Miniature Atomic Beam Clocks: Design And Vacuum Requirements

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Atomic Clock Miniaturization Background and Objectives

Atomic clocks have evolved significantly since their inception in the 1950s, transitioning from room-sized devices to increasingly compact instruments. The miniaturization journey of atomic clocks represents one of the most remarkable technological progressions in precision timekeeping. Initially developed for scientific and military applications, these devices have gradually found their way into telecommunications, navigation systems, and various industrial applications where precise timing is critical.

The evolution of miniature atomic beam clocks specifically addresses the growing demand for portable, high-precision timing devices that maintain the fundamental accuracy advantages of atomic timekeeping while dramatically reducing size, weight, and power consumption. Traditional atomic clocks rely on cesium beam or hydrogen maser technologies that inherently require substantial space and power, limiting their deployment scenarios.

Recent technological advancements in micro-electromechanical systems (MEMS), vacuum technology, and low-power electronics have created new possibilities for significant size reduction while preserving essential performance characteristics. The primary objective of miniature atomic beam clock development is to achieve a balance between compactness and timing precision that enables deployment in mobile platforms, satellites, and portable equipment where conventional atomic clocks would be impractical.

The technical goals for miniature atomic beam clocks include achieving stability performance of 10^-11 to 10^-13 over one day, reducing volume to less than 100 cubic centimeters, limiting power consumption to under 1 watt, and ensuring operational lifetimes of 5-10 years. These ambitious targets represent a significant challenge given the physics constraints of atomic resonance detection and the engineering challenges of maintaining precise vacuum conditions in miniaturized chambers.

Vacuum requirements present a particularly critical aspect of miniaturization efforts. Atomic beam clocks require high-quality vacuum environments (typically 10^-6 to 10^-8 torr) to minimize collisions between atoms and background gases that would otherwise degrade clock performance. Traditional vacuum systems employ bulky pumps and chambers that are incompatible with miniaturization goals, necessitating innovative approaches to vacuum generation and maintenance in small volumes.

The trajectory of this technology points toward chip-scale atomic clocks (CSACs) that integrate multiple components onto semiconductor substrates. While current CSACs primarily utilize coherent population trapping rather than beam technology, the lessons learned from their development inform the miniaturization pathway for beam-based designs. The ultimate vision is to create atomic beam clocks small enough to be integrated into handheld devices while delivering performance suitable for advanced navigation, secure communications, and distributed network synchronization.

The evolution of miniature atomic beam clocks specifically addresses the growing demand for portable, high-precision timing devices that maintain the fundamental accuracy advantages of atomic timekeeping while dramatically reducing size, weight, and power consumption. Traditional atomic clocks rely on cesium beam or hydrogen maser technologies that inherently require substantial space and power, limiting their deployment scenarios.

Recent technological advancements in micro-electromechanical systems (MEMS), vacuum technology, and low-power electronics have created new possibilities for significant size reduction while preserving essential performance characteristics. The primary objective of miniature atomic beam clock development is to achieve a balance between compactness and timing precision that enables deployment in mobile platforms, satellites, and portable equipment where conventional atomic clocks would be impractical.

The technical goals for miniature atomic beam clocks include achieving stability performance of 10^-11 to 10^-13 over one day, reducing volume to less than 100 cubic centimeters, limiting power consumption to under 1 watt, and ensuring operational lifetimes of 5-10 years. These ambitious targets represent a significant challenge given the physics constraints of atomic resonance detection and the engineering challenges of maintaining precise vacuum conditions in miniaturized chambers.

Vacuum requirements present a particularly critical aspect of miniaturization efforts. Atomic beam clocks require high-quality vacuum environments (typically 10^-6 to 10^-8 torr) to minimize collisions between atoms and background gases that would otherwise degrade clock performance. Traditional vacuum systems employ bulky pumps and chambers that are incompatible with miniaturization goals, necessitating innovative approaches to vacuum generation and maintenance in small volumes.

