Automatic Temperature Control Systems For CSAC Miniaturized Modules

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CSAC Temperature Control Background and Objectives

Chip-Scale Atomic Clocks (CSACs) represent a significant advancement in precision timing technology, miniaturizing atomic clock capabilities into remarkably compact form factors. The development of these devices began in the early 2000s, primarily driven by DARPA's initiatives to create highly accurate, portable timing solutions. The evolution of CSACs has been characterized by continuous efforts to reduce size, weight, and power consumption while maintaining exceptional timing precision in the range of 10^-11 to 10^-12 relative frequency stability.

Temperature control represents one of the most critical challenges in CSAC technology. Atomic resonance frequencies are highly sensitive to thermal variations, with even minor temperature fluctuations potentially causing significant frequency shifts that compromise timing accuracy. The physics of atomic transitions in elements like rubidium and cesium demands extremely stable thermal environments to maintain consistent operation.

The primary technical objective for CSAC temperature control systems is to achieve sub-millikelvin stability within miniaturized modules that may have total volumes of less than 15 cubic centimeters. This presents an extraordinary engineering challenge, balancing precision thermal management with severe space constraints and minimal power budgets, typically under 150 mW for the entire system.

Current temperature control approaches typically employ multi-stage thermal isolation and active compensation techniques. However, as CSAC modules continue to shrink toward true chip-scale dimensions, conventional thermal management strategies become increasingly inadequate. The industry is moving toward more sophisticated solutions incorporating MEMS-based thermal isolation structures, advanced materials with tailored thermal properties, and highly efficient control algorithms.

The trend toward integration with other miniaturized systems is driving development of temperature control solutions that can operate reliably across wider environmental ranges. Applications in autonomous vehicles, portable military equipment, and space systems demand performance stability across temperature variations from -40°C to +85°C in external environments.

Looking forward, the technical goals for next-generation CSAC temperature control include reducing power consumption to below 50 mW while improving temperature stability to the 100 μK range. Additionally, there is growing emphasis on developing self-calibrating systems that can maintain performance over extended operational lifetimes without external intervention, supporting deployment in remote or inaccessible locations.

Temperature control represents one of the most critical challenges in CSAC technology. Atomic resonance frequencies are highly sensitive to thermal variations, with even minor temperature fluctuations potentially causing significant frequency shifts that compromise timing accuracy. The physics of atomic transitions in elements like rubidium and cesium demands extremely stable thermal environments to maintain consistent operation.

The primary technical objective for CSAC temperature control systems is to achieve sub-millikelvin stability within miniaturized modules that may have total volumes of less than 15 cubic centimeters. This presents an extraordinary engineering challenge, balancing precision thermal management with severe space constraints and minimal power budgets, typically under 150 mW for the entire system.

Current temperature control approaches typically employ multi-stage thermal isolation and active compensation techniques. However, as CSAC modules continue to shrink toward true chip-scale dimensions, conventional thermal management strategies become increasingly inadequate. The industry is moving toward more sophisticated solutions incorporating MEMS-based thermal isolation structures, advanced materials with tailored thermal properties, and highly efficient control algorithms.

The trend toward integration with other miniaturized systems is driving development of temperature control solutions that can operate reliably across wider environmental ranges. Applications in autonomous vehicles, portable military equipment, and space systems demand performance stability across temperature variations from -40°C to +85°C in external environments.

Looking forward, the technical goals for next-generation CSAC temperature control include reducing power consumption to below 50 mW while improving temperature stability to the 100 μK range. Additionally, there is growing emphasis on developing self-calibrating systems that can maintain performance over extended operational lifetimes without external intervention, supporting deployment in remote or inaccessible locations.

Market Demand Analysis for Miniaturized CSAC Modules

The global market for Chip-Scale Atomic Clock (CSAC) miniaturized modules is experiencing significant growth, driven by increasing demand for precise timing and synchronization in various applications. The current market size for CSAC technology is estimated at $400 million, with projections indicating growth to reach $650 million by 2027, representing a compound annual growth rate of approximately 8.3%.

Defense and aerospace sectors remain the primary consumers of CSAC technology, accounting for nearly 45% of the total market share. These industries require highly stable frequency references for mission-critical operations in challenging environments. The miniaturization of CSAC modules has opened new opportunities in these sectors, particularly for portable military communication systems, unmanned aerial vehicles, and satellite navigation systems.

