Miniaturized Clock Solutions For IoT Edge Devices: Tradeoffs And Use Cases

AUG 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

IoT Clock Miniaturization Background and Objectives

The evolution of Internet of Things (IoT) technology has witnessed exponential growth over the past decade, with connected devices becoming increasingly integrated into various aspects of daily life and industrial operations. Timekeeping mechanisms represent a critical component within these systems, serving as the foundation for synchronization, data timestamping, and scheduled operations. Traditional clock solutions, however, have posed significant challenges for IoT edge device implementation due to their size, power requirements, and cost implications.

The miniaturization of clock solutions for IoT edge devices has emerged as a crucial technological frontier, driven by the need for smaller form factors, extended battery life, and cost-effective deployment at scale. Historical developments in this domain trace back to the transition from mechanical oscillators to quartz crystal technology, which provided substantial improvements in accuracy and size reduction. More recently, MEMS (Micro-Electro-Mechanical Systems) oscillators have further revolutionized the field, enabling unprecedented levels of miniaturization while maintaining acceptable performance parameters.

Current technological objectives in IoT clock miniaturization focus on achieving optimal balance across multiple competing factors: physical dimensions, power consumption, frequency stability, temperature resilience, and manufacturing costs. The target specifications increasingly demand sub-millimeter form factors with power consumption in the nano-watt range during standby modes, while maintaining timing accuracy sufficient for the specific application requirements.

Market trends indicate a growing demand for specialized clock solutions tailored to distinct IoT use cases, ranging from ultra-low-power environmental sensors that may operate for years on a single battery to high-precision industrial control systems requiring superior timing stability. This diversification necessitates a nuanced approach to clock technology development rather than pursuing a one-size-fits-all solution.

The technological roadmap for miniaturized clock solutions encompasses several parallel development paths, including advanced MEMS fabrication techniques, novel materials exploration, integrated power management circuits, and innovative packaging methodologies. Additionally, software-based compensation mechanisms are increasingly employed to mitigate hardware limitations, particularly in addressing temperature drift and aging effects.

This technical exploration aims to comprehensively assess the current state of miniaturized clock technologies, identify critical performance tradeoffs, and evaluate their suitability across diverse IoT application scenarios. The ultimate objective is to provide strategic insights into optimal clock solution selection based on specific use case requirements and to highlight promising research directions that may overcome existing limitations in the near to medium term.

The miniaturization of clock solutions for IoT edge devices has emerged as a crucial technological frontier, driven by the need for smaller form factors, extended battery life, and cost-effective deployment at scale. Historical developments in this domain trace back to the transition from mechanical oscillators to quartz crystal technology, which provided substantial improvements in accuracy and size reduction. More recently, MEMS (Micro-Electro-Mechanical Systems) oscillators have further revolutionized the field, enabling unprecedented levels of miniaturization while maintaining acceptable performance parameters.

Current technological objectives in IoT clock miniaturization focus on achieving optimal balance across multiple competing factors: physical dimensions, power consumption, frequency stability, temperature resilience, and manufacturing costs. The target specifications increasingly demand sub-millimeter form factors with power consumption in the nano-watt range during standby modes, while maintaining timing accuracy sufficient for the specific application requirements.

Market trends indicate a growing demand for specialized clock solutions tailored to distinct IoT use cases, ranging from ultra-low-power environmental sensors that may operate for years on a single battery to high-precision industrial control systems requiring superior timing stability. This diversification necessitates a nuanced approach to clock technology development rather than pursuing a one-size-fits-all solution.

The technological roadmap for miniaturized clock solutions encompasses several parallel development paths, including advanced MEMS fabrication techniques, novel materials exploration, integrated power management circuits, and innovative packaging methodologies. Additionally, software-based compensation mechanisms are increasingly employed to mitigate hardware limitations, particularly in addressing temperature drift and aging effects.