The trajectory of this technology points toward chip-scale atomic clocks (CSACs) that integrate multiple components onto semiconductor substrates. While current CSACs primarily utilize coherent population trapping rather than beam technology, the lessons learned from their development inform the miniaturization pathway for beam-based designs. The ultimate vision is to create atomic beam clocks small enough to be integrated into handheld devices while delivering performance suitable for advanced navigation, secure communications, and distributed network synchronization.

Market Applications and Demand Analysis for Miniature Atomic Clocks

The miniature atomic clock market has experienced significant growth in recent years, driven by increasing demand for precise timing solutions across multiple industries. The global market for miniature atomic clocks was valued at approximately $400 million in 2022 and is projected to reach $650 million by 2027, representing a compound annual growth rate of 10.2%. This growth trajectory reflects the expanding applications of these high-precision timing devices beyond traditional military and aerospace sectors.

Telecommunications represents one of the largest market segments for miniature atomic clocks, accounting for roughly 30% of total demand. Network synchronization requirements for 5G infrastructure have created substantial demand for precise timing solutions, with miniature atomic clocks providing the stability necessary for maintaining network coherence across distributed systems. Industry analysts predict that as 5G deployment accelerates globally, demand for miniature atomic clocks in this sector will increase by 15-18% annually through 2026.

The navigation and positioning systems market constitutes another significant application area. GPS-denied environments and autonomous vehicle navigation systems require highly stable local timing references, creating a growing market for miniature atomic beam clocks. The automotive sector alone is expected to increase its consumption of precision timing devices by 22% year-over-year as advanced driver assistance systems and autonomous driving capabilities become more prevalent.

Financial services represent an emerging application area with substantial growth potential. High-frequency trading operations require timestamp precision measured in nanoseconds, creating demand for miniature atomic clocks in trading infrastructure. This sector is projected to grow at 14% annually as financial institutions continue to invest in reducing latency and improving transaction synchronization.

Space applications are driving innovation in miniaturization techniques for atomic clocks. The small satellite market, growing at over 20% annually, requires increasingly compact timing solutions for communication systems and scientific payloads. CubeSats and other small satellite platforms have specific size and power constraints that align perfectly with the development goals of miniature atomic beam clocks.

Industrial automation and smart grid applications are also emerging as significant market drivers. Distributed control systems in manufacturing environments and synchronized measurement units in power grids both benefit from precise timing references. The industrial Internet of Things (IIoT) market is expected to consume increasing numbers of miniature atomic clocks as edge computing applications require more precise synchronization.

Consumer applications remain limited but show potential for future growth. Personal navigation devices, specialized scientific equipment, and certain high-end consumer electronics represent niche markets that could expand as miniaturization and cost reduction efforts continue to make atomic clock technology more accessible.

Telecommunications represents one of the largest market segments for miniature atomic clocks, accounting for roughly 30% of total demand. Network synchronization requirements for 5G infrastructure have created substantial demand for precise timing solutions, with miniature atomic clocks providing the stability necessary for maintaining network coherence across distributed systems. Industry analysts predict that as 5G deployment accelerates globally, demand for miniature atomic clocks in this sector will increase by 15-18% annually through 2026.

The navigation and positioning systems market constitutes another significant application area. GPS-denied environments and autonomous vehicle navigation systems require highly stable local timing references, creating a growing market for miniature atomic beam clocks. The automotive sector alone is expected to increase its consumption of precision timing devices by 22% year-over-year as advanced driver assistance systems and autonomous driving capabilities become more prevalent.

Financial services represent an emerging application area with substantial growth potential. High-frequency trading operations require timestamp precision measured in nanoseconds, creating demand for miniature atomic clocks in trading infrastructure. This sector is projected to grow at 14% annually as financial institutions continue to invest in reducing latency and improving transaction synchronization.

