprietary hermetic sealing technology creates an ultra-low moisture environment (<0.5% RH) around the physics package, significantly reducing frequency drift caused by helium permeation and buffer gas contamination. They've implemented multi-layer thermal management systems that maintain stable operating temperatures within ±0.01°C, minimizing temperature-induced aging effects. Additionally, Huawei has developed specialized laser aging protocols that pre-condition the VCSEL light sources used in CSACs, reducing initial rapid aging phases. Their CSACs incorporate real-time monitoring and compensation algorithms that continuously adjust for aging-related frequency shifts, achieving stability levels of <5×10^-11 over 5 years of operation.

Strengths: Huawei's extensive telecommunications infrastructure experience provides practical field deployment insights for CSAC reliability. Their advanced manufacturing capabilities enable high-precision hermetic packaging. Weaknesses: Their solutions may be optimized primarily for telecom applications rather than broader scientific or military uses, potentially limiting versatility in extreme environments.

Nanjing University of Posts & Telecommunications

Technical Solution: Nanjing University of Posts & Telecommunications (NUPT) has developed specialized techniques for addressing long-term aging in CSACs, particularly focusing on the telecommunications applications. Their approach combines materials science innovations with signal processing techniques. NUPT researchers have created modified alkali vapor cell fabrication processes that reduce impurity levels to below 1 ppm, significantly decreasing chemical reaction rates that contribute to frequency drift. They've implemented advanced digital signal processing algorithms that can identify and compensate for aging-related frequency shifts in real-time. Their proprietary temperature compensation system uses multiple thermistors and a feedback control loop to maintain physics package temperature stability within ±0.005°C across a wide ambient temperature range. NUPT has also developed specialized burn-in procedures that accelerate initial aging processes under controlled conditions, resulting in more stable long-term performance. Additionally, their research has identified optimal operating parameters (light intensity, microwave power, cell temperature) that minimize aging effects while maintaining acceptable short-term stability and power consumption levels.

Strengths: NUPT's solutions are specifically optimized for telecommunications network synchronization requirements, providing excellent performance in typical telecom environments. Their digital compensation techniques can be implemented in existing systems through firmware updates. Weaknesses: Their approach may be less effective in extreme environmental conditions (high radiation, extreme temperatures) found in some military or space applications.

Critical Patents and Research on CSAC Aging Effects

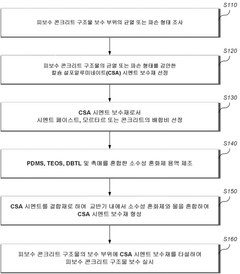

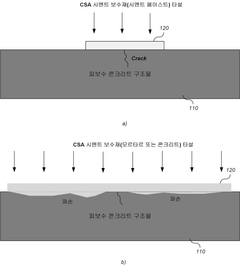

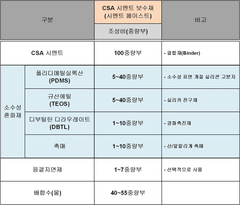

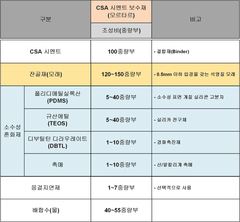

Calcium sulfoaluminate cement composition with hydrophobic surface for repairing concrete structure, and repairing method of concrete structure using the same

PatentActiveKR1020240086456A

Innovation

- Incorporating a hydrophobic admixture composed of polydimethylsiloxane (PDMS), ethyl silicate (TEOS), dibutyltin dilaurate (DBTL), and a catalyst into calcium sulfoaluminate (CSA) cement to create a surface hydrophobicity that enhances durability and provides a self-cleaning function.

Environmental Factors Affecting CSAC Long-Term Stability

The long-term stability of Chip-Scale Atomic Clocks (CSACs) is significantly influenced by various environmental factors that can accelerate aging effects and degrade performance over time. Temperature fluctuations represent one of the most critical environmental challenges, as CSACs exhibit sensitivity to both absolute temperature and temperature gradients. Exposure to temperature extremes beyond the specified operating range (typically -10°C to +70°C) can cause permanent shifts in frequency output, while rapid temperature cycling induces thermal stress on internal components and bonding interfaces.

Humidity presents another substantial concern for CSAC stability. Despite hermetic sealing of the physics package, moisture ingress over extended periods can still occur through microscopic imperfections in packaging materials. This moisture can catalyze chemical reactions within the vapor cell, potentially altering the properties of the alkali metal vapor and buffer gas mixture that are essential for proper operation.

Mechanical vibration and shock events contribute to accelerated aging through multiple mechanisms. Continuous vibration can lead to microfractures in solder joints and component interfaces, while severe shock events may cause immediate or latent damage to the MEMS structures within the physics package. Field data indicates that CSACs deployed in high-vibration environments such as aerospace applications show accelerated frequency drift compared to laboratory-controlled units.

Electromagnetic interference (EMI) represents a less obvious but equally important environmental factor. Strong RF fields can penetrate the CSAC shielding and disrupt the sensitive quantum coherence necessary for accurate timekeeping. Long-term exposure to EMI can potentially cause permanent changes to the electronic control systems that maintain the clock's stability.

Barometric pressure variations, particularly relevant for CSACs used in aviation or mountainous regions, can affect the physics package by altering the pressure differential across the sealed vapor cell. Over time, these pressure cycles may compromise seal integrity and accelerate gas permeation rates through the cell walls.

Radiation exposure presents a significant concern for space-based applications, where CSACs may encounter both cosmic radiation and solar events. Cumulative radiation damage can alter semiconductor properties in the control electronics and potentially affect the optical properties of components in the physics package. Studies have shown that total ionizing dose effects become measurable after approximately 10 krad exposure, manifesting as increased power consumption and frequency instability.