This technical exploration aims to comprehensively assess the current state of miniaturized clock technologies, identify critical performance tradeoffs, and evaluate their suitability across diverse IoT application scenarios. The ultimate objective is to provide strategic insights into optimal clock solution selection based on specific use case requirements and to highlight promising research directions that may overcome existing limitations in the near to medium term.

Market Demand Analysis for IoT Edge Timing Solutions

The IoT edge device market is experiencing unprecedented growth, with projections indicating a compound annual growth rate of 15.4% from 2023 to 2028. This expansion is driving significant demand for specialized timing solutions that can meet the unique requirements of edge computing environments. Traditional timing components designed for larger systems are increasingly inadequate for modern IoT applications where size, power consumption, and cost constraints are paramount.

Energy efficiency has emerged as the primary market driver for miniaturized clock solutions. With billions of IoT devices operating on limited power sources such as batteries or energy harvesting systems, the market demands timing components that can operate in the microwatt or even nanowatt range. Industry surveys indicate that extending battery life ranks as the top priority for 78% of IoT device manufacturers, directly influencing their component selection process.

Form factor requirements represent another critical market demand. As IoT devices continue to shrink in size, particularly in wearable technology, medical implants, and environmental sensors, the timing components must follow suit. The market increasingly favors solutions under 2mm² in footprint, with some applications pushing boundaries toward sub-1mm² implementations. This miniaturization trend is particularly pronounced in consumer wearables and medical device segments.

Cost sensitivity significantly shapes market dynamics for IoT timing solutions. Unlike traditional high-performance computing where precision may justify premium pricing, the IoT market operates on razor-thin margins. Volume deployment economics dictate that timing components must typically fall below $0.50 per unit to remain competitive, with mass-market consumer applications driving even lower price points.

Application-specific performance requirements are creating distinct market segments within the broader IoT timing solution space. While some applications prioritize ultra-low power consumption over precision, others demand tight frequency stability for wireless communications or precise data sampling. This diversification has led to the emergence of specialized timing solutions tailored to specific use cases rather than one-size-fits-all approaches.

Regional market analysis reveals varying adoption patterns, with North America and East Asia leading in innovation and implementation of advanced miniaturized timing solutions. European markets show stronger emphasis on reliability and certification compliance, particularly for industrial IoT applications. Emerging markets demonstrate growing demand focused primarily on cost-optimized solutions that can operate reliably in less controlled environments.

The market increasingly values integrated solutions that combine timing functionality with other features such as temperature sensing or power management, reducing overall component count and system complexity. This integration trend is expected to accelerate as system-in-package and advanced packaging technologies mature, further driving miniaturization and efficiency in IoT edge timing solutions.

Energy efficiency has emerged as the primary market driver for miniaturized clock solutions. With billions of IoT devices operating on limited power sources such as batteries or energy harvesting systems, the market demands timing components that can operate in the microwatt or even nanowatt range. Industry surveys indicate that extending battery life ranks as the top priority for 78% of IoT device manufacturers, directly influencing their component selection process.

Form factor requirements represent another critical market demand. As IoT devices continue to shrink in size, particularly in wearable technology, medical implants, and environmental sensors, the timing components must follow suit. The market increasingly favors solutions under 2mm² in footprint, with some applications pushing boundaries toward sub-1mm² implementations. This miniaturization trend is particularly pronounced in consumer wearables and medical device segments.

Cost sensitivity significantly shapes market dynamics for IoT timing solutions. Unlike traditional high-performance computing where precision may justify premium pricing, the IoT market operates on razor-thin margins. Volume deployment economics dictate that timing components must typically fall below $0.50 per unit to remain competitive, with mass-market consumer applications driving even lower price points.

Application-specific performance requirements are creating distinct market segments within the broader IoT timing solution space. While some applications prioritize ultra-low power consumption over precision, others demand tight frequency stability for wireless communications or precise data sampling. This diversification has led to the emergence of specialized timing solutions tailored to specific use cases rather than one-size-fits-all approaches.