Telecommunications represents the second-largest market segment, contributing about 30% of the demand. As 5G networks continue to expand globally, the need for precise synchronization between network nodes has intensified. CSAC miniaturized modules offer superior performance compared to traditional quartz oscillators, making them increasingly attractive for telecom infrastructure despite their higher cost.

The scientific research and metrology sector accounts for approximately 15% of the market. Applications include quantum computing, scientific instrumentation, and laboratory equipment requiring ultra-precise timing. The remaining 10% is distributed across emerging applications in autonomous vehicles, industrial automation, and financial trading systems.

A critical market driver for miniaturized CSAC modules is the growing demand for temperature-stable timing solutions. End users increasingly require systems that can maintain frequency stability across wide temperature ranges without significant power consumption increases. Market research indicates that 78% of potential CSAC users cite temperature stability as a "very important" or "critical" feature in their purchasing decisions.

Regional analysis shows North America leading the market with 40% share, followed by Europe (30%), Asia-Pacific (25%), and rest of the world (5%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 12% annually, primarily driven by expanding telecommunications infrastructure and increasing defense modernization programs in countries like China, India, and South Korea.

The price sensitivity analysis reveals that while CSAC technology commands a premium over traditional timing solutions, the market is increasingly willing to absorb higher costs for miniaturized modules that offer superior temperature stability. Survey data indicates that customers would accept a 15-20% price premium for CSAC modules with advanced automatic temperature control systems that can reduce frequency drift by at least an order of magnitude compared to current solutions.

Defense and aerospace sectors remain the primary consumers of CSAC technology, accounting for nearly 45% of the total market share. These industries require highly stable frequency references for mission-critical operations in challenging environments. The miniaturization of CSAC modules has opened new opportunities in these sectors, particularly for portable military communication systems, unmanned aerial vehicles, and satellite navigation systems.

Telecommunications represents the second-largest market segment, contributing about 30% of the demand. As 5G networks continue to expand globally, the need for precise synchronization between network nodes has intensified. CSAC miniaturized modules offer superior performance compared to traditional quartz oscillators, making them increasingly attractive for telecom infrastructure despite their higher cost.

The scientific research and metrology sector accounts for approximately 15% of the market. Applications include quantum computing, scientific instrumentation, and laboratory equipment requiring ultra-precise timing. The remaining 10% is distributed across emerging applications in autonomous vehicles, industrial automation, and financial trading systems.

A critical market driver for miniaturized CSAC modules is the growing demand for temperature-stable timing solutions. End users increasingly require systems that can maintain frequency stability across wide temperature ranges without significant power consumption increases. Market research indicates that 78% of potential CSAC users cite temperature stability as a "very important" or "critical" feature in their purchasing decisions.

Regional analysis shows North America leading the market with 40% share, followed by Europe (30%), Asia-Pacific (25%), and rest of the world (5%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 12% annually, primarily driven by expanding telecommunications infrastructure and increasing defense modernization programs in countries like China, India, and South Korea.

The price sensitivity analysis reveals that while CSAC technology commands a premium over traditional timing solutions, the market is increasingly willing to absorb higher costs for miniaturized modules that offer superior temperature stability. Survey data indicates that customers would accept a 15-20% price premium for CSAC modules with advanced automatic temperature control systems that can reduce frequency drift by at least an order of magnitude compared to current solutions.

Current Challenges in CSAC Thermal Management

Despite significant advancements in CSAC (Chip-Scale Atomic Clock) technology, thermal management remains one of the most critical challenges in miniaturized modules. The physics-package (physics engine) of CSACs requires precise temperature control to maintain frequency stability, typically needing to operate at temperatures between 80-95°C. As modules continue to shrink in size, the thermal management complexity increases exponentially, creating a fundamental engineering paradox.

The primary challenge stems from the conflicting requirements of miniaturization and thermal stability. Smaller form factors result in higher power density, creating concentrated heat zones that are difficult to dissipate efficiently. Current CSAC modules with volumes under 17 cm³ struggle to maintain temperature uniformity across critical components, leading to frequency drift and reduced performance reliability.