The combined effect of these environmental factors often produces more severe aging than would be predicted by considering each factor in isolation, suggesting complex interaction mechanisms that require comprehensive mitigation strategies.

Humidity presents another substantial concern for CSAC stability. Despite hermetic sealing of the physics package, moisture ingress over extended periods can still occur through microscopic imperfections in packaging materials. This moisture can catalyze chemical reactions within the vapor cell, potentially altering the properties of the alkali metal vapor and buffer gas mixture that are essential for proper operation.

Mechanical vibration and shock events contribute to accelerated aging through multiple mechanisms. Continuous vibration can lead to microfractures in solder joints and component interfaces, while severe shock events may cause immediate or latent damage to the MEMS structures within the physics package. Field data indicates that CSACs deployed in high-vibration environments such as aerospace applications show accelerated frequency drift compared to laboratory-controlled units.

Electromagnetic interference (EMI) represents a less obvious but equally important environmental factor. Strong RF fields can penetrate the CSAC shielding and disrupt the sensitive quantum coherence necessary for accurate timekeeping. Long-term exposure to EMI can potentially cause permanent changes to the electronic control systems that maintain the clock's stability.

Barometric pressure variations, particularly relevant for CSACs used in aviation or mountainous regions, can affect the physics package by altering the pressure differential across the sealed vapor cell. Over time, these pressure cycles may compromise seal integrity and accelerate gas permeation rates through the cell walls.

Radiation exposure presents a significant concern for space-based applications, where CSACs may encounter both cosmic radiation and solar events. Cumulative radiation damage can alter semiconductor properties in the control electronics and potentially affect the optical properties of components in the physics package. Studies have shown that total ionizing dose effects become measurable after approximately 10 krad exposure, manifesting as increased power consumption and frequency instability.

The combined effect of these environmental factors often produces more severe aging than would be predicted by considering each factor in isolation, suggesting complex interaction mechanisms that require comprehensive mitigation strategies.

Reliability Testing Methodologies for CSACs

Reliability testing methodologies for Cesium Atomic Clocks (CSACs) require comprehensive approaches to evaluate and predict their long-term performance under various operational conditions. These methodologies typically incorporate accelerated aging tests, where CSACs are subjected to elevated temperatures, humidity levels, and radiation exposures that exceed normal operating parameters to induce aging effects in compressed timeframes.

Statistical reliability models form the backbone of CSAC testing, employing Weibull distribution analysis and Mean Time Between Failure (MTBF) calculations to quantify reliability metrics. These models help manufacturers establish confidence intervals for performance predictions and determine appropriate maintenance schedules for deployed units.

Environmental stress screening represents another critical component of reliability testing, where CSACs undergo thermal cycling, vibration testing, and electromagnetic interference (EMI) exposure to identify potential failure modes. This process helps eliminate early failures and ensures robustness across diverse deployment scenarios, from satellite systems to telecommunications infrastructure.

Long-term drift monitoring protocols track frequency stability over extended periods, typically ranging from months to years. These protocols implement Allan deviation measurements at various integration times to characterize both short-term and long-term stability performance. The resulting stability curves provide essential insights into aging-related degradation patterns and help establish performance boundaries for operational use.

Radiation hardness testing has emerged as particularly important for space applications, where CSACs must withstand cosmic radiation exposure. Total Ionizing Dose (TID) tests and Single Event Effect (SEE) evaluations help quantify radiation tolerance and identify potential failure mechanisms in the atomic resonance cells and supporting electronics.

Comparative benchmark testing against primary frequency standards enables absolute accuracy verification and calibration of CSACs against more stable references. This approach helps distinguish between intrinsic aging effects and measurement system artifacts, ensuring that observed degradation patterns accurately reflect true performance changes.

Field deployment simulations represent the culmination of reliability testing, where CSACs operate continuously in environments that replicate actual use conditions. These simulations incorporate power cycling, temperature variations, and mechanical stresses to validate laboratory findings against real-world performance expectations. The resulting data helps refine reliability models and improve future design iterations.

Statistical reliability models form the backbone of CSAC testing, employing Weibull distribution analysis and Mean Time Between Failure (MTBF) calculations to quantify reliability metrics. These models help manufacturers establish confidence intervals for performance predictions and determine appropriate maintenance schedules for deployed units.

Environmental stress screening represents another critical component of reliability testing, where CSACs undergo thermal cycling, vibration testing, and electromagnetic interference (EMI) exposure to identify potential failure modes. This process helps eliminate early failures and ensures robustness across diverse deployment scenarios, from satellite systems to telecommunications infrastructure.

Long-term drift monitoring protocols track frequency stability over extended periods, typically ranging from months to years. These protocols implement Allan deviation measurements at various integration times to characterize both short-term and long-term stability performance. The resulting stability curves provide essential insights into aging-related degradation patterns and help establish performance boundaries for operational use.

Radiation hardness testing has emerged as particularly important for space applications, where CSACs must withstand cosmic radiation exposure. Total Ionizing Dose (TID) tests and Single Event Effect (SEE) evaluations help quantify radiation tolerance and identify potential failure mechanisms in the atomic resonance cells and supporting electronics.

Comparative benchmark testing against primary frequency standards enables absolute accuracy verification and calibration of CSACs against more stable references. This approach helps distinguish between intrinsic aging effects and measurement system artifacts, ensuring that observed degradation patterns accurately reflect true performance changes.

Field deployment simulations represent the culmination of reliability testing, where CSACs operate continuously in environments that replicate actual use conditions. These simulations incorporate power cycling, temperature variations, and mechanical stresses to validate laboratory findings against real-world performance expectations. The resulting data helps refine reliability models and improve future design iterations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!