Regional market analysis reveals varying adoption patterns, with North America and East Asia leading in innovation and implementation of advanced miniaturized timing solutions. European markets show stronger emphasis on reliability and certification compliance, particularly for industrial IoT applications. Emerging markets demonstrate growing demand focused primarily on cost-optimized solutions that can operate reliably in less controlled environments.

The market increasingly values integrated solutions that combine timing functionality with other features such as temperature sensing or power management, reducing overall component count and system complexity. This integration trend is expected to accelerate as system-in-package and advanced packaging technologies mature, further driving miniaturization and efficiency in IoT edge timing solutions.

Current State and Challenges in Miniaturized Clock Technology

The miniaturized clock technology landscape has evolved significantly over the past decade, with current solutions primarily dominated by quartz crystal oscillators (XOs), temperature-compensated crystal oscillators (TCXOs), and microelectromechanical systems (MEMS) timing devices. Each technology presents distinct advantages and limitations when applied to IoT edge devices, where power consumption, size, and reliability are paramount concerns.

Quartz crystal oscillators remain the industry standard for many applications due to their excellent frequency stability and relatively low cost. However, they face significant challenges in further miniaturization due to physical limitations of crystal resonators. The smallest commercially available quartz oscillators measure approximately 1.2 × 1.0 mm, with further size reduction compromising performance metrics.

MEMS-based timing solutions have gained substantial market traction, offering smaller form factors and better shock resistance than traditional quartz. Current MEMS oscillators can achieve dimensions as small as 1.0 × 0.8 mm while maintaining acceptable performance for many IoT applications. Despite these advances, MEMS solutions still struggle with frequency stability over temperature variations compared to TCXOs.

Power consumption presents another critical challenge. State-of-the-art low-power oscillators consume approximately 1-5 μA at 32.768 kHz, but this remains prohibitive for ultra-low-power IoT edge devices targeting multi-year battery life. The fundamental trade-off between power consumption and frequency stability continues to constrain design options.

Temperature stability represents a significant technical hurdle, particularly for outdoor and industrial IoT deployments. Current miniaturized solutions exhibit frequency drift of 20-100 ppm across industrial temperature ranges (-40°C to +85°C), necessitating compensation mechanisms that increase power consumption and solution complexity.

Manufacturing scalability poses additional challenges. While MEMS technologies offer theoretical advantages in mass production, yield issues and packaging complexities have limited cost reduction trajectories. The specialized equipment and clean room requirements for both quartz and MEMS manufacturing contribute to persistent cost floors.

Geographically, clock technology development remains concentrated in specific regions. Japan and Switzerland maintain leadership in high-precision quartz technology, while the United States and Taiwan lead in MEMS timing solutions. China has rapidly expanded manufacturing capacity but still lags in cutting-edge innovation for ultra-miniaturized solutions.

Integration challenges persist as system designers attempt to incorporate timing solutions with other components. The electromagnetic interference (EMI) generated by digital circuits can disrupt sensitive clock components, requiring careful isolation strategies that conflict with miniaturization goals. Additionally, the increasing demand for multi-frequency operation in IoT devices complicates the design of single-chip timing solutions.

Quartz crystal oscillators remain the industry standard for many applications due to their excellent frequency stability and relatively low cost. However, they face significant challenges in further miniaturization due to physical limitations of crystal resonators. The smallest commercially available quartz oscillators measure approximately 1.2 × 1.0 mm, with further size reduction compromising performance metrics.

MEMS-based timing solutions have gained substantial market traction, offering smaller form factors and better shock resistance than traditional quartz. Current MEMS oscillators can achieve dimensions as small as 1.0 × 0.8 mm while maintaining acceptable performance for many IoT applications. Despite these advances, MEMS solutions still struggle with frequency stability over temperature variations compared to TCXOs.