Space applications are driving innovation in miniaturization techniques for atomic clocks. The small satellite market, growing at over 20% annually, requires increasingly compact timing solutions for communication systems and scientific payloads. CubeSats and other small satellite platforms have specific size and power constraints that align perfectly with the development goals of miniature atomic beam clocks.

Industrial automation and smart grid applications are also emerging as significant market drivers. Distributed control systems in manufacturing environments and synchronized measurement units in power grids both benefit from precise timing references. The industrial Internet of Things (IIoT) market is expected to consume increasing numbers of miniature atomic clocks as edge computing applications require more precise synchronization.

Consumer applications remain limited but show potential for future growth. Personal navigation devices, specialized scientific equipment, and certain high-end consumer electronics represent niche markets that could expand as miniaturization and cost reduction efforts continue to make atomic clock technology more accessible.

Current Challenges in Miniature Atomic Beam Clock Technology

The miniaturization of atomic beam clocks presents significant technical challenges that have hindered widespread adoption despite their potential advantages in precision timekeeping. Current vacuum technology limitations represent one of the most critical barriers to effective miniaturization. Conventional atomic clocks require high-vacuum environments (typically 10^-6 to 10^-8 Torr) to minimize collisions between atoms and background gases, which degrade clock performance. Maintaining such vacuum levels in miniaturized packages demands innovative approaches to vacuum sealing and getter materials.

Power consumption remains another substantial obstacle. Traditional atomic beam clocks require significant energy for atom source heating, magnetic field generation, and vacuum maintenance. Miniaturized versions struggle to achieve comparable performance while operating within the power constraints of portable or space-limited applications, typically requiring less than 100 mW for practical deployment in field instruments or satellite systems.

Thermal management challenges intensify with miniaturization as component density increases. The proximity of heat-generating elements (particularly the atom source) to temperature-sensitive components creates thermal gradients that can induce frequency shifts and degrade stability. Current thermal isolation techniques often prove inadequate at the miniature scale, where conventional approaches to heat dissipation become less effective.

Signal-to-noise ratio degradation represents another fundamental challenge. As the physical dimensions decrease, the number of atoms available for interrogation reduces proportionally, weakening the signal. Simultaneously, the closer proximity of electronic components increases electromagnetic interference, elevating noise levels. This combination significantly impacts the achievable stability and precision of miniaturized atomic beam clocks.

Manufacturing complexity and reproducibility issues further complicate development efforts. The fabrication of miniaturized components requires extremely precise alignment and assembly processes. Current manufacturing techniques struggle to consistently produce components with the necessary tolerances, particularly for critical elements like beam collimators and detection systems, resulting in performance variations between supposedly identical units.

Long-term stability and aging effects present ongoing research challenges. Miniaturized atomic beam clocks often exhibit more pronounced drift characteristics compared to their larger counterparts due to material outgassing, seal degradation, and component aging. Current materials and designs have not fully addressed these long-term reliability concerns, limiting deployment in applications requiring extended operation without recalibration.

Integration with other systems presents additional hurdles, as miniaturized atomic beam clocks must interface effectively with existing electronic systems while maintaining their performance advantages. Current interface standards and protocols are not optimized for the unique requirements of these specialized timing devices, creating compatibility challenges in practical applications.

Power consumption remains another substantial obstacle. Traditional atomic beam clocks require significant energy for atom source heating, magnetic field generation, and vacuum maintenance. Miniaturized versions struggle to achieve comparable performance while operating within the power constraints of portable or space-limited applications, typically requiring less than 100 mW for practical deployment in field instruments or satellite systems.

Thermal management challenges intensify with miniaturization as component density increases. The proximity of heat-generating elements (particularly the atom source) to temperature-sensitive components creates thermal gradients that can induce frequency shifts and degrade stability. Current thermal isolation techniques often prove inadequate at the miniature scale, where conventional approaches to heat dissipation become less effective.

Signal-to-noise ratio degradation represents another fundamental challenge. As the physical dimensions decrease, the number of atoms available for interrogation reduces proportionally, weakening the signal. Simultaneously, the closer proximity of electronic components increases electromagnetic interference, elevating noise levels. This combination significantly impacts the achievable stability and precision of miniaturized atomic beam clocks.