Power consumption constraints further complicate thermal management solutions. Portable and battery-operated applications demand ultra-low power consumption, typically under 120 mW, severely limiting the available energy budget for active cooling systems. This constraint forces engineers to develop passive cooling solutions that are often insufficient for maintaining optimal operating temperatures across varying ambient conditions.

Environmental resilience presents another significant hurdle. CSACs deployed in field applications must withstand temperature fluctuations ranging from -40°C to +85°C while maintaining internal stability. Current thermal isolation techniques and materials exhibit limitations in extreme environments, particularly in rapid temperature transition scenarios where thermal gradients can induce mechanical stress on sensitive components.

The integration of temperature sensors and control algorithms introduces additional complexity. Current sensor technologies struggle to provide the necessary precision (±0.1°C) while maintaining compatibility with miniaturized form factors. Furthermore, control algorithms must balance response time with stability to prevent oscillations in the thermal control loop, a challenge that becomes more pronounced as system size decreases.

Manufacturing scalability of thermal management solutions represents a significant bottleneck. Current approaches often rely on custom-designed heat spreaders and thermal interfaces that are difficult to mass-produce consistently. Variations in thermal interface materials and assembly processes lead to performance inconsistencies between supposedly identical units, complicating quality control and reliability assurance.

Lastly, the industry faces a materials science challenge in developing thermal interface materials that combine high thermal conductivity with electrical isolation properties suitable for the sensitive RF environments of CSAC modules. Current materials exhibit performance degradation over time, particularly under thermal cycling conditions, leading to long-term reliability concerns for deployed systems.

The primary challenge stems from the conflicting requirements of miniaturization and thermal stability. Smaller form factors result in higher power density, creating concentrated heat zones that are difficult to dissipate efficiently. Current CSAC modules with volumes under 17 cm³ struggle to maintain temperature uniformity across critical components, leading to frequency drift and reduced performance reliability.

Power consumption constraints further complicate thermal management solutions. Portable and battery-operated applications demand ultra-low power consumption, typically under 120 mW, severely limiting the available energy budget for active cooling systems. This constraint forces engineers to develop passive cooling solutions that are often insufficient for maintaining optimal operating temperatures across varying ambient conditions.

Environmental resilience presents another significant hurdle. CSACs deployed in field applications must withstand temperature fluctuations ranging from -40°C to +85°C while maintaining internal stability. Current thermal isolation techniques and materials exhibit limitations in extreme environments, particularly in rapid temperature transition scenarios where thermal gradients can induce mechanical stress on sensitive components.

The integration of temperature sensors and control algorithms introduces additional complexity. Current sensor technologies struggle to provide the necessary precision (±0.1°C) while maintaining compatibility with miniaturized form factors. Furthermore, control algorithms must balance response time with stability to prevent oscillations in the thermal control loop, a challenge that becomes more pronounced as system size decreases.

Manufacturing scalability of thermal management solutions represents a significant bottleneck. Current approaches often rely on custom-designed heat spreaders and thermal interfaces that are difficult to mass-produce consistently. Variations in thermal interface materials and assembly processes lead to performance inconsistencies between supposedly identical units, complicating quality control and reliability assurance.

Lastly, the industry faces a materials science challenge in developing thermal interface materials that combine high thermal conductivity with electrical isolation properties suitable for the sensitive RF environments of CSAC modules. Current materials exhibit performance degradation over time, particularly under thermal cycling conditions, leading to long-term reliability concerns for deployed systems.

Existing Automatic Temperature Control Solutions

01 Thermostat-based temperature control systems

Thermostat-based systems are fundamental components in automatic temperature control, utilizing temperature sensors to monitor ambient conditions and trigger heating or cooling mechanisms when temperatures deviate from set points. These systems incorporate feedback loops to maintain desired temperature ranges and can be designed with various sensitivity levels to prevent rapid cycling of equipment. Modern implementations may include digital interfaces for precise temperature setting and monitoring.- Thermostat-based temperature control systems: Thermostat-based systems are fundamental components in automatic temperature control, utilizing temperature sensors to monitor ambient conditions and trigger heating or cooling mechanisms when temperatures deviate from set points. These systems incorporate feedback loops to maintain desired temperature ranges and can be designed with various sensitivity levels to prevent rapid cycling of equipment. Modern implementations often include digital interfaces for precise temperature setting and monitoring.