Power consumption presents another critical challenge. State-of-the-art low-power oscillators consume approximately 1-5 μA at 32.768 kHz, but this remains prohibitive for ultra-low-power IoT edge devices targeting multi-year battery life. The fundamental trade-off between power consumption and frequency stability continues to constrain design options.

Temperature stability represents a significant technical hurdle, particularly for outdoor and industrial IoT deployments. Current miniaturized solutions exhibit frequency drift of 20-100 ppm across industrial temperature ranges (-40°C to +85°C), necessitating compensation mechanisms that increase power consumption and solution complexity.

Manufacturing scalability poses additional challenges. While MEMS technologies offer theoretical advantages in mass production, yield issues and packaging complexities have limited cost reduction trajectories. The specialized equipment and clean room requirements for both quartz and MEMS manufacturing contribute to persistent cost floors.

Geographically, clock technology development remains concentrated in specific regions. Japan and Switzerland maintain leadership in high-precision quartz technology, while the United States and Taiwan lead in MEMS timing solutions. China has rapidly expanded manufacturing capacity but still lags in cutting-edge innovation for ultra-miniaturized solutions.

Integration challenges persist as system designers attempt to incorporate timing solutions with other components. The electromagnetic interference (EMI) generated by digital circuits can disrupt sensitive clock components, requiring careful isolation strategies that conflict with miniaturization goals. Additionally, the increasing demand for multi-frequency operation in IoT devices complicates the design of single-chip timing solutions.

Current Technical Approaches to IoT Clock Miniaturization

01 MEMS-based miniaturized clock technologies

Micro-Electro-Mechanical Systems (MEMS) technology enables significant miniaturization of clock components through integration of mechanical elements, sensors, actuators, and electronics on a micro-scale. These MEMS-based clock solutions offer reduced size while maintaining precision timing capabilities, making them suitable for portable electronic devices where space constraints are critical. The technology allows for batch fabrication techniques similar to integrated circuits, resulting in cost-effective production of miniaturized timing solutions.- MEMS-based miniaturization techniques for clock components: Micro-Electro-Mechanical Systems (MEMS) technology enables significant miniaturization of clock components through the integration of mechanical elements, sensors, actuators, and electronics on a micro-scale. This approach allows for the development of highly compact oscillators and resonators that maintain precise timing while dramatically reducing the overall footprint. MEMS-based clock solutions offer advantages in terms of size reduction, power efficiency, and reliability for portable electronic devices and IoT applications.

- System-on-Chip (SoC) integration for clock miniaturization: System-on-Chip integration approaches enable significant clock miniaturization by incorporating timing circuits directly into larger integrated circuits. This technique eliminates the need for separate clock components by embedding oscillators, phase-locked loops, and timing control systems within the main processor or application-specific integrated circuit. The integration reduces board space requirements while improving signal integrity by minimizing transmission distances between the clock generator and dependent circuits.

- Advanced packaging technologies for clock miniaturization: Advanced packaging technologies enable significant size reduction in clock solutions through techniques such as wafer-level packaging, chip-scale packaging, and 3D stacking. These methods allow for the vertical integration of clock components, reducing the horizontal footprint while maintaining or improving performance. Multi-chip modules that combine the oscillator, frequency divider circuits, and control logic in a single compact package further contribute to miniaturization while protecting sensitive timing components from environmental factors.

- Novel materials and fabrication techniques for miniaturized clocks: Innovative materials and fabrication techniques enable the development of ultra-compact clock solutions. These include the use of advanced piezoelectric materials, thin-film technology, and nanoscale fabrication processes that allow for smaller resonating structures while maintaining frequency stability. Novel approaches such as atomic layer deposition and precision etching techniques facilitate the creation of miniaturized timing components with improved performance characteristics, including better temperature stability and lower power consumption.

- Power optimization techniques for miniaturized clock systems: Power optimization techniques are essential for miniaturized clock systems, as they enable further size reduction through smaller power supply components and reduced thermal management requirements. These techniques include adaptive clock frequency scaling, power gating of unused clock domains, and low-power oscillator designs. By implementing sophisticated power management algorithms and energy-efficient circuit designs, clock solutions can achieve significant miniaturization while extending battery life in portable applications.