Manufacturing complexity and reproducibility issues further complicate development efforts. The fabrication of miniaturized components requires extremely precise alignment and assembly processes. Current manufacturing techniques struggle to consistently produce components with the necessary tolerances, particularly for critical elements like beam collimators and detection systems, resulting in performance variations between supposedly identical units.

Long-term stability and aging effects present ongoing research challenges. Miniaturized atomic beam clocks often exhibit more pronounced drift characteristics compared to their larger counterparts due to material outgassing, seal degradation, and component aging. Current materials and designs have not fully addressed these long-term reliability concerns, limiting deployment in applications requiring extended operation without recalibration.

Integration with other systems presents additional hurdles, as miniaturized atomic beam clocks must interface effectively with existing electronic systems while maintaining their performance advantages. Current interface standards and protocols are not optimized for the unique requirements of these specialized timing devices, creating compatibility challenges in practical applications.

Current Vacuum Technology Solutions for Miniature Atomic Clocks

01 Vacuum level requirements for miniature atomic beam clocks

Miniature atomic beam clocks require specific vacuum levels to maintain proper operation. These vacuum requirements typically range from high vacuum to ultra-high vacuum conditions to ensure minimal collision between atoms and background gases. The vacuum environment is critical for maintaining the coherence of the atomic beam and reducing frequency shifts that could affect clock accuracy. Proper vacuum levels also help in extending the mean free path of atoms in the beam, which is essential for precise time-keeping.- Vacuum level requirements for miniature atomic beam clocks: Miniature atomic beam clocks require specific vacuum levels to maintain proper operation. The vacuum environment is critical for ensuring the free movement of atoms in the beam path with minimal collisions with background gases. Typically, these clocks need ultra-high vacuum conditions in the range of 10^-6 to 10^-9 Torr to function effectively. The vacuum requirements directly impact the clock's stability, accuracy, and long-term performance.

- Vacuum sealing and packaging technologies: Advanced sealing and packaging technologies are essential for maintaining vacuum conditions in miniature atomic beam clocks. These include hermetic sealing methods, specialized glass-to-metal seals, and ceramic packaging that can withstand temperature variations while maintaining vacuum integrity. The packaging must also provide electromagnetic shielding while allowing optical access for laser interrogation of the atomic species. These technologies enable long-term vacuum stability without requiring continuous pumping in field applications.

- Vacuum pumping and getter technologies: Miniature atomic beam clocks employ specialized vacuum pumping and getter technologies to achieve and maintain the required vacuum levels. Non-evaporable getters (NEGs) and ion pumps are commonly integrated into the clock package to continuously remove residual gases. These active pumping elements are designed to be compact and low-power to suit the miniaturized form factor. Some designs incorporate passive getter materials that can be activated periodically to extend the operational lifetime of the vacuum system without external pumping equipment.

- Vacuum chamber design for atomic beam path optimization: The vacuum chamber design in miniature atomic beam clocks is optimized to create an efficient atomic beam path while maintaining the required vacuum levels. This includes specialized collimation structures, differential pumping regions, and beam-forming components that allow atoms to travel with minimal scattering. The chamber geometry must balance the need for a compact form factor with sufficient space for the atomic beam to develop properly. Advanced designs incorporate multiple chambers with different vacuum levels to optimize both the atomic source region and the interrogation region.

- Vacuum monitoring and control systems: Sophisticated vacuum monitoring and control systems are integrated into miniature atomic beam clocks to ensure optimal performance. These systems include miniaturized pressure sensors, temperature monitors, and feedback control mechanisms that can adjust operating parameters based on vacuum conditions. Some advanced designs incorporate self-diagnostic capabilities that can detect vacuum degradation and implement compensatory measures. These monitoring systems are critical for maintaining long-term stability and reliability, especially in applications where regular maintenance is not feasible.