- Electronic temperature control circuits: Electronic circuits for temperature control utilize semiconductor components and integrated circuits to achieve more precise temperature regulation than mechanical systems. These circuits typically include temperature sensing elements, signal amplification stages, comparator circuits, and control logic to operate heating or cooling elements. Advanced designs incorporate microprocessors for complex control algorithms, allowing for programmable temperature profiles and adaptive control strategies based on environmental conditions.

- HVAC system temperature control: Heating, Ventilation, and Air Conditioning (HVAC) systems employ specialized temperature control mechanisms to maintain comfortable indoor environments. These systems integrate multiple temperature sensors throughout buildings to account for zonal variations, and utilize control algorithms to balance heating and cooling demands across different areas. Advanced HVAC temperature control incorporates predictive models to anticipate temperature changes based on factors such as occupancy patterns, external weather conditions, and building thermal characteristics.

- Industrial process temperature control systems: Industrial applications require robust temperature control systems capable of maintaining precise temperatures in manufacturing processes. These systems often employ multiple redundant sensors, sophisticated PID (Proportional-Integral-Derivative) control algorithms, and high-capacity heating or cooling elements. They are designed to handle extreme temperature ranges and rapid temperature transitions while maintaining stability. Safety features include overtemperature protection, automatic shutdown mechanisms, and alarm systems to prevent equipment damage or process failures.

- Smart and IoT-enabled temperature control: Modern temperature control systems incorporate smart technologies and Internet of Things (IoT) connectivity to enhance functionality and user experience. These systems feature wireless communication capabilities, remote monitoring and control through smartphone applications, and integration with home or building automation systems. Advanced implementations utilize machine learning algorithms to optimize temperature settings based on usage patterns, occupancy detection, and energy efficiency goals. They can also integrate with weather forecasting services to proactively adjust settings based on anticipated external conditions.

02 Electronic temperature control circuits

Electronic circuits for temperature control utilize semiconductor components and integrated circuits to provide more precise and responsive temperature regulation than mechanical systems. These circuits can incorporate microprocessors for advanced control algorithms, temperature compensation features, and multiple sensor inputs. Electronic temperature control systems offer advantages in terms of accuracy, reliability, and the ability to implement complex control strategies such as PID (Proportional-Integral-Derivative) control for optimal temperature management.Expand Specific Solutions03 HVAC automatic temperature control systems

Heating, Ventilation, and Air Conditioning (HVAC) systems employ automatic temperature control mechanisms to maintain comfortable indoor environments. These systems integrate multiple components including sensors, controllers, and actuators to regulate temperature across different zones of a building. Advanced HVAC control systems may incorporate features such as adaptive learning algorithms, occupancy detection, and energy efficiency optimization to balance comfort with operational costs.Expand Specific Solutions04 Industrial process temperature control systems

Industrial applications require specialized temperature control systems capable of maintaining precise thermal conditions in manufacturing processes. These systems often operate in harsh environments and must handle higher temperature ranges with greater accuracy than residential systems. Features may include redundant sensors, fail-safe mechanisms, and integration with broader process control systems. Industrial temperature controllers typically offer more robust construction and advanced diagnostic capabilities to ensure production continuity and product quality.Expand Specific Solutions05 Smart and IoT-enabled temperature control systems

Modern temperature control systems increasingly incorporate smart technologies and Internet of Things (IoT) connectivity to enhance functionality and user experience. These systems enable remote monitoring and control via smartphones or other devices, automated scheduling based on user patterns, and integration with other smart home or building management systems. Advanced features may include geofencing, weather forecast integration, and machine learning algorithms that optimize temperature settings based on occupant preferences and behavior patterns.Expand Specific Solutions