02 System-on-Chip (SoC) clock integration approaches

System-on-Chip integration approaches incorporate clock generation and distribution circuits directly into semiconductor chips, eliminating the need for separate timing components. These solutions utilize advanced semiconductor fabrication techniques to embed oscillators, phase-locked loops (PLLs), and clock distribution networks within the same silicon die as processing elements. This integration significantly reduces the overall footprint of timing solutions while improving signal integrity by minimizing transmission distances between clock sources and destination circuits.Expand Specific Solutions03 Advanced packaging techniques for clock miniaturization

Innovative packaging technologies enable further miniaturization of clock components through techniques such as 3D stacking, wafer-level packaging, and system-in-package approaches. These methods allow for vertical integration of clock components, reducing the horizontal footprint significantly. Advanced interconnect technologies facilitate dense connections between stacked dies while maintaining signal integrity. Specialized materials and thermal management solutions address heat dissipation challenges in these compact configurations, ensuring reliable operation despite the reduced size.Expand Specific Solutions04 Low-power miniaturized oscillator designs

Novel oscillator designs focus on reducing both size and power consumption through innovative circuit topologies and material selection. These designs incorporate specialized materials with favorable piezoelectric properties to create smaller resonators while maintaining frequency stability. Advanced circuit techniques compensate for temperature variations and other environmental factors that typically affect timing accuracy in miniaturized components. The reduced power requirements enable smaller energy storage components, contributing to overall size reduction of the timing solution.Expand Specific Solutions05 Atomic clock miniaturization techniques

Miniaturization of atomic clock technology brings laboratory-grade timing precision to portable applications through innovative physics packages and control electronics. These solutions utilize quantum properties of atoms to create highly stable frequency references in dramatically reduced form factors. Advanced fabrication techniques enable integration of vapor cells, lasers, and photodetectors in compact assemblies. Specialized control algorithms optimize performance while minimizing component count and size, making previously bulky atomic clock technology viable for mobile and space-constrained applications.Expand Specific Solutions

Key Industry Players in Miniaturized Clock Solutions

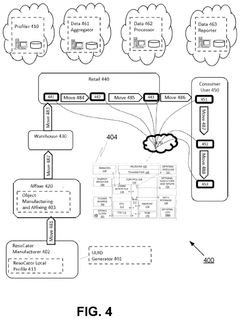

The IoT edge device miniaturized clock solutions market is currently in a growth phase, with increasing demand driven by the proliferation of IoT applications requiring precise timing in compact form factors. The market is projected to expand significantly as edge computing adoption accelerates, with key players positioning themselves across the value chain. Intel, Qualcomm, and NXP Semiconductors lead in semiconductor solutions, while IBM and Dell focus on integrated systems. Technical maturity varies across approaches, with MEMS-based solutions from STMicroelectronics gaining traction for power efficiency, while Intel and Qualcomm advance in temperature-compensated oscillators. Academic institutions like Delft University and Beijing University of Posts & Telecommunications are contributing breakthrough research in quantum timing technologies that may reshape future implementations.

Intel Corp.