02 Vacuum chamber design and sealing techniques

The design of vacuum chambers for miniature atomic beam clocks involves specialized sealing techniques to maintain the required vacuum levels. These designs often incorporate hermetic sealing methods, specialized materials for vacuum integrity, and compact geometries suitable for miniaturization. Advanced sealing techniques may include laser welding, glass-to-metal seals, or specialized bonding methods that ensure long-term vacuum stability while allowing for the necessary optical and electrical feedthroughs required for clock operation.Expand Specific Solutions03 Vacuum pumping systems and gettering technologies

Miniature atomic beam clocks employ specialized vacuum pumping systems and gettering technologies to achieve and maintain the required vacuum levels. These may include ion pumps, non-evaporable getters (NEGs), or passive pumping mechanisms designed specifically for compact applications. Gettering materials absorb residual gases within the vacuum chamber, helping to maintain ultra-high vacuum conditions over extended periods without requiring continuous active pumping, which is crucial for portable and space-based applications.Expand Specific Solutions04 Vacuum monitoring and control systems

Vacuum monitoring and control systems are essential components of miniature atomic beam clocks to ensure optimal performance. These systems may include pressure sensors, feedback control mechanisms, and diagnostic tools that continuously monitor vacuum conditions. Advanced monitoring systems can detect vacuum degradation and implement corrective measures to maintain the required vacuum levels, ensuring long-term stability and reliability of the atomic clock, particularly in challenging environments or during extended operation periods.Expand Specific Solutions05 Materials selection for vacuum compatibility

The selection of materials for miniature atomic beam clocks must consider vacuum compatibility to prevent outgassing that could compromise vacuum levels. Materials must have low outgassing rates, be bakeable for initial vacuum preparation, and maintain structural integrity under vacuum conditions. Special consideration is given to materials that can withstand the thermal cycling often required in atomic clock operation while not introducing contaminants that could affect the atomic beam properties or degrade vacuum quality over time.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Atomic Clock Development

The miniature atomic beam clock market is in a growth phase, characterized by increasing demand for precise timing solutions in telecommunications, navigation, and defense sectors. The market size is expanding as applications diversify beyond traditional military use into commercial sectors, with projections showing significant growth potential. Technologically, the field demonstrates varying maturity levels, with established players like Honeywell International, Texas Instruments, and Thales SA leading commercial development, while research institutions such as CSEM, Cornell University, and Peking University drive innovation. Chinese entities including the National Time Service Center and Chengdu Spaceon Electronics are rapidly advancing their capabilities, particularly in vacuum technology and miniaturization, challenging traditional Western dominance in this precision timing technology landscape.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced miniature atomic beam clocks utilizing Coherent Population Trapping (CPT) technology. Their design incorporates a vertical cavity surface-emitting laser (VCSEL) with precise wavelength control to create resonance with alkali atoms (typically cesium or rubidium). The vacuum system employs non-evaporable getters (NEGs) to maintain ultra-high vacuum (UHV) conditions of 10^-8 to 10^-9 Torr necessary for atomic beam operation. Honeywell's approach includes a miniaturized physics package with integrated optics and a sophisticated vacuum sealing technique using anodic bonding of silicon and glass components. Their clocks achieve stability performance of approximately 10^-11 over one day while significantly reducing power consumption to under 120 mW and volume to less than 15 cm³. The design incorporates MEMS fabrication techniques for mass production capability while maintaining high performance standards required for precision timing applications.

Strengths: Industry-leading miniaturization while maintaining high performance metrics; established manufacturing infrastructure for mass production; extensive experience in defense and aerospace applications providing reliability data. Weaknesses: Higher cost compared to quartz alternatives; requires specialized expertise for maintenance; temperature sensitivity requires additional compensation circuitry.