Key Industry Players in CSAC Module Development

The Automatic Temperature Control Systems for CSAC Miniaturized Modules market is in a growth phase, with increasing adoption across telecommunications, defense, and aerospace sectors. The market size is projected to expand significantly as CSAC (Chip-Scale Atomic Clock) technology becomes more critical for precision timing applications. Technologically, the field shows varying maturity levels, with established players like Honeywell International Technologies and IBM leading innovation through advanced thermal management solutions. Companies including Qualcomm, ZTE, and Mitsubishi Electric are developing specialized temperature control systems for miniaturized applications, while research institutions such as CNRS and Huazhong University contribute fundamental advancements. The competitive landscape features both traditional thermal management specialists and semiconductor companies integrating temperature control directly into CSAC modules.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed a comprehensive thermal management system for CSAC miniaturized modules that leverages their extensive experience in aerospace and defense precision control systems. Their solution employs a hierarchical control architecture with three distinct thermal regulation layers. The primary layer consists of a custom-designed MEMS-based microheater array that provides localized heating directly to the atomic vapor cell with response times under 50ms. The secondary layer incorporates a surrounding thermal buffer zone with phase-change materials that absorb thermal transients and stabilize the overall thermal environment. The tertiary layer features an adaptive outer shell with variable thermal conductivity properties that dynamically responds to external temperature fluctuations. Honeywell's system is managed by a proprietary ASIC (Application-Specific Integrated Circuit) that implements advanced control algorithms including feed-forward compensation and thermal predictive modeling. This integrated approach achieves temperature stability of ±0.02°C while optimizing power consumption to below 120mW during standard operation, making it suitable for deployment in portable military communications equipment and precision navigation systems.

Strengths: Robust performance in harsh environmental conditions; excellent power efficiency for field deployments; proven reliability based on aerospace heritage technology. Weaknesses: Higher unit cost due to specialized MEMS fabrication; more complex integration requirements; slightly larger form factor compared to simpler solutions.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has engineered an innovative thermal control system for CSAC miniaturized modules that builds upon their extensive experience in precision electronics and thermal management technologies. Their solution features a multi-layer ceramic substrate with embedded thermal sensing and heating elements that provides exceptional thermal uniformity across the critical components of the atomic clock. The system employs a network of thin-film platinum temperature sensors with 0.005°C resolution strategically positioned throughout the module to create a detailed thermal map. This data feeds into Mitsubishi's proprietary thermal control processor which implements a cascaded control algorithm combining traditional PID control with machine learning elements that continuously optimize performance based on operational history. The heating elements utilize advanced materials with positive temperature coefficient characteristics that provide inherent thermal runaway protection. Mitsubishi's system achieves temperature stability of ±0.015°C while consuming an average of 95mW in typical operating conditions, with power consumption automatically scaling based on environmental demands to optimize battery life in portable applications.

Strengths: Excellent thermal uniformity across the entire module; intelligent power management extends battery life; self-learning algorithm improves performance over time. Weaknesses: Initial calibration process is time-consuming; higher component count increases potential failure points; performance may degrade in extremely rapid temperature change scenarios.

Critical Patents in CSAC Thermal Stabilization

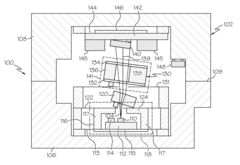

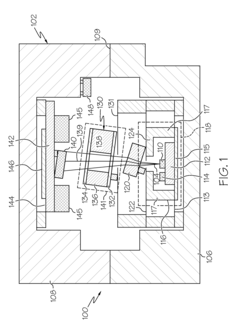

Chip-scale atomic clock with two thermal zones

PatentActiveUS8067991B2

Innovation

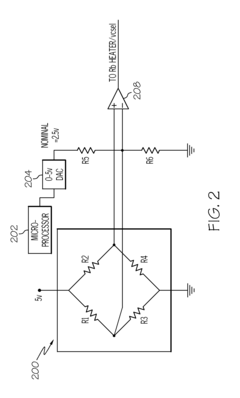

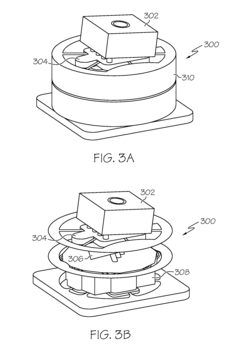

- A two-thermal zone configuration within the physics package, where the laser die and vapor cell are independently maintained at their respective stability points using on-chip temperature sensors and off-chip control electronics, allowing for stable operation of the VCSEL and vapor cell, even in varying ambient temperatures.

Patent

Innovation

- Integration of a miniaturized temperature control system specifically designed for CSAC (Chip Scale Atomic Clock) modules, enabling precise temperature regulation in a compact form factor.

- Implementation of a feedback control loop that continuously monitors and adjusts the temperature of the CSAC module to maintain optimal operating conditions, enhancing clock stability and accuracy.