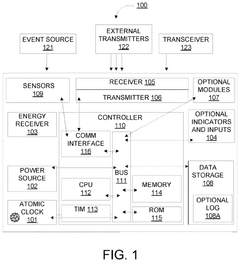

Technical Solution: Intel's miniaturized clock solutions for IoT edge devices center around their Quark and Atom processor families, which integrate specialized timing subsystems optimized for IoT applications. Their approach implements a hierarchical clock architecture that separates high-precision system clocks from ultra-low-power always-on timers. The Intel Platform Clock Generator (PCG) technology integrates multiple clock domains into a single silicon die, reducing component count and board space requirements. For battery-powered IoT devices, Intel has developed sub-threshold voltage oscillators that operate at extremely low power levels (as little as 500nA) while maintaining timing accuracy sufficient for periodic wake-up functions. Their Enhanced SpeedStep technology dynamically scales clock frequencies based on processing demands, with transitions between power states occurring in microseconds. Intel's clock solutions also incorporate temperature compensation algorithms that adjust for frequency drift across industrial temperature ranges (-40°C to +85°C). For IoT applications requiring precise synchronization, Intel supports the Precision Time Protocol (PTP) with hardware timestamping capabilities integrated into their networking interfaces, enabling sub-microsecond synchronization across distributed IoT deployments.

Strengths: Comprehensive integration reduces overall system complexity and component count; advanced power management features optimize battery life; robust support for networking time synchronization protocols enables precise coordination in distributed IoT systems. Weaknesses: Solutions typically optimized for higher-performance IoT edge computing rather than ultra-constrained sensor nodes; power consumption still higher than specialized microcontroller solutions; larger physical footprint compared to dedicated timing-only solutions.

NXP Semiconductors (Thailand) Co., Ltd.

Technical Solution: NXP's miniaturized clock solutions for IoT edge devices center around their ultra-low-power Real-Time Clock (RTC) modules, specifically designed for battery-operated IoT applications. Their technology implements a dual-oscillator architecture that combines a high-precision 32.768 kHz crystal oscillator for accurate timekeeping with an ultra-low-power RC oscillator that operates during device sleep modes. This approach enables power consumption as low as 100nA in timekeeping mode while maintaining accuracy within ±5ppm. NXP's PCF85263A RTC chip integrates temperature compensation algorithms that automatically adjust for frequency variations caused by temperature fluctuations, ensuring reliable performance across industrial temperature ranges (-40°C to +85°C). The solution also features programmable alarm functions, automatic backup power switching, and I2C/SPI interfaces for seamless integration with various microcontrollers commonly used in IoT applications.

Strengths: Extremely low power consumption optimized for battery-powered devices with years of operation; integrated temperature compensation improves accuracy in varying environmental conditions; small form factor (2mm x 3mm packages) ideal for space-constrained IoT devices. Weaknesses: Higher cost compared to basic oscillator solutions; requires initial calibration for maximum accuracy; crystal-based solutions still vulnerable to mechanical shock and vibration in harsh IoT deployments.

Core Patents and Innovations in Miniaturized Timing

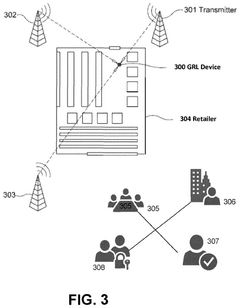

Solid-state electronic miniature clock with enhanced thermal management and antenna performance

PatentPendingUS20250232629A1

Innovation

- The development of chip-scale solid-state miniature atomic clocks (SMACs) using electron paramagnetic resonance systems and miniature atomic clocks, integrated with sensors and antennas, for precise timing and location determination, enabling trilateration and triangulation through terrestrial signals.

Power management techniques for computing platforms in low temperature environments

PatentWO2021258391A1

Innovation

- Adaptive power management techniques specifically designed for IoT devices operating in low temperature environments, addressing the challenges of boot processes and system operation.

- Cost-effective approach to low temperature operation for edge computing systems that avoids the drawbacks of existing expensive solutions.

- Specialized boot process optimization for IoT edge devices that ensures reliable startup in challenging low temperature conditions.

Power Consumption vs Accuracy Tradeoffs

In the realm of IoT edge devices, power consumption and accuracy represent a fundamental tradeoff that significantly impacts design decisions for miniaturized clock solutions. Edge devices typically operate under strict power constraints, often relying on small batteries or energy harvesting techniques for extended deployment periods. The power consumption of timing components can constitute a substantial portion of the overall system power budget, particularly in sleep or low-power modes where other components are inactive.