CSEM Centre Suisse d'Electronique et Microtechnique SA

Technical Solution: CSEM has pioneered a distinctive approach to miniature atomic beam clocks through their patented microfabricated double-resonance rubidium atomic clock technology. Their design features a microfabricated alkali vapor cell with buffer gas, created using anodic bonding of silicon and glass wafers. The vacuum requirements are maintained at approximately 10^-7 Torr using innovative getter materials integrated directly into the cell structure. CSEM's approach employs a unique light-induced atomic desorption (LIAD) technique to control vapor density without excessive heating, significantly reducing power consumption. The physics package incorporates a miniaturized magnetron cavity resonator with dimensions optimized for the hyperfine transition frequency of rubidium. This design achieves frequency stability of 3×10^-12 at 1000 seconds while consuming only about 150 mW of power. The entire physics package is contained within a volume of approximately 10 cm³, making it suitable for portable applications requiring precise timing. CSEM has also developed specialized fabrication processes that enable mass production while maintaining the stringent vacuum integrity required for long-term operation.

Strengths: Exceptional frequency stability for the size; innovative vapor cell fabrication techniques; low power consumption suitable for battery operation; established track record in commercial applications. Weaknesses: More complex manufacturing process compared to simpler clock technologies; requires specialized equipment for production; performance still below that of larger atomic frequency standards.

Key Patents and Innovations in Atomic Beam Vacuum Systems

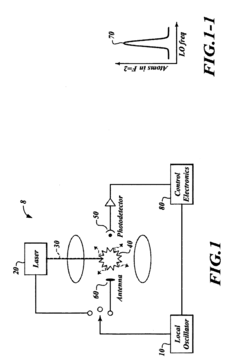

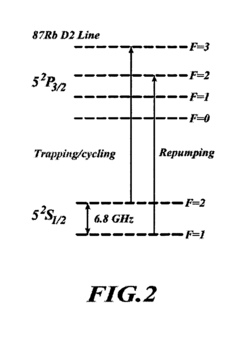

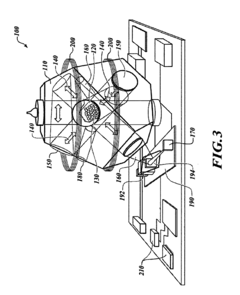

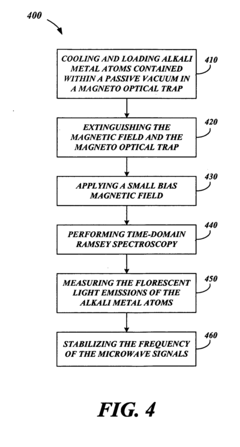

Cold atom micro primary standard

PatentInactiveEP2154586B1

Innovation

- A miniaturized atomic clock design based on Rubidium-87 atoms utilizing a Magneto Optical Trap, a single Vertical Cavity Surface Emitting Laser, and a Micro-Electromechanical System resonator, which reduces size to approximately 5 cm^3 and power consumption to less than 10 mW, achieving a narrow clock linewidth and long-term stability with autonomous operation.

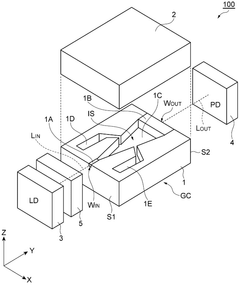

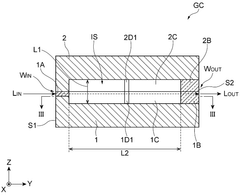

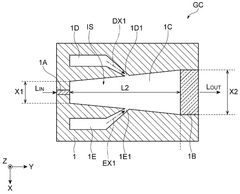

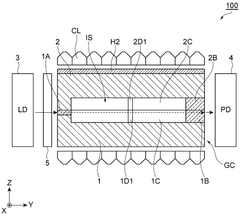

Atomic clock structure

PatentWO2025004484A1

Innovation

- A miniaturized atomic clock structure featuring a plate-shaped substrate with an internal gas space, optically coupled to a laser element and photodetector, where the laser beam is introduced through a side surface, and includes a gas cell with a laser beam inlet and outlet, utilizing a VCSEL laser and photodiode, and an optical component like lenses or quarter-wave plates for precise control of laser light interaction with alkali metal gases.