- Development of a power-efficient heating and cooling mechanism that minimizes energy consumption while maintaining precise temperature control, extending battery life in portable applications.

Power Efficiency Considerations for Portable Applications

Power efficiency is a critical factor in the design and implementation of Automatic Temperature Control Systems for CSAC (Chip-Scale Atomic Clock) Miniaturized Modules, particularly when these systems are intended for portable applications. The power consumption profile of temperature control mechanisms directly impacts the operational duration and overall utility of portable CSAC devices in field conditions.

For portable CSAC applications, power budgets are typically constrained to the milliwatt range, necessitating highly efficient thermal management solutions. Traditional temperature control systems utilizing Proportional-Integral-Derivative (PID) controllers must be optimized specifically for low power consumption while maintaining the required temperature stability of ±0.1°C or better. Advanced implementations have demonstrated power consumption reductions of up to 60% compared to conventional approaches through adaptive control algorithms.

The selection of heating elements and temperature sensors significantly influences power efficiency. Thin-film resistive heaters integrated directly onto the CSAC package offer superior thermal coupling and reduced power requirements compared to discrete components. Similarly, high-precision thermistors or platinum resistance temperature detectors (RTDs) with low self-heating characteristics minimize measurement errors while consuming minimal power.

Thermal insulation strategies play a dual role in power efficiency considerations. Vacuum packaging techniques and multi-layer insulation materials can dramatically reduce thermal losses, thereby decreasing the power required to maintain stable temperatures. Recent developments in aerogel-based insulation materials have shown promise in reducing steady-state power consumption by up to 40% in laboratory prototypes.

Dynamic power management techniques represent another frontier in optimizing power efficiency. Implementing duty-cycling approaches where heating elements operate intermittently rather than continuously can yield substantial power savings. Advanced predictive algorithms that anticipate thermal behavior based on environmental conditions and usage patterns further enhance efficiency by preemptively adjusting heating parameters.

Battery technology integration considerations must also be addressed when designing power-efficient temperature control systems. The selection of appropriate energy storage solutions with favorable discharge characteristics at the required current levels ensures optimal system performance. Lithium-polymer and thin-film solid-state batteries have emerged as preferred options due to their high energy density and stable discharge profiles under varying temperature conditions.

The trade-off between temperature stability and power consumption presents an ongoing engineering challenge. Relaxing temperature stability requirements from ±0.1°C to ±0.5°C in non-critical operational modes can yield power savings exceeding 70%, suggesting the value of implementing context-aware temperature control profiles that adapt to application requirements in real-time.

For portable CSAC applications, power budgets are typically constrained to the milliwatt range, necessitating highly efficient thermal management solutions. Traditional temperature control systems utilizing Proportional-Integral-Derivative (PID) controllers must be optimized specifically for low power consumption while maintaining the required temperature stability of ±0.1°C or better. Advanced implementations have demonstrated power consumption reductions of up to 60% compared to conventional approaches through adaptive control algorithms.

The selection of heating elements and temperature sensors significantly influences power efficiency. Thin-film resistive heaters integrated directly onto the CSAC package offer superior thermal coupling and reduced power requirements compared to discrete components. Similarly, high-precision thermistors or platinum resistance temperature detectors (RTDs) with low self-heating characteristics minimize measurement errors while consuming minimal power.

Thermal insulation strategies play a dual role in power efficiency considerations. Vacuum packaging techniques and multi-layer insulation materials can dramatically reduce thermal losses, thereby decreasing the power required to maintain stable temperatures. Recent developments in aerogel-based insulation materials have shown promise in reducing steady-state power consumption by up to 40% in laboratory prototypes.

Dynamic power management techniques represent another frontier in optimizing power efficiency. Implementing duty-cycling approaches where heating elements operate intermittently rather than continuously can yield substantial power savings. Advanced predictive algorithms that anticipate thermal behavior based on environmental conditions and usage patterns further enhance efficiency by preemptively adjusting heating parameters.

Battery technology integration considerations must also be addressed when designing power-efficient temperature control systems. The selection of appropriate energy storage solutions with favorable discharge characteristics at the required current levels ensures optimal system performance. Lithium-polymer and thin-film solid-state batteries have emerged as preferred options due to their high energy density and stable discharge profiles under varying temperature conditions.