High-accuracy clock solutions, such as Temperature Compensated Crystal Oscillators (TCXOs) and Oven Controlled Crystal Oscillators (OCXOs), offer excellent stability and precision but demand considerably higher power. A typical TCXO might consume 1-5mW, while an OCXO could require 100mW or more during operation. These power requirements become prohibitive for many IoT applications where devices must operate for months or years without battery replacement.

Conversely, lower-power alternatives like simple crystal oscillators or RC oscillators significantly reduce power consumption to the microwatt range but introduce greater frequency drift and susceptibility to environmental variations. This reduced accuracy directly impacts timing-sensitive applications, potentially causing synchronization failures, communication errors, or degraded sensor data quality.

The relationship between power and accuracy is rarely linear. Diminishing returns often appear when pursuing extremely high accuracy, where power consumption increases exponentially for marginal improvements in stability. This nonlinear relationship necessitates careful optimization based on application requirements.

Several innovative approaches have emerged to address this tradeoff. Adaptive clock systems dynamically adjust their power consumption based on application needs, operating in low-power mode during periods of reduced activity and temporarily increasing accuracy during critical operations. Temperature-aware compensation techniques that consume less power than traditional TCXOs have also been developed, offering reasonable stability without the associated energy costs.

Application-specific optimization represents another strategy, where designers analyze the actual timing requirements of specific use cases rather than defaulting to unnecessarily precise solutions. For instance, environmental monitoring applications may tolerate greater timing drift than financial transaction systems, allowing for substantial power savings through appropriate technology selection.

The industry continues to advance toward more efficient solutions that challenge the traditional power-accuracy tradeoff curve, with emerging technologies like MEMS-based oscillators and advanced low-power crystal designs promising better performance per watt metrics for next-generation IoT deployments.

High-accuracy clock solutions, such as Temperature Compensated Crystal Oscillators (TCXOs) and Oven Controlled Crystal Oscillators (OCXOs), offer excellent stability and precision but demand considerably higher power. A typical TCXO might consume 1-5mW, while an OCXO could require 100mW or more during operation. These power requirements become prohibitive for many IoT applications where devices must operate for months or years without battery replacement.

Conversely, lower-power alternatives like simple crystal oscillators or RC oscillators significantly reduce power consumption to the microwatt range but introduce greater frequency drift and susceptibility to environmental variations. This reduced accuracy directly impacts timing-sensitive applications, potentially causing synchronization failures, communication errors, or degraded sensor data quality.

The relationship between power and accuracy is rarely linear. Diminishing returns often appear when pursuing extremely high accuracy, where power consumption increases exponentially for marginal improvements in stability. This nonlinear relationship necessitates careful optimization based on application requirements.

Several innovative approaches have emerged to address this tradeoff. Adaptive clock systems dynamically adjust their power consumption based on application needs, operating in low-power mode during periods of reduced activity and temporarily increasing accuracy during critical operations. Temperature-aware compensation techniques that consume less power than traditional TCXOs have also been developed, offering reasonable stability without the associated energy costs.

Application-specific optimization represents another strategy, where designers analyze the actual timing requirements of specific use cases rather than defaulting to unnecessarily precise solutions. For instance, environmental monitoring applications may tolerate greater timing drift than financial transaction systems, allowing for substantial power savings through appropriate technology selection.

The industry continues to advance toward more efficient solutions that challenge the traditional power-accuracy tradeoff curve, with emerging technologies like MEMS-based oscillators and advanced low-power crystal designs promising better performance per watt metrics for next-generation IoT deployments.

Environmental Impact and Sustainability Considerations

The environmental footprint of miniaturized clock solutions for IoT edge devices represents a critical consideration in their design, deployment, and end-of-life management. As IoT deployments scale to billions of devices, the cumulative environmental impact of timing components becomes increasingly significant despite their small individual size.