Materials Science Advancements for Vacuum Integrity

The advancement of materials science has played a pivotal role in enhancing the vacuum integrity of miniature atomic beam clocks. Traditional vacuum systems in atomic clocks faced significant challenges related to outgassing, permeation, and long-term stability, which directly impacted clock performance and reliability. Recent developments in ultra-low outgassing materials have revolutionized the field, with specialized glass-ceramic composites demonstrating outgassing rates below 10^-14 mbar·L/s·cm², a critical threshold for maintaining the high vacuum levels required in miniaturized atomic beam clocks.

Novel metal alloys, particularly titanium-based compounds with modified surface treatments, have shown exceptional vacuum compatibility while maintaining structural integrity under thermal cycling conditions. These materials exhibit reduced hydrogen permeation rates compared to conventional stainless steel, addressing one of the primary contamination concerns in vacuum systems. Additionally, specialized surface coatings using atomic layer deposition techniques have created near-perfect barriers against gas diffusion, extending the vacuum lifetime by orders of magnitude.

Nano-engineered getter materials represent another breakthrough, with selective gas absorption capabilities that maintain vacuum quality over extended periods. These advanced getters, often incorporating zirconium-aluminum-iron compounds, can be activated at lower temperatures (below 300°C), making them compatible with temperature-sensitive components in miniaturized clock assemblies. Their integration directly into the vacuum package has eliminated the need for separate pumping ports, contributing significantly to miniaturization efforts.

Vacuum-compatible adhesives and bonding technologies have also evolved substantially, with new formulations achieving hermetic seals while maintaining outgassing rates below 10^-12 mbar·L/s. Glass-to-metal and ceramic-to-metal sealing techniques have been refined to withstand thermal cycling between -40°C and +85°C without compromising vacuum integrity, a critical requirement for portable atomic clock applications.

Additive manufacturing has enabled the creation of complex vacuum chambers with integrated thermal management features and optimized atomic beam pathways. These structures, often utilizing specialized aluminum alloys or titanium composites, maintain dimensional stability while providing superior vacuum characteristics. The ability to create monolithic structures has reduced potential leak paths and simplified assembly processes, directly addressing reliability concerns in field-deployable atomic clocks.

Novel metal alloys, particularly titanium-based compounds with modified surface treatments, have shown exceptional vacuum compatibility while maintaining structural integrity under thermal cycling conditions. These materials exhibit reduced hydrogen permeation rates compared to conventional stainless steel, addressing one of the primary contamination concerns in vacuum systems. Additionally, specialized surface coatings using atomic layer deposition techniques have created near-perfect barriers against gas diffusion, extending the vacuum lifetime by orders of magnitude.

Nano-engineered getter materials represent another breakthrough, with selective gas absorption capabilities that maintain vacuum quality over extended periods. These advanced getters, often incorporating zirconium-aluminum-iron compounds, can be activated at lower temperatures (below 300°C), making them compatible with temperature-sensitive components in miniaturized clock assemblies. Their integration directly into the vacuum package has eliminated the need for separate pumping ports, contributing significantly to miniaturization efforts.

Vacuum-compatible adhesives and bonding technologies have also evolved substantially, with new formulations achieving hermetic seals while maintaining outgassing rates below 10^-12 mbar·L/s. Glass-to-metal and ceramic-to-metal sealing techniques have been refined to withstand thermal cycling between -40°C and +85°C without compromising vacuum integrity, a critical requirement for portable atomic clock applications.

Additive manufacturing has enabled the creation of complex vacuum chambers with integrated thermal management features and optimized atomic beam pathways. These structures, often utilizing specialized aluminum alloys or titanium composites, maintain dimensional stability while providing superior vacuum characteristics. The ability to create monolithic structures has reduced potential leak paths and simplified assembly processes, directly addressing reliability concerns in field-deployable atomic clocks.