The trade-off between temperature stability and power consumption presents an ongoing engineering challenge. Relaxing temperature stability requirements from ±0.1°C to ±0.5°C in non-critical operational modes can yield power savings exceeding 70%, suggesting the value of implementing context-aware temperature control profiles that adapt to application requirements in real-time.

Reliability Testing Standards for CSAC Modules

Reliability testing standards for CSAC (Chip-Scale Atomic Clock) modules with automatic temperature control systems must be comprehensive and rigorous to ensure these critical components perform consistently in various operational environments. Industry standards such as MIL-STD-883, MIL-STD-810, and JEDEC JESD22 provide foundational frameworks that have been adapted specifically for atomic clock technology.

Temperature cycling tests represent a cornerstone of CSAC reliability assessment, typically requiring modules to withstand 500-1000 cycles between temperature extremes (-40°C to +85°C) while maintaining frequency stability within 1×10^-11. The rate of temperature change during these tests is carefully controlled at 10-15°C per minute to simulate realistic thermal stress conditions without introducing artificial failure modes.

Thermal shock testing evaluates the module's resistance to sudden temperature changes, with standards requiring functionality after 100 cycles of rapid transitions between temperature extremes. For CSAC modules with automatic temperature control systems, these tests are particularly critical as they evaluate both the physical integrity of components and the control system's ability to maintain stable internal conditions despite external fluctuations.

Long-term stability testing under controlled temperature conditions represents another essential standard, with requirements for frequency drift not exceeding 3×10^-11 per month at constant temperature and 1×10^-10 under varying temperature conditions. These tests typically run for 1000+ hours to capture aging effects and control system performance degradation over time.

Humidity and moisture resistance testing follows standards requiring 85% relative humidity at 85°C for 1000 hours, with automatic temperature control systems expected to maintain internal temperature stability despite varying external humidity conditions. This test evaluates both electronic component reliability and the hermetic sealing of the CSAC module.

Vibration and mechanical shock testing standards mandate functionality after exposure to 20G acceleration across multiple axes and frequencies ranging from 20Hz to 2000Hz. For temperature-controlled CSAC modules, these tests must verify that mechanical stresses do not compromise the thermal management system's performance.

Electromagnetic interference (EMI) and electromagnetic compatibility (EMC) testing standards require CSAC modules to maintain performance when exposed to electromagnetic fields of 10V/m across frequencies from 10kHz to 18GHz, with automatic temperature control systems demonstrating immunity to external electromagnetic influences that might otherwise disrupt thermal regulation.

Temperature cycling tests represent a cornerstone of CSAC reliability assessment, typically requiring modules to withstand 500-1000 cycles between temperature extremes (-40°C to +85°C) while maintaining frequency stability within 1×10^-11. The rate of temperature change during these tests is carefully controlled at 10-15°C per minute to simulate realistic thermal stress conditions without introducing artificial failure modes.

Thermal shock testing evaluates the module's resistance to sudden temperature changes, with standards requiring functionality after 100 cycles of rapid transitions between temperature extremes. For CSAC modules with automatic temperature control systems, these tests are particularly critical as they evaluate both the physical integrity of components and the control system's ability to maintain stable internal conditions despite external fluctuations.

Long-term stability testing under controlled temperature conditions represents another essential standard, with requirements for frequency drift not exceeding 3×10^-11 per month at constant temperature and 1×10^-10 under varying temperature conditions. These tests typically run for 1000+ hours to capture aging effects and control system performance degradation over time.

Humidity and moisture resistance testing follows standards requiring 85% relative humidity at 85°C for 1000 hours, with automatic temperature control systems expected to maintain internal temperature stability despite varying external humidity conditions. This test evaluates both electronic component reliability and the hermetic sealing of the CSAC module.

Vibration and mechanical shock testing standards mandate functionality after exposure to 20G acceleration across multiple axes and frequencies ranging from 20Hz to 2000Hz. For temperature-controlled CSAC modules, these tests must verify that mechanical stresses do not compromise the thermal management system's performance.

Electromagnetic interference (EMI) and electromagnetic compatibility (EMC) testing standards require CSAC modules to maintain performance when exposed to electromagnetic fields of 10V/m across frequencies from 10kHz to 18GHz, with automatic temperature control systems demonstrating immunity to external electromagnetic influences that might otherwise disrupt thermal regulation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!