Material selection presents one of the primary environmental challenges. Traditional quartz oscillators contain non-biodegradable components and may utilize rare earth elements with environmentally destructive mining practices. MEMS-based alternatives often reduce dependence on these materials but introduce their own sustainability concerns through silicon processing and specialized manufacturing requirements.

Energy consumption throughout the device lifecycle constitutes another major environmental factor. While low-power clock solutions reduce operational energy demands, the manufacturing energy footprint—particularly for highly precise timing components—can be substantial. Research indicates that manufacturing a single precision oscillator may consume up to 1000 times the energy it will use during its operational lifetime.

Device longevity and reliability directly impact sustainability metrics. Clock solutions with higher drift rates necessitate more frequent recalibration or replacement, generating additional electronic waste. Temperature-compensated oscillators that maintain accuracy across environmental conditions can significantly extend useful device life, reducing replacement frequency and associated resource consumption.

End-of-life considerations reveal further sustainability challenges. The miniaturized, integrated nature of modern clock solutions often complicates component separation and recycling efforts. Many timing components contain trace amounts of hazardous substances that require specialized handling during disposal, yet their small size makes recovery economically challenging.

Emerging sustainable design approaches are addressing these concerns through several pathways. Bio-based materials for packaging and substrate components show promise for reducing non-biodegradable waste. Energy harvesting technologies paired with ultra-low-power clock solutions create self-sustaining timing systems that minimize battery replacement needs and associated waste streams.

Regulatory frameworks increasingly influence clock solution design and deployment. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations worldwide have accelerated the transition to lead-free oscillators and timing components. Extended Producer Responsibility policies are pushing manufacturers to consider full lifecycle impacts during the design phase.

Quantitative lifecycle assessment studies demonstrate that optimizing clock solution selection for specific use cases yields significant sustainability benefits. For instance, agricultural IoT deployments may benefit more from robust, long-lasting timing components despite higher initial resource costs, while consumer applications might prioritize recyclability and reduced manufacturing footprint.

Material selection presents one of the primary environmental challenges. Traditional quartz oscillators contain non-biodegradable components and may utilize rare earth elements with environmentally destructive mining practices. MEMS-based alternatives often reduce dependence on these materials but introduce their own sustainability concerns through silicon processing and specialized manufacturing requirements.

Energy consumption throughout the device lifecycle constitutes another major environmental factor. While low-power clock solutions reduce operational energy demands, the manufacturing energy footprint—particularly for highly precise timing components—can be substantial. Research indicates that manufacturing a single precision oscillator may consume up to 1000 times the energy it will use during its operational lifetime.

Device longevity and reliability directly impact sustainability metrics. Clock solutions with higher drift rates necessitate more frequent recalibration or replacement, generating additional electronic waste. Temperature-compensated oscillators that maintain accuracy across environmental conditions can significantly extend useful device life, reducing replacement frequency and associated resource consumption.

End-of-life considerations reveal further sustainability challenges. The miniaturized, integrated nature of modern clock solutions often complicates component separation and recycling efforts. Many timing components contain trace amounts of hazardous substances that require specialized handling during disposal, yet their small size makes recovery economically challenging.

Emerging sustainable design approaches are addressing these concerns through several pathways. Bio-based materials for packaging and substrate components show promise for reducing non-biodegradable waste. Energy harvesting technologies paired with ultra-low-power clock solutions create self-sustaining timing systems that minimize battery replacement needs and associated waste streams.

Regulatory frameworks increasingly influence clock solution design and deployment. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations worldwide have accelerated the transition to lead-free oscillators and timing components. Extended Producer Responsibility policies are pushing manufacturers to consider full lifecycle impacts during the design phase.

Quantitative lifecycle assessment studies demonstrate that optimizing clock solution selection for specific use cases yields significant sustainability benefits. For instance, agricultural IoT deployments may benefit more from robust, long-lasting timing components despite higher initial resource costs, while consumer applications might prioritize recyclability and reduced manufacturing footprint.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!