Power Consumption Optimization Strategies

Power consumption remains a critical challenge in the development of miniature atomic beam clocks, requiring innovative optimization strategies to ensure practical deployment in portable and space applications. Current miniature atomic beam clocks typically consume between 10-30W of power, significantly higher than what is acceptable for many mobile applications that require sub-1W operation. The optimization of power consumption must address multiple components simultaneously while maintaining clock performance.

The primary power consumption sources in miniature atomic beam clocks include the atomic beam source (oven), vacuum pumps, microwave generation circuitry, detection systems, and control electronics. The atomic beam source often represents 30-40% of total power consumption, as it requires temperatures of 80-150°C to generate sufficient atomic flux. Implementing pulsed operation of the atomic beam source can reduce average power consumption by 40-60%, activating the source only during measurement cycles.

Vacuum system optimization presents another significant opportunity for power reduction. Traditional ion pumps consume 1-5W continuously, but newer micro-fabricated vacuum pumps utilizing MEMS technology can operate at 100-500mW. Additionally, implementing passive pumping elements such as non-evaporable getters (NEGs) can maintain vacuum levels with minimal power requirements, though they necessitate periodic regeneration cycles.

Microwave synthesis chains traditionally consume 1-3W in conventional designs. Implementing direct digital synthesis (DDS) techniques with advanced CMOS technology can reduce this to 100-300mW while maintaining frequency stability. Further power savings can be achieved through duty-cycling approaches, where the microwave generation operates only during interrogation phases.

Detection system optimization involves replacing traditional photomultiplier tubes with low-power photodiodes coupled with efficient signal processing. Advanced CMOS-based transimpedance amplifiers can reduce detection system power from hundreds of milliwatts to tens of milliwatts while maintaining adequate signal-to-noise ratios.

Control electronics represent another area for significant improvement. Implementing application-specific integrated circuits (ASICs) for clock control functions can reduce power consumption by 70-80% compared to discrete component implementations. Additionally, dynamic power management techniques that adjust clock operation based on stability requirements can further reduce average power consumption by 30-50%, particularly in applications where continuous high-precision timing is not always necessary.

The primary power consumption sources in miniature atomic beam clocks include the atomic beam source (oven), vacuum pumps, microwave generation circuitry, detection systems, and control electronics. The atomic beam source often represents 30-40% of total power consumption, as it requires temperatures of 80-150°C to generate sufficient atomic flux. Implementing pulsed operation of the atomic beam source can reduce average power consumption by 40-60%, activating the source only during measurement cycles.

Vacuum system optimization presents another significant opportunity for power reduction. Traditional ion pumps consume 1-5W continuously, but newer micro-fabricated vacuum pumps utilizing MEMS technology can operate at 100-500mW. Additionally, implementing passive pumping elements such as non-evaporable getters (NEGs) can maintain vacuum levels with minimal power requirements, though they necessitate periodic regeneration cycles.

Microwave synthesis chains traditionally consume 1-3W in conventional designs. Implementing direct digital synthesis (DDS) techniques with advanced CMOS technology can reduce this to 100-300mW while maintaining frequency stability. Further power savings can be achieved through duty-cycling approaches, where the microwave generation operates only during interrogation phases.

Detection system optimization involves replacing traditional photomultiplier tubes with low-power photodiodes coupled with efficient signal processing. Advanced CMOS-based transimpedance amplifiers can reduce detection system power from hundreds of milliwatts to tens of milliwatts while maintaining adequate signal-to-noise ratios.

Control electronics represent another area for significant improvement. Implementing application-specific integrated circuits (ASICs) for clock control functions can reduce power consumption by 70-80% compared to discrete component implementations. Additionally, dynamic power management techniques that adjust clock operation based on stability requirements can further reduce average power consumption by 30-50%, particularly in applications where continuous high-precision timing is not always necessary.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!